Calibrate Rotameter and Orifice Meter and Explore Reynolds

advertisement

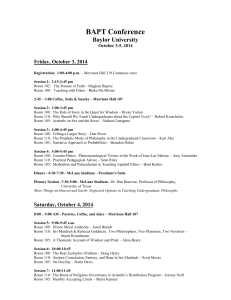

Calibrate Flow Meters Lab, CM3215 F. Morrison CM3215 Fundamentals of Chemical Engineering Laboratory Calibrate Rotameter and Orifice Meter and Explore Reynolds # Professor Faith Morrison Department of Chemical Engineering Michigan Technological University 1 © Faith A. Morrison, Michigan Tech U. Orifice Flow Meters • Obstruct flow • Build upstream pressure • Δ is a function of 2 Image source: www.cheresources.com/flowmeas.shtml © Faith A. Morrison, Michigan Tech U. 1 Calibrate Flow Meters Lab, CM3215 F. Morrison Orifice Flow Meters Orifice plate: (view straight-on) Flowrate, 1 2 Pressure drop across the orifice is correlated with flow rate (mechanical energy balance) Δ Δ Δ 2 (SI-SO, steady, const., no rxn, no phase chg, const, no heat xfer) , 3 © Faith A. Morrison, Michigan Tech U. Orifice Flow Meters MEB: Apply MEB between upstream point (1) and a point in the vena contracta (2): Δ Δ 2 D , Δ 0 2 Mass balance: Combine and eliminate 4 4 4 © Faith A. Morrison, Michigan Tech U. 2 Calibrate Flow Meters Lab, CM3215 F. Morrison Orifice Flow Meters Apply MEB between upstream point and a point in the vena contracta; combine with mass balance: D 2 4 1 Q: What should you plot versus what to get a straight line correlation? (answer in prelab) Reference: Morrison, An Introduction to Fluid Mechanics, Cambridge, 2013, page 837, problem 43. 5 © Faith A. Morrison, Michigan Tech U. Orifice Flow Meters CM3215 Lab 6 © Faith A. Morrison, Michigan Tech U. 3 Calibrate Flow Meters Lab, CM3215 F. Morrison Rotameter Flow Meters Reading on the rotameter (0-100%) is linearly correlated with flow rate 7 www.alicatscientific.com/images/rotameter_big.gif © Faith A. Morrison, Michigan Tech U. Rotameter Flow Meters Think of the float cap as a pointer Reading on the rotameter (0-100%) is linearly correlated with flow rate 8 www.alicatscientific.com/images/rotameter_big.gif © Faith A. Morrison, Michigan Tech U. 4 Calibrate Flow Meters Lab, CM3215 F. Morrison Reynolds Number Re vz D This combination of experimentally measureable variables is the key number that correlates with the flow regime that is observed. In a pipe: •Laminar (Re < 2100) •Transitional •Turbulent (Re > 4000) 9 © Faith A. Morrison, Michigan Tech U. O. Reynolds’ Dye Experiment, 1883 Transitional flow Turbulent flow Images: www.flometrics.com/reynolds_experiment.htm accessed 4 Feb 2002 10 © Faith A. Morrison, Michigan Tech U. 5 Calibrate Flow Meters Lab, CM3215 F. Morrison Flow Regimes in a Pipe Dye-injection needle Laminar Re 2100 2100 Re Re 4000 4000 •smooth •one direction only •predictable Transitional Turbulent •chaotic - fluctuations within fluid •transverse motions •unpredictable - deal with average motion •most common 11 © Faith A. Morrison, Michigan Tech U. Data may be organized in terms of two dimensionless parameters: density average velocity true pipe inner diameter viscosity pressure drop pipe length Reynolds Number Flow rate Re vz D (This is a definition) Fanning Friction Factor Pressure Drop 1 P0 PL 4 f 2 L 1 v z D 2 (This comes from applying the definition of friction factor to pipe flow) 12 © Faith A. Morrison, Michigan Tech U. 6 Calibrate Flow Meters Lab, CM3215 F. Morrison Data may be organized in terms of two dimensionless parameters: density average velocity true pipe inner diameter viscosity pressure drop pipe length Reynolds Number Flow rate For now, we (This is a measure definition) this vz D Re Fanning Friction Factor Pressure Drop 1 P0 PL 4 f 2 L 1 v z D 2 (This comes from applying the definition of friction factor to pipe flow) 13 © Faith A. Morrison, Michigan Tech U. Data may be organized in terms of two dimensionless parameters: density average velocity true pipe inner diameter viscosity pressure drop pipe length Reynolds Number Flow rate vz D Re Fanning Friction Factor Pressure Drop 1 P0 PL 4 f 2 L 1 v z D 2 For now, we (This is a measure definition) this In a few (This comes from weeks, weapplying the definition of friction measure this factor to pipe flow) as well 14 © Faith A. Morrison, Michigan Tech U. 7 Calibrate Flow Meters Lab, CM3215 F. Morrison Experimental Notes • Measure orifice pressure drop with DP meter (low pressures) or Bourdon gauges (high pressures) • Determine uncertainty for both measurements (reading error, calibration error, error propagation) • DP meter has valid output only from 4-20mA – above 20mA it is over range • What is lowest accurate Δ that you can measure with the Honeywell DP meter? With the Bourdon gauges? Consider your uncertainties. • True triplicates must include all sources of random error (All steps that it takes to move the system to the operating condition must be taken for each replicate. Thus, setting the flowrate with the needle valve and the rotameter must be done for each replicate.) • Watch level of Tank-01 (there is no overflow protection) 15 © Faith A. Morrison, Michigan Tech U. Report Notes • Design your graphs to communicate a point clearly (chart design) • The axes of your graphs must reflect the correct number of significant figures for your data • Calculate averages of triplicates (needed for replicate error) • Do not use the averages in calibration-curve fitting (use unaveraged data and LINEST). • Use LINEST to determine confidence intervals on slope and intercept • True inner diameter of type L copper tubing may be found in the Copper Tube Handbook (see lab website). The sizes ¼, ½, and 3/8 are called nominal pipe sizes. 16 © Faith A. Morrison, Michigan Tech U. 8 Calibrate Flow Meters Lab, CM3215 F. Morrison CM3215 Fundamentals of Chemical Engineering Laboratory Lab: Calibrate Rotameter and Explore Reynolds Number •Pump water through pipes of various diameters •Measure flow rate with pail-and-scale method •Calibrate the rotameter •Calibrate the orifice meter (measure Δ ) •Calculate Re for each run •Determine if flow is laminar, turbulent, transitional •Use appropriate statistics, sig figs 17 © Faith A. Morrison, Michigan Tech U. PreLab Assignment • Familiarize yourself with Reynolds number, rotameters, and orifice meters. • Find a good estimate of the calibration curve for the DP meter at your lab station and have the equation in your lab notebook. • Prepare a safety section • Prepare data acquisition tables • Answer these questions in your lab notebook: 1. What should you plot (what versus what) to get a straight line correlation out of the orifice meter calibration data? 2. In this experiment we calibrate the rotameter for flow directed through ½”, 3/8”, and ¼” pipes (nominal sizes); will the calibration curve be the same for these three cases or different? 3. What is “dead heading” the pump? 18 © Faith A. Morrison, Michigan Tech U. 9 Calibrate Flow Meters Lab, CM3215 F. Morrison Comments on DP Meter calibration curves 19 www.honeywellprocess.com/ ST 3000 Smart Pressure Transmitter Models Specifications 34-ST-03-65 © Faith A. Morrison, Michigan Tech U. Station 1 Archive (uncorrected) 4.0 historical average 3.5 3.0 p, psi 2.5 2.0 First, look carefully at the data. 1.5 1.0 0.5 0.0 4.0 6.0 8.0 10.0 12.0 current, mA 14.0 16.0 18.0 20.0 20 © Faith A. Morrison, Michigan Tech U. 10 Calibrate Flow Meters Lab, CM3215 F. Morrison Station 1 Archive (corrected for obvious errors) 4.0 historical average 3.5 We are permitted to correct or omit “blunders” 3.0 p, psi 2.5 2.0 22 0.2308 1.5 0.0011 , 1.0 / / 0.982 0.027 , 0.5 0.0 4.0 6.0 8.0 10.0 12.0 14.0 16.0 18.0 20.0 current, mA 21 © Faith A. Morrison, Michigan Tech U. Station 1 Archive (corrected for obvious errors) 4.0 large guarantees that the means , are historical average good estimates 3.5 of the true values (assuming only random errors are present) 3.0 p, psi 2.5 Small standard errors 2.0 22 0.2308 1.5 1.0 / 0.0011 , / 0.982 0.027 , 0.5 0.0 4.0 6.0 8.0 10.0 12.0 current, mA 14.0 16.0 18.0 20.0 22 © Faith A. Morrison, Michigan Tech U. 11 Calibrate Flow Meters Lab, CM3215 F. Morrison Station 1 Archive (corrected for obvious errors) 4.0 historical average 3.5 3.0 p, psi 2.5 Historical, 95% CI: 2.0 1.5 0.2308 0.0022 0.98 0.05 / 1.0 0.5 0.0 4.0 6.0 8.0 10.0 12.0 14.0 16.0 18.0 20.0 current, mA We are 95% confident that the true values of the slope and intercept are within these intervals. 23 © Faith A. Morrison, Michigan Tech U. Historical, 95% CI: 0.2308 0.0022 0.98 0.05 Station 1 Archive Note that the historical average almost goes through the point ,Δ 4,0 / 4.0 historical average 3.5 3.0 p, psi 2.5 2.0 1.5 1.0 Can you comment on that? 0.5 0.0 4.0 6.0 8.0 10.0 12.0 current, mA 14.0 16.0 18.0 20.0 24 © Faith A. Morrison, Michigan Tech U. 12 Calibrate Flow Meters Lab, CM3215 F. Morrison Historical, 95% CI: 0.2308 0.0022 0.98 0.05 Station 1 Archive / 4.0 historical average 3.5 3.0 Δ equation: Δ ; ; p, psi 2.5 2.0 1.5 1.0 0.5 0.0 4.0 slope 6.0 8.0 10.0 12.0 14.0 16.0 18.0 20.0 current, mA (4.0,0) If we know this point is on our correlation line, we can solve for a value of , independent of the systematic offset in the data. 25 © Faith A. Morrison, Michigan Tech U. Summary • We can omit “blunders” from data sets • We are always looking for possible sources of systematic error • When a systematic error is identified (leftover water in unequal amounts on the two sides of the DP meter), we are justified in making adjustments to our correlations 26 © Faith A. Morrison, Michigan Tech U. 13