TOWN FOOD INTERVIEW - Hubs Virginia Peanuts

advertisement

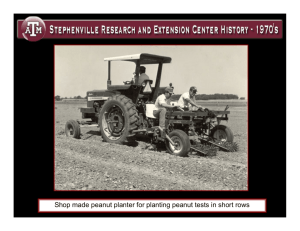

Virginia Moore | Lynchburg Cemetery | Appalachian Trail What crunchy product is a state agricultural hallmark? A visit with the families who give us … Peanuts www.Virginialiving.com October 2009 $4.95 Photograph by Casey Templeton food town interview Striper is the “king” of fish The passions of Poquoson Smithfield Foods’ Joe Luter III Deep Roots For the 200 farmers in southeastern Virginia’s peanut belt, this is a special time of the year: harvest season. Low prices have shrunk production volumes, but nobody is giving up on an iconic food crop that goes back nearly 170 years. After all, Virginia farms still grow some of the world’s best (and biggest) peanuts, and state processors still put the salty, crunchy morsels on tables across America. As one Surry farmer says, “I have peanuts in a field that belonged to my greatgreat-grandfather. This is a family tradition.” By Ben Swenson | Photography by Casey Templeton 104 | V i r g i n i a L i v i n g Opposite page: James Porter Jr. leveling peanuts in a truck bed V i r Porter g i n i has a Lworked i v i n in g the peanut at Indika Farms. Like his father, business all his life. Here: Todd Cutchin’s peanut farm in Sedley. | 105 In the rising light of a cool spring dawn, brothers Billy and Jesse Gwaltney are preparing for a long day at Indika Farms. They’re glad to finally be moving; heavy rains have held them up for more than a week. That the work can finally begin doesn’t make their task any less daunting, though. They will work until 9:00 p.m. and plant as many as 100 acres. The Gwaltneys are sowing a peanut crop, following in the footsteps of their father, William Gwaltney, Sr., who began growing them in the 1940s. Billy and Jesse have already prepared the ground, plowing long rows, or beds, 36 inches apart. Today, they will attach a planter to their tractor. The planter seems a cumbersome accessory; it is squat and wide, with springs, discs and hydraulic lines stretching the length of it. For all its bulk, however, the planter is a precision instrument, gliding effortlessly over eight beds at a time, depositing one peanut seed every three inches—no more, no less. In a few days, the plants will sprout, and the Gwaltneys will begin the time-honored practice of tending a peanut crop. 106 | V i r g i n i a L i v i n g Indeed, the Gwaltneys, and about 200 other farmers, are continuing a more-than160-year-old tradition in southeast Virginia, one that has left an indelible mark on the region’s landscape and culture. It’s hard to miss: the country stores, weathered lettering and all, pawning peanuts to passersby; the level, gray fields stretching to distant tree lines, full of neat rows of bright peanut plants; the aged brick processing plants in downtown Suffolk and the modern facilities that have replaced them. Literally and figuratively, the peanut has deep roots in the fields and towns in this part of the state—chiefly the counties of Dinwiddie, Greensville, Prince George, Sussex, Surry, Isle of Wight and Southampton and the city of Suffolk. “I have peanuts growing this year in a field that belonged to my great-great-grandfather,” says Kevin Monahan, who farms near the town of Dendron in Surry County. “There’s a family tradition here, and peanuts are something that I enjoy growing and harvesting. It requires a lot of time and labor, but there’s nothing like the smell of green peanuts in the field at harvest time.” But tradition only partly explains the endurance of this annual crop, even as the peanut industry has been battered in recent years by oversupply and lower prices. Quality drives demand for any product, agricultural or otherwise, and few dispute the fact that Virginia, while only the ninth-largest American producer of peanuts by number of acres planted, makes some of the best peanuts in the world. Of the four types of peanuts grown in the United States—Valencia, Runner, Spanish and Virginia—the last is most highly prized for its extraordinarily large kernels. Even though the Virginia-type peanut is grown in other states, it is the only kind planted in the commonwealth. The largest size, or grade, of Virginia peanut is called “super extra large,” and it most often ends up as finger foods and gourmet products. “Virginia peanuts are well known,” says Dell Cotton, Virginia’s top peanut promoter. Cotton serves Above: Joe Blythe, 71, has been growing peanuts for 40 years. as executive secretary for the Virginia Peanut Growers’ Association, a farmers’ trade group, and program director for the Virginia Peanut Board, a state agency that administers funds to promote the industry. “There’s not a comparable size in other types of peanuts, so farmers of Virginia-type peanuts get more money for them. For instance, the Runners grown in much of the Southeast are mostly the same medium size.” Despite the food’s popularity, peanut production in Virginia has steadily dropped over the past several years, owing largely to a decline in available farmland, an oversupply of peanuts and a 2002 federal farm bill that did away with a guaranteed price per ton for peanuts. Whereas Virginia farmers once grew in the neighborhood of 100,000 acres of peanuts annually, the commonwealth now lags far behind other states— among them, the Carolinas and Texas. In 1988, for example, Virginia’s peanut farmers planted 91,000 acres and got more than $600 per ton, thanks to legislation that guaranteed a high price per ton. In 2008, Virginians produced a fraction of that, just 23,000 acres, receiving a price of around $450 per ton. Monahan explains that falling prices are a major reason that many farmers stopped growing peanuts in favor of other crops such as soybeans and cotton. “Peanuts require a lot of specialized machinery that is only good for that one crop,” he says. “A lot of this machinery is getting old, and farmers are having a hard time investing in the repairs and new equipment if they don’t know that they’re going to make a return on that investment. You can only farm for so many years at a loss.” Even with the tough market conditions, the Gwaltneys, along with other peanut farmers in this state, say they are in this business for the long haul, if only because they have too much money and passion invested in it to quit. “The day I stop growing peanuts is the day I quit farming,” says Billy Gwaltney, 53, an amiable country farmer who speaks with the drawl common south of the James River. As with all farmers, a good peanut crop will help the Gwaltneys handily—and the brothers are optimistic that this year’s harvest will turn out well as long as the weather remains in their favor. Indika Farms (pronounced inDIKE-uh) is a family business. As children, the Gwaltney brothers would get off the school bus in front of the farm’s office and help see to the day’s chores. Their mother, Dot, still comes down to help out at the height of the harvest season. Indika Farms has expanded over the years, though Billy Gwaltney notes that the 1,500 acres he and his brother work constitute only a medium-sized farm. This year, the Gwaltneys will not only grow their own peanuts—about 300 acres of them—but they will also buy peanuts from seven farmers around Windsor in Isle of Wight County, where Indika Farms is located. Indika Farms is somewhat unique because it is a commissioned buyer for Birdsong Peanuts, a Suffolk-based peanut distributor. Area farmers sell their peanuts to the Gwaltneys, who are permitted to write checks for Birdsong. The Gwaltneys have a processing operation on-site, and they clean and shell the peanuts they grow, as well as the ones they buy from other farmers, before the crop is trucked to Birdsong. The Gwaltneys are unlike many other farmers, too, in that much of their harvest becomes socalled “seed peanuts”—that is, peanuts of a certain grade and quality that will be the seeds used to plant next year’s crop. Because of how the plants grow, Virginia’s peanut belt is limited to land with specific soil conditions. The peanuts are planted in early May, and about a month later the shin-high, oval-leafed plant blooms. The plant’s delicate, yellow flowers send stems, or “pegs,” into the soil below. From each of the 40 or so pegs, a peanut grows underground. Peanut crops demand sandy soil because the ground must be loose enough to allow the pegs to push down a few inches into the dirt. West of Dinwiddie, east of Suffolk and north of the James River, the ground isn’t suitable. Virginia’s peanut belt, then, has clearly defined boundaries. Peanut plants are more sensitive than one might think. They are susceptible to disease and fungus, and the dewy mornings and humid summer days so common in southern Virginia are the perfect petri dish for organisms that can ruin a crop. “Every time I take that out, it costs me $3,000,” laments Jesse Gwaltney, 48, pointing toward his sprayer—a tractor with a large tank and arms that spread out horizontally to coat the rows of peanuts with fungicides necessary to ensure the crop’s survival. Come September, after a few months of meticulous care, the peanuts are harvested. Peanut farmers use a “digger” to do the job. It turns the entire plant—leaves, pegs and peanuts—upside down. Rather than immediately whisking away the peanuts for processing, however, farmers do a curious thing: They leave them in the field to dry. The peanuts themselves consist mostly of water, and allowing them to dry in the field for a week reduces their moisture content and gets them ready to be shelled and processed. “We pray for hot, dry days with no frost,” says Billy Gwaltney. “Frost can ruin them.” Virginia’s weather is actually a mixed blessing. While the weather fosters peanut-destroying fungi and bacteria, it is also what makes Virginia peanuts stand out from those—even of the same type— that are cultivated in more southerly locations. “We let them dry naturally for seven days, and our climate is one of the reasons that our peanuts are some of the best in the world,” says Gwaltney. “These peanuts are cured. Down south, they do a good job, too, but they have hotter weather, which dries the peanuts out quickly and changes the complex of the oil. Our 60-, 70-, 80-degree days cure them a lot slower and keep that good flavor in there.” All four varieties of peanut plants make peanuts of different grades, each of which has a specific use. Clockwise from top left: Jimmy Creasey, a veteran season worker at Severn Peanut Co.; Clint Williams levels peanuts; a tractor at Todd Cutchin’s farm; farmer Joe Blythe; unpicked peanut plants. Smaller peanuts are pressed for oil, while medium-sized peanuts (those that the Gwaltneys use for seed) are typically sold to processors that make candy and peanut butter. Large peanuts are generally used for products in which the peanut remains whole—flavored or chocolatecovered peanuts, for instance. The largest Virginia-type peanuts—constituting only a small fraction of any farmer’s harvest—are designated super extra large, and these are the gems of the state industry. They become the salted cocktail peanuts and other specialty products, such as inthe-shell, that are a favorite among consumers. The Gwaltneys’ tidy office— the epicenter of Indika Farms—is dwarfed by mammoth silver holding tanks that store the peanuts the farmers have grown and bought. These tanks, like everything else at Indika Farms, are an important part of getting the peanuts from the ground to the table. Once the peanuts have been collected from the field and had their V i r g i n i a L i v i n g | 107 stems removed by a picker, they are inspected by regulators and moved to the tanks, where they await their turn in the adjacent “sheller.” For all but in-the-shell peanuts, the hulls must be removed and the peanuts separated according to size. The sheller at Indika Farms occupies fully half of a warehouse-sized building. It is a highly mechanized series of instruments that remove the kernels from their shells in rotating drums. The peanuts pass over a series of screens, computerized air jets and gravity separators and emerge whole, clean and ready to be trucked away. At every step of the way, the Gwaltneys, like other peanut farmers around the country, rely on technologies that have made peanut farming more efficient and profitable. Their tractor has a global positioning system and can literally drive itself. “My dad wouldn’t believe how far peanut farming has come,” says Billy Gwaltney. Peanut farming has come a long way since they were first grown commercially in the 1840s near the town of Wakefield, in Sussex County. In those days, peanuts were considered a curiosity, even good animal feed. Not until the turn of the century, boosted by new technologies as well as the research of renowned biologist George Washington Carver, who found about 300 uses for peanuts, were they grown on a large scale. As peanuts became a popular staple food in the century that followed, demand for them flourished. It has remained strong ever since. Dell Cotton explains that the public’s appetite for peanuts usually increases about 2 or 3 percent each year. Unlike other products, peanuts rarely encounter spikes or declines in popularity, remaining instead a commodity with predictably strong appeal among consumers. In the town of Waverly, a few miles west of Wakefield on Route 108 | V i r g i n i a L i v i n g Left: a plant with some 40 pegs (stems), each holding a peanut. Below: Dot Gwaltney and her son Billy at Indika Farms. for instance—and 30 or so employees to process about 1 million pounds of peanuts a year. The peanuts begin their journey through Hubs’ production line in eight-pound baskets, in which they are given a blanching, or hot water bath, of several minutes. Each of the baskets moves in line through a trough containing the hot water. After the blanching, the continuous cooker ferries the baskets through a second trough, this one containing hot oil, in which the peanuts are roasted. The peanuts are dried quickly, salted, measured by weight and put into packages of all sizes. Throughout the process, Hubs’ employees perform quality control to make sure that only peanuts of superior quality are sold. The company’s cooking process— In a Nutshell: Number of Virginia peanut farmers: About 460, the main artery through peanut country, a nondescript building at the Miles B. Carpenter Museum complex pays tribute to the heritage of the peanut. “First Peanut Museum in U.S.A.” boasts the sign on the white clapboard structure, which houses artifacts, pictures and folk art from the Virginia peanut’s storied past—decades-old peanut shellers and graders, for instance, all handoperated. Shirley Yancey, president of the museum’s board of directors, seems to have an encyclopedic knowledge of the peanut’s history in this state. Born during the Great Depression, Yancey is a lifelong resident of Waverly. She remembers well her father’s fall harvest of peanuts in the 1930s and ’40s, prior to the advent of equipment that allowed one or two farmers to grow hundreds of acres. Yancey says the crop helped see her family through hard times. Before machines replaced human labor, turned peanut plants were “shocked,” or stacked on six-foothigh stakes to dry. “My mother and I would go out where the peanuts had been shocked … where some peanuts would be left on the ground,” she says. “We would pick a hundred pounds of peanuts and put them in a burlap bag and sell them. We got 10 dollars for that bag. I bought 200 my clothes for school and had some money left over.” Growing peanuts is only the first part of the business, of course. The second part is processing them for consumers. Hubbard Peanut Company, tucked away in the tiny Southampton County village of Sedley, population 1,100, is not the biggest processor in the state, but it is one of the oldest and was the first to process the highest grade—super extra large—on a wide scale. In Sedley, residents keep neat houses with well-groomed lawns, and life seems to drift by at a leisurely pace. A dish on the counter of the town’s post office offers patrons—what else?— peanuts. “Hubs” was founded here in 1954, in a small Cape Cod home owned by H. J. Hubbard and his wife, Dot. They began cooking and selling the peanuts grown so abundantly in the surrounding countryside. Hubs has grown a lot since those days. In the 1960s, the firm built the first of many additions, creating an industrial processing facility next to the original home, which now serves as the company office. The plant uses modern equipment—a continuous cooker, a cooling tunnel and a salting machine, Price per ton for peanuts: $600 1988 $450 2008 Farmland in acres in Virginia devoted to peanuts: 91,000 23,000 1988 2008 Counties and cities in Virginia where peanuts are grown: Dinwiddie Greensville Prince George Sussex Surry Isle of Wight Southampton and the city of Suffolk M a p B y L u n a Al f o r d blanching them in water and roasting them in oil—has remained unchanged since Dot Hubbard began cooking them five decades ago. Hubs’ sleek, spotless production facility has streamlined the process, allowing the company to process a volume of peanuts beyond H.J.’s and Dot’s wildest imaginings. Lynne Rabil, one of four Hubbard children and now Hubs’ president, maintains an office in a room of the original home. She knows her workspace well—it was the bedroom she and her twin sisters shared as young girls. Among her responsibilities is acquiring the super extra large Virginia-type peanuts that the company uses to make Hubs’ products. One of Rabil’s local suppliers is Birdsong Peanuts. And one of Birdsong’s many peanut providers is Indika Farms, where the Gwaltneys grow and buy peanuts around Windsor. This, of course, means that some of the very same peanuts that Rabil processes at Hubs came out of the ground only a few miles down the road at Indika Farms. From Sedley, Hubs peanuts are sold around Virginia and the country, directly to individuals, organizations and stores. Hubs prefers to deal as closely with consumers as possible, only rarely selling their peanuts through a distributor. Hubs’ employees, some of whom have been with the company for decades, pride themselves on their company’s history, the connection to the land that surrounds them and the quality of the product they put on tables. “Being a family business that started here and has stayed here is important to us,” says Rabil. “My mother prepared peanuts the way that farmers’ wives had for generations. Now we take the best of the field, the best of the crop, and prepare them the same old way it had always been done.” Of course, Hubs has some competi- Eat ’em, Buy ’em For Pete’s Sake, Courtland 757.653.9031 Sells peanut pie, fried catfish and barbecued pork. Virginia Diner, Wakefield 1.888.823.4637 or VaDiner.com Offers many varieties of seasoned peanuts and peanut pie. Retail stores: Plantation Peanuts (PlantationPeanuts.com) and Wakefield Peanut Co. (WakefieldPeanutCo.com), both on Rte. 460 in Wakefield. Above: the quality control and packaging operation at Hubbard Peanut Company tion. There are more than a dozen processors in Virginia, the largest being Suffolk-based Planters Nuts (with their iconic Mr. Peanut logo). Other companies have established a strong reputation in the state, too. Virginia Diner Restaurant, for instance, is a fixture along Route 460 in Wakefield, and the gourmet peanut products the firm sells under its own brand name are familiar in many parts of the state; some children sell Virginia Diner peanuts for school fund-raisers. Bacon’s Castle Brand Peanuts and Red Fox Peanut Company are two other, smaller companies in the industry. Virginia’s peanut growers and processors face many challenges, but Dell Cotton believes that none is insurmountable. Indeed, Cotton has witnessed firsthand the industry’s peaks and troughs over the last two decades—including last year’s salmonella scare. He contends that Virginia’s peanut growers, and the industry as a whole, have plenty of reasons for optimism. Peanuts are a cheap source of nutrition, he notes, and thus remain popular during eco- nomic downturns. And they do not require cooking once in the consumers’ hands. What’s more, he thinks that Mother Nature might help end the oversupply problem. “It’s been awfully wet,” he says, “and the number of acres planted will be low this year. That should work all the surplus out of the system.” Above all, Cotton knows that peanuts are in the blood of farmers in southeast Virginia—people like Billy and Jesse Gwaltney. While there will always be bad seasons and challenging market conditions, not to mention the relentless encroachment of exurban sprawl, these issues can’t devalue the labor that goes into putting Virginia peanuts on family tables, or change the trusted traditions that define Virginia’s peanut belt. And as long as consumers reach for a tin of cocktail peanuts, and as long as the Hotel Roanoke and other establishments continue to serve peanut soup, Virginia’s peanut growers and processors will be happy to serve the demand. For that reason, the yearly cycle of planting, growing and harvesting peanuts goes on. “We may put a few other crops in the ground,” says Billy Gwaltney, “but first and foremost, we’re peanut farmers.” • V i r g i n i a L i v i n g | 109