Global Heat Pump Performance Review.

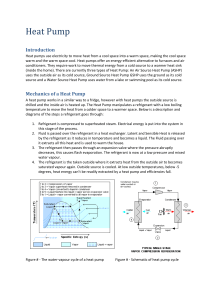

advertisement