shadecloth tech guide

TECHNICAL GUIDE – NUMBER ONE

ProTEX SHADECLOTH

E1 October 2007

Nolan Warehouses

www.nolans.com.au

COMPANY PROFILE

Nolan Warehouses , established in 1920, is a merchant wholesaler whose products can be segregated into three main groupings:

Industrial Fabrics, Automotive & Marine and Contact & Commercial.

The business trades from six fully stocked branches throughout

Australia, located concentrically with the country’s population.

The company is classified by the Australian Securities and Investments Commission (ASIC) as a ‘Large Reporting

Entity’, satisfying the latter’s minimum classification criteria of net assets and turnover.

The Nolan team at the Adelaide conference 2007.

Over many years, Nolan Warehouses has established a solid network of trading partners around the world, and longstanding business relationships with its customer base, most of whom are fabricators or installers. This is because nearly all the products the company supplies require conversion into a practically usable or consumable form. Nonetheless, in its area of expertise, the company is well known in the Architect and Specifier community.

The company prides itself on its technical expertise, and rigorous approach to new product selection and testing, which goes a long way to ensuring that its product portfolio is at the very least, of merchantable quality and fit for purpose. This is particularly significant, since the key features that determine product quality cannot be determined by superficial examination. Many of its brands, through prolonged field life and performance, have become synonymous with their end application.

Head office and warehouse in Alexandria, Sydney.

Firemen attending blaze at Adelaide warehouse in 1963.

Liveried delivery truck at Circular Quay, Sydney, circa 1930.

Over its 87 year history, the company has prospered through depression, world war, and significant changes in strategic direction. Its various branches have survived fire, major flooding and even earthquake! It remains proudly third generation family owned and operated.

Nolan Warehouses

www.nolans.com.au

TABLE OF CONTENTS

Glossary of Technical Terms

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

Introduction

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4

The Products

Yarn Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5

Types of Knit Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5

Protex Commercial Grade Shadecloth . . . . . . . . . . . . . . . . . . . . . . . . . .

6

Protex Premium Grade Shadecloth . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6

Relevant Properties, Test Methods and Their Significance

Shade Factor, UVR Block and PAR . . . . . . . . . . . . . . . . . . . . . . . . . .

7- 8

Thermal Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8

Physical Properties Specified by AS 4174 . . . . . . . . . . . . . . . . . . . .

8 - 9

Chemical Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9

Flammability

Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9

Description of AS 1530 P t II and P t III Tests . . . . . . . . . . . . . . . .

9 -10

Fire Regulations for Shade Structures . . . . . . . . . . . . . . . . . . . . . . . . .

10

Engineering Properties of ProTEX Parasol

. . . . . . . . . . . . . . . . .

11-13

Fabrication

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14

Non-Tension Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14 -15

Tension Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15

Design and Installation of Supports . . . . . . . . . . . . . . . . . . . . . . . . . .

15

Standard Design Details

The Concept . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16

Design Parameters and Specifications . . . . . . . . . . . . . . . . . . . . . . . .

16

Requirements for Access To and Use Of the Standard Details . . . . .

16

Shade Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16 -19

Request for Engineering Design Certification . . . . . . . . . . . . . . . . . . .

20

Standard Shade Structures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21- 26

Appendix A

Copy of Formal Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27

Appendix B

Copy of AS 1530 P t II and P t III Test Certificates . . . . . . . . . . .

28 - 30

Appendix C

Test Results for “Sunguard” B138 Thread . . . . . . . . . . . . . . . . . . . . .

31

Appendix D

Chemical Resistance of Polyethylene . . . . . . . . . . . . . . . . . . . . . .

32- 35

Appendix E

Relationship Between Cable Tension and Curvature . . . . . . . . . .

36 - 37

Appendix F

Shadesail Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

38 - 39

Product Colour Ranges

. . . . . . . . . . . . . . . . . . . . . . . . . .

inside back cover

1

2

LIST OF TABLES & FIGURES

TABLE 1 – Properties of Polyethylene Yarn

TABLE 2 – Shading Properties of ProTEX Shadecloth, as defined by AS 4174

TABLE 3 – Protex Parasol Shade Factor, UVR Block and UPF by Colour

TABLE 4 – Bursting Pressure AS 2001.2.19

TABLE 5 – Ultimate Tensile Strength AS 2001.2.3.2

TABLE 6 – Tear Strength AS 2001.2.10

TABLE 7 – Percent Increment or Decrement in Strength after UV Exposure

TABLE 8 – Results of AS 1530 pt III Flammability Tests

TABLE 9 – Measured Uniaxial Elastic Properties of ProTEX Parasol Fabric

TABLE 10 – Estimated Biaxial Elastic Properties of ProTEX Parasol Fabric

FIGURE 1 – Molecular Structure of Ethylene

FIGURE 2 – AS 1530 P t III Testing Apparatus

FIGURE 3 – Stress Strain Curve for Protex Parasol

FIGURE 4 – Creep Results for ProTEX Parasol

FIGURE 5 – Cyclic Loading Results for ProTEX Parasol

FIGURE 6 – Recommended Edge Support (Method One)

FIGURE 7 – Recommended Edge Support (Method Two)

FIGURE 8 – ‘V’ Grip Fastening System

FIGURE 9 – Shade Diagrams for Standard Designs (Sydney) at Summer Solstice

FIGURE 10 – Shade Diagrams for Standard Designs (Sydney) at Equinox.

IMPORTANT:

The contents of this technical paper are the copyright of Nolan O’Rourke and Company

Pty Ltd. No part may be reproduced without explicit permission. Second Edition, first printing, October MMVII.

DISCLAIMER:

This guide is designed to provide appropriate technical information to specifiers, fabricators, installers and consumers. The information contained herein or otherwise supplied is based on our own general knowledge, research, and advice obtained from consultants and experienced fabricators in the industry. The information is provided in good faith, but no warranty is given or is to be implied with respect to its accuracy or applicability.

ACKNOWLEDGEMENTS:

• Tony Dockrill and Shane Linton, of Izzat Consulting Engineers, for engineering design,

Protex ‘Parasol’ testing, and advice.

• John Greenwood, of John Greenwood and Associates, for advice on shade audit and design.

• Roger Cole, of CPA Advertising, for layout and production of the technical manual.

GLOSSARY OF TECHNICAL TERMS

Biaxial Loading Load in both warp and weft directions.

Co-efficient of Shadow The relative proportion of shade cast directly below a structure.

Cover Factor A measure of percentage area of the cloth covered by yarns and fibre.

Creep A time dependent increase in strain under constant applied load.

Daily Shade Co-efficient A measure of the quantity of shade provided compared to the size of the structure.

Elastic Modulus The relationship between applied stress (a force) and resultant strain

(a deflection).

Flammability Index A measure to what extent the test specimen burns and the heat

(AS 1530 pt II) generated measures from 0 (low risk) to 100 (high risk).

FR or Flame Retardant A term used to describe yarns or fabrics that have had their inherent burning characteristics altered by addition of chemical suppressants.

Limiting Oxygen Index The minimum percentage of oxygen that must be present in the atmosphere for an object to ignite and burn. A value less than 21 means the object ignites fairly readily.

Moment The tendency to produce rotation caused by an applied force; calculated as the product of that applied and the perpendicular distance to a fixed point.

PAR Transmitted (i.e. Photosynthetically Active Radiation) is effectively the proportion of visible light passing through the material (i.e 400nm to 770nm).

It is a measure of how much effective light would reach plants shaded by the cloth.

Poissons Ratio A measure of the proportional extent to which the width contracts to an applied load in the length direction and vice versa.

Shade Factor The percentage of ultra violet and visible light, i.e. radiation of

(Shade Co-efficient) wavelengths between 290nm and 770nm not transmitted through shadecloth.

Smoke Developed Index A measure of the smoke emitted, on a scale of 0 (low risk) to

(AS 1530 pt III ) 10 (high risk).

Specific Gravity Ratio of an object’s density relative to water. A value less than 1 means the object is lighter than water.

Spread of Flame Index A measure of how quickly a fire propagates, expressed on a scale of

(AS 1530 pt III ) 0 (low risk) to 10 (high risk).

Tenacity A measure of a yarns tensile strength.

Uniaxial Loading Load in one direction.

UPF (Ultra-violet A measure of the duration of exposure required to accumulate a

Protection Factor) sunburning dose of radiation relative to that if no protection is available.

UVR Block The percentage of Ultra-Violet Radiation, of wavelengths between

290nm and 400nm, not transmitted through shadecloth.

Warp Longitudinal direction along a roll of fabric.

Weft Horizontal direction across a roll of fabric.

3

INTRODUCTION

ProTEX is the masthead brand for a range of outdoor textiles and fabrics marketed by Nolan Warehouses. The name, deliberately chosen as an alternative spelling of

‘protects’, is a clear statement of its function. The word

‘pro’ is an abbreviation of ‘professional’, or highest standard; and ‘TEX’, a truncation of the word ‘textile’, which is the product descriptor. The ProTEX concept is visually reinforced by the logo, with the umbrella shaped

‘T’ providing protection from the elements, represented by burning sun and black storm clouds.

The brand itself is underpinned by a rigorous product development process, based on three basic principles:-

1. Selection of an appropriate standard, preferably

Australian, but where this does not exist, the most applicable European, American or Japanese.

2. Rigorous and exhaustive testing, both in the laboratory and the field, with particular emphasis on the resistance to the deleterious effects of ultra-violet light.

3. Provision of a warranty that states the product meets the chosen specification, and is fit for purpose for a reasonably expected field life; provided it is selected, fabricated, installed and maintained, in accordance with the advice provided in the ‘Technical Guides’.

The principal objective of this Technical Guide is therefore to fully document the above product development process for the ProTEX ranges of knitted shadecloth, and provide the relevant information necessary to satisfy the conditions of our warranty.

The adopted standard for material performance is

Australian Standard AS 4174 – 1994 “Synthetic

Shadecloth”, which in turn specifies Australian Standard

AS 2001 “Method of Test for Textiles” for physical properties and light fastness. Testing has been independently undertaken to these standards by AWTA

Textile Testing.

The determination of engineering properties has been undertaken by the consultants Izzat Consulting Engineers

Pty Ltd, based on laboratory testing undertaken by the

University of Newcastle. Design engineers usually require estimates of the Elastic Properties of the material, and these are provided for the commercial grade shadecloth

‘Parasol’. Results of cyclic and creep testing at the recommended design working loads are also presented.

There is no standard in Australia or overseas, for product selection or installation. Whilst larger structures are usually designed by engineers, and constructed under engineering supervision, many smaller ones are not, which has been of concern to regulators and insurers, with good reason.

In late 1999, a young teenager was killed when a shadestructure, on which she and her friends were frolicking, suddenly collapsed. The South Australian

Coroner recommended:-

“The creation of a complementary Standard (to the existing Australian Standards for playgrounds) in relation to shade sail structures (which)… should make provision for at least the following factors:-

• standards for the design and construction, particularly dealing with footings, metal fabrication, welding standards, rust-proofing, strength of materials, etc;

• standards for tensioning of the structure, including recommended methods of performing and checking this aspect;

• formula for calculation of the stresses involved, taking into account such variables as wind, storms, etc;

• standards for the frequency of maintenance, and particularly retensioning;

• minimum height standards above play equipment to prevent access to the sail surfaces;

• standards for materials to be used;

• design standards for the layout of play equipment, and the placement of ground-level hazards such as borders;

• levels of signage required to warn of the dangers of climbing on the structure.

At the date of publication of this ‘Technical Guide’, such a standard had not been prepared by Standards Australia.

Consequently, included herein are a series of standard details and specifications for typical tensioned shade structures of surface area less than fifty square metres.

These provide the details recommended by the coroner, and have been prepared by Izzat Consulting Engineers Pty

Ltd. For a modest fee, the consultants can verify these to be suited for a specific site, by checking local terrain (for wind loading risk) and ground conditions (for foundation design criteria), then issue an engineering certificate for that particular location. The procedure for obtaining certification is outlined within this guide.

For structures larger than fifty square metres in area, professional engineering advice specific to the project should be sought at the design stage. Some states (e.g.

Queensland) require installers to be licensed.

The Building Code of Australia (BCA) has prescriptive requirements for the fire hazard properties of materials, linings and surface finishes in buildings. Although subject to interpretation, shadecloth structures may fall within the ambit of these regulations, and in this context a conservative approach has been adopted in this guide.

4

THE CONTENTS OF THIS TECHNICAL GUIDE ARE COPYRIGHT OCTOBER 2007. NO PART MAY BE REPRODUCED WITHOUT EXPLICIT PERMISSION.

THE PRODUCTS

Yarn Characteristics

ProTEX shadecloth is manufactured from UV-stabilised

High-density polyethylene. Since the characteristics of the finished cloth are significantly dependent on the properties of the yarn, it is instructive to examine them in some detail.

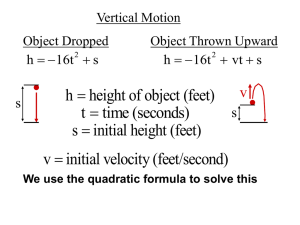

Ethylene is comprised of Carbon and Hydrogen molecules, and has the simple molecular structure shown in FIGURE 1 . This becomes a polymer when the basic structure between the dashed lines is linked together repetitively in continuous chain. Low density (LDPE) and high density polyethylene (HDPE) are almost identical except that HDPE is more linear in structure, with less branching of the polymer chains, which results in better tensile properties. The characteristics of polyethylene yarn are shown in TABLE 1 .

FIGURE 1

TABLE 1 – Properties of Polyethylene Yarn

Tenacity (grams/denier ) 4.0 to 5.5

Melting Point (°Celsius )

Specific Gravity

Moisture Regain (%)

Limiting Oxygen Index

110 to 120

0.93 to 0.96

< 0.01

17

Tenacity is a measure of basic tensile strength, which during the yarn’s production is maximised by annealing or strain hardening. Specific gravity is the yarn’s density relative to water; and moisture regain the amount of water it absorbs when initially dry, then exposed to 65% humidity at 20ºC. The respective values of these parameters mean that polyethylene is lighter than water, which gives the benefit of a high strength to weight ratio; and does not absorb liquid, a real plus for stain resistance.

Polyethylene can be broken down by the action of Ultra-

Violet light, and without appropriate UV stabilisers, polyethylene yarn would degrade rather quickly. The stabiliser or inhibitor in fact acts as a sacrificial component, like the way zinc is added to provide corrosion resistance in galvanised iron.

Polyethylene is relatively chemically inert, but unfortunately the UV stabilisers are not; and are particularly affected by the group of elements known as halogens

(e.g. Chlorine, Bromine, Iodine, Fluorine) which are highly reactive diatomic molecules in their natural form. This is why concentrated bleach (a chlorine based compound) is not recommended for cleaning, and it is prudent to limit warranty for shade structures suspended over swimming pools.

The “Limiting Oxygen Index” (LOI) is the minimum percentage of oxygen that must be present in the atmosphere surrounding the yarn for it to ignite and burn.

The proportion of oxygen in the air is normally 21%, and therefore polyethylene, which has an LOI below this level, ignites fairly readily. However, because of its low melting point, the yarn forms molten droplets that fall away when exposed to flame, dispersing the feed source. In practical terms, this limits the flammability hazard of horizontally suspended shadecloth.

Flammability characteristics can be altered by the addition of flame retardants, which unfortunately can be halogen based, and the necessity to use high levels of these to achieve efficacy, not only detrimentally affects stabilisers, but can also have a significant negative impact on the physical and mechanical properties of the yarn.

For this reason, the ProTEX ranges of shadecloth are not at the moment, knitted from flame retarded yarn, but even so, still meet the Building Code Regulatory requirements (refer TABLE 8 ). Recent research has led to the development of non-halogenated, UV stable, amine based flame retardants, which are effective in low concentrations, and do not affect stabilisers. Once these are field proven, the ProTEX commercial ranges will be FR treated accordingly.

Types of Knit Construction

There are essentially two types of knit in shadecloth –

(i) monofilament only, or (ii) monofilament and tape, and

ProTEX Parasol is of the latter construction. The ‘Monofilament only’ knit is popular with fabricators because of its higher strength, and relatively lighter weight.

However, the advantage of the ‘Monofilament and Tape’ construction is that the inclusion of the tape with its wider profile, increases the shade factor and UVR block, which is the general purpose for installing shadecloth.

However, because the tape is not strain hardened, it increases the overall weight of the cloth without contributing much more to its physical strength. Thus, a

‘Monofilament Only’, tends to have a higher strength to weight ratio than a ‘Monofilament and Tape’ construction.

The right selection of cloth depends on the circumstances, but generally ‘Monofilament and Tape’ construction is recommended for applications where protection from UV is the paramount concern (e.g a Childrens’ playground), as opposed to structural efficiency (e.g a car-park). Nonetheless, there is no engineering reason why ProTEX Parasol cannot be used for either, since the applied and working loads are at least an order of magnitude lower than its ultimate breaking strength.

THE CONTENTS OF THIS TECHNICAL GUIDE ARE COPYRIGHT OCTOBER 2007. NO PART MAY BE REPRODUCED WITHOUT EXPLICIT PERMISSION.

5

THE PRODUCTS

(continued)

Commercial Grade Shadecloth

ProTEX ‘Parasol’ shadecloth is knitted with a lock-stitch construction, which provides dimensional stability and minimises unravelling when cut. It has a high strength to weight ratio, and can be easily tensioned in both warp and weft directions. All finished product is stentored, or heat set, to minimise shrinkage, and to improve lay-flat characteristics, which can be a significant factor in reducing cutting and fabrication costs.

Brandname:

Construction:

Weight:

Width:

Roll length:

Roll diameter:

ProTEX ‘Parasol’

Monofilament and tape.

325 grams /square metre (± 5%)

3.0 metres

50 metres

37cm

✓

✓

Total roll weight: 50 kilograms

Identifying marks: None. Identifiable by tape insert in weft direction

PRODUCT FEATURES

✓

UV Stabilised Yarn

✓

Up to 95% UVR Block

✓

Colour Fast

✓

High Strength

✓

Heat Set

Abrasion Resistant

Ten Year Limited

Warranty

Colours available: (Ex-stock) – Beach Sand, Red, Harvest, Forest Green, Terracotta, Ocean Blue, Navy,

Ivory, Gun Metal, Black. (Indent only) – Yellow, Sky Blue, Foggy Grey, Chestnut Brown, Silver

(for colour samples refer inside back cover)

Premium Grade Shadecloth

Brandname: ProTEX ‘Sombrero’

Construction: Monofilament

Weight: 240 grams /square metre (± 5%)

Width: 4.0 metres

Roll length:

Roll diameter:

Total roll weight:

50 metres

38cm

50 kilograms

Colours available: Black, Dark Green, Sand

( for colour samples refer inside back cover)

6

THE CONTENTS OF THIS TECHNICAL GUIDE ARE COPYRIGHT OCTOBER 2007. NO PART MAY BE REPRODUCED WITHOUT EXPLICIT PERMISSION.

RELEVANT PROPERTIES, TEST METHODS

AND THEIR SIGNIFICANCE

Shade Factor, UVR Block and PAR

Visible light, ranging in wavelength between 400nm and

770 nm (nanometres or one millionth of a millimetre), represents only a small proportion of the sun’s energy reaching the earth’s surface. Just below this band of wavelengths is the Ultra-Violet spectrum, and although representing less than five percent of the total impinging radiation, it is biologically the most damaging, especially

UVB (of wavelength between 290nm and 320nm).

Hence, for good reason, the Australian Standard for

Synthetic Shadecloth (AS 4174 -1994) distinguishes between these radiation bands in penetration tests on shadecloth. The “Shade Factor” (sometimes reported as

“Shade Co-efficient”) is defined as “the percentage of normally incident (i.e. impinging at 90%) radiation between 290nm and 770nm ( i.e. both Ultra-Violet and visible light) not transmitted through the material”.

The “UVR Block” is the percentage of Ultra-Violet

Radiation, of wavelengths between 290nm and 400nm

(i.e. Both UVA and UVB) that is not transmitted. In terms of assessing the degree of protection offered against sunburn, it is the single most important determinant of shadecloth performance.

The “PAR transmitted”, (i.e. Photosynthetically Active

Radiation) is effectively the proportion of visible light passing through the material (i.e 400nm to 770nm). It is a measure of how much effective light would reach plant life shaded by the cloth.

The standard also specifies “Cover Factor”, which although determined by the degree of radiation penetration of the specific wavelength 350nm, is designed to be a measure of the percentage area of the cloth covered by yarns and fibre, or density, rather than shading effectiveness.

For ProTEX shadecloth, the values of these factors lie within the range quoted in TABLE 2 . The Australian standard does not specify minimum performance requirements for any of these factors.

TABLE 2 – Shading Properties of ProTEX

Shadecloth, as defined by AS 4174

Product

Parasol

Factor (%) Block (%)

73 to 94

Sombrero 65 to 73

89 to 94

64 to 73 n/a

35 to 27

Like all tests, those that determine the shading performance factors are subject to measurement error, and hence the reported results are the average of ten samples taken from a single metre of cloth. The word

‘error’ here is used in its scientific sense, and does not mean ‘mistake’, but differences in test measurements, which can vary by several percentage points, due to variations in the knit profile across the roll. Knitted cloth has an open, loose structure, and small changes in say, yarn tension during manufacture, can have an inordinate effect on the size of the interstices of the finished material, which in turn affect the calculated UV protection factors. This is further exacerbated by variation between production batches.

For example, the measured results of UVR transmission in two separate tests on the same colour (proTEX Parasol

Beach Sand) undertaken on different dates, varied by more than twenty-five percent! But, if expressed as a proportion of the UVR block, this absolute error is only 2%.

The distorting effect of this error becomes very obvious if one is converting the results to an equivalent Ultra Violet

Protection Factor (UPF), which is common practice amongst some specifiers.

UPF is a directly comparable number to more familiar

SPF or “Sun Protection Factor”, which is applicable to sunscreen lotions, and is a number that generally ranges between 0 and 50. It is a measure of the duration of exposure required to accumulate a sunburning dose of radiation relative to that if no protection was applied. For example, an SPF 30 product will allow only 1/30th of the sunburning dose through the UV filter, and it will therefore take thirty times as long for sunburn to occur.

Thus, if it takes five minutes in the noon sun for skin damage to occur without protection, the same degree of damage will occur over 150 minutes, or two and a half hours, if a 30+ sunscreen is applied.

UPF is calculated by dividing the fraction of UV transmitted into a hundred, and is usually rounded up or down to the nearest half decile (i,e, 5, 10, 15, 20 etc).

When converted to UPF, the upper and lower values for the Beach Sand UVR Block tests quoted above, correspond to 10 and 20 respectively, an error of ± 30% on the average UPF of 15.

Because of the degree of measurement error, it is conceptually flawed logic to draw conclusions based on small relative differences in UVR Block; or even on the relative degree of protection offered by one particular colour relative to another, based on the comparison of test results.

THE CONTENTS OF THIS TECHNICAL GUIDE ARE COPYRIGHT OCTOBER 2007. NO PART MAY BE REPRODUCED WITHOUT EXPLICIT PERMISSION.

7

8

RELEVANT PROPERTIES, TEST METHODS AND THEIR SIGNIFICANCE (cont.)

These factors do vary according to colour pigment used in the cloth, but not to the extent that is implied by ranking

(refer TABLE 3 ). While as a general rule, darker colours

(particularly black) are better UV absorbers than lighter ones, the degree of variation implied is not really an indication of colour efficiency, but much more likely the manifestation of measurement error.

TABLE 3 – ProTEX Parasol Shade Factor,

UVR Block and UPF by Colour

Colour

Black

Beach Sand

Forest Green

Gun Metal

Ocean Blue

Harvest

Terracotta

Ivory

Navy

Red

Factor (%)

94.2

86.4

92.2

92.5

90.9

86.6

84.4

73.3

87.7

79.6

Block (%)

94.4

94.2

93.8

93.3

93.1

93.1

90.4

90.5

90.3

88.7

15

15

10

10

20

15

15

15

10

10 identify a test that is meaningful. Intuitively, one would expect that the darker colours would have a higher level of heat absorption and transmission than lighter ones.

Physical Properties Specified by AS 4174

AS 4174 specifies minimum strength requirements for shadecloth. The test methods however, are different for knitted and woven cloth, and caution should therefore be exercised when comparing test results for different brand products. All ProTEX product is knitted.

AS 4174 stipulates that knitted shadecloth be tested to either AS 2001.2.4, (method A), or AS 2001.2.19, both of which are a measure of bursting pressure. The former test utilises a hydraulic diaphragm, with the result at failure expressed as a pressure (kPa); and the latter a steel ball, with result at failure expressed as a force

(Newtons). ProTEX Parasol exceeds (by at least a factor of four) the minimum requirements of the Australian

Standard AS 4174, for the highest category (‘Heavy’) as shown in TABLE 4 .

TABLE 4 – Bursting Pressure AS 2001.2.19

Test Method

ProTEX

Results

Minimum

Requirements of AS 4174

Bursting Force

Parasol

1887 N ± 113

Sombrero

1629 N ± 110

400 N

(‘Heavy’

Designation)

The UPF values for shadecloth may seem relatively low, compared to the advertised SPF values of sunscreen, and the recommendations of Cancer Councils for clothing. But these have to be taken in the context of what is technically possible to achieve in shadecloth, and other benefits in terms of visible light transmission, ventilation and heat transfer. Because of the error bands noted above, a healthy scepticism should be maintained of published claims for UVR Block. The average value for most brands of commercial grade Shadecloth, including

Parasol, is less than 95%, which implies a UPF factor of less than twenty, which as a rule of thumb, should be taken as the norm.

The expectation that a shadecloth structure by itself is sufficient to provide total protection is misconceived, particularly if it is a tensioned type (as most are), which opens up the interstices in the cloth, and also given the amount of reflected radiation likely to bypass any open form. Nonetheless, shadecloth, in conjunction with other measures, such as wearing a hat or sunscreen, has a cumulative protective effect, and certainly is as good as, or better than the protection often offered by natural foliage.

Thermal Properties

Presently there is no data available on the solar heat characteristics of the ProTEX product, as it is difficult to

For woven shadecloth, AS 4174 specifies the test method

AS 2001.2.3, (“Grab” Test) which measures the breaking force of a 100mm strip expressed in Newtons, with the stipulated result dependent on the grade designation of the shadecloth. The results for all ProTEX product are shown in TABLE 5 .

The breaking force of the material is considerably more than its tear strength. Simplistically, the former is a measure of the ultimate strength of the knitted yarn matrix, and the latter of how difficult the matrix is to separate. Tear strength is tested using AS 2001.2.10, in which a sample is cut partially through, and the force required to initiate and continue tearing measured. The results for ProTEX Shadecloth are shown in TABLE 6 .

There are no minimum requirements for tear strength specified in AS 4174.

TABLE 6 – Tear Strength AS 2001.2.10

Property

ProTEX

Parasol

ProTEX

Sombrero

Tear Strength Warp: 179 ±12N Warp: 148 ±10N

Weft: 220 ± 17N Weft: 152 ±7N

Property

Breaking Force

TABLE 5 – Ultimate Tensile Strength AS 2001.2.3.2

ProTEX Parasol ProTEX Sombrero

Minimum Requirements of AS 4174

Warp: 1168N Weft: 2099N Warp: 1013N Weft: 1367N 500 N (‘Heavy’ Designation)

THE CONTENTS OF THIS TECHNICAL GUIDE ARE COPYRIGHT OCTOBER 2007. NO PART MAY BE REPRODUCED WITHOUT EXPLICIT PERMISSION.

The range of results (i.e between the plus and minus values) shown in TABLE 4 and TABLE 6 are included to illustrate the extent of ‘error’ that can be expected in tests of this nature. As with the estimation of UPF, the effect of error becomes particularly magnified if one subtracts one set of results from another, as occurs in the assessment of the effects of ultra-violet light.

AS 4174 specifies that shadecloth retain at least 80% of its initial breaking strength after exposure to an intense

UV radiation source for 2000 hours. To ensure compliance with this requirement, samples of ProTEX

Parasol shadecloth were exposed to a 500 Watt MBTF lamp for 2016 hours, and then tested for strength loss.

The results are summarised in TABLE 7 .

TABLE 7 – Percent increment (+) or decrement (–) in strength after

UV exposure ( ProTEX Parasol)

Tensile Strength Bursting Force Tear Strength

AS 2001.2.3.2

AS 2001.2.19

AS 2001.2.10

Warp: +6.3%

Weft: – 5.3%

Warp: +12.2% Warp: – 2.2%

Weft: n/a Weft: +11.4%

Paradoxically, HDPE yarn can experience some increase in strength under the action of UV radiation, but an increment in one direction, and a decrement in the other, as implied by the results in TABLE 7 , can be discounted as physically improbable. Based on the standard deviation of these results, a statistical analysis (Student ‘t’ test) shows them to be ‘not significant’, and therefore should be discounted. Thus, there is no evidence of strength degradation due to UV exposure in ProTEX Parasol under the conditions of the test, estimated (very roughly) to be equivalent to six to eight months field life.

Chemical Properties

High density Polyethylene is resistant to most acids and alkalis, and fungal attack. It does not absorb water, which is a significant factor in resisting staining and inhibiting mildew growth. These characteristics make HDPE ideal as a base yarn for a lightweight, strong shadecloth.

A summary of the chemical resistance of HDPE is contained in APPENDIX D . This is general information only, since colour pigment may be affected by a particular chemical, even though HDPE itself may not.

HDPE has only a weak resistance to halogens, such as chlorine; and halogenated hydro-carbons. It is also affected by strong oxidising agents, such as hydrogen peroxide; chlorox (bleach); and some alcohols.

Using such chemicals for cleaning should be avoided. Dirt or mildew is usually the result of contaminants caught in the interstices of the cloth, and should be easily removed using a high pressure hose. For stubborn stains, scrub with a brush and a weak solution of household detergent.

Careful consideration should be given to the environment in which ProTEX shadecloth is used. For example, when suspended over a swimming pool, it will be exposed to chlorine emissions, and its effective life may be reduced.

FLAMMABILITY

Standards

There are more than twelve separate Australian Standard fire tests that are applicable to textiles. Apart from the plethora of choice, the difficulty is the selection of one that is appropriate to the expected use of the material.

Given that shadecloth is invariably used in an external environment, either as a self-supporting structure, or attached to a building, it is logical to use tests that are designed to reflect that environment. There are also building regulations, applicable to shadecloth structures, that specify results for AS 1530 pt III.

This test is intended primarily for building components, but is widely used to test textiles, despite questions of its relevance to thin, planer forms. There is also some confusion in the marketplace, regarding the meaning of the term ‘FR’, or ‘Flame Retardant’, in which context overseas test methods are often quoted. These are usually

‘strip burn’ type tests, similar to AS 1530 pt II.

For these reasons, the appropriate selection of Australian tests for shadecloth would be both AS 1530 pt III, and

AS 1530 pt II.

Description of the AS 1530 pt II and pt III Tests

AS 1530 pt III is designed to assess the full gambit of combustion risk, namely ignitability, flame propagation, heat release, and smoke emitted.

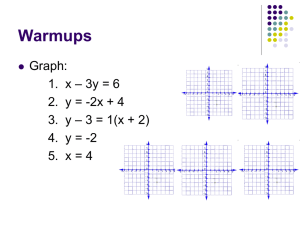

The test entails subjecting a vertically mounted 600mm x 600mm sample to both radiated heat and an ignition source, and its burning behaviour from ignition to extinction is observed. The intense radiated heat causes the sample to emit volatile substances, or even melt, and the ignition source ensures that these burn, refer FIGURE

2 . The results are expressed in the form of four indices, sometimes termed “Early Fire Hazard Indices”, not to be confused with the “Flammability Index” of AS 1530 pt II.

Only two of these indices – the “Spread of Flame Index”, and the “Smoke Developed Index” are referred to in the

Building Code of Australia. The “Spread of Flame Index” is a measure of how quickly a fire propagates, expressed on a scale of 0 to 10. The higher the value, the worse the result. The “Smoke Developed Index” is also expressed on a scale of 0 to 10, with each increment representing a bifold increase of the smoke emitted. The results of

AS 1530 pt III flammability tests for ProTEX Parasol are summarised in TABLE 8 , and copies of the test certificates attached as APPENDIX B .

THE CONTENTS OF THIS TECHNICAL GUIDE ARE COPYRIGHT OCTOBER 2007. NO PART MAY BE REPRODUCED WITHOUT EXPLICIT PERMISSION.

9

10

FLAMMABILITY

(continued)

TABLE 8 – Results of AS 1530 pt III

Flammability Test for ProTEX Parasol

Shadecloth

I ndex

Test Results

General

Requirements

(Range 0 to 10) of the Building

Code of Australia

Spread of Flame

Index

Smoke Developed

Index

8

5

9 (max)

8 (max)

AS 1530 Part II is a “Strip Flame” test in which a small

535mm x 75mm piece (‘strip’) of material is subjected to flame generated by a standard quantity of alcohol, and the burning behaviour observed. An empirical

“Flammability Index” is calculated from measurements of how quickly or to what extent the specimen burns, and the heat generated. This “Flammability Index” is expressed on a scale of zero (low risk) to 100 (high risk).

The Flammability Index for ProTEX Parasol is 19. (Refer test certificate in APPENDIX B ).

Fire Regulations for Shade Structures

The Building Code of Australia has prescriptive requirements for materials used in, or attached to buildings, which may affect shade structures. Unfortunately, the

BCA does not define the word “building’, but other state legislation does. For example, the Victorian Building

Control Commission’s definition of it includes “structure, temporary structure and any part of a building or structure”, which is broad enough to encompass say, a stand alone tensioned membrane. However, these types of structures would be classified as Class 10a “nonhabitable buildings”, and like single, detached domestic dwellings (Class 1 buildings), are not subject to any specific flammability regulatory requirement.

Shadesails attached to a building fall into a classic ‘grey area’. If deemed to be part of the building, then it would be subject to the “General Requirements” of the code. These are outlined in Section C “Fire Resistance” and Clause 2 of Specification C 1.10 “Fire Hazard

Properties”; and refer specifically to Class 2 through class

9 buildings, which include nearly all possible types of buildings including multiple occupancy units, boarding houses, nursing homes, schools, offices, shopping complexes, etc.

The “General Requirements” refer to the AS 1530 pt III test method, and specify:-

(A) a spread-of-flame index of not more than 9; and

(B) a smoke-developed index of not more than 8, if the spread-of-flame index is more than 5.

Exceptions are firstly, the special provisions applicable to attachments to external walls that have a particular

Fire Resistance Limit (FRL), or that are located above designated fire exits. In this case Clause 2.4 “Attachments not to impair fire-resistance” of Specification C1.1

states:-

A combustible material may be used…in a sunscreen… or other attachment…if:-

(i) the material…complies with the Fire Hazard

Properties prescribed in clause 2 of Specification

C1.10 (i.e the General Provisions previously described) and

(ii) it is not located near or directly above a required

(fire) exit, so as to make (it) unusable in a fire; and

(iii) it does not otherwise constitute an undue risk of fire spread via the façade of the building.”

These latter two conditions are clearly subject to interpretation, but as an illustration of what is not acceptable, the code uses the example of “a timber framed, combustible pergola on the external façade (load bearing wall) of a three storey, class 2 building…” (i.e. a block of flats).

The second exception applies to healthcare (class 9a) and public assembly buildings (Class 9b). Strictly speaking, the requirements apply to internal finishes, but could in some circumstances apply to shadecloth, used say on the interior of a glass atrium, or as verandah enclosures. As

“wall and ceiling linings”, these fall under Specification

C1.10a, which as a recent addition to the code, refers to completely different flammability criteria, namely “group numbers” derived from testing to AS ISO 9705, or alternatively AS / NZS 3837.

ProTEX Parasol complies with the requirements of

Specification C1.10, as shown in TABLE 8 , but has not been assessed to Specification C1.10a.

FIGURE 2

AS 1530 P t III Testing Apparatus

Pilot flame

Test specimen sample

Photoelectric cell measures smoke density

Smoke hood

Gas radiant panel

THE CONTENTS OF THIS TECHNICAL GUIDE ARE COPYRIGHT OCTOBER 2007. NO PART MAY BE REPRODUCED WITHOUT EXPLICIT PERMISSION.

ENGINEERING PROPERTIES OF PROTEX PARASOL

The tensile strength test, specified by AS 4174, measures ultimate loads, which in practice is not particularly useful. This is because at failure, the material is extended up to 40%, and so strain hardened as to be rendered useless. For this reason, the safe working loads applied to the cloth in tensioning are very much less than the ultimate. By way of example, ProTEX Parasol (under uniaxial loading) has a rated ultimate tensile strength of 12 kN/m (kiloNewtons /metre) in the warp direction, and 21 kN/m in the weft. However, a typical value of pretension used in common shade structures is 0.25

kN/m, which is less than 1.5% of the ultimate loads.

A typical stress/strain curve for expected range applied working loads between zero and 3.0 kN/m is shown on

FIGURE 3 (refer page 12). At these loads, the relationship between stress and strain is linear, and very similar in both the warp and weft directions. At this range of loading, the Elastic Modulus or Tensile Stiffness (i.e. the slope of the stress /strain curve) can be assumed to be roughly the same in each direction (an average of 28.5

kN/m).

Note that FIGURE 3 plots the immediate response of the test specimen to applied loading, and under these conditions of test, little deflection or strain was recorded until a load of 0.6 kN/m, which is more than double the maximum recommended pretension. This anomaly occurs because in practice, the fabric exhibits creep, which is a time dependent increase in strain under a constant applied load.

FIGURE 4 (refer page 13) shows such a plot for a constant load of 0.5 kN/m. At time zero, the immediate response to the applied load is negligible, which is consistent with the behaviour exhibited in the uniaxial tensile test.

However, after one hour, the strain is up to 1.6% in the warp direction and 1.25% in the weft direction respectively. On average, under the same constant applied load, a further extension of 0.5% and another

0.25% occurred after ten and twenty-four hours respectively, with the effect more pronounced in the weft than warp direction.

An argument therefore, could be mounted to adjust the axes in the load elongation plot ( FIGURE 3 ) to account for this phenomenon. However, the adjustment does not affect the slope of the curve and therefore the calculation of Elastic Modulus.

The results for load and elongation shown in FIGURE 3 are based on uniaxial (i.e. in one direction) loading. However, in practice the material is invariably stressed in both the warp and weft directions at the same time. The strain (i.e.

the deformation) in the material under biaxial loading

(i.e. in two directions) is less than that under uniaxial loading, because of contraction caused by the other load applied on the perpendicular axis, and dependent on the magnitude of that load.

In addition, the Elastic Modulus of the material is not constant, but becomes stiffer under the action of cyclic loading. FIGURE 5 (refer page 13) plots the results of cyclic testing in the warp direction for loads between

0.25 kN/m and 1.5 kN/m, and shows that the Elastic

Modulus has increased by two and a half times after 10 cycles, and remains fairly constant thereafter.

Based on our experience, and analysis of the testing described, the consultants Izzat Pty Ltd have estimated

ProTEX Parasol’s elastic material properties for engineering design purposes. The estimates are listed in

TABLE 9 and TABLE 10 . Caution should be used when using these figures in finite element analysis, as critical assumptions are made on membrane behaviour that may affect computational accuracy. If in any doubt as to the validity of these assumptions, the consultants should be contacted directly.

TABLE 9 – Measured Uniaxial Elastic

Properties of ProTEX Parasol Fabric

Stress Ratio

1: 0

0 :1

Ex (kN/m) Ey (kN/m)

TABLE 10 – Estimated Biaxial Elastic

Properties of ProTEX Parasol Fabric

Stress Ratio Ex (kN/m) Ey (kN/m)

2: 1

1:1

1: 2

24

22

20

22 v

0.30

0.30

Where:- The stress ratio is the ratio of tension in the length (x) direction to tension in the width (y) direction.

Ex (kN/m) is the tensile elastic modulus in the length (or warp) direction

Ey (kN/m) is the tensile elastic modulus in the width (or weft) direction v is Poisson’s ratio in either direction

The first assumption is the estimate of Poissons Ratio, which is a measure of the proportional extent to which the width contracts for an applied load in the length direction, and vice versa. This theoretically could be measured from standard uniaxial tests, but in practice this is not easy due to the test sample shape, and the distorting effect on lateral deflection of the supporting clamps of the testing apparatus. The respective poissons ratios in each direction also vary in the biaxial loading case, dependent on the relative applied tensions. The values adopted are based on field experience, and biaxial test results for similar materials.

The second assumption relates to the estimates of Elastic

Modulus, and the range shown is designed to simulate the contracting effect of biaxial loading. However, the prospect of significant further stiffening of the material, demonstrated by the cyclic loading tests, should be taken into account and the sensitivity of the consequent changes to these E values should be tested in any finite element model.

20

32

–

24

–

26

0.30

THE CONTENTS OF THIS TECHNICAL GUIDE ARE COPYRIGHT OCTOBER 2007. NO PART MAY BE REPRODUCED WITHOUT EXPLICIT PERMISSION.

11

12

2.7

2.4

3.0

ENGINEERING PROPERTIES OF PROTEX PARASOL (cont.)

FIGURE 3

Load vs Percentage Elongation Graph

Average Warp

Average Weft

1.5

1.2

0.9

2.1

1.8

0.6

0.3

0.0

0.0

1.0

2.0

3.0

4.0

5.0

6.0

Percentage Elongation (%)

7.0

8.0

9.0

10.0

THE CONTENTS OF THIS TECHNICAL GUIDE ARE COPYRIGHT OCTOBER 2007. NO PART MAY BE REPRODUCED WITHOUT EXPLICIT PERMISSION.

Warp

FIGURE 4

Creep Test

Weft Average

3.0%

2.5%

2.0%

1.5%

1.0%

0.5%

0.0%

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

Time ( hours)

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0.0

0.0

1.0

FIGURE 5

Cyclic Tensile Test

(One hundred cycles every ten shown)

2.0

3.0

4.0

Percent Extension

5.0

6.0

7.0

8.0

THE CONTENTS OF THIS TECHNICAL GUIDE ARE COPYRIGHT OCTOBER 2007. NO PART MAY BE REPRODUCED WITHOUT EXPLICIT PERMISSION.

13

14

FABRICATION

General

When cut, ProTEX shadecloth will fray if the edge is not seamed, particularly if the exposed edge is allowed to flap in the wind. For strength and aesthetic reasons, the edge and join seam should be overlapped twice, and preferably double stitched.

A “lock-stitch” is preferred to a “chain-stitch”. Although the latter has more “give”, it can have an abrasive effect on the sewing thread, and in failure tends to “un-zip” along the underside.

Although once widely used, cotton thread, or a polycotton blend is not recommended. Cotton is not a particularly durable material for use in an outdoor environment. It does not have a very high strength, and without treatment, frays, rots and mildews. This is why one sees evidence of seam failure on jobs where the fabric still has a lot of life left.

The use of a UV stabilised, 100% polyester thread (such as "SUNGUARD") has proved to be durable in the field.

Polyester, however does lose strength under the action of sunlight. Although tests (refer APPENDIX C ) show that size B138 is probably adequate, the heavier size B208 is recommended.

Recently, PTFE (PolyTetraFluorEthylene) thread, (such as

“PROFILEN”) has started to become more widely used.

Although costly, it has far more durability and a much longer life than other types of thread.

placed on the friction induced between the batten and the substrate. Any loosening of the batten over time will concentrate stress at the nail locations, possibly leading to tear.

FIGURE 6

25mm

SP4 eyelet

(21mm diameter )

FIGURE 7

Stitch

Folded 50mm

Seat-belt Webbing

Double

Stitching

Non-Tension Applications

Even in non-tension applications, the cloth will be subject to windload, which will induce stress in the cloth and the isolated fixing points. For this reason, one must ensure that all fixing points are structurally adequate, and fittings soundly secured. Caution should be exercised when connecting to a stud frame or wall of a building, as these have limited resistance to overturning moment, and there is a real risk of structural damage occurring in a high wind. Preferably, the sail should be supported independently. It should also be taken down while the likelihood of strong wind conditions exist, to avoid the potentially high loads at the fixing locations.

Ideally the cloth should be supported uniformly along the whole of its edge. Even with isolated connecting points, it is possible to convert the concentrated load to a more uniformly distributed load in the fabric. There are two recommended ways of doing this.

Method one is to fold and sew 50mm of UV stabilised, reinforced rayon seat belt webbing along the edge, and punch SP4 eyelets through this reinforcing at the desired locations, as shown on FIGURE 6 .

Method two is to sew a six millimetre nylon cord along the edge trim, and use Plaspaline ® Ropeclamps at the desired fixing locations, as shown on FIGURE 7 . This method is more flexible, as the clamps do not penetrate the fabric and can be easily relocated.

Where the cloth is to be fixed using timber battens, the supporting edge should be wrapped at least once around the batten before nailing. Even then, reliance is being

25mm

6mm diameter Cord

Shadecloth

FIGURE 8

Plastic Insert Piece

Plaspiline

Clamp

Aluminium Channel

THE CONTENTS OF THIS TECHNICAL GUIDE ARE COPYRIGHT OCTOBER 2007. NO PART MAY BE REPRODUCED WITHOUT EXPLICIT PERMISSION.

The V-grip V136 fastening system ® is another method of attachment, which provides a clean, tight professional looking finish. The system entails fixing an aluminium section and inserting a locking strip between it and the shadecloth, as shown in FIGURE 8 . The system has the advantage of allowing the cloth to be easily removed or replaced, and no seaming of the edge is required. The shadecloth can be installed then cut on site.

Tension Applications

Because of its higher inherent strength, only Parasol from the ProTEX range should be used in tension structures.

It is important that it is not overtensioned, if the shape and elasticity of the material is to be retained. The higher the load, the greater the risk of deformation or sagging over time. The maximum recommended pre-stress is

0.25 kN/m in both the warp and weft directions.

Tension structures rely on applied force for both shaping the fabric, and structural integrity. The applied forces and windload on the supports can be significant, and professional engineering advice should always be sought at the design stage.

Pre-stress in the cloth is invariably induced by tensioning a cable along the edge of the fabric, which is cut in a curved shape. The flatter the curve, the higher the tension in the cable, which is equal to the radius of curvature times the reactive stress of the cloth (Refer APPENDIX E ).

The reactive stress applied by cloth is dependent on its deformation or strain, the characteristics of which can be different in the warp and weft directions. This can be a complicating factor in design, and one of the advantages of ProTEX Parasol is that its stress /strain characteristics are similar in each direction.

For example, to minimise lateral loading at supports, it is desirable that the tension in the cable is constant (which it will be anyway if it is continuous). Most tension structures are designed for the condition of equal stress in both warp and weft directions, in which case for

ProTEX Parasol, the relative strain is about equal, thus making patterning that much simpler.

This is because, under these design conditions, the finished radius of curvature will be equal for each span and a theoretical engineering relationship exists between cable tension, reactive stress and tensioned chord depth for any given span (refer APPENDIX E ). This may prove useful as a guide for setting out, or estimating the applied stress or cable tension in the finished structure.

There is a simpler method. For the same design conditions, the ratio of depth to span can be approximated by the formula:-

d = kL

2 where: d = depth at mid-point

L = span and k is a constant.

If, for the longest span, the ratio of d to L is assumed to be 0.1, the proportional value of the expected finished depth of other spans can be determined by multiplying this longest span depth by the ratio of the square of the lengths, as follows:-

dn = d

1

x (Ln /L

1

)

2 where dn and Ln refer to the depth and length respectively of any other span. This rule of thumb may prove useful for initial shaping, determining expected shading envelopes of proposed designs, or estimating the relative quantities of material required.

There are a number of ways of making a sheath for a tensioning cable. The simplest is to incorporate it into the edge seam. Another method is to create a pouch using seat belt webbing, or use the webbing itself as the tensioning medium. 50mm UV stabilised rayon seat belt webbing has a breaking strength of 20kN. It is therefore suited for use in smaller structures (i.e. < 50m 2 ). The webbing can be continuous, and neatly looped at the corners to provide an attachment point to a turnbuckle or other tensioning device. One problem with this method is that the webbing is a lot stiffer than the shadecloth itself, and because of this, the sail can become baggy as the shadecloth deforms with time.

Design and Installation of Supports

The force of wind should not be underestimated, and is the reason the supporting structures and cables of large area shadesails appear so robust. Professional engineering advice should always be sought on the design of the supports.

Wind design stresses are in the order of 1.5kN/m, which is still very much less than the ultimate stress of the cloth. Typically then, the wind failure mode is loss of elasticity rather than tear or burst. Failure can also occur for other reasons, such as the accumulation of hail.

Shadesails are invariably attached by a corner to a column or other fitting, and the treatment of these requires some thought. It is crucial that the tensile load in the cable is transferred directly to the supports. The reactive stress in the fabric tends to drag it away from the supports, and reinforcement at these corner points is recommended.

Connection to a column without a backstay results in a significant bending or overturning moment being applied to the column, which is resisted by the bolts at the base, and the reactive forces on the side and bottom of the footing. In this cantilevered loading case, deflection in the column can be very noticeable, and is usually the basis for determining column size.

Staying the column reduces both deflection and applied moment, but the axial load is higher. A pin jointed base ensures that the applied bending moment is further reduced, which means an elegantly slim column can be used, but consideration must be given to lateral stability.

This can be attained by using a tripod as support, or additional guy wires.

THE CONTENTS OF THIS TECHNICAL GUIDE ARE COPYRIGHT OCTOBER 2007. NO PART MAY BE REPRODUCED WITHOUT EXPLICIT PERMISSION.

15

16

STANDARD DESIGN DETAILS

The Concept

Commissioned by Nolan Warehouses, Izzat Consulting

Engineers has prepared standard engineering details for a selection of typical shade structures. Each comprises a template with a choice of proportionate dimensions that can be sized up to a shaded area of approximately fifty square metres. In some cases, the templates can be combined to form a much larger composite structure.

There are essentially four design templates available:-

• A tensioned square Hypar structure (drawing number

S 3227 S-02), in four sizes – 3 metres x 3 metres, 4 metres x 4 metres, 5 metres x 5 metres and 6 metres x 6 metres

• A single right-angled isosceles triangle (drawing number S 3227 S-03), also in four sizes, that is the hypotenuse of length of 3, 4, 5 or 6 metres.

• A framed square structure module (drawing numbers

S 3227 S-04 and 05), of dimensions 6 metres x 6 metres, which can be erected in isolation or in connected multiples.

• An array of up to six right-angled isosceles triangles, each connected to a central column (drawing number

S 3227 S-06). The individual triangles can be of four varied sizes the same as for the single triangle above.

Design Parameters and Specifications

Drawing S 01 outlines the design parameters, and the specifications for construction, including concrete foundations, reinforcement and structural steelwork.

Additional specification relevant to a particular template, such as the relevant cable pre-stress applicable, is shown on the drawing for that template.

The crucial design parameter is that of the effect of windload, and Australian Standard AS/NZ 1170.2 : 2000 is the design code used in this context. As shown on the specification, Izzat has adopted a particular design

‘Regional wind speed’, which is equivalent to a 500 year recurrence interval for non-cyclonic regions of Australia, which encompasses all of the continent except coastal regions north of latitude 30° South, that is north of

Grafton, and Green Head, on the east and west coast respectively. For cyclonic regions, the adopted wind speed is equivalent to a 20 year recurrence interval. The difference is significant. A 500 year return period is equivalent to an annual probability of exceedance of zero point two percent, whereas a twenty year return period is equivalent to five percent.

The ‘Regional Wind Speed’ is not the only parameter that determines the design wind pressures. Important also are wind direction, terrain, elevation and degree of shielding by natural topography or other structures; all of which have particular factors developed in the code.

This is why the information requested by the consultants

(refer ‘Certification Request Form) is necessary for determination of the wind design factors specific to a particular site.

Requirements for Access To and

Use Of the Standard Details

Note that the standard details published in this guide are illustrated devoid of dimensions. This is to ensure their proper use, as each design needs to be customised for a particular site. By filling in the ‘Request for Certification form’ (refer page 20), and paying the current consulting fee, an authorised user obtains a licence to use the drawing and design details for a particular project, which is designated a new job number, and its own design certification by Izzat Consulting Engineers. The resultant site specific drawings can be reproduced as required for a council permit, client submission or construction; but cannot be reproduced or used for a different project or location. This is not just to protect copyright, but for safety considerations, as there is some danger in using these standard details without specific site customisation.

Note also that the drawings specify ‘Parasol’ Shadecloth, and Nolan Warehouses’ fittings, details of which are presented in APPENDIX F . The consultant’s design is based on the engineering characteristics of both the cloth and the fittings, and obvious caution should be exercised if alternate products are planned to be substituted, as these may have quite different performance characteristics. For this reason, Izzat Consulting will not certify the standard drawings if the specified products are not proposed to be used, unless the engineering properties of both cloth and fittings are provided. Re-checking the design in this context will entail additional fees.

Shade Diagrams

The principal objective of constructing a shade structure is to provide shade, but it is surprising how often the planning in this context is overlooked.

The degree of risk due to exposure to Ultra-violet radiation

(UVR) is dependent on the season, time of day and geographic location. The single most important factor is the height of the sun. The higher the sun, the higher the levels of solar UVR experienced. This rather obvious fact usually dictates the base design parameters of a shade structure, but what is often ignored is the potential degree of exposure at earlier and later times of the day. At 4.00

pm in summer, when the sun is well below its noon elevation, the UVR is still sufficient to cause sunburn of the average fair-skinned person in twenty minutes. However, the shade cast by the structure at that time of day may not be providing the protection where it is required.

THE CONTENTS OF THIS TECHNICAL GUIDE ARE COPYRIGHT OCTOBER 2007. NO PART MAY BE REPRODUCED WITHOUT EXPLICIT PERMISSION.

Four particular days per year are important yardsticks for defining the boundaries of the extent of shadow cast by a structure:-

• The summer solstice – this occurs on the 21st

December, and is the longest day of the year. On this day, the sun is at its highest summer zenith at noon; and rises and sets at its furthest point south.

• The equinox – this occurs twice a year on the 21st

March, and 23rd September. On these days, the sun at noon is midway between its summer and winter zeniths; and rises and sets due east and west respectively.

• The winter solstice – this occurs on the 21st June, and is the shortest day of the year. On this day, the sun is at its lowest winter zenith at noon; and rises and sets at its furthest point north.

Clearly, in terms of designing for shade protection, the summer solstice and equinox are of primary interest. As an indication of the shading efficiency of Izzat’s standard structures, shade diagrams on these dates for various orientations (in Sydney) were produced by the architectural consultants John Greenwood and Associates, and are reproduced in FIGURE 9 and FIGURE 10 .

The Daily Shade Coefficient is the quantity of shade provided compared to the size of the structure. This was calculated by averaging the shade area projections at the three times of day shown, and dividing by the surface area of the structure. The higher the value, the more efficient the structure.

The Co-efficient of Shadow is the relative proportion of shade cast directly under the structure itself. This is an important consideration where the structure is designed to protect a fixed installation, such as play equipment.

The following observations were made by John Greenwood and Associates:-

A. Shade Area

• “The rectangular structures demonstrated very little difference in the size of the shade area created in all

(latitudes). Surprisingly, the triangular performed better than the rectangular with regard to the shade area created.

• “Orientation of rectangular structures makes very little difference to shade efficiency. With triangular structures, the best result is achieved with the low point to north, and the hypotenuse running north-south.

B. Shade Proximity

• “The supported frame structure cast shadow closest to its structure, due to its continuous low edge – the varying column heights of the hypar and triangular structures resulted in greatest distances between shadow and structure.

• “The deviation in the proximity of shadow to the structure is greatest when sun angles are low. Shadow is closest to the structure at solar noon.

• “The triangular form is least effective in terms of shade proximity – generally its value in ‘whole-of-day’ shade is very limited. Its use may be appropriate in northern locations or when solar protection is required only around solar noon, rather than earlier or later in the day. If ‘whole of day’ shade is required, the rectangular forms offer better results.

• “Multiple triangular sails may be effective when used in combination, over areas where consistent and continuous shade is not required.

“The high number of variables associated with different shade projects make it difficult to develop specific and useful guidelines for generic shadestructures. The variables that need to be considered include, but are not limited to the following:-

• Times when solar protection is needed

• Location of the site

• Exact area where solar protection is required

• Usage of the site – whether structure type is appropriate and fit for purpose

• Context – aesthetic considerations

• Topography

• Wind exposure

To these need to be added the interaction with other structures or trees, the potential effects of tree growth and the expected life of the project.

It is therefore strongly recommended that a holistic approach be taken in this context. John Greenwood and

Associates has developed an excellent, easy to use computer program www.webshade.com.au

which allows the planning of shade provision on any site to be easily accomplished.

THE CONTENTS OF THIS TECHNICAL GUIDE ARE COPYRIGHT OCTOBER 2007. NO PART MAY BE REPRODUCED WITHOUT EXPLICIT PERMISSION.

17

STANDARD DESIGN DETAILS

(continued)

FIGURE 9

Standard Shade Diagrams – Sydney, 22nd December

area of fabric area of shade at 10 am area of shade at noon area of shade at 2pm

(green outline) (green outline) (green outline) daily shade co-efficient co-efficient of shadow cast area of shade/ under structure area of fabric (shown shaded)

1 0.787

36m 2 36m 2 26m 2 36m 2 33m 2 36m 2 26m 2

1 0.759

36m 2 36m 2 25m 2 36m 2 32m 2 36m 2 25m 2

36.06m

2 23m 2 36.12m

2 32m 2 36.32m

2 22m 2

1.005

0.713

36m 2

1.005

0.666

36m 2 36.29m

2 21m 2 36.20m

2 30m 2 36.09m

2 21m 2

1.049

0.593

18m 2 17.27m

2 9m 2 18.96 m 2 15m 2 20.42m

2 8m 2

18

1.006

0.500

18 m 2

36m 2

15.13m

2 5m 2 18.20 m 2 15m 2 20.98 m 2 7m 2

36.17m

2 22m 2 36.19m

2 30m 2 36.04m

2 22m 2

1.004

0.685

THE CONTENTS OF THIS TECHNICAL GUIDE ARE COPYRIGHT OCTOBER 2007. NO PART MAY BE REPRODUCED WITHOUT EXPLICIT PERMISSION.

FIGURE 10

Standard Shade Diagrams – Sydney, 22nd March

area of fabric area of shade at 10 am area of shade at noon area of shade at 2pm

(green outline) (green outline) (green outline) daily shade co-efficient area of shade/ area of fabric

1

36m 2 36m 2 36m 2 36m 2

1

36m 2 36m 2 36m 2 36m 2

1.007

36m 2 36.15 m 2 36.32 m 2 36.30m

2

1.003

36m 2 35.90 m 2 36.37m

2 36.02m

2

1.176

1.8 m 2 19 2 21.29m

2 23.16m

2

1.045

1.8 m 2 15.13m

2 18.83m

2 22.49m

2

THE CONTENTS OF THIS TECHNICAL GUIDE ARE COPYRIGHT OCTOBER 2007. NO PART MAY BE REPRODUCED WITHOUT EXPLICIT PERMISSION.

19

Request for Engineering Design Certification

1. Project Originator

( i.e. Fabricator, Project Manager or Specifier):

Please fill in relevant details:

Your Company or Partnership Name:

Mailing address:

Tel:

Email:

Fax:

Contact Name:

2. Project Designation

( These details will appear on the drawing):

Client Name:

Address:

Mob:

Project Originator’s Job Number:

3. Site Details:

a. Project Location and address (if different from client address):

20 b. Foundation Conditions: i. Sand ii. Rock iii. Clay:- Soft Medium Hard

4. Choice of Structure:

a. Tensioned Hypar Size: 3 x 3 4 x 4 5 x 5 b. Single Isosceles Triangle Hypoteneuse Lengths: 3 x 3

6 x 6

4 x 4 c. Framed Structure Number of Modules: d. Multi – Isosceles Triangles: No. of Triangles: 1

Please state size: 3 x 3

2 3

4 x 4

5 x 5 6 x 6

4

5 x 5

5 6

6 x 6

5. Other Information

– Please provide: a. Panoramic photographic views of the site b. A sketch of the site:

• Showing dimensions • True north • Orientation of the proposed structure

• Proximity of on site or neighbouring buildings • Position of the main access road

• Positions from which the panoramic views were taken

Please mail or fax completed form to: Nolan Warehouses, P.O Box 246, Rosebery NSW 1445

Fax: 02 9669 3266 and mark to the attention of the ‘Marketing Manager ’

THE CONTENTS OF THIS TECHNICAL GUIDE ARE COPYRIGHT OCTOBER 2007. NO PART MAY BE REPRODUCED WITHOUT EXPLICIT PERMISSION.

THE CONTENTS OF THIS TECHNICAL GUIDE ARE COPYRIGHT OCTOBER 2007. NO PART MAY BE REPRODUCED WITHOUT EXPLICIT PERMISSION.

21

22

THE CONTENTS OF THIS TECHNICAL GUIDE ARE COPYRIGHT OCTOBER 2007. NO PART MAY BE REPRODUCED WITHOUT EXPLICIT PERMISSION.

THE CONTENTS OF THIS TECHNICAL GUIDE ARE COPYRIGHT OCTOBER 2007. NO PART MAY BE REPRODUCED WITHOUT EXPLICIT PERMISSION.

23

24

THE CONTENTS OF THIS TECHNICAL GUIDE ARE COPYRIGHT OCTOBER 2007. NO PART MAY BE REPRODUCED WITHOUT EXPLICIT PERMISSION.

THE CONTENTS OF THIS TECHNICAL GUIDE ARE COPYRIGHT OCTOBER 2007. NO PART MAY BE REPRODUCED WITHOUT EXPLICIT PERMISSION.

25

26

THE CONTENTS OF THIS TECHNICAL GUIDE ARE COPYRIGHT OCTOBER 2007. NO PART MAY BE REPRODUCED WITHOUT EXPLICIT PERMISSION.

APPENDIX A – Formal Warranty

“PARASOL” COMMERCIAL GRADE

KNITTED SHADECLOTH

Nolan O’Rourke and Company P/L, ABN 80 000 021 492, trading as Nolan W arehouses, importers of the ProTEX ranges of knitted shadecloth; and the manufacturer jointly guarantee for a period of ten years from the date of purchase, that the Commercial Grade shadecloth marketed under the name ProTEX “Parasol” will not become unserviceable due to UV degradation; or due to recommended usage.

Nolan Warehouses further warrants that “Parasol” meets the physical requirements for and tested to Australian Standard AS 2001 “Method of T specifications published in Nolan W arehouses Technical Guide number one “ProTEX

Shadecloth” (Oct 2007) for other engineering properties and stability; including creep, elastic recovery, strength retention and colour fastness.

This warranty does not cover:-

• Colour change or variation, dimensional change, and product deterioration normally associated with outdoor weathering.

• Damage due to over-tensioning or installation contrary to advice published in the Nolan

Warehouses Technical Guide; vandalism or misuse; storm, wind or hail; chemical attack

(including by halogens or halogenic compounds; organic solvents and concentrated acids) and fire.

• Flaws of a cosmetic nature, such as marks or creasing, provided these are consistent with the acceptance criteria of the typical quality control procedures for a modern, automated knitting plant.

The warranty is not transferable and applies only to the original purchaser of the product; and does not transcend Nolan W arehouses normal “Conditions of Sale”. Liability is limited

-rata basis to replacement of material only

, or refund of original purchase price, on a pro of life served; with 100% of value for the first year declining at 10% per year thereafter. Liability for negligence or any consequential loss is expressly excluded.

Claims must be made in writing with proof of purchase provided.

In the event of dispute as to cause, the technical determination of the manufacturer, or recognized industry association, or independent testing laboratory will be the sole basis for resolution.

THE CONTENTS OF THIS TECHNICAL GUIDE ARE COPYRIGHT OCTOBER 2007. NO PART MAY BE REPRODUCED WITHOUT EXPLICIT PERMISSION.

27

28

APPENDIX B – Test Certificates

29

30

APPENDIX B

(continued)

APPENDIX C

Test Results for “SUNGUARD” B138 Thread

SHADECLOTH

Thread Recommendation

As the primary use of Shadecloth material is for outdoor applications, the key factors for thread selection include (1) Overall Seam Strength, and (2) Ultraviolet Resistance.

Based on data provided to the industry by the leading supplier of sewing thread fibers,

The Dupont Company continues to recommend continuous filament polyester thread as the Number 1 selection for outdoor uses when UV exposure exists. Dupont polyester fibers exhibit the highest degree of UV Resistance, demonstrating a gradual degradation of tensile strength.

Laboratory Test

Fabric Factors: Tear Resistance in Warp Direction – 134N (30.1 pounds)

Tear Resistance in Weft Direction – 226N (50.6 pounds)

Breaking Force in Warp Direction – 699N (157.1 pounds)

Breaking Force in Weft Direction – 1789N (400.7 pounds)

Thread Test : Two pieces of Shadecloth material were sewn together using a lockstitch application with “SUNGUARD” Size B138 polyester in both the needle and bobbin. The initial seam strength registered at 170 pounds. Through accelerated weatherometer testing, after approximately 5 years of UV exposure, the seam strength degrades to about 85 pounds or 50% of the initial level. Continuing at the same rate of degradation, after a period of

10 years, the seam strength would be at 42 pounds.

Conclusion : At 30.1 pounds, the Shadecloth material will tear in the warp direction.

This would be the weakest link of all fabric factors. Therefore, use of

“SUNGUARD” Size B138 Polyester provides adequate strength during the useful life of the Shadecloth material, registering 85 pounds after

5 years and 42 pounds after 10 years.

THE CONTENTS OF THIS TECHNICAL GUIDE ARE COPYRIGHT OCTOBER 2007. NO PART MAY BE REPRODUCED WITHOUT EXPLICIT PERMISSION.

31

32

APPENDIX D

Chemical Resistance of Polyethylene

S = Satisfactory L = Limited Resistance ( some attack ) U = Unsatisfactory – = Testing Possibly Required

AGENT ( % at Temp °C )

Acetaldehyde 40% 20°

100% 20°

100% 60°

Acetic Acid

Acetic Acid-Glacial

Acetic Anhydride

Acetone

Acetophenone

Acetylene

Andipic Acid

10% 20°

60°

20% 20°

60°

50% 20°

60°

80 -100% 20°

60°

20°

60°

20°

60°

20°

60°

20°

60°

20°

60°

20°

60°

Allyl Alcohol 96% 20°

60°

Allyl Chloride 20°

60°

Alum 20°

60°

Aluminium Chloride 20°

60°

Aluminium Fluoride 20°

60°

Aluminium Hydroxide 20°

60°

Aluminium Nitrate 20°

60°

Aluminium Oxychloride 20°

60°

Aluminium Sulphate 20°

60°

Ammonia ( Dry Gas)

Ammonia ( Liquid )

Ammonium Carbonate

Ammonium Chloride

20°

60°

100% 20°

60°

20°

60°

20°

60°

Density

Low High

S

S

S