pneumatic tire compounding - RMA: Rubber Manufacturers

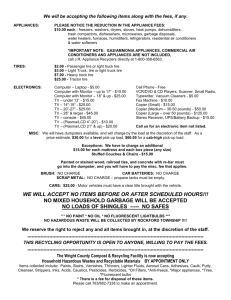

advertisement

PNEUMATIC TIRE COMPOUNDING by Walter H. Waddell, Roop S. Bhakuni, William W. Barbin, and Paul H. Sandstrom The Goodyear Tire 8 Rubber Company Akron. OH The pneumatic tire is a toroidal, high performance polymeric composbte which exhibits characteristics of aflexible membrane pressure container pro viding load carrying capabllity,cushioning, and road handling abilities. Itencir cies the rim of a wheel to absorb end control forces between the axle and the road in a transient environment and thus transmits driving and braking torque, transmits corneringforces, and performs all functions essential to locomotion These features can be attributed to its deformabiiity and damping characleristics (Ref. 1). The first tires were solid rubber carriage tires exhibited in London, United Kinudomin 1851 and were used for transoorlation until theearlvvears .. of this century.~herequirementsof speed and cdmfort led to the development of pneumatic tires. The pneumatic tire is a complex system of interacting rub bery components, each with specific properties for maximum effectiveness The performance of a tire depends on the component properties, the interac tions of these components, and the service conditions of the tire (Ref. 2). Tire Components Thetireis acompositeofseverairubberycomponentseachofwhich servas a specific and unique function, These components are developed or fw mulated, designed, and fabricated to meet the mobility requirements of vehicles which include carrying of the load, control of vehicle, handling, rida, tractton, durability, etc. Tire components are made from materials such as natural rubber andlor synthetic rubbers (Ref. 3),chemicals which function as antidegradants, curatives, processing aids (Ref. 4), reinforcing fillers such as carbon black and silica, and cordscamposed of textile, f~berglass,and steel wire (usually brass coated). These materials are selected based on thdr physico-chemical properties and their interactions with other constituenl materials to provide a broad range of mechanical properties. Figure 1 show the componentsof a radial passengertire. A tire can be divided into two majoc segments:(i)thetread area, which includes the tread compound,base,cushion and overlay; and (ii) the casing, which includes the carcass plies, beits. sidewall, bead, inneriiner, apex, chafer, etc. A p e x . The apex Is formuiated for good dynamic stiffness, flex fatigue, tea strength, adhesion, and durability. Base. The base is formuiated to have low hysteresis, good adhesion, fatigue, tear, and durability. Beadlnsulation. The bead usually consistsof multiplestrandsofhightensile, brass-plated steel, coated with rubber and formed into Inextensible hoops to seal the tire against the rim and provide hoop tension to prevent air leakage. it acts as a load transfer mechanism between the tire and the rim. Be11 Coat. The belts are layers of rubber-coatedcord, eithertextile, fiberglass or steel, which wrap circumferentiallyaround the plies. The coat compound is maliyformuiatedto providegoodadhesiontothecord, tear,fatigue,end age resistance. Chafer. Thechafer protects the plies from wearing and cutting against the rim, distributes the hoop stress of the bead and prevents moisture and dirt from penetrating into the tire. Innerliner. The inneriiner is formulated to provide good air and moisture 'mpermeability, flex fatigue resistance, and aged durability. Ply Coat. The ply is a rubber-coatedcord that serves as the reinforcing eiemeotofatirecarcassby locking the bead intothecarcass.Pliesprovidetensiie resistance to Inflationpressure along the cord direction. Sidewall. The sidewall compound is formulated for resistance to weathering, ozone, abrasion, tear, radial and circumferential cracking, and for good Mgue life. Tread. The tread is des~gnedand compounded for abrasion resistance, traC- . Mn lo* roll~noresistance, durablllty and protection of the caslng It provides ~ hiclional contact for transtkssion of driving, braking, and cornering forces. Wedge. The shoulder wedge is placed under the belt edge to reduce lnterpiy shear strain and is formulated for high dynamic stiffness, resilience, good laligue, adhesion and tear resistance. Compounding Individualcompoundsare designed and formulated to meet the specificset d performancerequirements of the tire component. This is primarily accomplished through selection of elastomer type(s), selection of chemicals for vulcanization,selection of materials for facile processing and tire manufactur'kg, and selectionof materials for in-service performance.Table 1 lsa summary d !he desirable properties of tire compounds and Table 2 a summary of the tatMratorytests used to evaluate tire compound physical performance.Table 3 is a summary of the general composition of individual tire compounds: elasbmers, reinforcing fillers, cure system, and additional Important Ingredients. Itis important tonote that each compound hasaspecific recipe formulated kr its expected tire application, i.e. tread, sidewall, inneriiner, etc. However, in addition lo the exact recipe, compoundphysical properliesandfinal tire performanceareverydependentupon exact processingconditions.They includethe nixingsequence (sequence of adding the chemical ingredients), mlxing time, nixing energy and stock temperature, and downstream processing methods such as remiliing, calendering, and extruding, etc. from the expandable biadder before vulcanization begins. Since each componentof the tire undergoes a different rate of cure (time-temperature cycle) and can have very different proximities to the bladder and mold, it Is important to produce the optimum state of cure (plateau) for each component during the tire curing cycle. This is accomplished by selection of and adjustment of the cure ingredients, namely sulfur, activators, acceierators, and retarders. The cured Greshouidhave the final form and physical properties, including final cure State. required for service. Tables 4 through 11 provide formulas and physical properties for importanl tire components. Table 12 provides examples of innertube and curins biadder formulas. Finally it is important tonotethal theexampies provided heriare representative in that each compounderwiii adiust the recioe for soecilicorocessing constraints and performance requirernents of the barticuiar tire broduct interactions Interactions between the individual compounds and components of the tire system occur during tire fabrication, curing, and service life. The first type of interaction is physical, but also may have important chemical implications. it Is based upon the migration of soluble irigredients. This occurs whenever chemicals used as curatives (sulfur, accelerators, activators), processing aids (oils, peptizers, tackifiers) and antidegradants (antioxidants, antiozonants, waxes), for example, differ in concentration in two adjoining components Migration of curatives will result in levels different from the original optimized formulation and may lead todifferent statesof cure, particularly at theinterface. Migration of antidegradants from the sidewall compound into the carcass will resuit in lower concentrations and may lead to premature weathering. The second type of interaction is again physical since compounds are designed to have acertain modulus.The hardestcompositionsare thoseof lhe bead area and the belts, which contain the highest amounts of the most rein. i0rc:ng carbon blacks. The m~iticomponenl!;re system is designed lo have C3mPoundsoecreaseste~v1isein moouius 2s thevare sit~atedtanherirom ~. lne ~ high modulus componenis in order to distribute the stress and minimize con. ditions for interfacial separation. ~ Curing Both the cure rate of and the final cure state of a rubber compound are important. Without exception, accelerators are used lo increase the rate of sulfur vulcanizationoftirecompounds and to improve their physical properties and age resistance.The most important characteristics of acceleratorsare their effect on scorch (period after addition before vuicanization begins), cure (period required for full vulcanization) and plateau times (period during which Propertiesare constant). Scorch time is important because once vulcanization has initiated, stocks cannot be processed as readily. The rate of cure or cure time is important since production must achieve the desired final state of cure within the shortest time after cure has initiated. The tirecuring process involvesapplying specified temperatures and pressures over a period of time to effect simultaneous vulcanization of the various rubbercompoundsin the tiretoformonec0m~osite.Thisisaccomplishedinan automatic curing press which uses steam to maintain temperature in the sheU around the metal mold. it also has an attached heat-resistant rubber bladder to supply internal heat and pressure. When the press is completely closed, the tread and sidewall components are forced into the mold pattern by pressure ~ The components of a tire composite have optimum physical properties when removed from the mold and cooled to ambient temperature. However, thereisno assurancethat the same condition will persist after the tire is subioctedtoserviceconditionssincechangescanoccurfrom (i) heat generated in the tire by energy loss when high temperatures are achieved by friction due to haking, and (ii) any increased crosslinking caused by thermo- and mechanodiemical oxidation, which can potentially lead to embrinlement, cracking or decreased resistance to tear. Accelerated aging tests commonly used in the hboratoryshowtrendsbut may notcorrelateclosely withallservice~onditions. The normal aging process can be retarded by addition of antioxidants, for example, secondary arylamines added to inhibit mechano-chemical oxidation such as flex-cracking. Thermo-oxidation stability Is promoted by using low . suifurlhigh accelerator (semi-efficient) cure systems. Weathering effects the outer surface of the tire, particularly the sidewalls. Thus, chemical antiozonants are added to the black sidewall compound at levels tested for effectiveness under both static and dynamic tire service conditions. However, the antiozonant is continually depleted from the sidewall surfacebyreactionwithozone,and by physicalabrasioncaused bycurbscuffing and washino. In addition.. ail .oractical chemical antiozonants for rubber are s!aining materials and therefore can only be used in limited amounts. Suitably Mended petroleum waxes serve as effective protectants against ozone under static conditions, but must be used in conjunction with highly active chemical antiozonants for dynamic protection of the tire. - References 1. F. J. Kovac. Tire Technology, The Goodyear Tire & Rubber Co., Akron, OH (1978) 2 J. C. Ambeiang, Chpt. 11, Tke Vanderbilr Rubber Handbook, 12th Ed. (1978) 3.M. Morton, Editor, Rubber Technology, 2nd Ed., Krleger Publishing (1981) 4. H. Long, Editor, Basic Compounding and Processing OJ Rubber, Rubber Division, American Chemical Society, Inc., Lancaster Press (1985) 600 60 I Table 2 Laboratory Testing of Tlre Compounds ASTM Tests Compound Tread Wire Coat Sidewall, Wire Coat, Ply Coat, lnnerliner Sidewall uium Tread, Wire Coat, PLY Coat Sidewall Ply coat, lnnerliner Table 1 Desirable Properties of Tlre Components Tread Sidewall Wire Coat Ply Coat Polymers and Coated Fabric lnneriiner Wire Coat Tread, Wire Coat, Ply Coat Maximum Traction Adhesion Wire Oxidative Stability Cleanability Afinimum Rolling Resistance Wear Cut Growth Groove Cracking Weather Cracking Flex Cracking Heat Buildup Curb Scuffing Heat Buildup Buildup Permeability 602 Table 3 Composltlon of Tlre Compounds Tread Sidewall NR BR SBR NR BR SBR EPDM Table 4 Passenger Tlre Tread Reclpe : WOFLEX 1 5 0 2 SBR Elastomers Reinforcing Fillers Blacks: N-1lo, N-220, N-299, N-330 Non-blacF: N-550, N-660 Silica Silica Cure System Low/Normal Sulfur Adapled lo Polymer Additional I n p d i e n ~ s H l Q h l ~ Anlldegradants: Adhesion ~ d Aromatic VANWAX H Special Promoters: promoters: 0 1 1 AGERITE RESIN D Coball HsxamethyleneANTOZlTE 67P, Stearate, tetramine, VANOX 2 Naphthenale. Rerorclnol or .Born Decanoate h ~ ~ ~ ~ ~ 100°C Storage Modulus, MPa (psi) 004 Table 5 Truck Tread Reclpes Radial TSR 20 Natural Rubber BUDENE 1207 PLIOFLEX 1712 SAF Black (N-110) ANTOZITE 67P AGERITE RESIN D VANWAX H Special Aromatic Oil Stearic Acid Zinc Oxide Sulfur DURAX VANTARD PVi MORFAX METHYL TUADS Total 100 .. -. 50 2 2 1.5 4 2 4 1.75 1.75 0.5 -. -169.50 Rheonieter at ISOOC ( 3 0 0 " ~ ) Isl, minutes t'c (SO), minutes Table 6 Passenger Tire Sldewall Recipes Bias Black, Radial .. 50 68.75 55 2 1.5 3 12.5 2 3.3 1.55 ' .. -. 1 0.15 zm% , 7.4 12.0 Physical Properties Cured 22 minutes at ISO'C (300m/,.~ stress at 3009b, MPa (psi) Tensile strength, MPa (psi) Elongation at Break, 96 % Rebound: at 2 2 " (72"~). ~ 12.2 36.8 */1STMDI054 cured32 minutes at 150°C ( 3 0 0 ~ 0 50 50 -. .. 50 2 10 *. .. .. 2 2 2 3 .. -. 3 1.75 1 AMAX -, 12.3 (1790) 27.1 (3920) 550 81.9 SMR.5 Natural Rubber BR1220 Chiorobutyl 1066 Mstalon 6505 HAF Black (N-330) VANPLAST R Naphthenic Oil VANTALC 6H Titanox 1000 Titanium Dioxide Nucap 200 Treated Clay Stearic Acid AGERITE RESIN D ANTOZITE 67P VANWAX H Special SP 1077 Resin Ullramarine Blue Zinc Oxide Sulfur Vultac 5 WAX 11.8(1710) 17.6 (2550) 41 5 70 Told White. Exxon Formula BA5152 .. .. - 176.75 21 5.3 Rheorneter at 160°C (320'0 : ( tsl, minutes tc'90, minutes 3.0 12.6 3.6 16.8 Properties Cured at 160" (320°@ 13 min. 1 7 min. 7.1 (1030) 20.2 (2930) 580 70 5.3 (760) 11.3 (1630) 630 Stress at 300%, MPa (psi) Tensile slrength, MPa (psi) Elongation, % Rebound*, % 22°C .. ;1S?'hI D l 054, cured 30 minutes i. Ozone Craclcing Stalic, cracks in mm Dynamic, cracks in mm 0 0.5-1 O . 0 0 BR 1220 HAF Black (N-330) GPF Black (N-660) Aromatic Oil ANTOZITE 67P AGERITE SUPERLITE Arofene 1055B Zinc Oxide Stearlc Acid AMAX Sulfur Total Rheometer at: .. 55 .. 5 1 .. .. 10 2 0.8 4 177.8 150°C (300°@ tsl, minutes t'c (SO), minutes 4.6 14.0 Physical Properties Cured 18 minutes at 150'C (30O0@ Stress at 300%, MPa (psi) Tensile strength, MPa (psi) Elongation at Break, % Rebound, % 22°C 100°C SWAT Adhesion, N 18.5 (2680) 24.5 (3550) 405 56 80 577 610 61 1 Table 11 Tfre Apex and Bead Insulation Reclples TSR 20 Natural Rubber PLIOFLEX'?500 SBR HAF Black (N-330) GPF Black i~-moj Aromatic Oil Rosin Oil VANPLAST R Stearic Acid Resorcinol Hexamethylenetetramine Zinc Oxide AGERITE RESIN D Diisopropylbenzothiazoie sulfenamide VANTARD PVt Sulfur DURAX Total Apex Innertube 100 100 .. 70 8 25 -. .. 1 3 3 3 .. 1.5 0.2 3 .202.7 Rheometer at 150°C (300°F) 4.2 17.2 Properties cured at 150°C (300°F) 18 min. Stress at 3W%, MPa (psi) Tensile strength, MPa (psi) Elongation, % Hardness, Shore A 11.8(1710) 13.9 (2010) 120 87 Dynamic Mechanical Properties I'ibrotester, 100°C (212°F) ASTM 2231 - - Storage Modulus, MPa (psi) Resilience, % Tan delta .. 80 .. tsl, minutes tc'90, minutes Table 12 Innertube and Curing Bladder Reclples 20.3 (2940) 63 0.076 .. .. 1 5 2 0.5 1 .. Curing Bladder 100 5 .. 55 .5 -. 5 ... -. 10 - - 204.5 180 oil is shown in U.S. Patent No. 3,031,423 oodyear Tire &Rubber Company 170°C (338°F) 190°C (374°F) 3.0 11.0 8 170" (338-4 4.9 (710) 10.4 (1510) 600 50 3.5 20.0 20 190°C (374°F) 4.6 (700) 12.8 (1850) 720 68