Designing a Flyback Power Supply Using The N3856x Series

advertisement

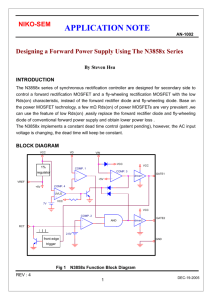

NIKO-SEM APPLICATION NOTE AN-1001 Designing a Flyback Power Supply Using The N3856x Series By Steven Hsu INTRODUCTION The main advantages of the flyback power supply are cost-effective , simplicity and ease of reach green mode power consumption requirment without any extra stand-by power circuit. The N3856x series of synchronous rectification controller are designed for secondary side to control a low Rds(on) power MOSFET, instead of the turn-on duty of the output rectifier diode. Base on the power MOSFET technology , a few mΩ Rds(on) of power MOSFETs are very prevalent ,we can use the feature of low Rds(on) ,easily replace the output rectifier diode of conventional flyback power supply and obtain lower power loss . The N3856x builded a adjustable slope current dectecter for detecting the current vis MOSFET in the discontinuous mode operating. It also builded a comparator for comparing the saw-tooth waveform of RT/CT pin with internal 1/3 VCC voltage to generate a constant pulse width in the continuous mode operating. BLOCK DIAGRAM VCC GND 10K PGND Aout D COMP. OSC BUFFER - RT/CT DRIVER GATE + 1/3 VCC 20mV ADJ. SLOPE CURRENT DETECTER DRAIN BIAS Fig 1 N3856x Function Block Diagram 1 Jan-20-2004 NIKO-SEM APPLICATION NOTE AN-1001 PIN FUNCTIONS GATE ( Pin 1 ) : This pin is driver output of N3856x, It’s capable of source and sink 1A current ,directly connected to the Gate of synchronous rectification MOSFET or series with a small resistance of resistor . PGND ( Pin 2 ) : This is the Power GND for the output totem pole driver of the ship . GND ( Pin 3 ) : This is the signal GND for the control logic signals of the ship. BIAS (Pin 4 ) : The pin connected a resistor to VCC ,In the discontinuous mode operating , if adjust the resistance will cause a different slope voltage between the Gate and Source of MOSFET , the down slope Vgs waveform is determined turn-off time when the voltage reach the threshold voltage level of the MOSFET. DRAIN ( Pin 5 ) : The pin is directly connected to the Drain pin of the synchronous rectification MOSFET for detecting the drop voltage between Source and Drain . Aout ( Pin 6 ) : This pin is internal comparator output to control “pin1” output duty , it also provided the primary control function by a pulse transformer in the continuous mode operating .It could connect a resistor to VCC pin to modify the rise time of turn-on , keep this pin is floating if doesn’t use . RT/CT (Pin 7 ) : This pin connected a resistor and capacitor to generate a saw-tooth waveform Comparing with internal reference voltage(1/3 VCC) .When the saw-tooth waveform reach the voltage level will cause output driver turning low voltage and MOSFET is off. The charging current will discharge via internal circuit. VCC (Pin 8 ) : This pin is for supply voltage for the ship, it is also a synchronization pin for the control logic ,so it can’t connect any filtering capacitor for normal operating . 2 Jan-20-2004 NIKO-SEM APPLICATION NOTE AN-1001 TRANSFORMER DESIGN One of the most important factors in design of a flyback power supply is the design of the transformer .Usualy ,we recommended the Maximum duty is 0.5 in conventional flyback power supply for obtaining a best efficiency , but in the synchronous rectification application ,we recommended the Maximum duty is 0.3 , and let the synchronous rectfication MOSFET have more turn-on period ,resulting a lower power loss during energy tranfer to output stage. For the N3856x controller application ,we need to provide a AUX winding for the supply voltage and synchronization purpose . The AUX winding is approximately supply a 12V via a fast recovery diode(1N4148) to VCC pin of the N3856x derectly without any filtering capacitor , the AUX winding should be placed near by the main output winding for obtaining a best connection and less leakage inductance, a higher leakage inductance may cause more spike voltage on VCC pin that could increase turn-on delay time for the N3856x. OPERATION DISCONTINUE MODE OPERATING In the discontinue mode operating , when the primary power MOSFET is turn-off ,then the transformer begin to release the storing energy to secondary output , the down slope current flows through source and drain of the MOSFET , formed a drop voltage comparing with internal reference voltage 20mV by the adjustable slope current detecter ,when the drop voltage is over 20mV, the driver output high level to turn on the MOSFET , if the drop voltage down to 20mV ,will generate a down slope voltage waveform for the driver output ,if the voltage reach to the threshold level of power MOSFET, therefore power MOSFET is turn-off, then wait next operating period ,the MOSFET is turn-on again . There are two detecting pins on the adjustable slope current detecter ,one is pin 5 ,another is pin 3, the pin 5 is directly connected to the drain of MOSFET , the pin 3 is connected to the source of MOSFET . For the diffent Rds(on) MOSFET ,we designed a adjustable slope function for tunning a best turn-off point in the discontinuous mode operating ,see the Fig 2 , adjust the resistance of the bias resistor ,let Vgs voltage down to the min. voltage level (near to 0V) before the resonant waveform beginning (T2) resulting by Land C ,If the resistance of bias resistor is smaller ,the slope will be faster . HOW TO ADJUST THE BIAS RESISTOR ( R1) In the discontinue mode operating ,set the output load heavier ,then adjust the bias resirtor 3 Jan-20-2004 NIKO-SEM APPLICATION NOTE AN-1001 until the Vgs slope down to 0V before he resonant waveform beginning (T2) resulting by Land C , and checking no load codition waveform ,if switching action is not normal , reducing the resistance until waveform is normal . T1 T2 T3 WAVEFORM OF SECONDARY WINDING SECONDARY WINDING CURRENT ; VSD 20mV reference DELAY TIME THE SLOPE OF VGS IS ADJUSTED BY “BIAS” PIN . VGS GATE – GND WAVEFORM 4 Jan-20-2004 NIKO-SEM APPLICATION NOTE AN-1001 Fig 2 Control waveform for the discontinue mode CONTINUE MODE OPERATING In the continue mode operating , the output control dead time is used by a comparator , RT/CT(pin 7) connected a resistor (RT) to VCC ,and connect a capacitor (CT) to GND , the pin 7 is charging current via RT to CT and forming a saw-tooth waveform voltage, the voltage is reaching 1/3VCC , then the comparator will become low level ,therefore the driver output changed to low and turn off the MOSFET . See the Fig 3 , the dead time appears on the end of T1 period . HOW TO ADJUST DEAD TIME First, adjust output load from light load to high load slowly ,check the waveform of GATE –GND When the output load into the boundary of the discontinue mode and continue mode ,checking the dead time of the waveform of GATE –GND, it appears or not , if dead time not appear , then reducing resistance of RT or the capacitance of CT , if dead time appear , check dead time is OK or not ,adjust it to the best point . T2=0 T1 T3 duty cylce dead time delay time GATE - GND WAVEFORM 1/3VCC VCT PIN 7 VGS 5 Jan-20-2004 NIKO-SEM APPLICATION NOTE AN-1001 Fig 3 Control waveform for the continue mode See the Fig 4 , showing Delay Time and Dead Time on 120W power supply application , Fig 4 Delay Time and Dead Time measurement on 120W,19V/6.3A power application 6 Jan-20-2004 NIKO-SEM APPLICATION NOTE AN-1001 POWER SUPPLY DESIGN CRITERIA REQUIRED D1 B+ 1N4148 T1 1 R10 G Q2 IRFB4710 5 6 + C5 D3 4 8 ZD1 + C6 S D S D D2 SB3100 Vo + Q1 G IRFB4710 C3 18V U1 N3856V 1 PWM CONTROLLER Q3 C2 470P R1 2 3 4 GATE VCC PGND RT/CT GND AOUT BIAS DRAIN 8 7 6 RT CT 5 16K R9 R7 U3 4 3 1 R4 R6 2 PC817 U2 C4 TL431 Pin 5 of the U1 is directly connected to "drain" pin of the Q1 , and this trace can't be connected to other components . Pin 2,3 of the U1are directly connected to "source" pin of the Q1 , and this trace can't be connect other components . R5 R8 1) 2) 3) 4) 5) 6) 7) Fig 5 Typical Flyback power supply using the N3856x Series Recommended operating frequency for the best efficiency --- fs = 50K~60KHz Maximum duty cycle --- Dmax ≈ 0.3 Recommended low Rds(on) power MOSFET for the synchronous rectification --- less than 16mΩ . Recommended AUX winding voltage is approximately 12V. Adjusted bias resistor R1 for tuning a turn-off point in the discontinue mode operating. Adjusted RT or CT for tuning a dead time in the continue mode operating ,RT is required for 1% precision resistor and CT is reuired for 1~2%NPO or other low temperature drift characteristic capacitor . Schottky diode D2 is required(about1/3 output current rating) for reducing conduction loss during delay time and dead time because the body diode Vf of the MOSFET> schottky diode Vf , if in the 2 pcs of MOSFETs parallel application , the body diode Vf of the parralel MOSFETs will be decreased, we may remove the schottky diode D2 . 7 Jan-20-2004 NIKO-SEM APPLICATION NOTE AN-1001 Synchronous signal from primary side application See the Fig 5 , showing synchronous signal from primary side application in the continue mode operating ,the RT/CT pin (pin 7) is shorted to PGND (pin 2) . the synchronous signal from primary side must be ahead of the gate waveform of Q2 , let Q1 is turn-off before Q2 turn-on . D1 B+ T1 R10 1 1N4148 5 SB3100 D2 6 + C5 D4 4 S 8 D G + C4 1 Q2 VREF C6 0.1U SYNC X'FRM T2A * Q3 2SC945 + 2 PWM CONTROLER 3 C2 CT 4 470P R1 R9 C3 Q1 U1 GATE VCC PGND RT/CT GND AOUT BIAS DRAIN 8 7 6 5 Q5 2SC945 R3 1K N3856V T2B 16K Q4 2SA733 D3 1N4148 * R7 U3 PC817 4 3 1 R4 R6 2 U2 R8 Fig 5 TL431 C3 R5 Synchronous signal from primary side , using the N3856x Series 8 Jan-20-2004 NIKO-SEM APPLICATION NOTE AN-1001 See the Fig 6 , showing the another synchronous signal from primary side application . D1 B+ T1 R11 1 1N4148 5 SB3100 D2 6 Vo + C5 D4 4 S 8 D C4 C4 470P PWM CONTROLER R9 2K D5 C6 102p SYNC X'FRM T2A * Q3 Q2 1 2 2SC945 3 C2 4 470P R1 R10 R7 C3 Q1 G + + U1 GATE VCC PGND RT/CT GND AOUT BIAS DRAIN 8 7 6 5 Q5 2SC945 R2 1K N3856V T2B 16K 470 D3 * 1N4148 R5 U3 PC817 4 3 1 R3 R6 2 U2 R8 Fig 6 C1 TL431 R4 Synchronous signal from primary side , using the N3856x Series 9 Jan-20-2004 NIKO-SEM APPLICATION NOTE AN-1001 See the Fig 7 , we can connect synchronous rectification MOSFET to the GND , and it is implemented for multiple output application . B+ 1 T1 D1 5 R1 D2 2 4 1N4148 6 8 Vo1 + C1 U1 3 + C2 7 9 1 10 3 2 4 C4 Q1 Q2 IRFB4710 PWM CONTROLER 470P N3856V GATE VCC PGND RT/CT GND AOUT BIAS DRAIN R3 8 7 6 R2 47K + C3 5 C5 470P 16K D3 3A/100V R4 Vo2 Q3 IRFB4710 D4 + C6 3A/100V R5 U2 4 PC817 3 1 R6 R7 2 U3 R8 Fig 7 TL431 R2 or C5 is adjusted for the maximum duty cycle of synchronou rectifier MOSFET C7 R9 Multiple output and the MOSFET on the low side application 10 Jan-20-2004 NIKO-SEM APPLICATION NOTE AN-1001 DEMO BOARD DESCRIPTION The Fig .8 presents a demo board for the N3856x , This board replaces the output rectifier diode with synchronous rectification MOSFET in flyback power supply and includes all the components needs by the N3856x to operate, R3 and C1 can be adjusted for diffferent switching frequency and turn-on duty demand GND GATE DRAIN VCC D1 1N4148 1 2 C2 470P 3 4 U1 GATE VCC PGND RT/CT GND AOUT BIAS DRAIN N3856V 8 7 C1 R3 470P 51K 6 5 R1 16K Fig 8 Demo board layout----componects Fig 9 Demo board layout----component side Fig 10 Demo board layout--- soldering side 11 Jan-20-2004