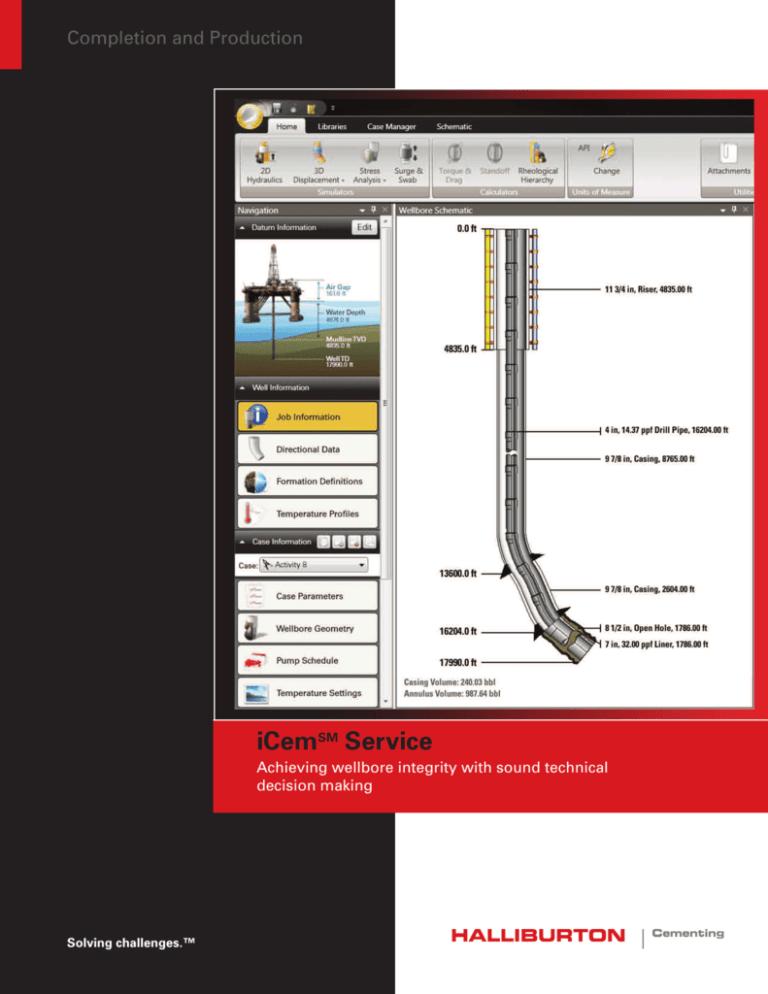

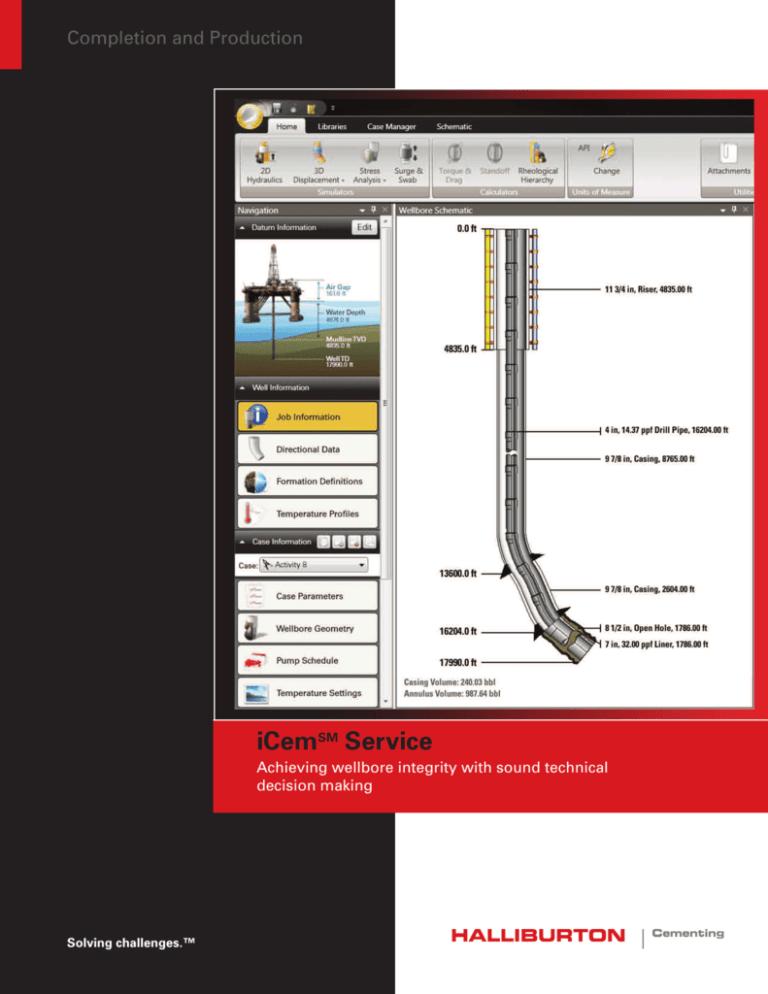

Completion and Production

iCemSM Service

Achieving wellbore integrity with sound technical

decision making

Solving challenges.™

iCemSM Service

Achieving wellbore integrity with sound technical decision making

Wellbore architecture challenges are complex and every cementing job presents technical and operational challenges.

With iCemSM service, Halliburton offers an advanced way to work collaboratively with operators to increase the

probability of wellbore-integrity success. iCem service is a comprehensive cementing design tool to assess and monitor

specific variables before, during and after a cement job in order to help reduce operational risk and increase

operational success.

Key wellbore architecture design data derived from a collaborative process between the operator and the service

company can be entered in to the iCem service tool and used to run various simulations or calculations including:

Two-dimensional Equivalent Circulating Density

(ECD) hydraulic simulation

Three-dimensional spacer and

cement placement simulation

Cement sheath stress analysis is a finite element analysis model to predict the risk of cement

failure during various stress-inducing operations to generate thermal and mechanical

properties required to retain zonal isolation

Tracking surge pressure against the fracture gradient and swab pressure

against pore pressure according to casing shoe measured depth

Optimize fluid rheologies by assessing the likelihood of fluid

bypass based on pressure drop versus flow rate for each

successive fluid

Centralization optimizer includes plot detailing

standoff of each centralizer and the mid-point

Rotational torque, slackoff weight, static weight and pickup

weight as a function of casing shoe measured depth

These variables can be assessed individually and collectively for primary cementing, reverse cementing, balanced plugs,

or a post-cementing-operation analysis to name just a few. Different results can be compared simultaneously for

vigorous design evaluation. This enables continual improvement through post-job analysis to help optimize future

designs.

1

iCemSM Service – Available Results*

Animated 2D Fluid Positions

Wellbore schematic displaying fluid movement playback during job simulation with various calculated

surface and downhole values (pressure, density, rate, hole cleaning, etc) by depth and time.

Interactive 3D

Displacement Visualizer

Three-dimensional visualization tool-kit with pipe and annular intermixing concentration

views over time, including a displacement efficiency plot.

Stress Analysis Summary

WellLife® Remaining Capacity charts and optimal (and user entered) mechanical properties

required to withstand well construction, completion and production stresses.

Balanced Plug Snapshot

Wellbore schematic showing the height of all fluids in place at the end of the job.

Flow Potential

Predicts formation fluid flow potential before or immediately after cement is in place.

Critical Static Gel Strength (CSGS) Plot

Determine the required cement static gel strength time period.

Erodibility Profile

Shows effectiveness of spacer at cleaning gelled mud out of the annulus.

Pressure to Break Circulation Plot

Pressure required to break gelled mud circulation in comparison to weak zone fracture gradient to

avoid formation breakdown. Can casing be run all the way to total depth before breaking circulation

or must circulation be broken in stages while running the casing?

Critical Velocity Data Table

Reports Reynolds numbers required to achieve turbulence at multiple wellbore depths.

Time of Events Summary

Snapshot of events and stages encountered during the job simulation.

Pressure Imbalance at

Conclusion of Job

Horsepower, Pressure,

& Freefall Data Table

Custom X-Y graph

Pressure across the plug.

Includes horsepower, ECDs, and freefall intervals during the job simulation.

Create custom plots with any of the simulated or entered variables

Custom Numerical Dashboard

Display

Display of real-time data acquired from the rig operations for monitoring during the actual job.

Data Listing

Ability to export all raw data (design and real time) to Microsoft Excel® for further evaluation.

ECD & Hydrostatic Pressure Plot

Circulating pressure and hydrostatic pressure over job simulation plotted at multiple weak zones

(fracture zones) and overpressure zones (pore pressure zones).

Calculated Surface Pressure Plot

Wellhead and pump pressure including surface iron.

Job Summary Plot

Four job variables (ECD, surface pressure, density, and rate) on one plot.

Downhole Pressure Profiles Plot

Prediction of minimum and maximum pressures throughout the entire job to help stay within

fracture gradient and pore pressure at all depths.

Final Density & Hydrostatic

Profile Plot

For foam jobs, shows final in-place slurry density and cumulative hydrostatic pressure

at every depth.

Temperature Profile Plot

Casing and annulus temperature profile evolution with undisturbed (geothermal) temperature baseline

over job simulation plotted at all depths illustrating the calculated dynamic temperature profile.

Slurry Placement Temperatures Plot

Temperature tracker for first sack of lead cement, first sack of tail cement, and last sack of tail cement.

Rate In & Rate Out Plot

Rates in and out used to illustrate the expansion and compression of foamed fluids as well as the

affects of free fall.

Rheological Hierarchy Plot

Comparison of the pressure drop versus flow rate for each successive fluid to help ensure correct

alignment or prediction of the likelihood of spacer bypassing mud, spacer bypassing cement, etc.

Hookload Plot

Standoff Plot

Torque Plot

Simulates hook load throughout job simulation.

Drag Plot

Includes slack-off weight, static weight, pickup weight as a function of casing shoe measured depth.

Surge & Swab Pressures Plot

Surge pressure tracked against the fracture gradient and swab pressure tracked against the pore

pressure, at every depth, as a function of casing shoe measured depth going in or coming out.

Downhole Surge & Swab Profiles Plot

Surge pressure and swab pressure as a function of well depth compared to the fracture

and pore pressure gradients.

Centralizer placement, standoff at each centralizer, and standoff at mid-point between centralizers.

Simulation of rotational torque applied to the casing during installation into the wellbore.

*Results support meeting or exceeding API 65-2 specifications.

2

iCemSM Service

iCemSM Service – Three-Dimensional Displacement Simulation

Based on computational fluid dynamics, the 3D simulator

models multiple aspects of mud displacement during

cementing and demonstrates the effect of the key

mud-displacement variables that affect successful cement

placement.

• Models the mud/spacer/cement interfaces over time

within the wellbore environment at all depths to help

determine optimum fluid designs

• Uses rheological data including fluid compatibility

tests and best-fit rheological models

The simulator is formulated on general curvilinear

coordinate mesh system whose boundaries can conform to

highly eccentric annuli and/or localized washout to help:

• Predict the amount of required spacer and cement

volumes to avoid contamination and to achieve top

of cement (TOC)

• Determine optimum casing stand off to reduce

the probability of channeling

• Determine optimum pump rate for successful cement

placement

• Determine impact of pipe rotation and reciprocation

to reduce channeling and achieve desired top of cement

The same data can be represented both in a graph (above) or

a cross section of the well (below) to help determine a volume

of each fluid for optimized displacement. Notice the 70% of

cement (red) in the graph above correlates to the 70% coverage

below. In this example further iterations are required to develop

a design that eliminates channeling.

Fluids can be assessed at any cross section of the well at any

given time. This helps determine fluid volumes necessary to

achieve optimal displacement efficiency and minimize

cement contamination.

3

iCemSM Service – Two-Dimensional Hydraulic Simulation

iCem service provides a comprehensive suite of hydraulic modeling for simulating cementing operations:

• Equivalent Circulating Density (ECD) management

• Surge and swab

• The effect of dynamic temperature on fluid properties

• Mud removal and erodibility

• Pump schedule design with and without foam cement

along with automatic calculation of cement sacks

required to achieve top of cement (TOC)

• Advanced rheological modeling

• Balanced plug with or without stinger

• Standoff

• Integrated fluid-flow potential calculations

• Complex land and offshore wellbore geometry designs

• Automatic pump rate adjustment to stay below

fracture gradient

• Torque and drag

Dynamic temperature modeling allows a more accurate design of cement slurries for complex downhole environments by

enabling temperature-evolution via heat-transfer modeling.

Chart on the left is an interactive graph over the entire job

time showing casing and annular temperature profiles

including bottom-hole circulating temperature.

Chart on the right is a temperature tracker over the entire job

time for key cement stages to help enable optimized

laboratory slurry testing prior to the job.

4

iCemSM Service – Cement Sheath Stress Analysis

Wells are subjected to substantial stresses from

operationally induced pressure events and temperature

cycling. The annular seal can succumb to the

cumulative effect of these forces, compromising zonal

isolation and reducing the economics of the well by

inhibiting production and/or requiring costly

remediation. WellLife® service, Halliburton’s original

modeling software is a globally recognized finite element

analysis model to predict the risk of cement failure

throughout the life of the well. The power and reliability

of this software is the foundation for the Cement Sheath

Stress Analysis within iCem service.

Cement failure phenomena that can be modeled include

de-bonding from casing, de-bonding from the

formation, radial cracking, and deterioration. The

Cement Sheath Stress Analysis identifies the probability

of the loss of zonal isolation during various

stress-inducing operations.

The Cement Sheath Stress Analysis simulator can model

various critical phases that the cement is exposed to after

placement including:

• Cement Hydration

• Shoe Pressure Testing

• Fracturing / Stimulation

• Completion Fluid Change Out

• Injection and Production

• Evacuation / Unloading

• Well Kill

Examining the effect of these phases of well operations on

the cement sheath helps design a solution that will help

ensure zonal isolation for the life of the well.

The model simulates the well structure, properties of

formation, and long-term critical well conditions to predict

the competence of a cement sheath. Going further, the

model then generates thermal and mechanical properties

required to survive downhole stress conditions. The

properties revealed in the modeling include Young’s

Modulus, Poisson’s Ratio, shrinkage, thermal expansion,

compressive strength, tensile strength, thermal conductivity,

and specific heat.

The ability to withstand the downhole stresses is presented

via histograms. These charts show the percent of remaining

capacity available before succumbing to a stress-related

cement failure phenomena. If the sheath is shown to have a

high risk of failure, iCem service has a powerful module that

allows modification to the various cement-property options

via the “What If” analysis. This capability allows users to

compare differing solutions, comparing the risk and reward

of the various solution options, in order to create an

optimized solution.

Histograms indicate the remaining capacity of the cement

sheath to withstand cumulative stress and resist failure.

5

iCemSM Service – Real-Time Data Acquisition and Monitoring

Real-time acquisition and monitoring of cementing job data allows a view of the cementing job while it is being run to

monitor the compliance with the plan of the job parameters and make adjustments to further optimize displacement

rates in real time. iCem service is capable of customized charts to present a robust set of data on variables such as

pressure, rate, volume, and density for the cementing job while it is being pumped.

Charts generated in real time provide both a dynamic graph (above left) and numerical display (above right).

During cementing operations, actual job

volumes, densities, pump rates, and

pressures can be compared in real-time

to the pre-job simulation of the job plan.

The raw rig data can be used to calculate

downhole variables such as equivalent

circulating densities (ECDs) at actual

depths and conditions. These “actual vs.

planned” comparisons enable quality

reviews to help optimize future designs.

Comparison of the planned stage slurry volume (red)

versus actual pump totals (blue).

6

iCemSM Service – From the Field

Before

After

Challenge – Middle East

Poor cement bond logs (CBLs) in previous wells in the field.

Solution

Halliburton ran several scenarios and recommended

subsequent wells in the field should rely on the following

plan modifications.

• Increasing casing centralization to 70% standoff

• Modifications to the drilling fluid rheology

• Increase spacer volumes up to 60 barrels

Results

• Dramatically improved cement bond logs

CBLs for iCem service-optimized wells (right) showed

significant improvements over CBLs from previous wells (left).

Challenge – Shale

Highly stressed formation subjecting wells to excessive washout, sloughing shales, stuck pipe, and poor cement jobs.

Solution – The three-dimensional displacement simulation revealed risks of debonding and causes of sheath failure

over time due to wellbore stresses and led to changes:

• Wellbore fluid conditioning

• Optimized centralizer placement for proper standoff

• Cement spacer properties

• Resilient cement sheath mechanical properties to address completion and production wellbore stresses

Results

• After implementing changes, CBL indicated dramatic improvements in placement coverage over previous wells

• Previously required remediation work was avoided

HALLIBURTON

www.halliburton.com

Sales of Halliburton products and services will be in accord solely with the

terms and conditions contained in the contract between Halliburton and

the customer that is applicable to the sale.

H08264

08/11 © 2011 Halliburton. All Rights Reserved.