UH-60 Flight Control and Hydraulic Systems - AASF1-NY

advertisement

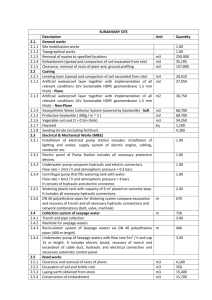

United States Army Aviation Center Fort Rucker, Alabama JULY 2002 STUDENT HANDOUT TITLE: UH­60 FLIGHT CONTROL AND HYDRAULIC SYSTEMS FILE NUMBER: 4747­9 PROPONENT FOR THIS STUDENT HANDOUT IS: AVIATION TRAINING BRIGADE ATTN: ATZQ­ATB­AD­C Fort Rucker, Alabama 36362­5000 FOREIGN DISCLOSURE RESTRICTIONS: The materials contained in this student handout have been reviewed by the instructor/training developer and determined to be public domain materials. This product is releasable to military students from all requesting foreign countries without restrictions. D­3 TERMINAL LEARNING OBJECTIVE (TLO): At the completion of this lesson the student will: ACTION: Perform operational procedures that pertain to the UH­60 Flight Controls and Hydraulic System. CONDITION: As a UH­60 aviator, given a UH­60 aircraft, TM 1­1520­237­10, and TM 1­1520­237­10CL. STANDARD: In Accordance With (IAW) TM 1­1520­237­10, TM 1­1520­237­10CL and TC 1­212. SAFETY REQUIREMENTS: Are addressed as NOTES, CAUTIONS, and WARNINGS throughout the student handout and your reference materials. RISK ASSESSMENT LEVEL: Low ENVIRONMENTAL CONSIDERATIONS: None A. ENABLING LEARNING OBJECTIVE (ELO) #1: ACTION: Identify the operational characteristics of the flight controls system of the UH­60. CONDITION: Given a list, without references. STANDARD: IAW TM 1­1520­237­10 and the student handout. Learning Step/Activity ­ Provide instruction to identify the operational characteristics of the flight controls system of the UH­60. a. Description. The primary flight control system consists of the lateral, longitudinal, collective pitch, and directional control subsystems. Control inputs are transferred from the cockpit to the rotor blades by mechanical linkages and hydraulic servos. Pilot control is assisted by a stability augmentation system (SAS), a flight path stabilization (FPS), and an electromechanical trim. Dual cockpit controls consist of the cyclic, collective, and T/R pedals. The pilot and copilot’s controls are routed separately to a combining linkage for each control axis. Output from the cockpit controls is carried by mechanical linkage, through pilot assist servos, to the mixing unit. The mixing unit provides proportional output signals, through mechanical linkages, to the main and tail rotor controls b. Collective control system. (1) Description. The collective control system provides vertical helicopter control. The collective sticks are connected through a series of control rods and bell cranks, a collective boost servo, and a mixing unit to the primary servos. The primary servos, independent of the cyclic swash plate’s position, raise or lower the main rotor swash plate. This causes the pitch angle of all blades to change. (2) Components. (a) Collective sticks. D­4 D­5 D­6 1. Pilot’s collective stick. The pilot’s collective stick has an adjustable friction lock to prevent the stick from creeping. 2. Copilot’s collective stick. The copilot’s collective stick stows aft to give the copilot leg clearance when entering and exiting his seat. The stick is stowed by rotating the grip 90° and pushing the stick aft. 3. Collective stick grips. a. Description. A grip, located on each stick, houses several switches and gives the pilot and copilot a means to operate their collective sticks. b. Collective switch box: buses contain the Servo off switch. This is a three­position toggle switch, which is flown on the center position. It is marked “1ST STG and 2ND STG”. (b) Boost servos. 1. Description. These servos are located in the hydraulic compartment forward of the mixing unit. The collective boost servo is on the right­hand side, and the yaw boost servo is on the far left­hand side of the pilot assist manifold. Boost servos make it easier for the pilot to move the pedals and collective stick and prevent SAS feedback into the flight controls in the yaw and pitch channels. 2. Stall force (power piston). Force is approximately 785 pounds at 3000 psi. (c) Mixing Unit. 1. Description. This mechanical unit combines, sums, and couples cyclic, collective, and yaw inputs. It provides proportional output signals, through mechanical linkages, to main and tail rotor controls. D­7 D­8 2. Coupling. Couplings are as follows: a. Collective to yaw (1° coll: 1.2° T/R). Increased collective will add pitch in T/R independent of T/R pedals. b. Collective to lateral (1° coll: .103° lat.) Compensates for lateral lead caused by thrust of T/R. c. Collective to longitudinal (1° coll: .290° long.) Compensates for down wash on stabilator. d. Yaw to longitudinal (1° T/R: .290° long.) Compensates for canted T/R, which creates lift, which tends to tilt nose down. (d) Primary servos. 1. Description. The UH­60 uses three interchangeable primary main rotor servo assemblies. These servos are equal area assemblies, which consist of two independent stages arranged in parallel configuration. They are referred to as the forward longitudinal, aft longitudinal, and lateral servos. The servos are operated by pilot inputs, from the collective and cyclic sticks and pedals, through a mixer unit. The servos are ballistically tolerant. 2. Purpose. The servos control the non­rotating swashplate, allowing the pilot to control the M/R system. 3. Two pressure switches, one for each stage, are located on top of each servo assembly. These switches will illuminate the first or second stage primary servo pressure caution lights if there is a loss of pressure. 4. Ballistic tolerant: If a power piston jam occurs between the housing and the piston either due to internal or external damage, shear separation will occur. The remaining good stage will react to aerodynamic loads. D­9 (3) Collective system operation. When the collective stick is raised, the following actions or movements take place: (a) Both collective sticks move up. (b) The collective boost servo piston moves forward. (c) The three main rotor primary servo pistons move aft. D­10 (d) The tail rotor servo piston moves left and increases positive pitch in the tail rotor to compensate for increased rotor torque. (e) Forward, aft, and lateral inputs to the swash plate move aft which causes the swash plate to move up. This action collectively increases pitch in the main rotor blades. (f) Lateral input moves slower and a lesser amount than forward and aft inputs. This movement allows the main rotor disc to tilt down on the left side, as necessary, to compensate for lateral lead caused by thrust from the tail rotor. (g) Aft input moves faster and farther than forward input. This movement allows the disc to tilt down in front. (h) The collective­to­longitudinal coupling compensates for an increased down wash on the stabilator from the main rotor. B. ENABLING LEARNING OBJECTIVE (ELO) #2: ACTION: Identify the operational characteristics of the cyclic control system. CONDITION: Given a list, without reference. STANDARD: IAW TM 1­1520­237­10 and the student handout. Learning Step/Activity ­ Provide instruction to identify cyclic control system operational characteristics. a. Description. The cyclic control system provides forward, rearward, and lateral control of the helicopter. The cyclic sticks are connected through a torque shaft, a series of control rods and bell cranks, a pitch trim assembly, a roll assembly, a SAS actuator, and a mixing unit to the primary servos. These control movements of the main rotor blades. b. Components. (1) Cyclic sticks. (a) Description. The Pilot’s and copilot’s cyclic sticks are mechanically coupled, lever­type controls. (b) Grips. Each grip has the same switch in the same location. (2) Trim. When trim is engaged, the pitch, roll, and yaw trim systems are activated to maintain the position of the cyclic and tail rotor controls. The trim actuators are controlled by the SAS 2/FPS computer trim program. The Trim On button activates and deactivates the program. The Cyclic trim release button also deactivates the trim program. The SAS 2/FPS computer will deactivate trim when it detects a problem. (3) SAS. The SAS actuators are located on top of the cabin roof in the pilot assist area. (a) SAS servos. SAS servos are electrically controlled, hydro mechanical actuators, which are located in the pitch, roll, and yaw axes. When turned on, they operate on 3,000­psi hydraulic pressure. (b) Switches. 1. Pressure switch. Located on the pilot assist module. When pressure drops below 2000 psi the switch illuminates the SAS OFF caution light. D­11 2. SAS 1 and SAS 2 control switch. This switch, located on the automated flight control panel, gives the pilot control of the SAS servos. (c) Actuators. 1. Pitch SAS actuator. This actuator provides rate dampening for a nose down or nose­up movement. It is located on the pitch trim assembly. When SAS is turned on the pitch boost servo is pressurized to 3,000­psi hydraulic pressure to prevent SAS feedback into the cockpit cyclic control. 2. Roll SAS actuator. This actuator is a dynamic rate stabilization system that gives rate dampening for the helicopter in the roll axis. When it is engaged, the cyclic does not move. 3. Yaw SAS actuator. This actuator provides rate dampening for directional heading changes. It is attached to the yaw boost servo. c. Operation of cyclic system with stick trim on. (1) Forward cyclic. Moving the cyclic stick forward causes the following actions or movements to take place: (a) Both cyclic sticks move forward. (b) The spring in the pitch trim servo compresses, which causes the pitch, trim servo to be immobile. However, if stick trim is OFF, the spring and pitch trim servo will move together. 1. The forward primary servo moves forward. 2. The aft primary servo moves aft. 3. Forward input to the swash plate moves down, and aft input to the swash plate moves up. (2) Aft cyclic. Moving the cyclic aft causes the servos and controls to move in the opposite direction. (3) Left lateral. Moving the cyclic stick left causes the following actions or movements to take place: D­12 (a) Both cyclic sticks move left. (b) The mixer moves. (c) The lateral primary servo moves aft. (d) Lateral input to the swash plate moves down. (4) Right lateral. Moving the cyclic stick right causes controls to move in the opposite direction. C. ENABLING LEARNING OBJECTIVE (ELO) #3: ACTION: Identify the operational characteristics of the tail rotor system of the UH­60. CONDITION: Given a list, without reference. STANDARD: IAW TM 1­1520­237­10 and the student handout. Learning Step/Activity ­ Provide instruction to identify the operational characteristics of the UH­60 tail rotor system. a. Description. The tail rotor (directional) control system determines the helicopter’s heading or yaw by controlling pitch of the tail rotor blades. The control pedals are connected through a series of control rods and bell cranks, a yaw boost servo, a mixing unit, cables, and quadrants to the tail rotor servo. This tail rotor servo moves the pitch change beam, which changes angles of the tail rotor blade. b. Components. (1) Tail rotor pedals. Pedals are coupled mechanically and permit the pilot and copilot to control the helicopter’s heading. They contain independent, toe­operated, wheel­brake controls. Each set of pedals can be adjusted to the pilot and copilot’s leg length. (2) Yaw boost servo. This servo reduces flight control friction, and prevents feedback from the Yaw SAS actuator in the cockpit controls. (3) Tail rotor cables (2 each). Two cables connect to the yaw controls (located aft of the mixer) to an aft quadrant (located just forward of the tail gearbox). (4) Tail rotor quadrant. (a) Description. A tail rotor quadrant, mounted on the tail gearbox, transmits movements of the tail rotor cable to the tail rotor servo. (b) Spring cylinders (2). Two spring cylinders, connected to the quadrant, allow the quadrant to operate normally in the event a cable breaks. (c) Micro switches (2). The two micro switches illuminate the TAIL ROTOR QUADRANT caution light if one of the tail rotor cables breaks. D­13 c. Tail rotor servo system. (1) Description. The UH­60 uses a tail rotor servo assembly, which consists of two independent stages arranged in a parallel configuration. The assembly is mounted in the tail gearbox. When pressurized it prevents all feedback from the tail rotor and allows the pilot 100% control of the tail rotor. (2) Components and operation. Major subcomponents of the servo system are identical to the boost servos. There is a stall force of 2,100 pounds (± 50) on each power piston. (a) Tail rotor servo. This servo is a two­stage component, and one stage is pressurized at any one time. (b) Centering spring. In the event both cables break, this spring places the pilot valve in a position that gives a positive pitch of 10.5° in the tail rotor if there is a pressurized tailrotor servo. d. Operation of tail rotor system. (1) Pushing the left pedal increases positive pitch in the tail rotor and causes the nose to yaw to the left. Pushing the left pedal moves the following components: (a) The yaw boost servo moves forward. (b) The tail rotor servo, in the tail gearbox, moves left. This movement increases positive pitch in the tail rotor blade. D­14 IN P U T C O N T R O L R O D IN B O A R D R E TE N TIO N P L AT E (2) JA M N U T TO R ETA IN S E A L R E TA IN E R 6 E A C H N U T S A N D W A S H ER S P IT C H C H A N G E S H A FT S E A L A N D R E TA IN E R TA IL R O TO R S E R V O TA IL R O T O R G E A R B O X TA IL R OT O R S E RV O IN STA LLAT IO N (2) Primary servo operation in relation to tail rotor control input. (a) The aft primary servo moves forward (contracts). (b) The forward primary servo moves aft (extends). (c) Aft servo input to the swash plate moves swash plate down. (d) Forward servo input to the swash plate moves swash plate up. NOTE: When the left pedal is pushed, the lift from the canted tail rotor tends to increase and tilt the nose down. The yaw­to­longitudinal coupling, described earlier compensates for this. If both cables break, a spring assembly, attached to the pilot valve on the tail rotor servo, will cause the servo to move to a positive pitch position (approximately +10.5°). D. ENABLING LEARNING OBJECTIVE (ELO) #4: ACTION: Identify the operational characteristics of the hydraulic system of the UH­60. CONDITION: Given a list and without reference. STANDARD: IAW TM 1­1520­237­10 and the student handout. Learning Step/Activity ­ Provide instruction on the operational characteristics of hydraulic system. a. Description. There are two redundant hydraulic systems with a backup pump that can supply either system. The #1 system is referred to as the first stage hydraulics, and the #2 system is referred to as the second stage hydraulics. The backup pump is considered the third stage hydraulics. System pressure (normally under no load) is 3,050 psi (±50). b. Components and location. (1) The three hydraulic pump modules are identical/interchangeable. D­15 (a) The #1 pump module supplies first stage primary servos and the first stage tail rotor servo. (b) The #2 pump module supplies second stage primary servos and pilot assist servos. (c) The backup pump module supplies first or second stage hydraulic loads, the second stage tail rotor servo, and the APU accumulator. (2) The two transfer modules are an integrated assembly of restrictors, switches, and valves, which connect hydraulic pressure from the pump to the servos and provide automatic switching to the backup pump in case the #1 or #2 system fails. They are interchangeable. (3) The two transfer module manifolds are not interchangeable. (a) The #1 transfer module manifold supplies hydraulic pressure to the first stage primary servos. (b) The #2 transfer module manifold supplies hydraulic pressure to the second stage primary servos. (4) The pilot assist module supplies second stage hydraulic pressure to the pilot assist module manifold. (5) The pilot assist module manifold supplies hydraulic pressure to the pilot assist servos. (6) The utility module routes backup hydraulic pressure to the #1 or #2 transfer modules , APU accumulator and the #2 tail rotor servo. (7) The three primary servos control the non­rotating swashplate, allowing the pilot to control the M/R system. (8) The system includes a first stage and a second stage tail rotor servo. (a) Under normal operation, the first stage tail rotor servo is pressurized by the first stage hydraulic system, and the backup pump can pressurize it, when the #1 pump fails. (b) The second stage tail rotor servo is pressurized by the backup pump. c. Hydraulic control switches. (1) Primary servo shutoff control switch. (a) This switch is located on the pilot and copilot's collective stick grips. (b) It has three positions, which are— 1. NORMAL. Both stages are operating. 2. FIRST STAGE PRIMARY SERVOS. First stage can be shut off if second stage is good and a jam does not exist. 3. SECOND STAGE PRIMARY SERVOS. Second stage can be shut off if first stage is good and a jam does not exist. (2) Tail rotor servo control switch. D­16 (a) This toggle switch is located on the miscellaneous switch panel. (b) It has two positions, which are­­ 1. NORMAL. Pressure is supplied to the first stage tail rotor servo by the # 1 hydraulic system. 2. BACKUP. Backup pump supplies pressure to the second stage tail rotor servo. (3) Boost servo switch. (a) This push button­type switch is located in the AUTO flight control panel in the center console. (b) It has two positions, which are ON and OFF. (4) SAS switches. (a) These two push button­type switches are located in the AUTO flight control panel in the center console. (b) The SAS 1 analog switch has two positions, which are ON and OFF. (c) The SAS 2 digital switch has two positions, which are ON and OFF. (5) Trim switch. (a) A push button switch located in the AUTO flight control panel in the center console. (b) It has two positions, which are ON and OFF. (6) Backup hydraulic pump switch. (a) This toggle switch is located on the left­hand side of the forward upper console. (b) It has three positions, which are OFF, ON, and AUTO. D­17 D­18 D­19 D­20 D­21 PRIM ARY SERVO SHUT­O FF ELECTRICAL INTERLO CK ver 1.02 1st & 2nd stage prim ary servos can 't b e sim u ltaniou sly shu t off (this w ould render the aircraft uncontrolable). A lack of pressure in any stage opens circuit to other stages S/O valve w hich is fail safe open. PILO T & C O PILO T C A N 'T SIMU LTA N IO U SLY SH U T O FF BO TH STAG ES C o­pilot P ilot C opilot's sw itch to 2nd stage off, #2 dc prim ary bus pow er closes 2nd stage S/O valve, lack of pressure in all three 2nd stage prim ary servos opens circuit to 1st stage S/O valve, pilot's 1st stage sw itch can't com plete circuit to close valve on only remaining servos. LAC K O F PR E SSU R E IN AN Y STA GE P R EVEN T S C O C KPIT SH U T OF F O F O TH E R S TA G E C opilot's sw itch to 2nd stage off, #2 dc prim ary bus pow er closes 2nd stage S/O valve. If pressure drops in 1st stage, the lack of pressure in 1st stage opens circuit to 2nd stage S/O valve and it re­opens. #1 P RI SE RV O P RE S S (L ow pressure on one or m ore 1st stage prim ary servo s) P ilo t Assist # 1 D C P rim a ry B us # 1 DC P rim ary B us #1 D C Prim ar y Bu s B ack­Up P um p P rim ary S e rvo shu t off valve is fail safe o pen. 2nd stage S /O valve 1st stage S /O valve P rim ary S e rvo shu t off valve is fail safe o pen. #2 D C P rim a ry Bu s #2 D C P rim a ry Bu s #2 D C P rim a ry B us B ack­Up P um p #2 P RI S E RV O PRE S S 1st stage T/R servo (Low pressu re on on e or m ore 2 nd stag e p rima ry servos) D­22 d. Indicator buttons. Seven red pop­out buttons are installed in the hydraulic systems for inspection purposes. These buttons cannot be reset externally. (1) The #1 pump has pressure and return filter buttons (differential pressure). (2) The #2 pump has pressure and return filter buttons (differential pressure). (3) The backup pump pressure and return filter buttons (differential pressure). (4) The pilot assist module has a pressure reducer pop­out button (over pressurization). e. Caution/advisory lights. The hydraulic systems incorporate 12 caution and 3 advisory lights to assist the aviator in monitoring the systems. (1) The caution lights are­­ (a) #1 RSVR LOW. (b) #1 HYD PUMP. (c) #1 TAIL ROTOR SERVO. (d) #1 PRI SERVO PRESS. (e) #2 RSVR LOW. (f) #2 HYD PUMP. (g) BOOST SERVO OFF. (h) SAS OFF. (i) #2 PRI SERVO PRESS. (j) BACKUP RSVR LOW. (2) advisory lights are­­ (a) BACKUP PUMP ON. (b) #2 TAIL ROTOR SERVO ON. (c) APU ACCUMULATOR LOW. (3) The following caution lights are computer controlled, and could come on with or without hydraulic failures— (a) TRIM FAIL (b) FLT PATH STAB E. ENABLING LEARNING OBJECTIVE (ELO) #5: ACTION: Identify the operational characteristics of the # 1 hydraulic system of the UH­60. CONDITION: Given a list, without reference. D­23 STANDARD: IAW TM 1­1520­237­10 and the student handout. Learning Step/Activity ­ Provide instruction on the operational characteristics the #1 hydraulic system. D­24 a. Description. The #1 system supplies hydraulic pressure through the #1 transfer module to the first stage primary servos and first stage tail rotor servo. b. Components. (1) Pump module. This is a combination pump and reservoir assembly. (a) Location. The pump module is located just inboard of the #1 generator on the left­hand accessory module. (b) Pump. This is a variable­delivery, pressure­compensated, piston­type component. 1. Pressure output. Output is 3,050 + 50 psi. 2. Flow rate. Flow rate is 6.2 gallons per minute (gpm) at 2,900 psi. 3. Shear feature. The pump shaft will shear at approximately 360 inch pounds of torque. (c) Filters (2). 1. Pressure filter. a. This filter is a wire mesh type that is disposable. It has no bypass provision because you do not want contaminated hydraulic fluid in the system. b. A differential pressure indicator button extends with a differential pressure of 70 ± l0 psi to let the aviator know when the filter is contaminated on preflight. 2. Return filter. This filter is identical to, and is interchangeable with, the pressure filter. A bypass valve opens with a differential pressure of 100 ± l0 psi. The bypass feature prevents a hydrostatic lock of the hydraulic system. (d) Relief valve. A high­pressure relief valve is located on the pressure side of the pump. 1. It opens to protect the system at 3,850 psi by allowing fluid to return to reservoir. 2. It resets at 3,300 psi. (e) Quick disconnects. The three quick disconnects are­­ 1. Pressure. 2. Return. 3. Ground (for hydraulic mule pressure hookup). D­25 D­26 (f) Reservoir. 1. Description. A spring­loaded, sliding­piston type reservoir that stores and provides fluid to the pump. The spring has 260 pounds of force, which preloads the hydraulic system to 10 to 15 psi. 2. Fluid. MIL­H­83282 (flame retardant) hydraulic oil is used in the reservoir except in extremely cold temperatures when MIL­H­5606 is used. Fluid capacity is­­ a. Full mark­­.86 quart (normal). b. Refill mark­­.52 quart. c. Overflow­­1.56 quarts. 3. Level indicator windows. A window is located on each side of the reservoir and color coded­­ a. Blue or Red­­OVERFULL. b. Green­­NORMAL. c. Red­­REFILL. 4. Piston markings. The piston is marked with a white line with a gold trim for reading fluid level in the reservoir. When checking fluid level, the aviator should look for the gold trim on the piston to be in the green. 5. Low­level sensing switch. This switch will close the circuit and illuminate the #1 PUMP RSVR LOW light on the caution/advisory panel (60% fluid remaining, .52 quart in reservoir). 6. Bleed valve. This valve is located on top of the reservoir. a. Manual bleeding. During servicing, this is accomplished by pushing down on valve and turning it 180º. b. Automatic bleeding. Valve opens at 50 psi to reduce pressure in reservoir caused by thermal expansion. (2) #1 transfer module. This module schedules pressure from the #1 module to all first stage system components and provides a means for backup pressure to supply first stage loads. (a) Location. The transfer module is connected to the pump module. (b) Pressure switch. This switch monitors system pressure and controls the #1 HYD PUMP caution light. 1. Light ON­­at 2,000 psi (± 50). 2. Light OFF­­at 2,350 psi. (c) Transfer valve. This valve is spring loaded to 1,000 psi to give priority to the #1 hydraulic system. It has two positions, which are­­ 1. NORMAL­­allows #I hydraulic system to supply first stage pressure. 2. TRANSFER­­allows the backup pump to supply first stage pressure when the backup D­27 pump pressure exceeds the #1 pump and spring force. (d) Shutoff valves (2). 1. First stage primary servo. This valve allows the pilot or copilot to shut off first stage hydraulic pressure to the primary servos. a. Type. It is a solenoid­operated valve, which is spring, loaded open and electrically closed. b. Operation. If pressure in the second stage primary servos is good and a jam does not exist, the primary servo shutoff switch on the collective sticks will close the first stage primary servo shutoff valve, and the #1 PRI SERVO caution light will illuminate. 2. First stage tail rotor servo. If a leak occurs, this valve will automatically shut off hydraulic pressure to the first stage tail rotor. a. Type. This is a solenoid­operated valve which is spring loaded open and electrically closed. b. Operation. (1) The tail rotor control switch on the miscellaneous switch panel will close the valve when it is placed in the backup position and illuminate the #1 TAIL RTR SERVO caution light and #2 TAIL RTR SERVO ON advisory light when the back­up hydraulic pump on advisory light illuminates. (2) If pressure drops below 2,000 psi, the pressure switch on the #1 TAIL RTR SERVO is activated; or, if a jam occurs in the #1 tail rotor servo, the first stage tail rotor shutoff valve will automatically close, the second stage shutoff valve will open, the #1 TAIL RTR SERVO caution light and #2 TAIL RTR SERVO ON advisory light will illuminate, when the backup pump comes on. (e) Screens (2). These disposable (100 micron) screens filter pressure fluid. (f) Check valves (4). 1. Pressure (2). A pressure check valve is located in the primary servo pressure line and in the tail rotor servo pressure line. 2. Return (2). Return check valves are located in the tail rotor and primary servo return line. (g) Cooling flow rate restrictors (2). Restrictors are located between the pressure and return lines of the backup system portion of the transfer module and are used to prevent heat buildup when the back­up system is pressurizing the #1 system when there is zero flow. (3) #1 transfer module manifold. This manifold routes pressure and return fluid from the transfer module to first stage loads. It also provides a mount for the #I transfer module. (a) Location. The manifold is located aft of the mixer unit and forward of the bridge on the main gearbox. (b) Operation. Quick disconnects are used to connect the first stage primary servos and transfer module to the manifold. The manifold receives inputs from the utility module for the backup system. D­28 c. Operation. The pump module supplies a hydraulic pressure of 3,050 psi (+50) to the #1 transfer module which routes the pressure through the #1 transfer module manifold to the first stage primary servos, and first stage tail rotor servo. F. ENABLING LEARNING OBJECTIVE (ELO) #6: ACTION: Identify the operational characteristics of the #2 Hydraulic system of the UH­60. CONDITION: Given a list, without reference. STANDARD: IAW TM 1­1520­237­10 and the student handout. Learning Step/Activity ­ Provide instruction on the operational characteristics of the #2 hydraulic system. a. Description. The #2 hydraulic system supplies hydraulic pressure through the #2 transfer module to the second stage of all primary servos and to all pilot assist servos. b. Components. (1) Pump module. This module is the same as the #I pump module and is located just inboard of the #2 generator on the right­hand accessory module. The sensing switch illuminates the #2 RSVR LOW caution light. (2) #2 transfer module. (a) Description. The transfer module is connected to the pump module, and it functions the same as the #1 transfer module. (b) Components. 1. Pressure switch. This switch monitors system pressure and controls the #2 HYD PUMP caution light. 2. Transfer valve. This valve functions the same as the #1 system valve. 3. Shutoff valves (2). a. Second stage primary servo. (1) Purpose. This valve allows the pilot or copilot to shut off second stage hydraulic pressure to the primary servos. (2) Type. This is the same type valve as the #1 system shutoff valve. (3) Operation. If pressure in the first stage primary servos is good and a jam does not exist, the primary servo shutoff switch on the collective sticks will close the second stage primary servo shutoff valve and illuminate the #2 PRI SERVO caution light. b. Pilot assist (shutoff valve). (1) Purpose. This valve automatically shuts off the pilot assist if a leak occurs. (2) Type. The valve is spring loaded open and electrically energized closed. (3) Operation. The #2 RSVR LOW caution light sensing switch automatically will close the pilot assist shutoff valve if a leak occurs. D­29 4. Screens. These are the same as #1 transfer module screens. 5. Check valves (4). a. Pressure (2). A pressure check valve is located in the primary servo pressure line and in the pilot assist. They prevent pressure from flowing back to the shuttle valve. b. Return (2). Return check valves are located in the primary servo and pilot assist return lines. 6. Cooling flow rate restrictors (2). Restrictors are located between the pressure and return lines of the backup system portion of the transfer module and are used to prevent heat buildup when the back­up system is pressurizing the #1 system when there is zero flow. a. Backup pump­­flow rate is .3 gpm. b. Pilot assist shutoff valve­­flow rate is at .5 to .6 gpm (when closed). 7. #2 transfer module manifold. This manifold functions the same as the #1 system manifold. It is located next to the #1 transfer module manifold and has quick disconnects like the #1 system. It receives inputs from the utility module for backup system operation if the #2 system fails. 8. Pilot assist module. a. Description. This module directs second stage hydraulic pressure to the pilot assist servos. It is located forward of the #2 pump module. b. Components. (1) Shutoff valves (3). These valves control hydraulic pressure to pilot assist servos. (2) Boost servos and SAS valves. These are spring loaded to the fail­safe (OPEN) position. (3) Pitch/trim valve. This valve is spring loaded and de­energized to the safe (NORMAL) closed position. (4) Pressure reducer with relief valve. (a) Pressure reducer. This component reduces pressure to 1,000 psi for the pitch/trim servo. (b) Relief valve. This component opens above 1,375 psi if pressure is not reduced linking the pressure to the return allowing fluid to bypass the pitch trim servo. (5) Pressure switch. This switch lights the caution/advisory, SAS OFF, light when pressure drops below 2,000 psi. 9. Pilot assist module manifold. This is a one­piece base plate production with no lines. It is attached to the pilot assist module. The manifold routes hydraulic pressure from the pilot assist module to the pilot assist servos. D­30 10. Pilot assist servos. a. Description. The UH­60A incorporates pilot assist functions for SAS, yaw boost, collective boost, and pitch trim. This is accomplished by two boost servos, SAS servos, and a pitch/trim servo. These functions are not necessary for flight. b. Purpose. Servos assist the pilot to overcome friction created by flight controls. They eliminate SAS feedback and friction to the flight controls caused by the engine controls and also provides a means for FPS inputs to go through the flight controls. c. Location. Servos are located in the hydraulic compartment and forward of the mixing unit mounted to the pilot assist manifold. c. Operation. The #2 hydraulic pump normally supplies hydraulic pressure to the #2 hydraulic system, through the #2 transfer module, #2 transfer module manifold, and pilot assist module, to the second stage of the primary servos and pilot assist servos. The second stage cannot supply pressure to the tail rotor servo. G. ENABLING LEARNING OBJECTIVE (ELO) #7: ACTION: Identify the operational characteristics of the backup hydraulic system. CONDITION: Given a list, without reference. STANDARD: IAW TM 1­1520­237­10 and the student handout. Learning Step/Activity ­ Provide instruction on the operational characteristics of the backup hydraulic system. a. Description. The backup system supplies hydraulic pressure through the utility module to the second stage tail rotor servo and through the #1 and #2 transfer module to all servos supplied by the #1 and #2 systems. Also, it supplies hydraulic charge to the APU accumulator for APU starts. b. Components. (1) Backup pump module. (a) Description. This component is the same as the first and second stage pump modules. It is located just forward of the #1 pump module. (b) Pump. The pump is the same as the #1 and #2 pumps except it is electrically driven. (c) Motor. This is a 115­volt, 3­phase, 12 3/4­horsepower, AC motor. Its power source is the #1 AC PRI bus, and its function is to drive the backup pump module. A thermal switch is incorporated that limits the motor’s ground operation to 165 + 5° C). The switch is disabled in flight by the drag beam switch. (d) Filters. These are the same as #1 and #2 pump module filters. (e) Quick disconnects. These are the same as #1 and #2 quick disconnects. (f) Reservoir. This is the same as the #1 and #2 reservoirs except that the backup reservoir has a depressurizing valve. This valve is electrically connected to the backup pump, and its purpose is to unload the AC motor on the backup pump during the start cycle. This gives the pump a chance to build up speed. The valve holds a wobble plate on the pump in a neutral or flat pitch position and will only D­31 allow the pump to build up to 700 psi during the start cycle for about one­half or 4 seconds (depending what the source of AC power is). (2) Utility module. (a) Description. This module directs the flow of hydraulic pressure from the backup pump to the #1 or #2 transfer module, second stage tail rotor, and APU accumulator. It is attached to the side of the pump module. (b) Components. 1. Velocity fuse. This fuse shuts off flow to the accumulator if flow rate exceeds 1.5 gpm. Normal flow rate is 1 gpm, and a rise of .5 gpm means a leak. It automatically will reset below 100 psi of inlet pressure. 2. Rescue hoist provision. The utility module has provisions for a rescue hoist winch. 3. Check valves (3). a. Two recharging check valves keep fluid in the system when the accumulator is being recharged. They operate on 2 to 8 psid. b. The return line check valve is located in the return line to the pump. It operates on 50 psid. 4. Pressure switch. When the backup pump is ON, this switch will illuminate the BACKUP PUMP ON advisory light on the caution/advisory panel. 5. Second stage tail rotor servo. a. Tail rotor servo. The servo receives hydraulic pressure from the backup hydraulic system through the second stage tail rotor servo shutoff valve. b. Second stage tail rotor shutoff valve. This valve is located, by itself, on the floor of the hydraulic compartment. It is spring loaded OPEN and electrically energized closed if the first stage tail rotor servo is on. (3) APU accumulator. (a) Description. The accumulator supplies a 3,000­psi hydraulic charge to the APU start motor. Hydraulic fluid in the accumulator is used to compress a charge of nitrogen. The accumulator located on the rear cabin ceiling holds a nitrogen charge of 1,450 psi and a hydraulic charge of 2,850 psi (± 150). (b) Operation and components. 1. Piston position indicator. The piston position indicator tape reads from 0% to 100%. Zero percent is full right, and 100% is full left. The piston position indicator should always be between 80% and 100%. 2. Pressure gage. When there is no hydraulic charge, this gage reads the nitrogen charge (1,450 psi) in the accumulator. 3. Manual start valve. This valve is used to release the charge manually in the event normal release fails. D­32 4. Accumulator hand pump. The hand pump, located in the rear cabin ceiling, is used to manually recharge the accumulator. (c) Recharging. The backup pump will recharge the accumulator regardless of what position the backup pump switch is in. When the accumulator nitrogen charge reaches 2600 psi, the APU ACCUM LOW advisory light will illuminate, and the backup pump will automatically come on. c. Backup system operation. (1) Description. The backup hydraulic system supplies hydraulic pressure for all hydraulic systems during ground operational checks. Also, it will supply first or second stage hydraulics in the event of a pressure loss to either system. The backup pump will pressurize the second stage tail rotor if a loss of hydraulic pressure occurs in the first stage. The backup pump will recharge the APU accumulator any time the accumulator is low. (2) Operation. The backup pump will operate­­ (a) On the ground if the­­ D­33 1. Motor is not overheated. 2. Switch is in the ON position. 3. APU accumulator is low. 4. Switch is in AUTO position and first or second stage pump pressure is low or first stage tail rotor pressure is low or #1 RSVR is low. (b) In flight if the­­ 1. Drag team switch will bypass thermal lockout on motor. 2. Backup pump switch is in the AUTO position (switch can be in any position). 3. #1 HYD PUMP caution light comes on any time pressure drops below 2,000 psi. At this time, the transfer valve will shuttle and allow the backup pump to come on line and supply hydraulic pressure to the #1 system. 4. #2 HYD PUMP caution light comes on any time pressure drops below 2,000 psi. At this time, the transfer valve will shuttle and allow the backup pump to come on line and supply hydraulic pressure to the #2 system. 5. #1 RSVR LOW caution light comes on when the reservoir is low. This will cause the first stage tail rotor shutoff valve to close and the second stage tail rotor shutoff valve to open. This, in turn, will allow the backup pump to come on line and supply the second stage tail rotor servo. At this time, the following caution/advisory lights will be illuminated: a. #1 RSVR LOW. b. #1 TAIL RTR SERVO. c. #2 TAIL RTR SERVO ON. d. BACKUP PUMP ON. 6. First stage TAIL RTR SERVO caution light comes on any time pressure drops below 2,000 psi. 7. Backup pump operation limitations. During prolonged ground operation of the backup pump using MIL­H­83282 or MIL­H­5605 with the rotor system static, the backup pump is limited to the following temperature/time/cool down limits because of hydraulic fluid overheating. (Refer to the current TM 1­1520­237­10 for limitations.) H. ENABLING LEARNING OBJECTIVE (ELO) #8: ACTION: Identify the operational characteristics of the leak isolation system. CONDITION: Given a list, without reference. STANDARD: IAW TM 1­1520­237­10 and the student handout. Learning Step/Activity ­ Provide instruction on the leak isolation system. a. Description. The system automatically turns off hydraulic pressure to the pilot assist servos, first stage tail rotor servo, and APU accumulator if a leak occurs. D­34 (1) APU accumulator. A 1.5­gpm velocity fuse will automatically shut off hydraulic pressure from the backup pump if a .5­gpm increase in flow rate (when above 1.0 gpm) or 30­psi drop in pressure across the velocity fuse occurs. (2) Pilot assist servos. The low­level sensing switch in the #2 pump module reservoir will close the pilot assist shutoff valve. (3) First stage tail rotor. The low­level sensing switch in the #1 pump module reservoir will close the first stage tail rotor shutoff valve. b. LDI test switch. (1) Purpose. This toggle switch is used to test the complete leak isolation system with the exception of the low­level switches and velocity fuse. (2) Location. It is located on the left­hand forward upper console next to the hydraulic backup pump switch. (3) Operation. Three positions­­NORMAL, TEST, and RESET. c. LDI test operation. (1) Conditions. (a) Reservoirs­all must be full. (b) Ground test­­must be performed on ground only. (c) APU running­must have APU ON for AC power. (d) Engines­at least one engine must be at ground idle (so pumps will be on line). (e) Backup pump­­switch must be in AUTO position. (f) Test switch­­must be in TEST position. (2) Indications. (a) #1 RSVR LOW. (b) #2 RSVR LOW (c) BACK­UP RSVR LOW (d) #1 TAIL RTR SERVO (e) BOOST SERVO OFF (f) SAS OFF (g) BACK­UP PUMP ON (h) #2 TAIL RTR SERVO ON D­35 (i) Both Master Caution Press to Reset lights. D­36 Learning Step/Activity #2 –PE#1 Problem: Write the answers to the questions below pertaining to the UH­60 Flight Controls and Hydraulics Systems. DIRECTIONS TO STUDENT: This PE covers instruction that you received on the operational characteristics of the Flight Controls and Hydraulics System. In the space provided write the answer, you may use the student handout and/or the Operator’s Manual to find the correct answer. Upon completion of this exercise, check your answers against the answer sheet provided at the end of this handout. If you have any questions on the material ask your instructor at the beginning of the next day’s instruction. 1. The mechanical mixing unit minimizes___________________________________________ 2. What hydraulic system pressurizes the collective boost servo? _________________________ 3. Where is the switch located that controls the boost servo pressure shutoff valve? _______________________________________. 4. Moving the cyclic forward or aft will cause the ______________ and ___________________ primary servo to move, tilting the swash plate forward or aft. 5. List the switches located on the cyclic that control trim. _____________________________ 6. How are the tail rotor pedals adjusted for comfort of the pilot's legs? ___________________ 7. How many control cables are in the tail rotor system? ______________________________ 8. Can the backup hydraulic pump supply pressure to both the #1 and #2 hydraulic systems? ________ 9. The components that are pressurized by the #1 hydraulic system are the ______________ and the ____________________ . 10. The switch marked ________ can manually turn off the first stage tail rotor servo. 11. The #2 hydraulic system supplies hydraulic pressure to the _______________________ and _______________________. 12. When the SAS OFF caution light illuminates, this indicates a __________________________. 13. The caution/advisory lights that will automatically bring on the backup pump in flight are _________________________________________________________________________ . 14. There are two components in the aircraft hydraulic systems that can only be pressurized by the backup pump. They are__________________ and the _________________________ . D­37 15. The leak detection/isolation system of the flight control hydraulic system prevents ______________ of hydraulic fluid in the event of a hydraulic leak. 16. A_______________ and ___________________ are on the right side upper deck to service the three hydraulic systems. 17. The primary servo shutoff switch will not shut off both states of primary servos at the same time because of a __________________________ . 18. When RPMR is above 30%, what position will the backup pump switch be in? ____________. 19. The collective and yaw boost servos are provided to _______________ cockpit control forces (pilot workload). 20. The caution light marked ________________ will illuminate when a tail rotor cable breaks. 21. The following is a list of caution/advisory lights that will illuminate when a leak occurs in the #1 tail rotor servo: ____________, ____________, ____________, and _____________. 22. A leak in the pilot's assist servos will cause the following caution lights to illuminate: _____________, _____________, ____________, ______________, and ______________ . 23. The________________ will allow the backup pump to come on automatically, regardless of the backup pump switch position, while in flight. 24. The backup pump will react within _______ seconds when a main generator is supplying aircraft (airframe) power. 25. The UH­60 is limited to a ______bank angle when a PRI SERVO PRESS caution light is on. 26. The airspeed of the UH­60 is limited to _____whenever one hydraulic system is inoperative. 27. While flying on an IMC flight plan (actual), you lose two hydraulic systems. You must limit your airspeed to ______________ . 28. How would you know if you had 2 Tail Rotor cables broken? _______________________________. 29. You have already experienced a leak in the #1 primary servos and have taken the proper corrective action. The following is a list of caution/ advisory lights illuminated: #1 HYD PUMP, #1 PRI SERVO PRESS, #1 RSVR LOW, BACKUP RSVR LOW, BACKUP PUMP ON. If the #2 PRI SERVO PRESS light illuminates, what is your pilot action?______________________________________________________. D­38 PRACTICAL EXERCISE ANSWER SHEET 1. control coupling 2. # 2 3. on the AFCS control panel 4. forward, aft 5. cyclic trim switch, trim release 6. pull to release pedal adjuster 7. two 8. yes 9. first primary servo, first stage tail rotor servo 10. tail servo (normal, backup) 11. second stage primary servo and pilot assist 12. loss of hydraulic pressure 13. #1 RSVR LOW, #1 tail rotor servo, #1 hydraulic pump, #2 hydraulic pump, APU ACCUM LOW. 14. APU accumulator and #2 tail rotor servo. 15. excessive loss 16. servicing pump, selector valve 17. electrical interlock system 18. AUTO 19. reduce 20. tail rotor quadrant 21. #1 RSVR LOW, #1 TAIL RTR SERVO, BACKUP PUMP ON, #2 TAIL RTR SERVO ON. 22. #2 RSVR LOW, BOOST SERVO OFF, SAS OFF, TRIM FAIL, FLT PATH STAB. 23. WOW switch. 24. .5 25. 30° 26. 170 KIAS 27. 140 KIAS 28. TAIL ROTOR QUADRANT caution light on, with no tail rotor control. 29. land as soon as possible. D­39