REPORT DOCUMENTATION PAGE

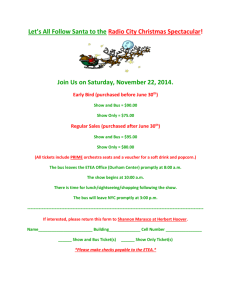

advertisement