parties interested in structural cast steel connectors - ICC-ES

advertisement

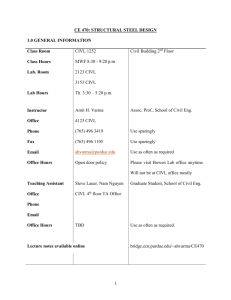

February 1, 2011 TO: PARTIES INTERESTED IN STRUCTURAL CAST STEEL CONNECTORS SUBJECT: Proposed Acceptance Criteria for Structural Cast Steel Connectors for Use as Bracing Connections in Accordance with AISC 341 Sections 13.3 and 14.4, Subject AC427-0211-R1 (BG/DZ) Dear Colleague: We are seeking your comments on the enclosed proposal for a new acceptance criteria, which is being posted for 30 days of public comment on the ICC-ES web site. Public comments will be considered in preparing a revised draft of the criteria, which we hope to present at a future Evaluation Committee hearing. The proposed new criteria provides conditions of acceptance for structural cast steel connectors. The connectors are intended to be used with concentric braced frames as bracing connections to connect the brace elements to other portions of the structure. The applicable references are Sections 13.3 and 14.4 of AISC 341-05, Seismic Provisions for Structural Steel Buildings. An evaluation report applicant has developed a series of connector elements cast from steel represented as complying with ASTM A 958. ASTM A 958 is not currently referenced in either AISC 341 or AISC 360-05, Specification for Steel Buildings. The enclosed public review primer from the report applicant provides information on the connectors and their suitability for use bracing connections for special or ordinary concentric braced frames. Neither AISC 341 nor AISC 360 is clear with respect to acceptance of other, nonreferenced steels such as ASTM A 958. In Chapter 9 and Appendix A of AISC 358-05s1-09, Supplement No. 1 to ANSI/AISC 358-05, Prequalified Connections for Special and Intermediate Steel Moment Frames for Seismic Applications, a specific grade and class of steel within ASTM A 958 has been accepted for producing the Kaiser Bolted Bracket Moment Connection. Appendix A to AISC 358-05s1-09 contains supplemental test and quality control provisions. The evaluation report applicant suggests that the existence of Appendix A would resolve the need for supplemental requirements acknowledged in AISC 360 Section C-A3.1a for use within a seismic load–resisting system. There are some differences to note as a prelude to this interpretation. First, Section 9.1 of AISC 358-05s1-09 states that “yielding and plastic hinge formation is intended to occur primarily in the beam, at the end of the bracket away from the column face.” This conclusion was based on 21 fullscale tests according to the accompanying commentary. We note that the Kaiser Bolted Brackets are connected to other members using either bolts or fillet welds. The report applicant’s cast steel connector is attached to the brace using complete AC427-0211-R1 2 joint penetration welds, which may affect whether the supplemental quality provisions in Appendix A of AISC 358 Supplement No. 1 are extensive enough. For special concentric braced frames, AISC 341 Section 13.3b indicates the plastic hinge may occur within the cast steel connectors, a possibility particularly when buckling of the brace assembly is in-plane. Therefore, the cast steel connector may be the most critical component of the braced frame assembly, as it could be the locus of a plastic hinging limit state; whereas the Kaiser Bolted Bracket is not the component of the moment frame that sustains plastic deformation, since plastic hinging occurs in the beam, not the bracket or column. AISC 341 and AISC 358 are relatively clear with respect to acceptance of alternative moment frame connection systems and their expected performance. It may not be prudent to rely on precedence established in AISC 358-05s1-09 for a moment frame connection due to differences in configurations, expected performance of member connections, failure mechanisms, and possibly qualification methods. For special moment frames, it is clear that their seismic resistance will be consistent with the performance requirements expected by the 2009 International Building Code® (IBC) and ASCE 705, Minimum Design Loads for Buildings and Other Structures, provided the beam-tocolumn connections comply with Sections 9.2 and 9.3 of AISC 341 and the assemblies are designed and constructed in accordance with the IBC and AISC 341. However, the demand requirements on the bracing connections, such as ability to sustain plastic deformations, are not as explicitly identified in AISC 341 and are not well correlated to the overall seismic performance of the special concentric braced frames. For example, AISC 341 Section 13.3b permits two methods for determining adequacy of bracing connections subject to flexure. Section 13.3b requires the bracing connection to develop 110 percent of the required flexural strength of the brace about its critical buckling axis (1.1RyMp), for which inelastic rotation will occur within brace. As an alternative, bracing connections that develop the required tensile strength of the brace (RyFyAg) and can accommodate inelastic rotation resulting from post buckling rotations of the brace, are permitted. While Section 13.3b is not specific as to how inelastic rotations can be accommodated, the AISC 341 commentary explains that detailing a single gusset plate according to Figure C-I-13.2 should be satisfactory to permit the exception. Neither AISC 341 nor the commentary is clear as to what other conditions need to be observed in order to apply the exception to provide for adequate strength, stiffness, and ductility. For example, no information is given on allowing the connectors to be a separate component from the brace and gusset of a concentrically braced frame. Typically, tubular braces are extended to a gusset and welded, and may need to be reinforced; while the applicant’s connector may be either welded or bolted to the gusset plate. Other possible conditions include the configuration (round vs. rectangular) and slenderness of the braces and the welding of the gusset plate to the beams and columns. For the report applicant’s connection, a complete joint penetration weld will attach the connector to the brace. Therefore, the connector and the complete joint penetration weld may be subjected to flexure if inelastic rotation is to occur in this region due to the relative fixity of the gusset plate, brace, and connector. The proposed content of AC427 is not clear as to what is needed to establish flexural behavior of the connector under seismic motions. AC427-0211-R1 3 As a result, the structural designer would need to detail assembly for expected performance without complete guidelines in either AISC 341 or the proposed AC427. The report applicant indicates the connector complies with the code except for the material. The scope of AC427 as proposed will encompass verification of connector configuration as complying with AISC 360 and AISC 341, and verification of cast steel properties and quality control as complying with Appendix A of AISC 35805s1-09. Our comments are: 1. Is the proposed criteria adequate for a unique connector within a seismic load– resisting system in that it specifies only material-related properties and quality control? There may need to be a global approach to assess deformation performance, since it is unclear whether the specific participation of each potential contributing hinge can be identified. AISC 341 is not clear as to how to qualify the concentrically braced systems where situations like this occur. We note that AISC 341 does stipulate full-scale testing for other lateral force–resisting systems such as moment frames and buckling restrained braced frames. Full-scale cyclic testing of the concentric braced frame may be needed to adequately support the design model of the AISC 341, due to differences in connector configuration and materials from the connections documented previously in the code. If there is agreement on this level of testing, the scope of testing needs to be explored to establish the critical variables such as number of replicates per prototype; testing protocol (cyclic excursion levels and quantity of cycles); intended brace configuration (diagonal, X, V or inverted V); brace size (slenderness ratio) and type; connection between connector and gusset plate (welded or bolted); gusset plate configuration; and permissible steel and welding materials. The extent to which the tested assemblies can be extrapolated to other assemblies also needs to be addressed. Also, input is needed on measures to confirm acceptable behavior of test assemblies. It is unclear what the minimum drift should be in creating a model to yield the assemblage in tension and assess the residual compression capacity after compression buckling has occurred in the assembly. In addition, potentially undesirable sources of inelastic deformations, such as connector yielding or weld fracture, should be determined and utilized to establish criteria for acceptable behavior. AISC 341 Commentary to Section 13.1 indicates the bracing members and their connections could be expected to undergo inelastic post-buckling deformations of 10 to 20 times the deformation at yield. 2. The evaluation report applicant seeks an evaluation report on an alternative connector that can used in any special or ordinary concentric braced frame permitted by AISC 341. The structural design of the entire bracing system, including the connectors, would also comply with AISC 341 without modification. In order to confirm whether a special or ordinary concentric braced frame incorporating the proprietary cast steel connectors performs adequately when designed in accordance with the IBC and AISC 341, we ask whether methods to confirm a rational analysis with validation testing needs to be incorporated within AC427-0211-R1 4 AC427. This approach would require a detailed structural analysis of selected special concentric braced frame configurations, and full-scale seismic tests of these configurations. The test results would be evaluated to confirm whether the structural design adequately predicts performance including expected or desired limit states. Parameters to be considered in selecting configurations have been identified in comment 1, above, such as brace type, size, steel grade, and orientation; connector type, size, and steel grade; and weldment size and process. Should AC427 incorporate full-scale seismic validation testing, what applicable parameters need to be observed in construction the specimens? Also, what conditions of acceptance need to be applied to verify reliable seismic performance of the proposed analysis methods? 3. Is the proposed criteria sufficient to permit a registered design professional to apply the IBC in determining performance of the connector due to tension, compression, and flexural loadings through the connector, welds, and bolting? It is understood that certain aspects, such as flexural loadings on the connectors, are addressed in other references, such as the AISC commentary, which would require specific approval by the registered design professional and the building official for each instance of application. 4. The design methodology should be clearly presented in the evaluation report, and should conform to AISC 341. While inelastic rotation out-of-plane of the brace line in the gusset plates or in the HSS or pipe brace would likely minimize combined axial compression and flexural stresses, the proposed AC427 does not provide for proof that this limit state can be achieved. Design details may need to clearly note this is needed to prevent to in-plane rotations of the assemblage. 5. Should welding of the cast steel connector to the brace element be limited to approved fabricators as defined in IBC Section 1704.4? The codes are not clear as to whether fabrication and special inspection at the jobsite is permitted, though certain inspection requirements (such as magnetic particle testing and ultrasonic testing) may be difficult to adequately implement outside the shop environment. If it is of interest, please review the draft criteria and send us your comments at the earliest opportunity. At the end of the 30-day comment period, we will post on our web site the correspondence we have received. To submit your comments, please use the form on the web site and attach any letters or other materials. If you would like an explanation of the “alternate criteria process,” under which we are soliciting comments, this too is available on the ICC-ES web site. Please do not try to communicate directly with any Evaluation Committee member about a criteria under consideration, as committee members cannot accept such communications. AC427-0211-R1 5 Thank you for your interest and your contributions. If you have any questions, please contact me at (800) 423-6587, extension 3260, or David Zhao, at extension 3721. You may also reach us by e-mail at es@icc-es.org. Yours very truly, Brian Gerber Principal Structural Engineer BG/md Enclosures cc: Evaluation Committee ICC-ES AC427 Public Review Primer Cast ConneX® High-Strength Connectors™ General Description Cast ConneX® High-Strength Connectors™ (Figure 1) were developed at the University of Toronto by Professors Jeffrey A. Packer and Constantin Christopoulos for use in the construction of Ordinary Concentrically Braced Frames (OCBF) and Special Concentrically Braced Frames (SCBF) designed according to AISC 341. The off-the-shelf connectors accommodate bolted (or welded) connection to a gusset plate on one end and complete joint penetration (CJP) welded connection to a round Hollow Structural Section (HSS) or Pipe brace member on the other. Thus, in practice, the cast connectors can be welded to the hollow section braces in the shop, with the brace-connector assembly being bolted (or welded) to the gussets in the field (Figures 2 and 3). Each Cast ConneX High-Strength Connector is standardized to accommodate all round HSS or Pipe members of a given outer diameter, regardless of their wall thickness or grade of steel (Figure 3). Typically, the connectors are used in conjunction with round HSS produced to ASTM A500, ASTM A501, CAN/CSA G40.20/21, EN 10210, EN 10219, ASTM A53 pipe, and API 5L line pipe. ® Figure 1 Cast ConneX High-Strength Connectors™ Figure 2 Shop welding of brace-connector assembly (top left), connector-brace assemblies (bottom left), connector-brace assembly installed in a braced frame (right) 1 Cast ConneX® High-Strength Connector™ Gusset connecting end H ipe or P S S El e ce Bra me nt Complete Joint Penetration groove weld Plastic hinge region during out-of-plane buckling Figure 3 High-Strength Connector shown in field-bolted configuration (left); CJP weld between connector and HSS (right) Code Compliancy Issues Involved Strength of the Connectors The requirements for bracing connections in SCBF and OCBF are outlined in AISC 341-05 Sections 13.3 and 14.4, respectively. Using the code provisions in AISC 360-05, one can readily demonstrate that the connectors, which are produced to ASTM A958 Grade SC8620 Class 80/50, a weldable, ductile, notch tough ASTM cast steel grade having a specified minimum yield strength of 50 ksi and a specified minimum tensile strength of 80 ksi, meet these requirements as follows: On one end, the connectors are joined via complete joint penetration groove weld to the hollow section brace [in accordance with IBC Section 2204.1] – a joint that is inherently as strong as the connected brace, thereby meeting the strength requirements of AISC 341-05 Sections 13.3 and 14.4; On their other end, the connectors are joined to a gusset plate via double-shear bolted connection [in accordance with IBC Section 2204.2] or fillet welded connection [in accordance with IBC Section 2204.1] – connections which can be detailed (by the Engineer of Record) using provisions in AISC 360-05 to meet the strength requirements of AISC 341-05 Sections 13.3 or 14.4. Further, as outlined in AISC 341-05 Section 13.3b, the “2tp rule” can be used to accommodate the requisite out-of-plane end rotation of the brace in SCBF assemblages (the free length of gusset plate is to be left beyond the end of the connector); In between, the connector’s solid steel “body” is analogous to a cap plate that transitions well within the conservative distribution slope of 2.5:1 described in AISC 360-05 Section K1.6 (refer to AISC Design Guide 24 page 83 for the cap-plate-to-round HSS case), thereby eliminating shearlag in the connection to the hollow section brace. 2 Steel Material and Quality Control Given that these connectors can be shown to meet the AISC 341-05 strength requirements for SCBF and OCBF brace connections, the only element of these connectors that is not specifically code compliant is the steel grade to which they are produced, as ASTM A958 Grade SC8620 Class 80/50 is not explicitly listed in AISC 360-05 or AISC 341-05. Additionally, it would be prudent to set requirements for quality control to ensure the soundness of the components in production, hence Cast Connex Corporation’s decision to approach ICC-ES for the development of a suitable Acceptance Criteria and ultimately for the creation of an ICC-ES Evaluation Report on Cast ConneX High-Strength Connectors. Recently, AISC TC-9, with the support of the Steel Founders’ Society of America, set casting and examination requirements in Appendix A of Supplement No. 1 to AISC 358-05 for similar seismic-resistant cast steel components produced to precisely the same ASTM cast steel grade as Cast ConneX HighStrength Connectors. Kaiser Bolted Brackets are similar to High-Strength Connectors in that they are a “capacity designed” element of a seismic load resisting system (SLRS). For clarity, this means that both the Kaiser Bolted Brackets and High-Strength Connectors are to remain elastic while transmitting force between other elements of the SLRS. Because of this similarity, ICC-ES has developed AC427 based on the casting and non-destructive examination requirements set out in Appendix A of Supplement No. 1 to AISC 358-05. In regards to the cast steel grade itself, we believe that the approval by AISC TC-9 for the use of ASTM A958 Grade SC8620 Class 80/50 material in a seismic application (Kaiser Bolted Brackets) is highly persuasive evidence that the material is suitable for similar seismic uses (i.e. as capacity designed elements in other seismic applications). Further, ASTM A958 is listed as a reference standard cast steel grade suitable for structural use in the Canadian equivalent to AISC 360, CAN/CSA S16-09. Additional Reference documents and Materials Please visit the publications section of Cast Connex Corporation’s website, www.castconnex.com, to access a number of related Journal and Conference papers published by researchers at the University of Toronto on these unique, seismic-resistant connectors. Please also feel free to view the following videos showing some of the full-scale tests that have been conducted on braces equipped with these connectors: Full-scale brace assembly test Full-scale braced frame test http://www.youtube.com/user/CastConneX#p/u/2/YD4o6ItXVAU http://www.youtube.com/user/CastConneX#p/u/1/_AOSYakbGBo Closing comments With our general position on the code compliancy of Cast ConneX High-Strength Connectors having been briefly discussed above, we would much appreciate it if you could carefully review AC427 and provide your comments to ICC-ES so that we can ultimately ensure the successful use of our connectors, which we believe enhance the safety and simplify the design and construction of steel braced frames. Sincerely, Cast ConneX Corporation 3 www.icc-es.org | (800) 423-6587 | (562) 699-0543 A Subsidiary of the International Code Council ® PROPOSED ACCEPTANCE CRITERIA FOR STRUCTURAL CAST STEEL CONNECTORS FOR USE AS BRACING CONNECTIONS IN ACCORDANCE WITH AISC 341-05 SECTIONS 13.3 AND 14.4 AC427 Proposed February 2011 PREFACE Evaluation reports issued by ICC Evaluation Service, LLC (ICC-ES), are based upon performance features of the International family of codes and other widely adopted code families, including the Uniform Codes, the BOCA National Codes, and the SBCCI Standard Codes. Section 104.11 of the International Building Code® reads as follows: The provisions of this code are not intended to prevent the installation of any materials or to prohibit any design or method of construction not specifically prescribed by this code, provided that any such alternative has been approved. An alternative material, design or method of construction shall be approved where the building official finds that the proposed design is satisfactory and complies with the intent of the provisions of this code, and that the material, method or work offered is, for the purpose intended, at least the equivalent of that prescribed in this code in quality, strength, effectiveness, fire resistance, durability and safety. Similar provisions are contained in the Uniform Codes, the National Codes, and the Standard Codes. ICC-ES may consider alternate criteria, provided the report applicant submits valid data demonstrating that the alternate criteria are at least equivalent to the criteria proposed in this document, and otherwise meet the applicable performance requirements of the codes. Notwithstanding that a product, material, or type or method of construction meets the requirements of the criteria proposed in this document, or that it can be demonstrated that valid alternate criteria are equivalent to the criteria in this document and otherwise meet the applicable performance requirements of the codes, ICC-ES retains the right to refuse to issue or renew an evaluation report, if the product, material, or type or method of construction is such that either unusual care with its installation or use shall be exercised for satisfactory performance, or malfunctioning is apt to cause unreasonable property damage or personal injury or sickness relative to the benefits to be achieved by the use of the product, material, or type or method of construction. Acceptance criteria are developed for use solely by ICC-ES for purposes of issuing ICC-ES evaluation reports. AC427-0211-R1 Page 2 February 2011 PROPOSED ACCEPTANCE CRITERIA FOR STRUCTURAL CAST STEEL CONNECTORS FOR USE AS BRACING CONNECTIONS IN ACCORDANCE WITH AISC 341 SECTIONS 13.3 AND 14.4 1.0 INTRODUCTION 1.1 Purpose: The purpose of this acceptance criteria is to establish casting and nondestructive examination requirements for structural cast steel connectors for use as bracing connections in accordance with AISC 341Sections 13.3 and 14.4 to be recognized in ICC Evaluation Service, LLC (ICC-ES), evaluation reports under the 2009 International Building Code® (IBC). The basis of recognition is IBC Section 104.11. The reason for the development of these criteria is to allow for the recognition of structural cast steel connectors that comply as bracing connections with AISC 341 Sections 13.3 and 14.4 except are produced from a cast steel grade that is beyond the scope of the IBC and referenced standards. 1.2 Scope: This criteria establishes procedures for casting and quality control including nondestructive examination of cast steel connectors that comply with AISC 341 Sections 13.3 and 14.4 as permitted by Section 2205 of the IBC. This criteria addresses material requirements relating to strength, weldability, ductility, notch toughness, and soundness. 1.3 Referenced Standards: 1.3.1 Council. 2009 International Building Code® (IBC), International Code PROPOSED ACCEPTANCE CRITERIA FOR STRUCTURAL CAST STEEL CONNECTORS FOR USE AS BRACING CONNECTIONS IN ACCORDANCE WITH AISC 341 SECTIONS 13.3 AND 14.4 1.3.2 AC427-0211-R1 Page 3 February 2011 AISC 303-05, Code of Standard Practice for Steel Buildings and Bridges, American Institute of Steel Construction. 1.3.3 AISC 341-05, Seismic Provisions for Structural Steel Buildings, American Institute of Steel Construction. 1.3.4 AISC 358-05s1-09, Supplement No. 1 to AISC 358-05, Prequalified Connections for Special and Intermediate Steel Moment Frames for Seismic Applications, American Institute of Steel Construction. 1.3.5 AISC 360-05, Specification for Structural Steel Buildings, American Institute of Steel Construction. 1.3.6 ANSI/AWS D1.1-2004, Structural Welding Code – Steel, American Welding Society. 1.3.7 ANSI/AWS D1.8-2005, Structural Welding Code – Seismic Supplement, American Welding Society. 1.3.8 ASTM A 958/A 958M-09, Standard Specification for Steel Castings, Carbon and Alloy, with Tensile Requirements, Chemical Requirements Similar to Standard Wrought Grades, ASTM International. 1.4 Definitions: Definitions in the IBC, AISC 303, AISC 341, AISC 358- 05s1-09, and AISC 360 apply to these criteria. Additionally: 1.4.1 Connector: A device incorporating two joints, one at each end, to transmit forces between attached structural steel elements. 2.0 BASIC INFORMATION 2.1 General: The following information shall be submitted: PROPOSED ACCEPTANCE CRITERIA FOR STRUCTURAL CAST STEEL CONNECTORS FOR USE AS BRACING CONNECTIONS IN ACCORDANCE WITH AISC 341 SECTIONS 13.3 AND 14.4 2.1.1 AC427-0211-R1 Page 4 February 2011 Product Description: Complete information concerning the connectors including: intended use(s), dimensions, available strength, material specifications, manufacturing process, and non-destructive examination requirements. In addition, statements concerning restrictions or limitations on use shall be submitted. Calculations deriving the critical gross section properties and supplemental gross section properties at bolting locations shall be submitted. Information establishing compatible connected elements, such as braces and gusset plates shall be submitted, subject to applicable code requirements. 2.1.2 Installation Instructions: Instructions shall include the following items: a. Description of how the product will be used or installed at the fabricator’s shop and the project site. b. Procedures establishing quality control at the fabricator’s shop. c. Procedures establishing quality control at project sites during installation. d. Requirements for product handling and storage. e. Requirements for welding or bolting the connectors to other structural elements. f. Special inspection shall be provided in accordance with Chapter 17 of the IBC and in accordance with this criteria. For each type of connector system, the manufacturer shall submit inspection procedures to verify proper usage. 2.1.3 Packaging and Identification: A description of the method of packaging and field identification of the connectors. Identification provisions shall include the evaluation report number and the name or logo of the inspection agency. PROPOSED ACCEPTANCE CRITERIA FOR STRUCTURAL CAST STEEL CONNECTORS FOR USE AS BRACING CONNECTIONS IN ACCORDANCE WITH AISC 341 SECTIONS 13.3 AND 14.4 2.1.4 AC427-0211-R1 Page 5 February 2011 Documentation: The following documents shall be submitted to the building official and the registered design professional: 2.1.4.1. Production inspection and non-destructive testing reports for each heat. 2.2 2.1.4.2. Tensile and Charpy V-Notch test reports for each heat. 2.1.4.3. Weld repair reports for each connector. Testing Laboratories: Testing laboratories shall comply with the ICC-ES Acceptance Criteria for Test Reports (AC85) and Section 4.2 of the ICCES Rules of Procedure for Evaluation Reports. 2.3 Test Reports: Test reports shall comply with AC85. The test reports shall include information described in the referenced standard, and visual records of the test specimens before, during, and after testing. 2.4 Product Sampling: Sampling of the connectors for tests under this criteria shall comply with Section 3.1 of AC85. 2.5 Structural Design: 2.5.1 General: The connector shall be designed to transmit forces between the attached structural steel elements, and the connector’s configuration shall be such that its available strength shall be determined in accordance with the provisions of AISC 341 and AISC 360. The connector shall demonstrate compliance with Sections 13.3a, 13.3b, 13.3c, and 14.4 of AISC 341 as a bracing connection capable developing the specified strengths of the connected braces. The registered design professional specifying the use of a connector complying with this criteria shall design the welded or bolted joints at PROPOSED ACCEPTANCE CRITERIA FOR STRUCTURAL CAST STEEL CONNECTORS FOR USE AS BRACING CONNECTIONS IN ACCORDANCE WITH AISC 341 SECTIONS 13.3 AND 14.4 AC427-0211-R1 Page 6 February 2011 either end of the connector to provide the required strength as outlined below. The required strength shall not exceed the available strength of the connector. The connector shall be considered within a protected zone and subject to provisions of Sections 7.4 and 13.6 of AISC 341. 2.5.2 Required Strength of Joints for Connectors Used as a Brace Member End Connection in a Seismic-Resistant Concentrically Braced Frame: Design and detailing shall comply with Section 13.3 of AISC 341for connectors used in Special Concentrically Braced Frames or Section 14.4 of AISC 341 for connectors used in Ordinary Concentrically Braced Frames. 2.5.3 Design Procedures: Details and examples of how the connector is designed, analyzed and detailed shall be submitted, including equations, with procedures and properties for design analysis. 2.5.4 Construction Documents: Structural design drawings and specifications, shop drawings and erection drawings shall comply with Section 5 of AISC 341. 2.6 Welding: 2.6.1 General: Where heat treatment of connectors complying with this criteria include quenching and tempering (QT), documentation establishing welding practices for QT materials shall be developed and submitted. A Welding Procedure Specification (WPS), prepared in accordance with Section 6.1 of AWS D1.8, and Section 1704.3.1, Table 1704.3 and Section 1708 of IBC, shall be developed for each welding position, welding process, electrode manufacturer, filler metal trade name for the electrode type selected; PROPOSED ACCEPTANCE CRITERIA FOR STRUCTURAL CAST STEEL CONNECTORS FOR USE AS BRACING CONNECTIONS IN ACCORDANCE WITH AISC 341 SECTIONS 13.3 AND 14.4 AC427-0211-R1 Page 7 February 2011 and for all essential variable changes in the Procedure Qualification Record (PQR) that exceed allowable tolerances. Each WPS shall be qualified by a documented PQR in accordance with Section 4 of AWS D1.1. 2.6.2 Welding the Cast Steel Connector to a Brace Element for Use as a Brace Member End Connection in Seismic-Resistant Concentrically Braced Frames: The welding shall comply with the requirements set forth for demand critical welds in AISC 341, AISC 360, ANSI/AWS D1.1, and ANSI/AWS D1.8 for welded connections in seismicresistant applications. 3.0 CAST STEEL GRADE 3.1 Cast steel grade shall comply with ASTM A 958 Grade SC 8620 Class 80/50, including Appendix A of AISC 358-05s1-09. 4.0 QUALITY CONTROL 4.1 The products shall be manufactured under an approved quality control program with inspections by an inspection agency complying with Section 1.3.1 of the ICC-ES Acceptance Criteria for Quality Documentation (AC10). Quality control shall comply with Section A.2 of AISC 358-05s1-09 for Cast Steel Connectors. 4.2 Quality documentation complying with the ICC-ES Acceptance Criteria for Quality Documentation (AC10) shall be submitted. 4.3 Fabrication and assembly work requiring special inspection is permitted to be done on the premises of approved fabricators. The quality assurance program for PROPOSED ACCEPTANCE CRITERIA FOR STRUCTURAL CAST STEEL CONNECTORS FOR USE AS BRACING CONNECTIONS IN ACCORDANCE WITH AISC 341 SECTIONS 13.3 AND 14.4 AC427-0211-R1 Page 8 February 2011 fabrication practices shall be documented and comply with the IAS Accreditation Criteria for Fabricator Inspection Programs for Structural Steel (AC172). 4.4 Jobsite quality assurance shall conform to Sections 1705, 1706 and 1708.4 of the IBC, Section 18 and Appendix Q of AISC 341, and applicable portions of AISC 303. 4.5 Special inspection shall be provided in accordance with Sections 1704.3 and 1707.2 of the IBC, Section 18 and Appendix Q of AISC 341, and Section 7 of AWS D1.8. 5.0 EVALUATION REPORT RECOGNITION The evaluation report shall include the following information: 5.1 Information described in Section 2.1, 2.5, and 2.6 of this criteria. 5.2 Illustrations of the connectors showing a typical installation and load direction. 5.3 Limitations on design, fabrication, and erection as determined in accordance with this criteria. 5.4 Fabrication program as described in Section 4.3 of this criteria. 5.5 Provisions for quality assurance and special inspection as described in Sections 4.4 and 4.5 of this criteria. ■