Game on - Montague Company

advertisement

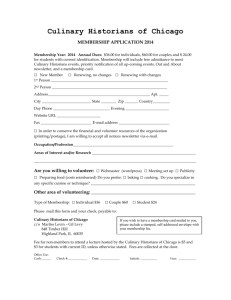

FOODSERVICE CONSULTANTS SOCIETY INTERNATIONAL FOODSERVICECONSULTANT.ORG Game on 1234 2013 AMERICAS EDITION p38 FCSI AT THE FIFA WORLD CUP 2014 — RIO AND BEYOND, BRAZIL — FOODSERVICE 2013 David Burke and Jody Adams are among the expert names looking to the future NAFEM The leading food equipment show previewed STAR BILLING New Energy Star regulations COVER Americas ; FCSI Issue 1 - Americas ; FSCI 1 14/01/2013 16:28 BRIGHTNESS FALLS The project finally opened in a 90,000 sq ft former shopping mall last autumn in downtown Niagara Falls with 25 state-of-the-art kitchens and labs and a student-run fine dining restaurant, New York-style deli, French pastry café, Barnes & Noble bookstore and wine store. The school, described by New York State Lieutenant Governor Robert Duffy at its dedication as “stunning”, quickly achieved the status of “the top-rated school of its kind on the East Coast,” Duffy noted. It proved to be “a great investment that shows how state, local and private partnerships can come together”. The project’s first steps toward that day began in spring 2010 when Klyzcek and the Culinary School director Mark Mistriner began to explore potential sites, touring them with foodservice consultants Cini-Little. The budget was set at $26m. Numerous sites were evaluated before the developer of the long closed Rainbow Mall agreed to donate it to the college. Confronting opponents, Klyczek never lost sight of the goal, which was to integrate book learning with hands-on training in a state-of-the-art setting. “The first challenge,” he says, “was the attitude of almost everybody, asking ‘why get into retail?’. We explained that we were not competing with existing restaurants, but rather creating a labour force that could help the community. “For every argument, we tried to present reasonable answers. They wondered why we would do this in Niagara Falls, NY, which had long been a desolate area compared to Niagara Falls on the Canadian side. We explained that it was perfect because it was affordable for us. Today, everyone sees the opportunity. The state and the city were behind us because they understood that a goal of ours was to stimulate and create more urban > A thorough revamp of the culinary, baking and pastry course at Niagara Falls Community College has created a shining example of what a modern culinary school can achieve. Susan Holaday reports veryone has a dream, but bringing dreams to fruition is a challenge. At Niagara Falls Community College, a 50-year-old institution on a rural campus in Sanborn, New York, US, the dream was expansion of the culinary and baking and pastry arts component that had existed for 20 years. The aim was to allow it not only to rise to its full potential, but to grow, encompassing new areas and offering students the opportunity to learn in a state-of-the-art environment geared to combining hands-on experience in the kitchen with classroom training. For college president James Klyczek, the dream of an expanded hospitality, pastry and baking arts programme in a living/learning laboratory involved convincing others of its value. Over seven years, he overcame such obstacles as community disapproval based on fears that the programme, with its retail components, would compete with and harm local businesses. County legislators and local business owners “were concerned that our restaurant would hurt local operators”, he says. “We asked them to be part of the process and planning on our advisory board.” 52 Training - Niagr ; FCSI Issue 1 - EAME - Base version ; FSCI 52 11/01/2013 12:50 TRAINING 1. CUISINE LAB Montague cooking suite, Gaylord ventilation hood, Marlo Manufacturing stainless steel tables 2. MIXOLOGY Regal Pinnacle Industries millwork (wine tasting tables, wine cabinet, credenza) 3. SAVOR BAR INTERIOR Perlick bar equipment 4. BAKERY Marlo For more go to foodserviceconsultant.org Fabricators wood topped tables, Globe mixers, Gaylord ventilation system 5. SAVOR CHEF’S TABLE Montague Suite beyond, * CaptiveAire ventilation hood beyond 6. CUISINE LAB Montague cooking suite, Gaylord ventilation hood, Marlo Manufacturing stainless steel tables 53 TRAINING VIEW FROM THE ARCHITECT “The best word to describe this project and undertaking is transformation. “It is considerably more than a renovation,” says architect Mike Mistriner at Cannon Design, Grand Island, New York. “This development of the Culinary Institute faced many interesting challenges, but probably the most significant was working with the existing building structure. The existing Rainbow Center site was a former parking garage converted to a shopping mall and food court which is now a thriving, state-of-the-art hospitability and culinary institute.” Challenges included; addressing the massive ventilation requirements with the existing structure; incorporating entirely new engineering systems; addressing a number of floor elevation changes; addressing myriad structural engineering issues development. We proved you can take advantage of the resources you have.” Two years ago, the school had 125 culinary enrollees. When the new facility opened last autumn, it had 350. “Most rewarding for us has been that many who opposed the project and saw it as wrong or not feasible are now behind it,” Klyczek adds. “There were a lot of roadblocks but we got through them.” Klyczek, other faculty members note, was “the driving force, even convincing the school’s own board members”. Culinary director Mark Mistriner notes that the students work in all retail components, learning the business side as well as food preparation and service. “They also do demos at Barnes & Noble and interact with the public which expands their LA PATISSERIE (above left): Structural Concepts merchandisers, Follet ice machine CUISINE LAB (above) Montague cooking suite, Woodstone tandoor oven, Gaylord ventilation system, Electrolux Combi Traulsen roll-in refrigerator horizons, and the teaching kitchens are wrapped in half walls of glass so visitors can observe.” Vendors, he adds, are also using it as a showcase for their equipment. The school has its own vineyard, producing the merlot and chardonnay used in the fine dining restaurant, Savor. Plans call for working with the college’s horticultural programme to create a greenhouse where herbs would be raised. > VIEW FROM THE CONSULTANTS FCSI consultants Bill and Pamela Eaton at Cini-Little point to the close personal attention students receive from instructors and their work on the newest, best equipment in a LEEDcertified facility that is revitalising Niagara Falls. Students, they add, can intern in a casino, produce pastries for the Niagara Falls Convention Center, and more. The goal, says Bill, is to have 800 students. The Institute’s eight labs relate to various tracks – Basic Cuisine, Advanced Cuisine, Bakery, Pastry II (with a Chocolate Room), Garde Manger, Saucier, Mixology (with wine tasting stations and full bar setup), and even an Ice Lab where they learn ice carving. Cooking labs accommodate 54 Training - Niagr ; FCSI Issue 1 - EAME - Base version ; FSCI 54 classes of 20 students at two per workstation. “I think it will be one of the best learning environments and will go to the top of the list in a very short time,” says Bill. “Perseverance makes things happen but this was a case of extreme perseverance making it happen. “Jim and Mark’s passion made it work and inspired us to say ‘we can do that’. We had moments where we wondered if we should’ve built a building that didn’t rain inside – it was an old abandoned mall for about 15 years and we wound up working around constraints like leaks, mould, and cracks.” Despite “horrible” moments, Cini-Little and the architect, Chef Mistriner’s brother, Mike of Cannon Design in Grand Island, New York, made it come together despite having to continually adjust and re-do things. A late August deadline presented challenges, adds Pam, who credits manufacturers for helping with the completion. The equipment, she adds, “lets the students experiment.” For more go to foodserviceconsultant.org 14/01/2013 18:13 TRAINING VIEW FROM THE SUPPLIER Communication makes learning possible. Gaylord Industries, a major supplier at the new Niagara Falls Culinary Institute, took on an instrumental role in helping the school deliver an excellent learning environment in its 25 state-of-the-art teaching kitchens and labs. The school’s goal was to create the best possible interaction between students and teachers. “The cornerstone of success for education is communication. With pans banging, equipment running and people talking, we found the noise level of our previous ventilation hoods was the biggest problem,” says James Klyczek, president of Niagara County Community College which opened the culinary school last fall. The dynamic of the rooms was changed with a quieter system that had the added benefit of energy conservation thanks to its automatic air modulation. Working closely with its foodservice consultants, Cini-Little and engineers, the ventilation system was designed around the school’s specific needs. William Eaton, CiniLittle’s chairman, notes that a cornerstone of the project was the multitude of exhaust ventilators together with the latest approach to air handling and modulation, leading to LEED-qualifying energy savings. “The results,” he says, “have been a stunning success and the team that came together to make it work was especially qualified.” At Gaylord, Bruce Lukens, business unit manager, explains that kitchens with island suites take 75% more air – and more air creates more SAVOR SUITE (top and far right) Montague cooking suite, CaptiveAire exhaust hood, Electrolux combi and blast chiller; (above, from left to right) Dr James P Klyczek, president of NCCC; Rob Sellet, regional sales manager for Gaylord Industries; Chef Mark A. Mistriner, chairman of NCCC’s Business and Hospitality Division 56 Training - Niagr ; FCSI Issue 1 - EAME - Base version ; FSCI 56 Equipment and companies involved in construction and design at Niagara Falls Community College “The state and the city were behind us because they understood that a goal of ours was to stimulate and create more urban development” sound. The kitchens were set up so if not all the cooking equipment is on, the exhaust fan on the hood doesn’t run at full speed. The multiple hoods share a single duct, and Demand Control Ventilation is installed to decrease the air volume on all connected hoods, creating energy and fan savings when modulated downward. A 10% reduction in fan speed at 90% results in a 27% reduction in energy. “This can translate into very large savings,” he adds. “These kitchens have lots of hoods and you can have a significant reduction in fan energy. In Western New York, we have very cold winters and warm summers. A reduction in flow can mean a 10% reduction in heating and cooling costs. This system uses the least amount of air possible with the most efficient hood design, so it’s a maximum opportunity for energy savings. Another benefit is that the facility is quieter, so you have a much better learning environment.” Gaylord’s eastern regional sales manager, Rob Sellet, agrees. “With our low volume exhaust hoods in combination with a Demand control ventilation system, the exhaust noise is virtually nonexistent. “ Initial list of equipment Gaylord Industries (hoods and demand control systems) Montague (cooking suites and most other cooking equipment) Electrolux (combis, blast chillers, warewashers and other tabletop equipment) Woodstone Ovens (tandoor oven and pizza oven) Traulsen (reach-ins and roll-ins) Delfield (u/c refrigerators) American Panel (walk-ins) Structural Concepts (merchandisers) Metro Shelving PowerSoak (pot washer and produce washer) Marlo Manufacturing (fabricator) Architect, interior architect and engineer Cannon Design, Grand Island, New York Project executive Mike Mistriner Project director Lynn DiCarlo Project designer Peter McCarthy Interior design Yvonne Beliveau Frederick Engineers at Cannon Mechanical Lauren Blas Electrical: Eric Lindstrom Structural interior designer at Cannon Valerie Sirianni Interior design Yvonne Beliveau Frederick General contractor LP Ciminelli, Erik Magboo, Mike Curtain, Michael Gzyl Contractor Buffalo Hotel Supply Jim Bedard, Alan Krakowiak For more go to foodserviceconsultant.org 11/01/2013 12:51 Where in the world is Montague? National Press Club, Washington D.C. NAFEM Booth #1222 Within the National Press Club – a centuries old building that has hosted presidents, premiers, kings and queens – you’ll find a Montague Excalibur™ Cooking Suite. Its chef inspired, fully-customized design includes multiple ovens, fryers, open burners and work stations integrated into a single, highly efficient culinary center. From historical institutions and hotels to country clubs and colleges, and everywhere in between, you’ll find Montague in kitchens wherever power, performance and perfection is required. That’s why, when it comes to professional cooking… Chefs worldwide, choose Montague. MADE IN USA Manufacturing the Finest in Commercial Cooking Equipment Since 1857 Since 1857 THE MONTAGUE COMPANY • 1830 STEARMAN AVE • HAYWARD, CA 94545 • 800 345-1830 • WWW.MONTAGUECOMPANY.COM 17446 P4C Nat Press Club v11 FOODCONSULT.indd 1 1/10/13 10:13 AM