File

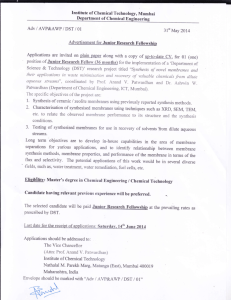

advertisement

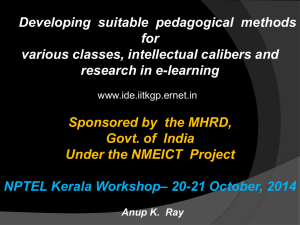

Chemical Process Industry, Chemical Engineering, Chemical Engineer Anand V. Patwardhan, IIT Kharagpur 1 A presentation for the 1st year Chemical Engineering UG students by Anand Vinayak Patwardhan Associate Professor Faculty Advisor (2006−entrants UG) Chemical Engineering Department Indian Institute of Technology Kharagpur Kharagpur−721302 India Email: avp@che.iitkgp.ernet.in Anand V. Patwardhan, IIT Kharagpur 2 Abbreviations used in this Presentation A.I.Ch.E. ChE ChEngineer I.I.Ch.E. MOC Q and Q QA American Institute of Chemical Engineers Chemical Engineering Chemical Engineer Indian Institute of Chemical Engineers Material of Construction Quality and Quantity (in the context of a Product) Quality Assurance Anand V. Patwardhan, IIT Kharagpur 3 CHEMICAL PROCESS INDUSTRY INTRODUCTION WHAT IS CHEMICAL PROCESS INDUSTRY ? ORIGINS AND DEVELOPMENT OF CHEMICAL PROCESS INDUSTRY Pre−scientific Chemical Industry Scientific Chemical Industry INDIAN CHEMICAL INDUSTRY TODAY Growth with Restraints Green Challenges to Chemical Industry SYSTEMATIC ANALYSIS OF CHEMICAL PROCESSES Mass and Energy Balances Conservation of Mass Conservation of Energy Anand V. Patwardhan, IIT Kharagpur 4 Thermochemistry Chemical Reaction Equilibrium Chemical Kinetics Ideal Gas Laws Phase Equilibrium Unit Operations Classification of Unit Operations Plant Equipment Chemical Reactors Heat Exchangers Mass Transfer Equipment Ancillary Equipment Transportation Equipment Anand V. Patwardhan, IIT Kharagpur 5 Process Flow Diagrams Flow Sheets Instrumentation and Control Economics WHAT IS ChE ? WHAT DOES A ChEngineer DO ? Research Fundamental Research Exploratory Research Process Research Process Development Process Design and Evaluation Plant Design Production and Supervision Plant Technical Service Anand V. Patwardhan, IIT Kharagpur 6 Product Sales Market Research Product Development Technical Sales and Customers Service ChEngineers IN THE COMING YEARS GENERAL ASPECTS OF ChE Communication Human Relations Professional Activities Technical Reading Anand V. Patwardhan, IIT Kharagpur 7 INTRODUCTION Products – all areas of everyday life Chemical fertilisers Food supplements Building materials (metals, concrete, roofing materials, paints, plastics) Clothing (synthetic fibres, dyes) Transportation (gasoline and other fuels) Written communication (paper, ink) Electronic communication (insulators, conductors) Health (drugs, pharmaceuticals, soaps, detergents, insecticides, disinfectants) Intermediates (consumed within the Industry) CHEMICAL INDUSTRY is a sprawling complex of raw material sources, manufacturing plants, and distribution facilities Anand V. Patwardhan, IIT Kharagpur 8 WHAT IS CHEMICAL PROCESS INDUSTRY ? Most processes involve a “Chemical Change”, chemical reactions physico−chemical change related mechanical changes Definition (just satisfactory !): An industry whose principal products are manufactured by processes based upon the chemical, physical, mathematical, and biological principles, which are included in the field of ChE discipline. Anand V. Patwardhan, IIT Kharagpur 9 Industry: Inorganic Chemicals Typical Products End Uses Sulphuric acid Fertilisers, chemicals Petroleum refining Paints Pigments Metal processing Explosives Nitric acid Explosives Fertilisers Sodium hydroxide Chemicals Rayon and film processing Petroleum refining Pulp and paper processing Lye Cleansers Soap Metal processing Anand V. Patwardhan, IIT Kharagpur 10 Industry: Organic Chemicals Typical Products Acetic anhydride Ethylene glycol End Uses Rayon Resins Plastics Antifreeze Cellophane Dynamite Synthetic fibres Formaldehyde Plastics Ethanol Formaldehyde Antifreeze Solvent Anand V. Patwardhan, IIT Kharagpur 11 Industry: Petroleum and Petrochemical Typical Products End Uses Gasoline Kerosene Oils Ammonia Ethanol Fuel Fuel Lubricating Heating Fertilisers Chemicals Acetaldehyde Solvent Other chemicals Alkyl aryl sulphonate Detergents Styrene Synthetic rubber Plastics Anand V. Patwardhan, IIT Kharagpur 12 Industry: Pulp and Paper Typical Products Paper Cardboard Fibreboard, etc. End Uses Books Records Newspapers, etc. Boxes Building materials Anand V. Patwardhan, IIT Kharagpur 13 Industry: Pigment and Paint Typical Products Zinc oxide (ZnO), Titanium dioxide (TiO2), Carbon black (C), Lead chromate, Iron oxides (FeO, Fe2O3, Fe3O4) Linseed oil Phenolic resins Alkyd resins, etc. End Uses Pigments for paints, inks Plastics Rubbers Ceramics Linoleum Drying oil Basic lacquer Varnishes Enamel constituents Anand V. Patwardhan, IIT Kharagpur 14 Industry: Rubber Typical Products Natural rubber (Isoprene), Synthetic rubbers (GR−S, neoprene, butyl) End Uses Automobile tyres Mouldings and sheetings Footwear Insulation Anand V. Patwardhan, IIT Kharagpur 15 Industry: Plastic Typical Products Phenol−formaldehyde, Polystyrene, Polymethylmethacrylate, Polyvinyl chloride, Polyethylene, Polyesters End Uses Various uses in all areas of everyday life Anand V. Patwardhan, IIT Kharagpur 16 Industry: Synthetic Fibre Typical Products Rayon, Nylon, Polyesters, Acrylics End Uses Cloth and clothing Anand V. Patwardhan, IIT Kharagpur 17 Industry: Mineral Typical Products Glass, Ceramics End Uses Windows Containers Bricks Pipe Anand V. Patwardhan, IIT Kharagpur 18 Industry: Cleansing Agent Typical Products Synthetic detergents (sodium alkyl aryl sulphonates), Wetting agents End Uses Household cleaning Industrial cleaning Anand V. Patwardhan, IIT Kharagpur 19 Industry: Biochemical Typical Products Pharmaceuticals, Drugs End Uses Health applications Medicinal applications Anand V. Patwardhan, IIT Kharagpur 20 Industry: Metal Typical Products Steel, Copper, Aluminium, Zirconium Uranium End Uses Building materials Machinery, etc. Nuclear fuel Anand V. Patwardhan, IIT Kharagpur 21 ORIGIN AND DEVELOPMENT OF CHEMICAL PROCESS INDUSTRY Pre−Scientific Chemical Industry Fermentation – oldest Chemical Industry ! (folk craft) Ethanol and Vinegar (dilute CH3COOH) HNO3 from Salt Petre (KNO3) and FeSO4 (heating the mixture and condensing the distilled HNO3) HNO3 – used in separation of Au from Ag H2SO4 – later – generate Cl2 for bleaching bath HCl – cheapest and most widely used mineral acid Alkali found in wood−ashes – early cleansing agents Anand V. Patwardhan, IIT Kharagpur 22 Scientific Chemical Industry Progress and growth slow little understanding of the scientific principles underlying processes during the initial periods Increased understanding of chemical sciences new developments in chemical processing Principal chemical industries in the early−19th century: alkalis, acids, metals manufacture Anand V. Patwardhan, IIT Kharagpur 23 INDIAN CHEMICAL INDUSTRY TODAY Phases of trials and turbulence Mid−30’s: batch processes for indigenous production of Inorganic Chemicals Then, Petroleum Refining, Organic Chemicals, Fertilisers, Agro−chemicals, Drugs and Pharmaceuticals, Paints and Varnishes, Toiletries and Cosmetics, Coal Chemicals, Rubber Chemicals, Fine and Specialty Chemicals, Plastics, Synthetic Fibres, Petrochemicals Well−planned network of specialised Institutions of Learning and Research need for Technological Transformation of Industry Anand V. Patwardhan, IIT Kharagpur 24 Growth with Restraints Major restraints: Matching with the international standards, rapidly changing demand pattern and customer preferences Continuous upgradation of process technology investments additional High cost of BORROWING of Capital Inadequate, inefficient, and yet highly expensive infrastructure and utilities like power, water, transport, etc. erosion of Indian industry’s competitiveness vis-à-vis imported goods. Make things worse high levels of Excise duties, local levies (consumers’ wallet !) + frequent removal / reduction of Customs tariff (manufacturers’ nightmare !) Anand V. Patwardhan, IIT Kharagpur 25 Safety, Health, and Environment within the plant and the surroundings: Central and State Governments’ Laws NGOs often oppose and resist the setting up of new projects which have certain locational advantages (alternative location extra capital + extra operating cost) Low manufacturing capacities Several Treaties: Chemicals Weapons Convention, Basel Convention, Montreal Protocol (O3−depleting substances), etc. Several Conventions: Prior Informed Consents (Dual Purpose Chemicals), Persistent Organic Pollutants, etc. Provisions of WTO, IPR, and other non−tariff barriers Dumping of goods from other countries ! Anand V. Patwardhan, IIT Kharagpur 26 “Responsible Care” and “ISO” certifications are becoming preconditions for International markets ! IT (E−commerce) bids struck instantly Customers and consumers becoming ever more demanding discriminating safer products, cleaner and environmentally benign processes erstwhile QC has become QA and Total Quality Management training cost for the manufacturer Technologies becoming more complex, equipment more sophisticated laxity and lapses at “operational” level are ill−afforded (1984 BHOPAL DISASTER of Union Carbide, remember ?) Anand V. Patwardhan, IIT Kharagpur 27 Green Challenges to Chemical Industry Threat Challenge Opportunity Two facets: From the developed world through several International conventions (existing and proposed) The way Indian Chemical Process Industry is structured very large number of small and medium scale manufacturers, not yet geared to meet “minimum safety standards” of environment and health protection laid down in Indian (Central and State) Laws. Demand for pollution−free processes: an overriding factor Research and Development on “Totally Clean Technologies”, and “Pollution−Free Alternatives” WILL HAVE TO BE an integral part of Industry’s business Opportunity in terms of more profit, in the long run Anand V. Patwardhan, IIT Kharagpur 28 SYSTEMATIC ANALYSIS OF CHEMICAL PROCESSES Production of large quantities at lowest possible cost, for many NEW molecules as well Experience−based improvements no longer sufficient Systematic analysis of chemical processes elucidated many underlying principles synthesis of new processes Mass and energy balances Thermochemistry Unit operations Plant equipment Ancillary equipment Process flow diagrams Instrumentation and control Vitamin−M: balances, operations, flow & control (Economics !) Anand V. Patwardhan, IIT Kharagpur 29 Mass and Energy Balances Fundamental principles that Engineers and Scientists employ in performing design calculations and predicting performance of equipment Conservation of mass Mass in − out + generated = accumulated Total mass involved, individual species, individual “atoms” Steady state processes, unsteady state processes Batch processes, continuous processes One equipment, several equipment, complete process Calculation of unknown quantity directly Check the validity of experimental data Express one or more of the independent relationships among the unknown quantities in a particular problem (mathematical modeling) Anand V. Patwardhan, IIT Kharagpur 30 Conservation of energy Energy in − out + generated = accumulated First law of thermodynamics ∆E = Q − W … for batch processes Q ∆H = Q − WS … for continuous processes = heat energy transferred across the system boundary W = work energy transferred across the system boundary WS = mechanical work energy transferred across the system boundary E = internal energy of the system H = enthalpy of the system ∆E, ∆H = changes in internal energy and enthalpy during the process Engineers are concerned with CHANGES in energy, rather than with ABSOLUTE energy Anand V. Patwardhan, IIT Kharagpur 31 Thermochemistry Concerned with the energy effects associated with chemical reactions Enthalpy is the most convenient term to work with Different types of enthalpy effects: Sensible heat (CP) Latent heat (λ) Heat of reaction (∆HR): enthalpy change of a system undergoing chemical reaction. If the reactants and products are at the same temperature and in their standard states (pure chemical, 1 atm), the heat of reaction is termed the standard heat of reaction. Chemical reaction equilibrium Chemical kinetics Ideal gas law Phase equilibrium Anand V. Patwardhan, IIT Kharagpur 32 Chemical reaction equilibrium 1. How far the reaction will go ? 2. How fast the reaction will go ? Chemical Thermodynamics provides the answer to the 1st question Chemical Kinetics provides the answer to the 2nd question Both Chemical Thermodynamics and Chemical Kinetics must be considered in an overall analysis of a chemical reaction Chemical reaction equilibrium calculations are structured around “free energy CHANGE” in a reacting system: ∆GR = R T ln (KR) Anand V. Patwardhan, IIT Kharagpur 33 Chemical kinetics 2. How fast the reaction will go ? (Question 2 of the previous slide) Study of reaction RATES and variables that affect these rates RATE: time rate of change in the amount of any of the components participating in the reaction Based on arbitrary factor related to the reacting system size, geometry (volume, interfacial area), mass, etc. dn 1 A R = A V dt dc = A ... in case V = constant dt R A =R ⎛ ⎜ ⎜ ⎝ c , P, T, catalyst variables A i R A = ±k ⎛ ⎜ ⎝ ⎞ ⎟ ⎠ ⎛ ⎜ ⎜ ⎝ c A i ⎞ ⎟ ⎟ ⎠ ⎞ ⎟ ⎟ ⎠ Anand V. Patwardhan, IIT Kharagpur 34 Ideal gas law P V = constant = n R T Works best at higher temperatures and lower pressures, that is, when R T ≥ 22.4 m3/kmol ⎛⎜ or L/mol⎞⎟, the ideal molar volume ⎜ ⎟ ⎜ ⎟ P ⎝ ⎠ At lower temperatures, and higher pressures, for REAL gases R T < 22.4 m3/kmol ⎛⎜ or L/mol⎞⎟ ⎜ ⎟ ⎜ ⎟ P ⎝ ⎠ For engineering calculations, the IDEAL GAS LAW is almost always valid Anand V. Patwardhan, IIT Kharagpur 35 Phase equilibrium PURE substances: Phase = state of matter − solid, liquid, gas (vapour) MIXTURES: a phase is characterised by uniformity or homogeneity of properties Most important equilibrium phase relationship: liquid and gas (vapour) Roult’s law: “partial pressure of any component in the vapour = vapour pressure of the pure component × mole fraction of the component in liquid” Henry’s law: “partial pressure of any component in the vapour = Henry’s constant for the given system × mole fraction of the component in liquid” Alternately, phase equilibrium calculations: Ki = yi/xi Anand V. Patwardhan, IIT Kharagpur 36 Unit Operations The seemingly different chemical, physical, or biological processes can be broken down into a series of separate and distinct steps called unit operations Distillation: purification of ethanol; separation of hydrocarbons (petroleum industry) Drying of grain; other foods (food industry); drying of lumber; filtered precipitates; rayon yarn Reactive absorption of O2 from air in a fermenter; reactive absorption of H2 in vegetable oil Evaporation of salt solutions; evaporation of sugar solutions Flow of liquid hydrocarbon; flow of milk Although the number of individual processes is great, each one can be separated into a series of steps or operations The individual operations have common techniques and are based on the same scientific principles The treatment of all processes is unified and simplified Anand V. Patwardhan, IIT Kharagpur 37 Some of the Important Unit Operations Fluid flow Heat transfer Evaporation Drying Distillation Absorption Adsorption Liquid−liquid extraction Liquid−solid leaching Crystallisation Membrane separation Mechanical−physical separations Anand V. Patwardhan, IIT Kharagpur 38 Fluid flow Concerns the principles that determine the flow of transportation of any fluid one point to another Heat transfer A unit operation that deals with the principles that govern accumulation and transfer of heat and energy from one place to another Evaporation A special case of heat transfer, which deals with the evaporation of the volatile solvent, such as water, from a non−volatile solute, such as salt or any other material in solution Drying An operation in which volatile liquids (usually water) are removed from solid materials Anand V. Patwardhan, IIT Kharagpur 39 Distillation An operation whereby components of a liquid mixture are separated by boiling because of the differences in their vapour pressures Absorption A process whereby a component is removed from a gas stream by treatment with a liquid Adsorption A process whereby a component is removed from a gas or a liquid stream by treatment with a solid (adsorbent) whereby the component is adsorbed either physically or chemisorbed on the solid’s surface Liquid−liquid extraction A process in which a solute in a liquid solution is removed by contact with another liquid (solvent) that is relatively immiscible with the solution Anand V. Patwardhan, IIT Kharagpur 40 Liquid−solid leaching It involves treating a finely divided solid with a liquid that dissolves out and removes a solute contained in the solid Crystallisation The removal of a solute such as a salt from a solution by precipitating the solute from the solution Membrane separation The removal of a component from a liquid mixture or a gas mixture by virtue of its molecular size and/or (±)affinity with the separating membrane and/or difference in the osmotic pressure Mechanical−Physical Separations Involves separation of solids, liquids, or gases by mechanical means, such as filtration, settling, and size reduction, which are classified as separate unit operations Anand V. Patwardhan, IIT Kharagpur 41 Unit operations are applicable to processes that are physical and chemical Most frequently, it is desirable to separate the original substance into its component parts Entirely mechanical: separation of solid from liquid during filtration; classification of granular solid into fractions of different particle size by screening; etc. Diffusional or mass transfer operations: involve changes in composition of solutions. This involves TRANSFER of one substance through another, on a molecular scale For example: water evaporation from a pool into an air stream flowing over the water surface. Water molecules diffuse through those of gas at the surface into the main portion of the air stream, from where they are carried away Sometimes, one molecular species may diffuse through another which is itself diffusing in the opposite direction Mass transfer is a result of concentration difference (driving force) Anand V. Patwardhan, IIT Kharagpur 42 Classification of DIFFUSIONAL unit operations 1. Contact of two immiscible phases, with mass transfer (or diffusion) through the surface (interface) between the phases 2. Contact of two miscible phases separated by a permeable or semi−permeable membrane, with diffusion through the membrane 3. Direct contact of miscible phases Anand V. Patwardhan, IIT Kharagpur 43 CONTACT OF TWO IMMISCIBLE PHASES The 3 states (S, L, G) permit 6 possibilities: 1) GAS−GAS: completely soluble in each other, hence infeasible category 2) GAS−LIQUID: If all components are present in appreciable amount in both GAS and LIQUID phases fractional distillation All the components of the solutions involved may not be present in appreciable amounts in both GAS and LIQUID phases. If the LIQUID phase is a pure liquid containing one component whereas the GAS phase contains 2 or more humidification / humidification Both phases may be solutions, each containing only one common component that distributes between phases gas absorption/desorption (stripping) Gas phase contains only one component and liquid several evaporation (but this is NOT a diffusional operation because the rate does NOT depend on concentration gradient, but on rate of heat transfer (temperature difference). However, if evaporation is only by diffusion of solvent diffusional operation Anand V. Patwardhan, IIT Kharagpur 44 CONTACT OF TWO IMMISCIBLE PHASES … 3) GAS−SOLID: If a solid solution is partially evaporated without the appearance of a LIQUID phase fractional sublimation (practically inconvenient) All components may NOT be present in both the phases desorption / adsorption drying / In case the GAS phase is a pure vapour sublimation of a pure solid / desublimation of a pure vapour non−diffusional, depends only the heat transfer rates Anand V. Patwardhan, IIT Kharagpur 45 CONTACT OF TWO IMMISCIBLE PHASES 4) LIQUID−LIQUID: Liquid−liquid extraction OR liquid extraction OR solvent extraction operations Anand V. Patwardhan, IIT Kharagpur 46 CONTACT OF TWO IMMISCIBLE PHASES 5) LIQUID−SOLID: Fractional solidification of a liquid / fractional melting of a solid Liquid−solid extraction OR leaching Crystallisation (heat transfer dependent rather than diffusional) Dissolution 6) SOLID−SOLID: Because of extraordinary slow rates of diffusion within solid phases, there is no industrial separation operation in this category Anand V. Patwardhan, IIT Kharagpur 47 CONTACT OF MEMBRANE MISCIBLE PHASES SEPARATED BY A 1) GAS−GAS: Gaseous diffusion OR effusion: if a gas mixture whose components are of different molecular weight is brought into contact with a porous diaphragm, the various components of the gas mixture will diffuse through the pores at different rates. This leads to different compositions on the opposite sides of the diaphragm and, consequently, to separation of the gas mixture 2) LIQUID−LIQUID: Separation of a crystalline substance from a colloid with a membrane permeable only to the crystalline substance dialysis 3) SOLID−SOLID: The operation in the solid−solid category has found little, if any, practical application in the chemical process industry Anand V. Patwardhan, IIT Kharagpur 48 DIRECT CONTACT MISCIBLE PHASES Very impractical because of the difficulty involved in maintaining Δc Formation of a Δc within a single LIQUID or GAS phase by imposition of a temperature gradient upon the fluid, thus making possible the separation of the components of the solution. For example, the separation Thermal diffusion of Uranium isotopes in the form of UF6 If a condensable vapour such as steam, is allowed to diffuse through a gas mixture, it will preferentially carry one of the components along with it, thus making a separation by an operation called sweep diffusion. If the two zones within the gas phase where the concentrations are different are separated by a screen containing large size openings, the operation is called atmolysis. If a gas mixture is subjected to a very rapid centrifugation, the compounds will be separated because of the slightly different forces acting on different components (ΔMW). The heavier molecules thus tend to accumulate at the periphery of the centrifuge. Anand V. Patwardhan, IIT Kharagpur 49 Plant Equipment Chemical reactors Heat exchangers Mass transfer equipment Distillation Absorption Adsorption Evaporation Extraction Drying Ancillary equipment Transportation equipmentc Anand V. Patwardhan, IIT Kharagpur 50 Distillation (Laboratory) 1. 2. 3. 4. Heat source Still pot Still head Thermometer/Boiling point temperature 5. 6. 7. 8. Condenser Cooling water in Cooling water out Distillate/receiving flask 9. Vacuum/gas inlet 10. Still receiver 11. Heat control 12. Stirrer speed control 13. Stirrer/heat plate 14. Heating (Oil/sand) bath 15. Stirrer bar/anti-bumping granules 16. Cooling bath Anand V. Patwardhan, IIT Kharagpur 51 Distillation (Industrial) Anand V. Patwardhan, IIT Kharagpur 52 CHEMICAL REACTORS Often the heart of a chemical process Where the raw materials are usually converted into products Reactor design is the vital step in the overall design of the process Chemical factors: mainly the kinetics. Sufficient residence time for the desired reaction to get the desired conversion Mass transfer factors: The rates of heterogeneous reactions may be controlled by the rates of diffusion of the reacting species, rather than chemical kinetics Heat transfer factors: These involve the removal, or addition, of the heat of reaction Safety factors: These involve the confinement of any hazardous reactants and products, as well as the control of the reaction and the process conditions The above factors are interrelated, and often contradictory design is a complex and difficult task Anand V. Patwardhan, IIT Kharagpur reactor 53 Reactors types The characteristics normally used to classify reactor design are: 1) Mode of operation: batch; continuous 2) Phases present: homogeneous; continuous 3) Reactor geometry: flow pattern and manner of contacting the phases 5 major classes of reactors are: 1) Batch 2) Stirred Tank 3) Tubular 4) Packed (Fixed) Bed 5) Fluidised Bed Anand V. Patwardhan, IIT Kharagpur 54 Batch processes All the reagents are added at the beginning Reaction proceeds Composition changes with time Reaction is stopped after the desired conversion is reached Product(s) is(are) withdrawn Suitable for small scale production, and for processes that use the same equipment to make a range of different products or grades Examples: pigments, dyestuffs, pharmaceuticals, some polymers Anand V. Patwardhan, IIT Kharagpur 55 Continuous processes Reactants fed continuously and products withdrawn continuously Almost always operates under steady state Usually lower production costs than batch processes Lacks flexibility of operation Usually suitable for large scale production Anand V. Patwardhan, IIT Kharagpur 56 Semi−batch processes Some of the reactants may be added to the batch as the reaction proceeds Some of the products may be withdrawn from the batch as the reaction proceeds Semi−continuous processes Basically a continuous process that is interrupted periodically, for example, for the regeneration of the catalyst Anand V. Patwardhan, IIT Kharagpur 57 Homogeneous processes Reactants, products, catalysts (if any) form one continuous phase, either gaseous or liquid Homogeneous gas phase reactions are almost always operated continuously, whereas homogeneous liquid phase reactions may be batch or continuous Tubular (pipeline) reactors are normally used for homogeneous gas phase reactions Both tubular and stirred tank reactors are used for homogeneous liquid phase reactions Anand V. Patwardhan, IIT Kharagpur 58 Heterogeneous processes Two or more phases exist The overriding problem is promotion of mass transfer rate between different phases Possible combination of phases are: Liquid−liquid: with immiscible phases Liquid−solid: with one or more liquid phases in contact with a solid; the solid may be a reactant or a catalyst Liquid−solid−gas: where the solid is normally a catalyst Gas−solid: where the solid may take part in the reaction or act as a catalyst Anand V. Patwardhan, IIT Kharagpur 59 Heterogeneous processes … Stirred tank reactor: Basic chemical reactor, modeling on a large scale the conventional laboratory reaction flask ! A tank fitted with a mechanical agitator and usually a cooling (heating) jacket or coil. Operated batch or continuous mode Several tanks in series is a possibility Tank size: a few litres to several thousand litres Homogeneous reactions Heterogeneous L−L, G−L, G−L−S reactions Degree of agitation is under designer’s control suitable for reactions that require good mass transfer and/or heat transfer rates When operated in a continuous manner, the composition in the reactor is constant, and is the same as that of the product (except for very rapid reactions) limits the conversion that can be obtained in Anand V. Patwardhan, IIT Kharagpur 60 one stage Heterogeneous processes … Tubular reactor: Generally used for gaseous reactions, but also suitable for liquid phase reactions If high heat transfer is required smaller diameter tubes to increase the surface−to−volume ratio Several tubes may be arranged in parallel For very high temperature reactions, tubes are arranged in furnace Two basic types of tubular reactors: 1) Solid as reactant(s) 2) Solid as catalyst(s) Anand V. Patwardhan, IIT Kharagpur 61 Heterogeneous processes … Tubular reactor … : 1) Solid as reactant(s): in extractive metallurgical industries 2) Solid as catalyst(s): catalytic reactors. Industrial packed bed catalytic reactors are used for gas and gas−liquid reactions. If high heat transfer rates are required, fluidised bed reactors are considered Fluidised bed reactors: the solids are suspended by the upward flow of the reacting fluids high heat and mass transfer rates. The solid may be a catalyst, a reactant, or an inert powder to promote heat transfer Anand V. Patwardhan, IIT Kharagpur 62 Operational factors that contribute to WASTE and EMMISSIONS in chemical reactors are: Incomplete conversion resulting from inadequate temperature control By−product formation resulting from inadequate mixing Catalyst deactivation resulting from poor feed control or purity control Improper design of the reactor itself Improper catalyst selection Anand V. Patwardhan, IIT Kharagpur 63 HEAT EXCHANGERS Transfer of heat to and from process fluids The chemical process industry uses 4 principal types of heat exchangers: 1) Double−pipe heat exchanger: concentric pipe arrangement. Made from standard fittings. Useful only for a small heat transfer area is required 2) Shell and tube heat exchanger: bundle of tubes enclosed in a cylindrical shell. The tube ends are fitted into tube−sheets, which separate the shell−side and tube−side. Baffles are provided to direct the fluid flow and to increase heat transfer. most commonly used, because of the following advantages: Large surface−to−volume ratio (compact) Good mechanical layout (good shape for pressure operations) Reliance on well established fabrication techniques Wide range of construction materials available Easily cleaned equipment Well established design procedures Anand V. Patwardhan, IIT Kharagpur 64 HEAT EXCHANGERS … 3) Plate and frame heat exchangers: very compact, high heat transfer rates 4) Direct contact heat exchanger: no wall to separate hot and cold streams, ∴ very high heat transfer rates are achieved. For example, reactor off−gas quenching, vacuum condensers, desuperheating, and humidification. Water cooling tower is an example of direct contact cooling. Considered whenever the process stream and coolant are compatible. The equipment is simple, for example, spray chamber, spray column, plate column, packed column Heat exchangers contribute to WASTE generation by the presence of CLING formation (process side), and SCALE formation (service side). This can be corrected by designing for lower film temperature and high turbulence. Anand V. Patwardhan, IIT Kharagpur 65 MASS TRANSFER EQUIPMENT 1) DISTILLATION Most widely used separation process Rectification of alcohol (practised since antiquity) crude oil fractionation of Based on differences in volatility between the mixture components The greater the relative volatility, the easier the separation Vapour flows up the column, liquid flows down the column Vapour and liquid are brought into contact on plates, or packings Part of the condensate (reflux) from the condenser is returned to the top of the column to provide the liquid flow above the feed point Part of the liquid from the base of the column is vaporised in the reboiler and returned to the column to provide the vapour flow Anand V. Patwardhan, IIT Kharagpur 66 1) DISTILLATION … In stripping section (below the feed), the more volatile components are stripped from the liquid. In enrichment (rectification) section (above the feed), the concentration of more volatile components increases In the case of multiple feed and/or multiple products, the basic operation remains the same; complicates the analysis Rectification section may be omitted, if the requirement is to strip the MVC from a relatively non−volatile solvent stripping column If the top product is required a vapour, the liquid condensed is sufficient only to provide the reflux to the column partial condenser In a partial condenser, the vapour leaving is in equilibrium with the reflux When the vapour is totally condensed, the reflux will have the same composition as the top product Anand V. Patwardhan, IIT Kharagpur 67 2) ADSORPTION Operation can be applied to either gas or liquid mixtures One or more components from a mixture are preferentially removed by a solid (called adsorbent) Influenced by the surface area of the adsorbent, nature of the substance to be adsorbed (adsorbate), pH of system (in case of liquids), and temperature of operation Normally performed in a column Either a packed bed or a fluidised bed The adsorbent, after its useful life, can either be discarded or regenerated Anand V. Patwardhan, IIT Kharagpur 68 3) ABSORPTION Intimate contacting of a mixture of gases with a liquid so that part of one or more constituents of the gas dissolves in the liquid. Usually packed column Also, plate column, bubble column, venturi scrubbers, mechanically agitated contactors, etc. Countercurrent packed column is the most common equipment: The gas stream moves upward through the packed bed against a physically absorbing and reacting liquid that is injected at the top of the column This results in the highest possible contacting efficiency Since the concentration of the gas stream decreases as it rises, it comes into contact with fresher liquid coming from the top This provides the maximum average driving force for the diffusion process Anand V. Patwardhan, IIT Kharagpur 69 4) EVAPORATION Operation involves heat transfer to a boiling liquid Results in an increase in the concentration of certain species in the feed stream Most common application: removal of water from a process stream Food, chemical, petrochemical industries Factors affecting: concentration of the liquid, solubility, pressure, temperature, scaling, materials of construction Major types of evaporators: Open kettle or pan evaporator Horizontal tube natural convection evaporator Vertical tube natural convection evaporator Forced convection evaporator Efficiency can be increased by operating the equipment in multiple effect mode Anand V. Patwardhan, IIT Kharagpur 70 4) EXTRACTION (L−L and S−L) Liquid−liquid extraction involves transfer of solutes from one liquid phase into another solvent Conducted in a mixer−settler, plate column, agitated column, packed column, etc. S−L extraction (Leaching) involves passing of a solvent over a solid phase to remove solute Conducted in a fixed−bed, moving bed, or agitated columns Anand V. Patwardhan, IIT Kharagpur 71 5) DRYING Involves removal of small amounts of water or other volatile liquids Drying removes the liquid as a vapour by warm gas (usually air) currents Batch or continuous processes 4 basic dryer types: Continuous tunnel dryer: warm air is blown over the trays Rotary dryer: inclined hollow cylinder that rotates. The wet solids are fed from one side, hot air is passed counter−currently over the wet solids Drum dryer: a heat cylinder in which the wet solids spread across the outside of the hot, rotating drum, are dried on this surface, and are then scraped off Spray dryer: a liquid or slurry is sprayed through a nozzle, and the fine droplets are dried by a hot gas. This may be operated co−currently, counter−currently, or in some combination of the two modes Anand V. Patwardhan, IIT Kharagpur 72 ANCILLARY EQUIPMENT These are devices for transporting gases and liquid to, from, or between various units of process equipment Some are simply conduits (pipes, ducts, fittings, stacks) Some control the flow of material (valves) Some provide mechanical driving force for the flow (fans, pumps, compressors) Storage facilities Holding tanks Materials−handling devices and techniques Utilities (gas, steam, water) Air, water, and solid waste control equipment Pollution prevention and loss prevention can be implemented by the use of seal−less pumps, bellow−sealed valves, and other specified equipment. Selection of proper equipment in the Design and Construction phase of a transport system is very important Anand V. Patwardhan, IIT Kharagpur 73 ANCILLARY EQUIPMENT … PIPES Pipes and tubings Pipes: larger diameter, thicker walls, hence can be threaded Tubings: smaller diameter, thinner walls, hence can NOT be threaded Many materials of construction = f (corrosivity of fluids, system pressure) Steel pipes can be LINED with Sn, plastic, rubber, lead, or other corrosion−resistant coating Special MOCs such as glass, porcelain, thermosetting plastic, or hard rubber are available Several techniques to join pipe sections For small pipes, threaded connections are most common For larger pipes, FLANGED fittings, WELDED connections Anand V. Patwardhan, IIT Kharagpur 74 ANCILLARY EQUIPMENT … DUCTS Only for gases Always thin−walled, generally used for flows at ambient pressure 0, ○, □, etc. shapes are available Larger cross sections à gases are often transported with low density and high flow rates Field−fabricated galvanised sheet steel, fibrous glass board, factory−fabricated round fibrous glass, spiral sheet metal, flexible duct materials, black steel, plastic and plastic−coated steel, cement, asbestos, copper For maximum resistance to corrosion, stainless steel and copper are used where their cost can be justified Aluminum sheet is used where lighter weight and superior resistance to moisture are needed Anand V. Patwardhan, IIT Kharagpur 75 FITTINGS A piece of equipment that has one or more of the following functions: 1. Joining of 2 pieces of straight pipes (coupling, union, etc.) 2. Changing the direction of pipeline (elbow, T, etc.) 3. Changing of pipeline diameter (reducer, bushing, etc.) 4. Joining of 2 streams (T , Y) Coupling: short piece of pipe threaded on the inside (some plastics are not threaded). Used to connect straight sections of pipe Union: Used to connect straight sections of pipe, but differs from the coupling in that it can be opened conveniently without disturbing the rest of the pipeline Elbow ╔═: an angle fitting for changing flow direction usually by 900 T joint ═╦═: change of direction or mixing of 2 streams Y joint Υ: similar to T joint Reducer: a coupling for 2 pipe sections of different diameter Bushing: a connector for 2 pipe sections of different diameter, but is threaded from both inside and outside Anand V. Patwardhan, IIT Kharagpur 76 VALVES Control the amount of flow, redirect the flow GATE valve and GLOBE valve are most commonly used GATE valve Contains a disk that slides perpendicular to the flow direction Primarily used for on−off control of a liquid flow Not suitable for adjusting the flow rates because small lateral adjustments of the disk cause extreme changes in the flow cross−sectional area. GLOBE valve Designed for flow control Liquid route is circuitous The seal is a horizontal ring in which a plug with a slightly beveled edge is inserted when the stem is closed Good flow control, but pressure losses are more than those in gate valve Anand V. Patwardhan, IIT Kharagpur 77 VALVES … Some other types of valves are: Check valve: permits the flow in one direction only Butterfly valve: operates in a damper−like fashion by rotating a flat plate to either || or ⊥ position relative to the flow Plug valve: a rotating tapered plug provides on−off service Needle valve: a variation of the globe valve, which gives improved flow control Diaphragm valve: specially designed to handle fluids such as very viscous liquids, slurries, or corrosive liquids that might clog the moving parts of the other valves Anand V. Patwardhan, IIT Kharagpur 78 FANS / BLOWERS For low pressure drop operation, generally < 2 lbf/in2 For generating pressure heads in the range of 2 – 14.7 lbf/in2 Operations at higher pressures require COMPERSSORS Centrifugal and axial flow type Centrifugal fans: the gas is introduced at the centre of the revolving wheel (eye), and is discharged at angles to the rotating blades Axial flow fans: the gas moves directly (forward) through the axis of rotation of the fan blades. Both types are used in industry Anand V. Patwardhan, IIT Kharagpur 79 PUMPS 1) RECIPROCATING PUMP (positive displacement type) Direct action of piston on the liquid in the cylinder During the piston compression, higher pressure forces the liquid through the discharge valve of the pump outlet During the piston retraction, the next batch of low−pressure liquid is drawn into the cylinder This cycle is repeated Anand V. Patwardhan, IIT Kharagpur 80 PUMPS … ROTARY PUMP (positive displacement type) Combination of liquid rotation and positive displacement the rotating elements MESH with the elements of stationary casing As the rotating elements come together, a pocket is created that first enlarges, drawing in liquid from the suction line As the rotation continues, the pocket of liquid is trapped, reduced in volume, and then forced into the discharge line at a higher pressure Flow rate = f (size and speed of rotation) Liquid of any viscosity without abrasive solids, can be handled Anand V. Patwardhan, IIT Kharagpur 81 PUMPS … CENTRIFUGAL PUMPS: Consists of an impeller rotating within a casing Fluid enters near the centre of the impeller, and thrown outward by the centrifugal force The kinetic energy of fluid increases from the centre to the tip of the impeller The kinetic energy is converted to higher pressure in the discharge line Anand V. Patwardhan, IIT Kharagpur 82 COMPRESSORS Same working principles Same classification as that of pumps Obvious difference: large decrease in GAS volume, but negligible change in LIQUID volume CENRIFUGAL: large volumes of GASES, at low−to−moderate pressure enhancements (ΔP = 0.5−50 lbf/in2) ROTARY: small capacities, at discharge pressures up to 100 lbf/in2 RECIPROCATING: most common type. Capable of compressing small gas flows to as much as 3,500 lbf/in2. With specially designed compressors, discharge pressures as high as 25,000 lbf/in2 can be reached, but these devices are capable of handling very small capacities, and do not work well for all gases Anand V. Patwardhan, IIT Kharagpur 83 STACKS (chimneys) Discharge of flue gases into atmosphere STUB (short stacks) fabricated of steel (unlined or refractory−lined) or refractory brick Extend a minimum distance up from the discharge of an induced draft fan Tall stacks Constructed of the same material as short stacks Provide a greater driving force (draft) Ensure more effective dispersion of flue gases into atmosphere Some chemical and utility applications use metal stacks made of double−wall with an air space The insulating air packet prevents condensation on the inside of the stack, thus avoiding corrosion of the metal sheets. Anand V. Patwardhan, IIT Kharagpur 84 Process Diagrams Key in defining, refining, and documenting a chemical process Authorised process blueprint Framework for SPECIFICATIONS used in equipment designation and design Single, authoritative document to define, construct, and operate the chemical process Also used in other processes and Industries Anand V. Patwardhan, IIT Kharagpur 85 Flow sheets Equipment symbols, process stream flow lines, equipment identification numbers and names, temperature and pressure designations, utility designations, mass / volumetric / molar flow rates of each process stream, material and energy balance tables pertaining to all process flow lines, physical properties of process streams Instrumentation Provides coherent picture of the overall process, point up some deficiencies in the process that may have been overlooked, for example, by−products and recycle requirements Basically, FLOW SHEET symbolically and pictorially represents the interrelations among the various flow streams and equipment, and permits easy calculations of M & E B. Universal symbols to represent equipment, equipment parts, valves, piping, etc. Anand V. Patwardhan, IIT Kharagpur 86 Flow sheets … (stages in its development) … Crude flow sheet: simple, free−hand block diagram (equipment only) Line drawing with process data (overall and component flow rates, utility and energy requirements, instrumentation) Highly detailed piping and instrumentation diagram (P & I D) OR 1. Block diagram 2. Graphic flow diagram 3. Process flow diagram 4. Process piping and instrumentation flow diagram 5. Utility piping and instrumentation flow diagram 6. The combination of (4) and (5) above Anand V. Patwardhan, IIT Kharagpur 87 Instrumentation and Process Control Measurement, Indication, Recording of necessary process data Necessity for knowing process data: so that the Operator and Production Engineer can know that the process is functioning properly or not. Automatic control: often desirable, because it reduces human intervention and human errors, and also gives faster and more accurate control Coupling of automatic controllers to electronic computers Necessary to have highly skilled and trained maintenance staff The more complex the system, the greater the chance for breakdown For designing an automatic process control system, it is absolutely essential to consider the INTERACTION of all components of a process to determine the overall behaviour (dynamics) of the process Anand V. Patwardhan, IIT Kharagpur 88 Economics The process is a failure if the product can not be sold at a profit Thorough market analysis (how much, what price) before the construction of a chemical process plant Often MORE SALE with LOWER PRICE ! PRESENT AND FUTURE COMPETITION During plant design: determine the least expensive (least fixed capital investment) design, with least expensive PRODUCT COST If the product is successful and profitable, a competitor may find the market attractive and enter it with (definitely) a somewhat better product produced at a lower price, and moreover, sold at a lower price, by an improved or the same process ! It is necessary for the older producer to improve her/his PROCESS and PRODUCT, or she/he will be FORCED OUT of the market. Anand V. Patwardhan, IIT Kharagpur 89 WHAT IS ChE ? Synthesis of Chemistry and Engineering Grew out of Industrial Chemistry fundamentals physical principles + chemistry “A ChEngineer carries out reactions on a large scale, developed by the chemist in the laboratory” – narrow, UNIT OPERATIONS are NOT included in this definition Unique characteristic of a ChEngineer: can talk to, and understands, both chemists and engineers A.I.Ch.E’s definition: “the application of principles of the chemical and physical sciences, together with the principles of economics and human relations, to fields that pertain directly to processes and process equipment, in which matter is treated to effect a change in state, energy content, or composition” Anand V. Patwardhan, IIT Kharagpur 90 WHAT DOES A ChEngineer DO ? Some major areas of work within “ChE” Research Process development Process design and evaluation Plant design Construction Production supervision Plant technical service Product sales o Market research o Product development o Technical sales and customer technical service The ChEngineer works closely with specialists in chemistry and other fields of engineering and pure science. Anand V. Patwardhan, IIT Kharagpur 91 RESEARCH Fundamental research Exploratory research Process research Anand V. Patwardhan, IIT Kharagpur 92 Fundamental research New knowledge of the principles of unit operations, industrial reaction kinetics, chemical process control, etc. Development of new theories, and their experimental testing. For example, turbulent fluid flow To increase the general knowledge rather than for specific application Requires excellent background in mathematics AND principles of ChE physics, chemistry, Specialises and becomes expert in one area, for example, mass transfer Anand V. Patwardhan, IIT Kharagpur 93 Exploratory research To find a particular reaction with commercial possibilities Less frequently the responsibility of a ChEngineer. Typically, it is the task of a Chemist To find a particular catalyst, reaction temperature, pressure → product having higher Octane Number A Chemist investigates several PURE compounds for the reaction in question. For example, CYCLOHEXANE is a common constituent of NAPHTHA (octane number = 78.6, too low for modern petrol) H2 C 0 H2C CH2 catalyst, 500 F H2C CH2 500 lb/in C H2 2 H C HC CH HC CH octane number = 113.6 C H + 3H2 ; conversion = 90% Other catalysts and conditions give different conversions Anand V. Patwardhan, IIT Kharagpur 94 Another reforming reaction is isomerisation For example, n−heptane may be converted to an isomeric heptane with a higher octane number 0 catalyst, 900 F CH3CH2CH2CH2CH2CH2CH3 octane number = 0 500 lb/in2 CH3 CH3CCH2CH2CH2CH2CH3 CH3 octane number = 93 The exploratory research group would try many catalysts and various operating conditions on a small laboratory scale to explore a wide range of possibilities. The research programme would extend over several months or even years Many attempts would prove infeasible A few results may be commercially promising, and will be passed on to the process research group Anand V. Patwardhan, IIT Kharagpur 95 Process research Takes promising results from exploratory research, and intensively studies them on a bench scale to determine their commercial feasibility Determines operating conditions for a commercial process Yields data for a preliminary economic evaluation Provides information for the design of a pilot plant Studies not only pure starting materials, but also the real feed Relatively more expensive because of more complex equipment requirement and greater operating costs. Demonstrates chemical feasibility of the new process, preliminary economic feasibility, market evaluation (satisfactory profit level) PROCESS DEVELOPMENT Anand V. Patwardhan, IIT Kharagpur 96 PROCESS DEVELOPMENT Admission of ignorance ! If all the fundamentals of ChE were well understood, it would be possible to build a full size plant based on the results of the extensive process research !! Large uncertainties regarding process operating conditions and product yield semi−works or pilot plant Expensive to build and operate, but saves much more money by eliminating uncertainties in the construction, start−up, and operation of the commercial plant Also required to produce new product for market research Pilot plant must duplicate the proposed plant the proposed full−size plant Planning the development programme Designing and building the pilot plant Operation of the pilot plant Correlation, presentation and evaluation of the data obtained Anand V. Patwardhan, IIT Kharagpur 97 PROCESS DESIGN AND EVALUATION Process Design Engineer is responsible for design of overall process Project Engineer is responsible for detailed design of equipment Process Design Engineer must look at many alternative process steps to determine an economic optimum Anand V. Patwardhan, IIT Kharagpur 98 Process Design includes the following major items: Process flow sheet showing all pieces of equipment, instrumentation and control, operating pressures, temperatures, flow rates Overall mass balances, equipment−wise mass balances, yields of products, composition of all streams Energy balances for all units, including heat exchangers requirements Specification of pump capacities, flow, and pressure requirements Specification of size and configuration of chemical reactors and storage tanks Determination of optimum operating conditions for the mass transfer operations required for the separation and purification of raw materials and products Estimation of utility requirements, such as steam, water, electricity and fuel Economic evaluation with an estimate of capital investment and operating cost Anand V. Patwardhan, IIT Kharagpur 99 The Process Design Engineer: Utilises all the data of process research and development Works closely with development engineer to determine most economical processing units and optimum operating conditions Must use her/his judgement in filling the gaps in the data Must estimate many quantities, using previous experience as well Must be well−grounded in the fundamentals of chemical kinetics and unit operations Must exercise her/his imagination and judgement to design a process with often incomplete data Must be to able use analytical as well as numerical methods of calculations, AND computers for the routine long calculations Must be fully familiar with the latest process design and simulation software Anand V. Patwardhan, IIT Kharagpur 100 PLANT DESIGN Translation of results of Process Design Engineer specifications construction of the plant complete plans and Complete plant design firm estimate of plant cost AND basis for contract between chemical company and construction firm Plant Design group: chemical, mechanical, electrical, civil engineers, supervised by Project Engineer who is frequently a ChEngineer having overall process knowledge Project Engineer: co−ordination of various specialists’ activities; analysis of data supplied by process design engineer; makes suggestions for modifying the fundamental process which result in substantial savings. MUST CONCERN with peripheral problems (water supply, other utilities, waste disposal, safety) Process Design Engineer and Project Engineer work closely in analysing the suggestions of Project Engineer Anand V. Patwardhan, IIT Kharagpur 101 Designer and Draftsman: work closely with Project Engineer Designer: a specialist of a particular phase of the plant. For example: after a ChEngineer has determined the number, size, and spacing of plates in a distillation column, a Mechanical Designer may specify the physical details of the column, Electrical Designer may specify the location and type of instrumentation and control, Structural Designer considers the support framework and foundations for the column and auxiliary equipment The Designers make suggestions to the project Engineer on specific points where money might be saved Designer: supervises the Draftsman who make the detailed drawings of each unit of the process Project Engineer: works closely with contractor; materials unavailability, change in a unit (based on further pilot plant data), changes in foundation (unexpected soil change) Project Engineer: present during start−up Anand V. Patwardhan, IIT Kharagpur 102 The Young Engineer: May start as an Assistant in Plant Design Group Becomes a Designer Project Engineer Many equipment (pump, heat exchanger, instrumentation, etc.): supplied by vendors. Vendor: a company specialising in the design and construction of a particular type of equipment Vendor may build a unit to the Plant Design group’s specifications (tailormade) OR may suggest a standard unit Vendor employs many engineers in the development, design, and sale of her/his equipment Anand V. Patwardhan, IIT Kharagpur 103 CONSTRUCTION Role of ChE is limited Construction Supervisor: Responsible for completing the plant in shortest time within the allotted budget Must establish a construction schedule, and must expedite it Must set up equipment delivery schedules Must carefully schedule manpower requirements, keeping in mind the craft union regulations Must maintain good labour relations to avoid poor workmanship, slowdowns, or complete work stoppages Must test the equipment after construction Must be available for start−up of the plant Anand V. Patwardhan, IIT Kharagpur 104 PRODUCTION SUPERVISION Production Supervisor: Gets the new plant running to give Q and Q of the product Checks the daily record Improves the plant operation (element of unknown in Design) Improves product Quality by removing contamination and reducing deterioration Reduces steam, water, power, materials requirement Reduces labour costs by maintaining good labour relations, efficient methods, and workable safety practices Develops efficient maintenance procedures to ensure minimum shutdown for routine repairs Sets up a procurement schedule to maintain adequate inventories of raw materials Anand V. Patwardhan, IIT Kharagpur 105 Production Supervisor (continued…): Finds and eliminates bottlenecks when an attempt is made to increase production (exploiting the overdesign) Sees her/his profits directly in terms of more efficient operation and additional production Works closely with Process Development and Design Group in modifying the plant Should be ready to abandon the old plant and move on to a new one Need a broad background in Engineering The Graduating ChEngineer: May start as Assistant Production Engineer in a small area of process With experience she/he becomes Production Engineer, Assistant Supervisor, Supervisor Plant Manager Anand V. Patwardhan, IIT Kharagpur 106 PLANT TECHNICAL SERVICE Assists the Operating Engineer in start−up and operation problems More technical and less routine duties Some companies consider Technical Services as a part of Production Department Extremely important in the start−up of the new process: Technical Service Engineer works closely with Process Development and Process Design groups during start−up, where minor design and construction errors are corrected The Engineers involved in start−up need a wealth of theoretical and practical knowledge to overcome the difficulties involved during the start−up and during operation Anand V. Patwardhan, IIT Kharagpur 107 PRODUCT SALES The ultimate economic justification of a chemical process 4 closely related areas of interest to ChEngineers: 1. Market research 2. Product development 3. Technical sales 4. Customer technical service Anand V. Patwardhan, IIT Kharagpur 108 MARKET RESEARCH Begins long before the new process is launched Fundamental question: “Will It Sell ?” Starts as soon as promising results are reported by the Exploratory Research Group For new product: contact potential users to determine their needs and establish whether a market exists. Pilot Plant produces sufficient samples for potential users For existing product: how much more could be sold ?; New uses Continual surveys of the chemical market to find out facts on general trends in New Products May suggest areas of possible economic return to the Exploratory Research Group Anand V. Patwardhan, IIT Kharagpur 109 PRODUCT DEVELOPMENT Uses of new products and new uses of existing product Applied research: problems solution of complex chemical and engineering Assists Market Research by suggesting and developing new uses Assists Technical Salesperson by developing a modified product for the use of a particular customer Assists Customer Service Group by suggesting processing methods which the customer might use with the product Some long term and exploratory; some immediate answers For example: Customer requires very high purity product. Usual product may not be sufficiently pure. The Product Development Engineer will work out means of purifying it (either before or after Sales) OR she/he might suggest a change in the customers’ process to eliminate the need for high purity saving customers’ money and selling less pure product Anand V. Patwardhan, IIT Kharagpur 110 TECHNICAL SALES & CUSTOMER TECHNICAL SERVICE These two are closely related Same Engineer may act in both capacities Customer satisfaction should be demonstrated Solution of customers’ problems during the use of product Some companies may have special groups; others expect their salespersons to handle the customers’ technical problems; Some companies assign this responsibility to their QA Departments Technical Salesperson may call the Product Development Group to answer customers’ questions Often this service is the key factor for Sales Contact with customers personality and interest need to be developed. Pleasant personality helps to get the customer, and core theoretical and practical knowledge helps retain the same Anand V. Patwardhan, IIT Kharagpur 111 ChEngineers IN THE COMING YEARS ChE improves lifeline, safety, health, energy, environment ChE faces serious macroeconomic problems, such as: ☺ Energy and feedstock for fertiliser and heavy chemical industry ☺ Infrastructure for transportation, energy, telecommunication ☺ Environment protection ☺ Development of agriculture and agro−industries ☺ Transformation of rural economy, industrialisation, privatisation Centre versus State Command Economy versus Liberalisation & Privatisation (the often misunderstood market economy) Internal (budget) and external balances World Trade Organisation and India Overriding problem of Indian competitiveness (rather, the lack of it) Anand V. Patwardhan, IIT Kharagpur 112 Identification of future scenarios and selection of appropriate ones: Collaboration of Professional Bodies (I.I.Ch.E, and others) will help Lack of transport infrastructure and transport fuel: blocks interaction with the World Trade Community Lack of electric power: puts the nation in uproar Role of renewable energy to be determined (hydro−power, wind−power, solar cells, biomass, etc.) vis-à-vis Coal, Natural Gas, Oil, Nuclear Power Modest quantity of proven Hydrocarbon reserves (≈ 30 × 109 ft3) may exhaust shortly Enhancement of energy utilisation efficiency ? Today, the feedstock for fertilisers (Natural Gas) competes with that of Power Industry. For long term benefits, Power Industry should not use Natural Gas Transport fuel: efforts are needed to use Hydrogen in fuel cells Nuclear energy: ecologically attractive, but useless today because of public opposition and high investments required Updated ENERGY POLICY is required URGENTLY Anand V. Patwardhan, IIT Kharagpur 113 Updated energy policy should be supplemented by all necessary programmes: possibly only by collaboration of Economists and Engineers on one hand, and benign and strong political will on the other hand: here, the ChEngineers are well placed to make a major contribution: The role of ChEngineers is evident but the problem of developing laws, standards, and trade−offs between the perceived Air Purity and investments is a problem for Governments and private institutes, etc., and health hazards pose a major challenge to the Medical profession Dealing with “trade−offs” between health risks and the cost of air cleaning is indeed a difficult task for politicians Serious environmental problems: CO2 warming greenhouse effect global If the oceans are heated up, they will loose part of their absorbed CO2 further global warming (self−accelerating or autocatalytic effect) We can not stop the rate of increase in energy usage to reduce CO2 ! ChEngineers can help solve these problems Anand V. Patwardhan, IIT Kharagpur 114 Certainly, the ChEngineers and the other technological professionals can do a lot to draw attention to the facts discussed here before An understanding between Economists and Engineers to develop joint advise to political problems and introduction of innovative technologies have to be worked out by ChEngineers. For example: Co−production of electric power, chemicals, and hydrocarbons Use of Dimethyl Ether (DME), as a carrier of energy from, say, the Middle east to India Use of DME in India for generation of electricity, and as fuel in diesel engines Use of DME as chemical feedstock Development of long range, high capacity, high voltage DC transmission Anand V. Patwardhan, IIT Kharagpur 115 GENERAL ASPECTS OF ChE COMMUNICATIONS Clear expression of technical ideas in oral and written communication Often the major contact is with the Administrative Manager OR Human Resources (HR) Manager (mostly neither an engineer nor a technologist), who decides on an Engineer’s promotion based on written reports All the reports should be written clearly and concisely with the reader (audience) in mind Writing and speaking are important in all fields of ChE from RESEARCH to SALES Anand V. Patwardhan, IIT Kharagpur 116 GENERAL ASPECTS OF ChE … HUMAN RELATIONS Many failures are NOT due to technical weakness, but can be attributed to failure of Engineer to work effectively in group/team: Must work effectively in group/team Must sell ideas effectively and tactfully Any effective group/team activity = f (sensitivity to and respect for rights and needs of others) Must realise that no matter how lucid her/his idea is to her/him, it may not be clear to others, and the idea may NOT be right ! Development and Design Engineers must work closely together and with their respective groups Production Engineer must work closely with other Engineers and with the Unionised Labour Force Technical Services Engineer must work closely with the operators of the Process, carefully explaining the suggested process changes Sales Engineer must be particularly sensitive to her/his customers’ needs (the customer is not always right, but it will do no good to tell point blank so !) Anand V. Patwardhan, IIT Kharagpur 117 GENERAL ASPECTS OF ChE PROFESSIONAL ACTIVITIES All Engineers should be active in their respective Professional Societies. For example, I.I.Ch.E. TECHNICAL READING The ChEngineer should keep up−to−date in her/his field, not only by attending professional meetings, but also by reading technical journals (periodicals). There are a number of general publications and many specialised publications in ChE Anand V. Patwardhan, IIT Kharagpur 118 If you wish to find out MORE about the Chemical Process Industry, read on the following lines: 1) Basic laws and processes of chemical technology 2) Raw materials, fuel, and power for Chemical Process Industry 3) Water conditioning in Chemical Process Industry 4) Catalysts and catalysis 5) Explosives and propellants 6) Industrial gases 7) Industrial carbon 8) Sulphur and sulphuric acid 9) Hydrochloric acid and miscellaneous inorganic chemicals 10) Nitrogen industries 11) Phosphorous industries 12) Salt and miscellaneous sodium compounds Anand V. Patwardhan, IIT Kharagpur 119 13) Alkali and chlorine products 14) Potassium industries 15) Barium and its compounds 16) Fertiliser industries 17) Portland cement, calcium, and magnesium compounds 18) Ceramic and refractories 19) Glass industries 20) Nuclear industries 21) Iron and steel 22) Energy conservation in Chemical Process Industries Anand V. Patwardhan, IIT Kharagpur 120 23) Petroleum refinery and petrochemicals 24) Synthetic fibres and film industries 25) Rubber industries 26) Plastic industries 27) Oils, fats, and waxes 28) Soaps and detergents 29) Essential oils 30) Surface coating industries 31) Pulp and paper industries Anand V. Patwardhan, IIT Kharagpur 121 32) Sugar and starch industries 33) Fermentation and distillery 34) Food processing industries 35) Leather and tannery 36) Dyes and dyes intermediates 37) Agrochemical industries 38) Coal and coal chemicals 39) Pollution control 40) Green technologies through ChE Anand V. Patwardhan, IIT Kharagpur 122 Acknowledgements 1st year B.Tech. (2006 entrants − ChE) students: suggested an INTRODUCTORY lecture on this topic Professor Dibyendu Mukherjee (Head, Chemical Engineering Department, IIT Kharagpur): instantly supported the idea My present and past students: shared their valuable experiences. I learn from them more than I can teach them All my teachers from UICT (Mumbai): introduced to me, not only the wonderful words and world of ChE, but also the tricks of the trade ! Some of my bosses, colleagues, and peers from M/s. Indian Organic Chemicals Limited (Khopoli, Raigad, Maharashtra) and M/s. Asian Paints Limited: mentored me in knowledge−based problem−solving All the Plant Operators in the above−mentioned organisations: imparted those lessons, which are not available in any text−book ! My esteemed colleagues in Chemical Engineering Department, IIT Kharagpur: for their latent contribution and support Anand V. Patwardhan, IIT Kharagpur 123 Anand V. Patwardhan, IIT Kharagpur 124