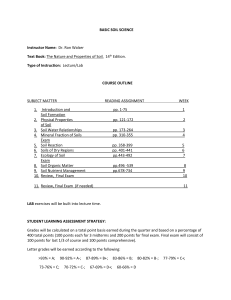

Chapter 4: Elementary Soils Engineering

advertisement