High-Temperature Combined Sensible/ Latent

advertisement

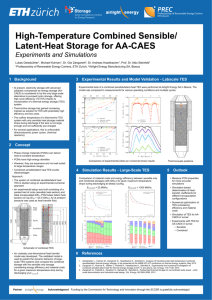

High-Temperature Combined Sensible/ Latent-Heat Storage Experiments and Simulations Lukas Geissbühler1, Michael Kolman1, Dr. Giw Zanganeh2, Dr. Andreas Haselbacher1, Prof. Dr. Aldo Steinfeld1,3 1Professorship of Renewable Energy Carriers, ETH Zurich, 2Airlight Energy Manufacturing SA, Biasca, 3Solar Technology Laboratory, PSI 3 1 Background • The outflow temperature of a thermal energy storage (TES) system with only sensible heat storage material drops during discharge if the tank is not large enough and not sufficiently pre-charged • For several applications, this could be unfavorable (thermodynamic power cycles) or even unacceptable (chemical reactions) Experimental tests of a combined sensible/latent-heat TES were performed at Airlight Energy SA in Biasca. The code was compared to measurements for various operating conditions. (Note: ṁd / ṁc = discharging / charging mass flow rate) ṁd /ṁc = 1 600 Temperature [ C] ṁd /ṁc = 1 600 500 580 Concept 400 560 300 540 200 520 100 500 • Phase change materials (PCMs) can deliver heat at constant temperature • PCMs have high energy densities • However, they are expensive and not well suited to large temperature ranges • Combined sensible/latent-heat TES avoids disadvantages 1 2 3 4 5 6 7 0 2 4 6 Time [h] ṁd /ṁc = 1/2 600 600 10 12 14 16 500 580 Temperature [ C] 8 Time [h] ṁdisch · ṁ ṁd= /ṁ0.5 1/2 ch c = 400 560 300 540 200 520 100 Heater 500 1 2 3 4 5 6 7 0 2 4 Time [h] 6 8 10 12 14 16 Time [h] Comparison of experimental (dots) an simulation (lines) results Insulation 4 Thermocouple positions Simulation Results - Large-Scale TES 5 • Numerical study of large-scale TES (rtank = 8 m, height variable) 1. Sensible: Rocks 2. Combined: Rocks with encapsulated AlSi12 on top Laboratory setup of combined sensible/ latent-heat TES Perforated Plate Ncycles ṁmax tc td 20 30 kg/s 5h 5h Tc Td Tout,max,c Tout,min,d 231 °C 575/565/ 555/550 °C 595 °C 220 °C Charging PCM Height above Tank Bottom [m] • Compare the necessary tank sizes for the following conditions: Air 10 Sensible, 3 Pre-Charge-Cycles Combined, 1 Pre-Charge-Cycle 8 PCM charge 6 discharge 4 2 Tmax,discharge = 20 C 0 200 300 400 500 600 Fluid Temperature [ C] Rocks Insulation 580 560 Sensible 1 Pre-Charge-Cycle Sensible, 3 Pre-Charge-Cycles Combined, 1 Pre-Charge-Cycle Discharging 540 0 1 2 3 Time [h] 6 Sensible Combined 1 Normalized Material Costs Fluid Outlet Temperature [ C] 600 1360 mm 2 Experimental Results and Code Validation - Labscale TES 4 5 0.95 0.9 Outlook • Investigate alternative PCMs • Determine missing properties for more accurate simulations • Upcoming experiments: • Parametric studies • Alternative PCMs • Different storage configurations • Optimization of tank design considering efficiency and capital costs • Advanced adiabatic compressed air energy storage (AA-CAES): Simulation of TES in tunnel • Experiments with TES in tunnel 0.85 0.8 20 25 30 35 40 45 Tmax,discharge References 394 mm Air Schematic of combined TES Partner 1. Zanganeh G., Pedretti A., Haselbacher A., Steinfeld A., Design of Packed-Bed Thermal Energy Storage Systems for HighTemperature Industrial Process Heat, Appl. Eng., 2014, in press 2. Zanganeh G., Commerford M., Haselbacher A., Pedretti A., Steinfeld A., Stabilization of the outflow temperature of a packed-bed thermal energy storage by combining rocks with phase change materials, Appl. Thermal Eng., 70:316-320, 2014 3. Zanganeh G., Pedretti A., Zavattoni S., Barbato M., Steinfeld A., Packed-bed thermal storage for Concentrated solar power – pilotscale demonstration and industrial-scale design, Sol. Energy, 86:3084-3098, 2012 4. Kenisarin M. M., High-temperature phase change materials for thermal energy storage. Ren. Sust. Energy Rev, 14:955-970, 2010 Acknowledgment Funding by the Commission for Technology and Innovation is gratefully acknowledged