High-Temperature Combined Sensible/ Latent

advertisement

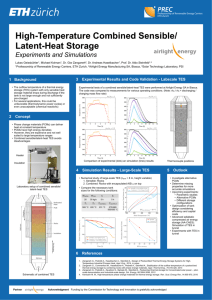

High-Temperature Combined Sensible/ Latent-Heat Storage for AA-CAES Experiments and Simulations Lukas Geissbühler1, Michael Kolman1, Dr. Giw Zanganeh2, Dr. Andreas Haselbacher1, Prof. Dr. Aldo Steinfeld1 1Professorship of Renewable Energy Carriers, ETH Zurich, 2Airlight Energy Manufacturing SA, Biasca 3 Experimental tests of a combined sensible/latent-heat TES were performed at Airlight Energy SA in Biasca. The model was compared to measurements for various operating conditions and multiple cycles. • At present, electricity storage with advanced adiabatic compressed air energy storage (AACAES) is considered to be the only large-scale alternative to pumped hydro storage, offering high cycle efficiency (70-75%) thanks to incorporation of a thermal energy storage (TES) system 0.0 1.0 Td ) [ ] Simulation Experiment, centerline Experiment, wall Td ) [ ] 0.4 Simulation Experiment, centerline Experiment, wall 0.2 (T 0.4 0.6 0.8 Td )/(Tc Td ) [ ] 4 Mat. Costs / Net Energy Output [$/kWh] xxx x x x x x 30 25 20 15 10 5 0 1 (t 2 100 Percentage of total material costs 410 6 7.6 8 9.2 11.4 10 Td,max [%] 4.3 4.7 6.8 80 43 42.5 6.2 6.8 6.5 12 4 Sensible, reference Combined 5.3 7.3 2 1 39.1 12.3 60.2 37.5 59.5 58.9 32.9 40 49.4 20 48.3 46.6 45 43.1 S14 S10 S8 Concrete PCM 6 C7 C6 ⌘ex > 98.5 % 4 6 8 10 37.8 34.5 33.2 32.4 C5 S2-13 S2-7 S2-6 Insulation Encapsulation Rocks 100 8.6 Outlook • Measure PCM properties for more accurate simulations • Simulation-based determination of heattransfer coefficients for different encapsulation configurations • Numerical optimization of TES considering efficiency and material costs 3 12 14 16 Td,max [%] 11.3 Thermocouple positions 5 4 0 14 5.6 41.9 60 0 • An unsteady one-dimensional heat transfer model was developed. The validated model is used to predict the dynamic behavior of largescale TES systems and compare the combined storage with the sensible only storage considering exergy efficiency and material costs for a given maximum temperature drop during discharging ( Td,max). 3 Dtpc )/Dtcycle [ ] 5 Percentage of total material costs 4 x x 0.00 ⌘ex > 95 % 836 1083 1237 1303 1348 1270 1680 200 0.20 Eout,cycle = 1000 MWhth Sensible, reference Combined Sensible, double insulation 35 Schematic of combined TES Partner 0.40 Eout,cycle = 23 MWhth Insulation 200 0.60 Comparison of material costs and exergy efficiency between sensible only and combined storages (with AlSi12) for given maximum temperature drops during discharging at steady cycling. 0 x x 1.0 0.80 Simulation Results - Large-Scale TES xxx x 394 0.90 Comparison of experimental (dots) an numerical (lines) results • An experimental setup was built consisting of a packed bed of rocks (sensible heat section) and steel encapsulated AlSi12 PCM tubes (latent heat section) on top (Etot = 42.3 kWhth). Air at ambient pressure was used as heat transfer fluid. Plate Td )/(Tc t/Dtc = 1 (T x/L [ ] 0.6 0.0 0.0 • The system of combined sensible/latent heat TES is studied using an experimental-numerical approach x x 0.95 t/Dtc = 2 Approach: x 3 2 0.85 1.00 0.8 • However, they are expensive and not well suited to large temperature ranges x 1 Simulation Experiment PCM • PCMs have high energy densities Rocks 0 1.00 Td )/(Tc t/Dtc = 1 1.0 • Phase change materials (PCMs) can deliver heat at constant temperature x x x x 1.0 0.4 0.2 Plate PCM 0.8 0.0 Concept • Combined sensible/latent heat TES avoids disadvantages 0.6 0.6 0.2 • For several applications, this is unfavorable (thermodynamic power cycles, chemical reactions) 120 90 0.4 PCM t/Dtc = 0 (T • The outflow temperature of a thermocline TES system with only sensible heat storage material drops during discharge if the tank is not large enough and not sufficiently pre-charged 2 0.2 0.8 x/L [ ] • Thermocline storage has gained increasing interest as solution for TES with potentially high efficiency and low costs. Experimental Results and Model Validation - Labscale TES Mat. Costs / Net Energy Output [$/kWh] 1 Background 6.7 20 23.6 26.3 80 7.3 9.4 13.9 10.3 15.2 17.1 15.9 60 37.1 14 35.6 34.6 31.9 0 • Experiments with TES for AA-CAES in tunnel • Sensible • Combined 29.8 26.4 40 20 • Simulation of TES for AACAES in tunnel 43 S16 40.7 S8 Concrete PCM 39.1 S6 37 34.5 30.6 C14 C8 C6 Insulation Encapsulation Rocks References 1. Geissbühler L., Kolman M., Zanganeh G., Haselbacher A., Steinfeld A., Analysis of industrial-scale high-temperature combined sensible/latent thermal energy storage, to be presented at the ASME-ATI-UIT conference on thermal energy systems, May 2015 2. Zanganeh G., Khanna R., Walser C.,Pedretti A., Haselbacher A., Steinfeld A., Experimental and numerical investigation of combined sensible-latent heat for thermal energy storage at 575 °C and above, Sol. Energy, 114:77-90, 2015 3. Zanganeh G., Pedretti A., Zavattoni S., Barbato M., Steinfeld A., Packed-bed thermal storage for concentrated solar power – pilotscale demonstration and industrial-scale design, Sol. Energy, 86:3084-3098, 2012 Acknowledgment Funding by the Commission for Technology and Innovation through the SCCER is gratefully acknowledged