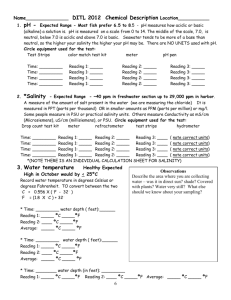

Fundamentals of Wettability

advertisement