Investor Presentation September 2015

advertisement

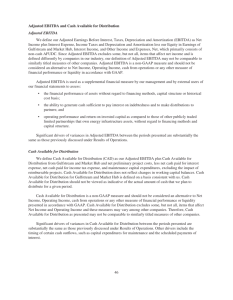

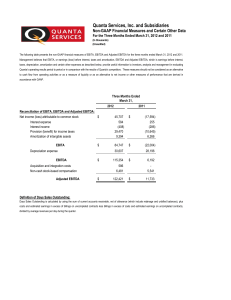

Investor Presentation September 2015 1 Disclaimer This presentation contains statements that constitute “forward looking statements” under the Private Securities Litigation Reform Act of 1995. All statements other than statements of historical facts contained in this presentation, including statements regarding our short-term and long-term growth strategies, efforts to develop and commercialize our products, future operations, future financial position, future revenue, projected costs, prospects, plans, objectives of management and expected market growth are forward-looking statements. These statements involve known and unknown risks, uncertainties and other important factors that may cause our actual results, performance or achievements to be materially different from any future results, performance or achievements expressed or implied by the forward-looking statements. The words “anticipate,” “believe,” “could,” “estimate,” “expect,” “intend,” “may,” “plan,” “potential,” “predict,” “project,” “should,” “target,” “will,” “would” and similar expressions are intended to identify forward-looking statements, although not all forward-looking statements contain these identifying words. These forward looking statements are only predictions and we may not actually achieve the plans, intentions or expectations disclosed in our forward-looking statements, so you should not rely on our forward-looking statements. Actual results or events could differ materially from the plans, intentions and expectations disclosed in the forward-looking statements we make. We have based these forward-looking statements largely on our current expectations and projections about future events and trends that we believe may affect our business, financial condition and operating results. The information in this presentation is current as of September 2015 and speaks only as of such date. We expressly disclaim any obligation to release any updates or revisions to any information presented herein, including any forward-looking statements, to reflect any change in our expectations or projections or any changes in events, conditions or circumstances on which any such information or statements are based for any reason, except as required by law, even as new information becomes available. All information and forward-looking statements in this presentation are qualified in their entirety by this cautionary statement. In addition to results presented in accordance with U.S. GAAP, this presentation and related tables include Adjusted EBIDTA, a non-GAAP financial measure. We have provided a reconciliation of this measure to the most directly comparable GAAP measure, which is available in “Reconciliations” starting on slide 20. We use Adjusted EBITDA as a measure of operating performance, because it does not include the impact of items that we do not consider indicative of our core operating performance, for planning purposes, including the preparation of our annual operating budget, to allocate resources to enhance the financial performance of our business and as a performance measure under our bonus plan. We also believe that the presentation of Adjusted EBITDA provides useful information to investors with respect to our results of operations and in assessing the performance and value of our business. Although we believe this non-GAAP financial measure enhances investors’ understanding of our business and performance, this non-GAAP financial measure should not be considered an alternative to or substitute for accompanying GAAP financial measures. The risk factors set forth in our Annual Report on Form 10-K for the year ended December 31, 2014 and filed with the SEC on March 13, 2015 pursuant to the Securities Exchange Act of 1934, as amended, are incorporated by reference into this presentation and should be read in their entirety alongside this presentation. 2 Disclaimer This presentation contains market data and industry forecasts that were obtained from industry publications, third party market research and publicly available information. These publications generally state that the information contained therein has been obtained from sources believed to be reliable, but the accuracy and completeness of such information is not guaranteed. This presentation also contains estimates and other statistical data made by independent parties and by us relating to market size and growth, size of insulation opportunity at various types of energy infrastructure facilities and other data about our industry. We obtained the industry and market data in this presentation from our own research as well as from industry and general publications, surveys and studies conducted by third parties, some of which may not be publicly available. For example, this presentation includes statistical data extracted from an off-the-shelf market research report (World Insulation - #2956) by The Freedonia Group, an independent international market research firm, and a separate custom market research report by Freedonia Custom Research, Inc., a wholly-owned subsidiary of The Freedonia Group, or Freedonia, which was commissioned by us and was issued in February 2014. Such data may be outdated and involves a number of assumptions and limitations and contains projections and estimates of the future performance of the industries in which we operate that are subject to a high degree of uncertainty. We caution you not to give undue weight to such projections, assumptions and estimates. The Freedonia Custom Research, Inc. Report, or the Freedonia Report, represents data, research opinion or viewpoints developed independently on our behalf and does not constitute a specific guide to action. In preparing the Freedonia Report, Freedonia used various sources, including publicly available third party financial statements; government statistical reports; press releases; industry magazines; and interviews with manufacturers of related products (including us), manufacturers of competitive products, distributors of related products and government and trade associations. The Freedonia Report speaks as of its final publication date (and not as of the date of this presentation). 3 Experienced Leadership Team Donald R. Young President, CEO and member of Board of Aspen Aerogels since 2001 Prior to 2001, worked in the U.S. and abroad in a range of senior operating roles for Cabot Corporation Graduate of Harvard College and earned an MBA from Harvard Business School Has served as CFO since 2006 More than 10 years of service as a SVP of New England Business Service, in senior financial and operating roles Earned a B.A. in Economics from Middlebury College and an MBA from the Wharton School of the University of Pennsylvania President & CEO John F. Fairbanks Vice President, CFO & Treasurer 4 Aspen Aerogels: An Energy Technology Company Designs, develops and manufactures innovative, high-performance aerogel insulation primarily used in largescale energy infrastructure process facilities Offers a superior combination of performance and long-term value End users save money, reduce energy use, preserve operating assets and protect workers Global network of energy-focused distributors, contractors and engineering firms Proven market adoption Used by 24 of the world’s 25 largest refining companies; 20 of 20 largest petrochemical companies Initial installations in approximately 30% of the world’s 640 refineries Installed base of >170 million sq. ft., >$400 million of product sales since 2008 Expanding capacity to meet demand Targeted Energy End Markets Geography 2014 Product Revenue by Region Europe 14% REFINERIES P E T R O C H E M I C AL P L AN T S USA 36% L N G & G AS PRODUCTION Asia Pacific 35% O I L S AN D S OFFSHORE POWER G E N E R AT I O N Latin America 9% Canada 6% 5 Unique Technological Advantages What are Aerogels? Our Breakthrough Technology Advantages vs. Traditional Insulation Aerogels are an amorphous silica solid Industrially robust Characterized by impressive material properties Best thermal performance of any widely used insulation product Unique product form Proprietary manufacturing process Reduced corrosion under insulation Patent-protected – 78 issued and 54 pending patents owned or co-owned worldwide Compact design and faster installation High durability and fire protection Lowest density solid -- ~97% air Lowest thermal conductivity Proven Manufacturing Process Our Aerogel Products Step 1: Fill fibrous batting with a liquid-solid solution Step 2: Extract solvents with supercritical carbon dioxide Step 3: Resulting dry,fiber-reinforced aerogel blanket Pyrogel XT / XT-E / XTF (hot insulation) Cryogel Z (cold insulation) 6 Disruptive Products with Compelling Value Proposition Best Thermal Performance Thermal Conductivity Traditional Insulation Pyrogel XT Two to five times better thermal performance Broad range of applications from -200°C to 650°C Temperature Range Reduced Corrosion Under Insulation Vapor Permeable Hydrophobic 50% to 80% reduced volume Space savings Compact Design & Faster Installation High Durability and Fire Protection Enhances plant safety Improves reliability Reduces a major maintenance expense Traditional Insulation Faster installation time with improved safety and logistics Excellent compression resistance, tensile strength, and vibration resiliency Fire protection Traditional Insulation; Installed on site Transport-ready; Supports modular construction 7 Overview of The Energy Insulation Market Energy Insulation End Markets – by Sector Energy Insulation End Markets – by Region $ Millions $ Millions $4,000 $4,000 $3,546 $3,546 $3,500 492 $3,000 523 $3,000 $2,814 $2,814 494 $2,000 $2,443 384 327 418 366 69 176 81 199 102 239 619 $2,500 $2,443 402 1,485 342 $2,000 1,089 903 $1,500 484 418 603 $1,000 $1,000 1,600 1,087 1,248 $0 2010 Power Generation Onshore Oil Production Gas Production $500 512 541 278 104 198 73 226 86 415 470 553 2013 2018 Canada Europe Middle East Africa $0 2013 2018 Petrochemical Offshore Oil Production Refinery 2010 USA Latin America Asia Pacific Source: Freedonia Custom Research Report - February 2014. 8 Global Distribution Network and Installed Base Distributor Contractor OEM Installed Base Installed in more than 40 countries worldwide 30 direct sales employees and 45 distributors Source: Company Management. 9 Industry-Leading End Users 10 Revenue Growth Revenue Growth 2009 to 2014 ($ in millions) $102.4 $86.1 $63.5 $43.2 $46.0 $28.6 2009 2010 2011 2012 2013 2014 11 Financial Overview 12 Financial Highlights Technology company with significant market adoption History of top-line growth Sufficient scale for positive cash flow from operations IPO proceeds are funding capacity expansions Expansions expected to offer attractive return on capital Modest ongoing maintenance capital expenditure requirements 13 2014 Financial Performance Strong top and bottom line growth Year Ended 12/31/14 12/31/13 $ 102,399 85,319 $ 86,094 75,363 $ 16,305 9,956 19% 13% 17,081 33,123 10,731 30,703 6,350 2,420 59% 8% (16,042) (19,972) 3,930 20% 10,183 8,781 119 10,061 4,426 3,670 122 4,355 (3,551) 1% 98% -97% ($ in thousands) Total Revenue Cost of Revenue Change Gross Profit Operating Expenses Operating Loss $ % EBITDA Add-backs: Depreciation & Amortization Stock-based Compensation Other Items Adjusted EBITDA $ 3,041 $ (1,815) $ 4,856 N.M. See slide 20 herein for a reconciliation of net income (loss), the most directly comparable GAAP measure, to Adjusted EBITDA for the periods presented. 14 First Half 2015 Financial Performance Revenue constrained, but solid bottom line growth Six Months Ended Change 6/30/15 6/30/14 $ 53,596 43,972 $ 48,978 42,207 Gross Profit Operating Expenses 9,624 15,066 6,771 17,789 2,853 (2,723) 42% -15% Operating Loss (5,442) (11,018) 5,576 51% 4,759 2,699 - 5,179 6,344 15 (420) (3,645) (15) ($ in thousands) Total Revenue Cost of Revenue $ % $ 4,618 1,765 9% 4% EBITDA Add-backs: Depreciation & Amortization Stock-based Compensation Other Items Adjusted EBITDA $ 2,016 $ 520 $ 1,496 -8% -57% -100% 288% See slide 21 herein for a reconciliation of net income (loss), the most directly comparable GAAP measure, to Adjusted EBITDA for the periods presented. 15 Quarterly Adjusted EBITDA History of Positive Adjusted EBITDA For the Three Months Ended LTM ($ in thousands) 3/31/14 6/30/14 9/30/14 12/31/14 3/31/15 6/30/15 6/30/15 Total Revenue Cost of Revenue $22,363 19,017 $26,615 23,190 $25,437 20,365 $27,984 22,748 $23,500 18,986 $30,096 24,987 $ 107,017 87,086 Gross Profit 3,346 3,425 5,072 5,236 4,514 5,109 19,931 Operating Expenses 6,244 11,546 7,437 7,895 7,259 7,807 30,398 (2,898) (8,121) (2,365) (2,659) (2,745) (2,698) (10,467) 2,631 339 15 2,547 6,006 - 2,513 1,054 - 2,492 1,382 104 2,184 1,295 - 2,574 1,404 - 9,763 5,135 104 432 $ 1,202 $ 1,319 734 $ 1,280 Operating Loss EBITDA Add-backs: Depreciation & Amortization Stock-based Compensation Other Items Adjusted EBITDA $ 87 $ $ $ 4,535 See slide 22 herein for a reconciliation of net income (loss), the most directly comparable GAAP measure, to Adjusted EBITDA for the periods presented. 16 Capacity Expansion Plan Annual Capacity (MM ft2 / year) Historical Projected 100 Plant 2 - Line 1 80 60 Line 3 Line 2 40 20 East Providence Line 1 Line 1 Expansion 0 2008A 2009A 2010A 2011A Nameplate Capacity(1), Year-End 2012A 2013A 2014A Effective Capacity(2), Annual 2015E 2016E 2017E 2018E Actual Production, Annual 1. 2. Nameplate capacity represents our projected maximum sustainable annual output Effective capacity is the capacity at which we can operate while maintaining the quality of our products and efficiency of our operations in a given period. Actual effective capacity is also impacted by the date within a given year on which we add the capacity. The projected nameplate and effective capacity for the years 2015 through 2018 are based on certain assumptions that the Company’s management believes are reasonable, but these assumptions could prove to be incorrect, which could result in actual capacity differing materially from the projections above. 17 Key Business Highlights 1) Disruptive insulation products offering superior value and performance 2) Attractive and growing energy infrastructure end markets 3) Substantial installed base with industry-leading end users 4) Significant growth opportunities: expanded market penetration and new projects 5) 29% 5-year revenue CAGR, EBITDA positive, growing profitability 6) Protected technology platform and proprietary manufacturing capability 7) Proven, scalable business model with attractive returns 8) Experienced management team with a demonstrated track record 18 Appendices 19 Reconciliation Year Ended 12/31/14 ($ in thousands) Net loss $ Interest expense Depreciation and amortization Stock-based compensation Loss on disposal of assets Gain on extinguishment of convertible notes Loss on exchange of convertible notes Costs associated with postponed public offering Write-off of construction in progress Adjusted EBITDA (66,324) 12/31/13 $ 50,281 10,183 8,781 119 $ 3,040 (47,611) 30,599 10,061 4,426 230 (8,898) 5,697 241 3,440 $ (1,815) Note: The table above presents a reconciliation of net income (loss), the most directly comparable GAAP measure, to Adjusted EBITDA for the periods presented. 20 Reconciliation Six Months Ended 6/30/15 6/30/14 ($ in thousands) Net loss $ Interest expense Depreciation and amortization Stock-based compensation Loss on disposal of assets Adjusted EBITDA (5,532) $ 90 4,759 2,699 $ 2,016 (61,196) 50,178 5,179 6,344 15 $ 520 Note: The table above presents a reconciliation of net income (loss), the most directly comparable GAAP measure, to Adjusted EBITDA for the periods presented. 21 Reconciliation Three Months Ended ($ in thousands) Net loss 3/31/14 6/30/14 9/30/14 12/31/14 3/31/15 6/30/15 $ (19,049) $ (42,148) $ (2,412) $ (2,715) $ (2,790) $ (2,743) Interest expense Depreciation and amortization Stock-based compensation Loss on disposal of assets Adjusted EBITDA 16,151 2,631 339 15 $ 87 34,027 2,547 6,006 $ 432 47 2,513 1,054 $ 1,202 56 2,492 1,382 104 $ 1,319 45 2,184 1,295 $ 734 45 2,574 1,404 $ 1,280 Note: The table above presents a reconciliation of net income (loss), the most directly comparable GAAP measure, to Adjusted EBITDA for the periods presented. 22 Investor Presentation September 2015 23