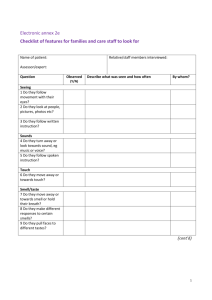

Fume Event MORs 2014 Jan-May

advertisement

Sheet1 FILE NO DATE MAKE/MODEL HEADLINE NARRATIVE REMOVED REMOVED AIRBUS - A320 200 - 232 PAN declared on final approach due to fumes in flight deck and passenger cabin. PAN declared due to fumes in the flight deck, pilots were on oxygen with masks and advised they needed no further assistance. Aircraft landed with no further incident. Supplementary 03/1/14: Strong smell of oily fumes on flight deck and at rear of cabin. Flight crew and two cabin crew at the rear used oxygen as a precaution. Pan declared at 10nm on finals for 27L. As it happened so late in approach oxygen used but no time to action fumes QRH. Stopped on taxiway and oxygen masks removed. Only a residual smell left. Cabin staff in rear galley reported strong fumes when securing cabin for landing. Crew reported feeling nausea and were instructed to don oxygen masks. Passengers appeared to be unaffected. Both rear cabin crew reported to hospital for medical checks. CAA Closure: The APU was removed and sent to the manufacturer for investigation. On initial inspection, black light was used to look for traces of oil in the bleed ducts and for any external leaks. No traces of oil were found. A borescope inspection was carried out looking for internal oil leaks or evidence of there having been oil leaks. Again, no traces were found. The APU was then test run. Black light was used during and after test and there was no evidence of oil in the bleed ducts or external oil leaks. Due to service wear, the APU has been disassembled and inspected. There were no findings after hardware inspection that would point to the APU being the source of the smell in cabin event. The root cause was not determined, however there have been no further reports since the APU was replaced. It was recommended that aircraft be monitored for any further events of this nature. REMOVED REMOVED AIRBUS - A320 200 - 232 Go-around flown due to ECAM warning 'F/CTL' with aircraft in alternate law. Electrical burning smell lasting 4mins. On Approach, at 4000 ' ECAM F/CTL Alternate Law, Protections Lost. Approach discontinued. SCCM reported electrical burning smell at rear of A/C. This smell dissipated after 4 minutes. Approach carried out as per ECAM resulting in a Flap 3 Direct law landing satis. Initial action to discontinue the approach. Route left turn to climb to SSA 6000' for TDODAR. SCCM reports burning smell from rear of A/C, PAN called made for urgency. Given radar vector ILS Approach R/W36. ECAM Action complete, NITS Brief given...N...Burning smell in A/C...I..Land...T...5mins S...Normal Landing. Smell dissipated after 4 mins. Approach flown Flap 3 Gear down AP ON in Alternate Law. Direct Law at AP Disconnect as per ECAM. Land satis. A/C stopped clear of R/W. Review carried out. Comms with SCCM advising all normal and to expect normal disembarkation on stand. Parked on stand and spoke to TRM on INT advising all normal and that the fire crew who were on stand to meet us could be stood down. Engineer called, AML completed. Verbal handover to next crew. Cabin crew and flight deck debrief, cabin crew ready to operate next sector Spoke to CM Spoke to Duty tech pilot and ASR Filed. Supplementary 11/02/14: On finals, ac started to climb. Noticed strong smell (acrid fumes ?? electrical) in rear galley and immediately reported to CSD via inter phone. CSD came to the galley and on returning to the fwd galley the alert call was made. NITS was given and CSD came to the rear to give this to us. AC landed and met by fire services. A few hours later, smoke was visible in the front of the cabin. Crew were seated for landing. Rear crew called me and said that there was a strong electrical burning smell in the rear. I went to investigate. The smell was as described. I called our pilots they said it was the same in the cockpit. The alert call was made. We went into cockpit and a NITS briefing was given. I wrote down the NITS details and repeated it back. Returned to cabin as we planned to land in five minutes. As short time prior to the smell of burning during decent the aircraft suddenly climbed- this was due to two cockpit computers failing. Our pilots decided not to land and check systems. I went to the rear galley to give a face to face NITS briefing as time so short. Crew briefed- normal landing. Aircraft followed by four fire engines. Captain gave a full debrief before leaving the aircraft. PAN PAN call made to ATC. DOMS advised- support offered to cabin crew. Whilst on the ground, engineers checked aircraft several cabin lights failed at one point rows one two and three had light grey smoke visible an hour and a half after landing. CAA Closure: Initial investigations by Line Engineering for the alternate law focused on the ADR 1 + 2 + 3 interface tests which were carried out with no fault found. The burning smell was investigated by examining the wiring and connectors in the avionics bay for any evidence of burning, none was found. The aircraft was released back into service. Tail Support Group (TSG) raised several work requests for intensive wiring checks of the air data system based on ACMS reports highlighting faults with ADR 1 and ADR 3. ADIRU 1 was replaced. Further reports of ADR 1 were received from the PFR, TSG then raised an additional work request to interchange ADIRU 1 and ADIRU 3. Hard fault remained with ADR 1 after this activity. Additional ASR subsequently raised for an additional alternate law event, with details of an FCU fault. TSG raised further work instructions for intensive wiring checks of the air data system, which reported no faults, and to replace the FCU and ELAC 2. TSG reviewed the flight data and determined the AOA 3 sensor was at fault and requested it to be replaced. Since re-entering service, the aircraft has been noted to operate without any further reoccurrence. The identification of the AOA 3 sensor and the FCU and ELAC are likely to be hard faults. The ADIRU is not suspected to be the root cause of this scenario, which is supported by the interchange of ADIRU 1 and ADIRU 3 which did not transfer the fault from ADR 1. Workshop report for the removed AOA confirmed an ingress of water in the sensor. The workshop report for the ADIRU is also requested to determine if this unit also had a hard fault as it was only on wing for 14 days. Page 1 Sheet1 REMOVED REMOVED AIRBUS - A319 100 - 131 Smell/fumes in passenger cabin. Strange sour, ‘cheesy’, stale smell noted by all crew inc Flight Crew upon taxi, take off, and top of descent. The purser had to use medication as the smell made him short of breath. Seemed like something in the air con, and not anything coming from the toilet at all. I have experienced this smell before. It was so bad today I had to cover my mouth & nose with my scarf on the jump seat. CAA Closure: Following these reported events, engine ground runs were carried out, switching between engines and packs to identify the potential sources of odour. On investigating the second event, the engineer carrying out the run suspected that there was an odour noticeable when the nr2 eng was running with the nr2 pack supplying air. Following this report, the manufacturer's recommended troubleshooting and an operator specific workpack, aimed at identifying and eliminating cabin odour, were carried out. During this troubleshooting, the pack 2 inlet duct was separated at the forward end with the juncture of the cross-feed duct and inspected for any evidence of oil, with none noted. Upon inspection of the APU, evidence of oil was found on some of the external components and there was also evidence of oil wetting in the load compressor cavity drain. An oil leak from this drain can potentially indicate a failed carbon seal that would allow for internal oil leakage into the APU compressor and subsequently into the air conditioning packs. It was suspected that the APU contaminated the nr2 pack and was subsequently locked out and replaced. Following replacement of the APU, the aircraft flew regular services for 1 month before the next reported odour. Again, all of the manufacturer's recommended troubleshooting and operator requirements was carried out. During the investigation, the nr1 engine LPT shaft end cap seal was replaced due to slight oil staining inside the inlet cone. Following the replacement, engine and APU runs were carried out using Aerotracer equipment to detect for any evidence of oil in the cabin air. There were no indications of oil being present in any APU/Engine/Pack configuration. All tests passed and the aircraft was returned to service. After further subsequent smells, the aircraft was refused for service due to the history of cabin odour and reports of a smell on boarding the aircraft. The aircraft was removed from service and engineering carried out the cabin odour workpacks as per previous cases. During inspections, a 'significant' volume of de-icing fluid was observed in the APU intake and plenum chamber. The location of this fluid made it very likely to be ingested into the air conditioning system via the APU. The fluid was removed and the APU intakes were cleaned and the aircraft returned to service. On the first sector post cleaning of de-icing fluid from the APU intake, the aircraft was again removed from service, with a significant quantity of de-icing fluid still clearly visible on the empennage despite the aircraft having flown two sectors. There was no evidence of this fluid having been ingested into the APU on this occasion and the intake was still clean from the previous input, but a visual inspection of the APU inlet guide vanes found that de-icing fluid residue was still present. An APU compressor wash was subsequently carried out to clear the internal APU components of any residual fluid. The aircraft was returned to service and there have been no further reports. The APU that was removed following the first two reports was inspected by the repair agent who advised the operator that while there was no initial indications of an internal oil leak, there was evidence of de-icing fluid ingestion. This was supported by the operator's finding of de-icing fluid pooled in the APU inlet door. It is suspected that the newly installed APU gradually ingested much of this fluid until such time that it was causing cabin odour events again. This gradual ingestion is supported by the month long interval between APU replacement and the third report. There has been no report of smells in the cabin or flight deck following the compressor cleaning of the APU which was carried out following the final report and the aircraft has flown over 100 sectors since. It is suspected that the de-icing fluid, which was originally ingested, was still present on some of the APU internal components despite the extensive external cleaning that was carried out. This internal contamination was allowed to continue entering the air conditioning system resulting in the reported cabin odour events. The APU compressor wash removed what remained of this residual fluid, thereby eliminating the cabin odour issues. The relatively high viscosity of de-icing fluid means it can potentially remain stagnant in ducting or on components for some time and might only move into an airflow when the aircraft is pitched at high angles e.g. climb. Once vaporised, a very small volume of fluid can generate a noticeable odour. As a result of this investigation, engineering are introducing a routine task to 2A checks to inspect the APU inlet ducts on all the fleet type for evidence of contamination or pooling fluids. APU compressor washing is also being added as a step in the existing cabin odour work packs where there is evidence of de-icing fluid ingestion. Page 2 Sheet1 REMOVED REMOVED AIRBUS - A320 200 - 232 PAN declared and goAt approx 1400 on finals with FO as PF, ATT indicator on PFD2 erratic with +- 45 degree roll indications. Control handed to Capt. ATT HDG selected to around flown due to FO3 as per ECAM. All indications lost on PFD2. Lost autopilot, autothrust (thrust lock at some point), and travel limit fault. Go around initiated in raw avionics failure on finals. data (no flt directors). Possible 1/2 knot flap overspeed in missed approach. PAN declared. Vectored for further ILS, manually flown in raw data and manual thrust by Capt (FO had no PFD indications). A confused scenario with a lot happening at a critical stage of flight. AC had similar fault on take-off on previous flight. Supplementary 06/02/14: I was Air 1 Controller 23R single rwy ops and had a trainee with me in position. We had just one aircraft on the frequency. At approximately 2nm from touchdown we observed the aircraft to begin a missed approach. There was no communication from the pilot at this point. We initiated the missed approach alarm to alert APP SOUTH and after the aircraft was established in the climb the trainee advised it to fly a standard missed approach and gave the QNH. The pilot replied with Roger and we visually saw the aircraft begin the turn to 360 degrees before we lost sight of it over the VCR. As the pilot has not confirmed the cleared level of 3500A the trainee advised him again of it, the pilot replied with a read back of 3500A and then STANDBY. From his voice we could tell that there was something wrong. Approximately 30 seconds later the pilot came back on frequency, declared a PAN and requested immediate return to the airfield with a complete avionics failure, he said they were hand flying the aircraft. I took control of the RT at this point and asked the pilot if he required radar vectors or Visual approach. He replied they needed radar vectors and we passed him back to APP SOUTH phoning them so they were aware what he wanted. We advised the Watch Manager of the PAN and the reason for it, he initiated a FULL EMERGENCY with the airport AFS. The aircraft made a subsequent approach and normal landing around 10 minutes later. The runway was inspected behind him as a precaution and was declared clear and serviceable. The pilot decided there was no need for him to talk to the AFS on 121.6 and was happy to taxi to stand. CAA Closure: Investigations found a failed DMC, which resulted in the loss of the First Officer's displays and the lower ECAM. The intermittent faults of the Rudder Travel Limiter are suspected to be responsible for the ECAM messages on the previous rejected take-off and during the event sector. The replaced terminal block was suspected as the cause for the transient FAC faults / ECAM messages during periods of high vibration. A failed ADIRU was responsible for the erratic attitude indications due to the failed oscillator on the CPU card was later rejected. The CPU card was replaced during the last shop visit and failed on the first subsequent flight. The subsequent loss of some IR3 computed parameters based on the lost ADR2 caused the loss of automatics and flight directors. Since the completion of all these actions, no recurring or similar events have been evident on this aircraft. It is assumed, from the content of the ASR, that the Flight Crew were not aware of the subsequent ADR2 failure after the initial IR2 fault, which may explain why the First Officer's position was not switched also to ADR3 and may have prevented the loss of automatics. Additionally, had the EIS DMC 3 selector been switched to the First Officer's position, the lost displays would have been restored. No technical recommendations have been identified that can prevent the likelihood of re-occurrence. Page 3 Sheet1 REMOVED REMOVED AIRBUS - A320 200 - 232 Go-around flown due to ECAM warning 'F/CTL' with aircraft in alternate law. Electrical burning smell lasting 4mins. On Approach, at 4000 ' ECAM F/CTL Alternate Law, Protections Lost. Approach discontinued. SCCM reported electrical burning smell at rear of A/C. This smell dissipated after 4 minutes. Approach carried out as per ECAM resulting in a Flap 3 Direct law landing satis. Initial action to discontinue the approach. Route left turn to climb to SSA 6000' for TDODAR. SCCM reports burning smell from rear of A/C, PAN called made for urgency. Given radar vector ILS Approach R/W36. ECAM Action complete, NITS Brief given...N...Burning smell in A/C...I..Land...T...5mins S...Normal Landing. Smell dissipated after 4 mins. Approach flown Flap 3 Gear down AP ON in Alternate Law. Direct Law at AP Disconnect as per ECAM. Land satis. A/C stopped clear of R/W. Review carried out. Comms with SCCM advising all normal and to expect normal disembarkation on stand. Parked on stand and spoke to TRM on INT advising all normal and that the fire crew who were on stand to meet us could be stood down. Engineer called, AML completed. Verbal handover to next crew. Cabin crew and flight deck debrief, cabin crew ready to operate next sector Spoke to CM Spoke to Duty tech pilot and ASR Filed. Supplementary 11/02/14: On finals, ac started to climb. Noticed strong smell (acrid fumes ?? electrical) in rear galley and immediately reported to CSD via inter phone. CSD came to the galley and on returning to the fwd galley the alert call was made. NITS was given and CSD came to the rear to give this to us. AC landed and met by fire services. A few hours later, smoke was visible in the front of the cabin. Crew were seated for landing. Rear crew called me and said that there was a strong electrical burning smell in the rear. I went to investigate. The smell was as described. I called our pilots they said it was the same in the cockpit. The alert call was made. We went into cockpit and a NITS briefing was given. I wrote down the NITS details and repeated it back. Returned to cabin as we planned to land in five minutes. As short time prior to the smell of burning during decent the aircraft suddenly climbed- this was due to two cockpit computers failing. Our pilots decided not to land and check systems. I went to the rear galley to give a face to face NITS briefing as time so short. Crew briefed- normal landing. Aircraft followed by four fire engines. Captain gave a full debrief before leaving the aircraft. PAN PAN call made to ATC. DOMS advised- support offered to cabin crew. Whilst on the ground, engineers checked aircraft several cabin lights failed at one point rows one two and three had light grey smoke visible an hour and a half after landing. CAA Closure: Initial investigations by Line Engineering for the alternate law focused on the ADR 1 + 2 + 3 interface tests which were carried out with no fault found. The burning smell was investigated by examining the wiring and connectors in the avionics bay for any evidence of burning, none was found. The aircraft was released back into service. Tail Support Group (TSG) raised several work requests for intensive wiring checks of the air data system based on ACMS reports highlighting faults with ADR 1 and ADR 3. ADIRU 1 was replaced. Further reports of ADR 1 were received from the PFR, TSG then raised an additional work request to interchange ADIRU 1 and ADIRU 3. Hard fault remained with ADR 1 after this activity. Additional ASR subsequently raised for an additional alternate law event, with details of an FCU fault. TSG raised further work instructions for intensive wiring checks of the air data system, which reported no faults, and to replace the FCU and ELAC 2. TSG reviewed the flight data and determined the AOA 3 sensor was at fault and requested it to be replaced. Since re-entering service, the aircraft has been noted to operate without any further reoccurrence. The identification of the AOA 3 sensor and the FCU and ELAC are likely to be hard faults. The ADIRU is not suspected to be the root cause of this scenario, which is supported by the interchange of ADIRU 1 and ADIRU 3 which did not transfer the fault from ADR 1. Workshop report for the removed AOA confirmed an ingress of water in the sensor. The workshop report for the ADIRU is also requested to determine if this unit also had a hard fault as it was only on wing for 14 days. REMOVED REMOVED AIRBUS - A320 200 - 232 Fumes in the flight deck during climb and on approach. On climb out, a strong oily smell was evident in the flight deck. After approx 5mins, the smell dissipated and flight crew elected to continue the flight. During final approach passing 4000', the strong oily smell returned. Flight crew donned oxygen until after landing. The landing was without further incident. ATC were informed that the flight crew were on oxygen and had fumes in the flight deck. Since the fumes event occurred at a late stage of the approach the crew did not action the smoke/fumes QRH check list as the priority was to establish communications on oxygen and complete a safe landing. In both cases of fumes the engine anti ice was on and the aircraft being reconfigured with flaps. The Cabin crew informed us that no unusual smells were evident in the cabin during both events. After vacating the runway the flight crew stopped the aircraft to complete the after landing checklist. The flight crew elected to turn the APU bleed on and the fumes cleared. The aircraft was taxied to stand without further incident. CAA Closure: This is the first reported event on this aircraft and there had been no recent engine or APU changes. The oil consumption rates were well within limits. Engine runs were carried out up to 51% due to wind conditions and workpacks performed AMM. High power ground runs were performed for 1h10mins but no smells were detected. The troubleshooting was unable to establish the cause of the event. Page 4 Sheet1 REMOVED REMOVED AIRBUS - A380 800 - 841 Strong, oily smell on flight deck, crew used oxygen. On take-off, the flight deck and fwd cabin area was filled with a very strong smell (only) of oil. This was identified from previous experience of this smell. Smell persisted until passing FL220 (about 20 minutes). During climb out the length of time that the smell persisted caused the captain to feel slightly nauseous. Crew oxygen was used by the Captain only and nausea subsided. Returned to normal breathing when smell subsided at FL220. Crew reported that smell very strong in front half of main cabin but not noticeable to rear of cabin Heavy captain on flight deck recognised the smell. Maintrol contacted in cruise and data given on oil quantities which showed engine 2 to be 1.5 quarts less than the other 3 engines which were equal. Engine 2 had been topped up with 1quart during transit. Anecdotal evidence from reviewing AML would indicate that engine 2 has been uplifting more oil than other engines. CAA Closure: Following the crew reports, physical inspections were completed on the aircraft by Engineering. They were unable to detect any recognisable odour on the aircraft, cabin or flight deck, when they were able to access the areas reported to have had the odour. This was some significant time following the landing. The investigations included engine borescopes, ground running with the Aerotracer, selecting alternate pack, engine and APU supplies at varying temperatures. No odour was noted by the engineers running the engines and APU or the Technical Services engineers present. The Aerotracer detected no sign of known oil or other fumes / odour for which it had been calibrated. The oil consumption and levels of oil during the flight were commented on as it was identified that the number two engine had slightly higher oil consumption / oil uplifts on that specific flight. The oil consumption on this engine has been stable since entry into service and is well within expected oil consumption limits. The engine only stands out as it happens to be the highest value out of all the installed engines. There is no reason that this engine should be any more likely to be the source of the cabin odour. Historically on this aircraft, there had been no reported incidents previously during service and one report following build and testing. The cause behind the pre-delivery event was attributable to extensive ground running, multiple starts and cranks leading to low air / oil pressure seal sealing. As the cabin odour has only been reported once, this ASR has remained open to allow for additional trouble-shooting should further evidence emerge during recent operation. No such evidence has become known. Engineering have been unable to reproduce the odour event or detect residual odour or unusual staining on any part of the aircraft. One small bottle of mustard salad dressing oil was found on the flight deck following the incident. This was unsealed but with the top fastened securely and it was not considered that this item is related to the event, nor was any staining observed in that general area. The root cause could not be determined and no further actions are recommended at this time. Engine Management will continue to monitor all fleets for sources of odour generated by engines and APUs. REMOVED REMOVED AIRBUS - A319 100 - 111 Fumes in cabin and flight Doors closed and awaiting pushback with both packs on, supplied by APU bleed. Weather was dense freezing fog. Smelled acrid burn smell of oil in deck caused cabin crew Cockpit. Funny feeling in throat, just considered whether to switch the APU Bleed off but APU performed auto shut down. Fumes Report filed and crew illness. and passengers were transferred to another A/C. Cabin crew than reported to me that they recognized smell of fumes of oil in the mid and aft cabin as well, together with some thin smoke. Crew member reported after the flights today that she had headache from that smell. That was not reported on the fumes report as I got this information later into the day. REMOVED REMOVED AIRBUS - A319 100 - 131 Fumes in the cabin after engine start up. REMOVED REMOVED AIRBUS - A319 100 - 131 Burning fumes in cabin. Source unidentified. REMOVED REMOVED AIRBUS - A320 200 - 232 Strong fumes at the back Several crew reported headaches and feeling unwell. of the aircraft causing cabin crew illness/incapacitation. REMOVED REMOVED BOEING - 737 400 - 436 Fumes (burning smell) in After disembarkation a burning smell was noticed throughout the cabin. Smell began to disperse after de-powering the a/c. A/c depowered and the cabin. engineers called. REMOVED REMOVED AIRBUS - A319 100 - 131 Fumes in the cabin caused cabin crew to feel nauseous and lightheaded. The source of the burning smell could not be identified and was noticed by passengers and cabin crew throughout the cabin. The smell did eventually cease after 2 or 3 minutes. After landing the aircraft was stopped and a further report was requested by the flight deck prior the aircraft parking on stand by which time no smell of burning was detected. The wind was very light and variable and we may have flown through some residual smoke from a ground based fire! It is possible the smell may have come from the air packs as large thrust changes may have moved any residual oil or fluids in the system lines. Tech log entry made and next flight deck crew advised On the return sector, there was a smell of fuel during take-off before the gear went in the vicinity of doors 2. The same smell was experienced on the outbound sector (562) however it was stronger. The smell lasted for a similar duration of approx 30 seconds. Immediately after take-off (before the gear went up) there was a smell of fuel in the vicinity of doors 2. This was the return sector, the same smell was experienced on the outbound sector however the smell was not as strong on the return sector. It lasted for similar duration (approx 30secs). Supplementary 21/03/14: Immediately after take-off( before the gear went up) there was a strong smell of fuel in the vicinity of doors 2. I was operating as NO 2 crew member which is a regular position for me to work. The smell hit me straight away as an unusual smell. My colleague operating NO 3 position confirmed the smell. The smell lasted approx 30 seconds then dissipated. Approx 45 mins into the flight my colleague remarked that she was feeling light headed, I myself felt slightly nauseous and light headed. Page 5 Sheet1 REMOVED REMOVED BOEING - 747 400 - 436 Fumes reported in cabin. Crew reported acrid smell but nothing visible near D3L/R and seats 29JK with additional suspect hotspot behind fuselage panel aft of D3R. QRH SMOKE NNC initiated and Capt kept comms open with crew communicator. IFE & PC power switches confirmed OFF in CSD office. As information flowed from crew to Capt smell appeared not to reduce after isolation of L & R UTILs so proceeded to switch off Pack 2 whilst crew used jemmy and BCF (total 2 discharged) into fuselage panel & seat 29J under which hot IFE box discovered. Hotspots observed to cool off after discharge of BCFs. PAN declared and Oceanic ATC forewarned of possible div. Once problem contained it was decided to continue to destination after consultation with MAINTROL and visual check of seats/panel and CSD office switches by Flt Crew. PAN later downgraded with ATC. Crew with further BCF positioned to monitor original hotspots. Cabin crew reported persistent headache, sore throat and sinus pain. Engineering inspected areas and found audio video unit at 29J with distinct burnt odour. Noted balling dust in floor area but no charring or smoke staining. No electronics or burns found within. Suspect possible wiring damage or AVU software download fail. CAA Closure: Maintenance action following this incident confirmed the burning smell was emanating from the Audio Video Unit (AVU) located under seat 29K. The AVU is part of the passenger in flight entertainment (IFE) system. On replacement of the AVU a full inspection of the area was carried out, checking for damaged cables/connectors/contacts with nothing found. Software could not be loaded to AVU following replacement so IFE in seats 28JK to 31JK isolated in accordance with MEL for return flight. At base, software loaded and system tested and found working satisfactorily. The aircraft was monitored for the next two sectors and IFE operation was normal. AVUs are repaired at the organisation's workshop. There are more than 8,000 AVUs from this manufacturer installed on the operator's fleet. A large number of AVUs are sent to the workshop each month for repair but are not tracked by serial number and it was not been possible to locate the AVU removed following this incident. The AVU consists of a metal box containing two cooling fans, a power supply and a number of electronic circuit boards. It is known that on rare occasions, discrete components such as capacitors and diodes can draw high current when they fail. This can cause a very strong smell of burning for a short time prior to the component failing open circuit. The cooling fans within the AVU vents this burning smell into the cabin. It is highly probable that the burning smell was caused by a failing electronic component. Considering the number of units in service and the fact the AVU has been in service since 1999, there are very few examples of AVU component failure causing a burning smell in the cabin. In addition, the components fail in a fail-safe manner in as much as the component fails open circuit, at which point the heat source for the burning smell is removed. Components in the AVU are designed to be self extinguishing and safety features within the AVU performed correctly to prevent the overheating component developing into a fire. No further action proposed following this incident. REMOVED REMOVED AIRBUS - A319 100 - 111 Fumes and misting in the As we were ready to go but awaiting departure due to slot restrictions, passengers informed the Crew that they could smell burning in the cabin. Cabin cabin prior to departure. Crew had already detected it and the CM had asked CC4 to return to the front of the cabin to confirm her suspicions about the smell. When she got to the forward galley she said that the Crew in the rear had already noticed the smell and were concerned about the misting. The oven and brewer was switched off, the toilet was checked and some water put into the bin to avoid any problems there. The Captain was informed. After a few minutes, the Captain walked through the cabin but the smell and misting was already beginning to disperse. To be on the safe side, the engineer was called and the holds were checked as we had electric wheelchairs stowed. Nothing was found and the smell, which was like burning paper, was attributed to de-icing fluid and we were cleared to go. REMOVED REMOVED AIRBUS - A321 200 - 231 Strong fumes in the Whilst at the holding point of the runway we had a strong smell of fumes in the cabin, especially at the rear of the aircraft. There was an aircraft in front cabin caused cabin crew of us and other aircraft around. This aircraft also had a problem with the APU on stand. I received a call illness. from crew member at doors 4 who informed me that it was unbearable and they were going to come further forward to see if it helped. I phoned the flight crew who said they were aware of the fumes smell and that we would be taking off in minutes and that hopefully it would subside. One crew member was close to going onto oxygen. Other crew also suffered headaches after.. I felt slightly light headed but this subsided after takeoff. The next day I have a sore throat.. Supplementary 26/03/14: Strong smell of fuel/fumes in cabin whilst at the holding point of 09R we had a strong smell of fuel in the cabin ( I was seated at doors 3r) it lasted for a considerable amount of time ( around 10-15 mins) there were a lot of other aircraft around us & in particular one in front. The crew at doors 4 also experienced it, they called the purser and flight crew to inform them. Flight crew said they were aware & knew it was particularly bad. After the smell had cleared I suffered with a headache for the remainder of the flight. Symptoms of fuel inhalation subsided after disembarking the aircraft. Supplementary 26/03/14: Upon taxiing out for take-off, we encountered an increasingly strong fume smell. After a while the fumes were so strong that the crew in the aft of the aircraft called flight crew and also left their seat area due to the fumes. Flight crew were aware of the fumes and knew it was particular bad /strong. I started feeling really light headed and dizzy and my heart/ pulse were raised very high. it was getting a bit like a razor blade in my throat. after takeoff the fumes smell cleared but my conditions did not fully. even after a good night’s sleep it still is there and I don’t feel 100% alright. I started 7 days ago on this particular aircraft and the APU was broken then, and still today. The aircraft needed start up help from ground equipment and the climate in the cabin was always hot / stuffy! So the air condition was working/blowing hard trying to get down to set temp as we were taxiing out as well!! REMOVED REMOVED BOEING - 747 400 - 436 Oil fumes in flight deck. During descent passing 15000 ft, dirty oily fume type smell entered flight deck. Lasted approx two minutes and returned approx three times during descent to around 8000ft. Noticed bitter taste in mouth during descent and after landing. Tech log entry made, ASR raised. Page 6 Sheet1 REMOVED REMOVED AIRBUS - A319 100 - 111 Fumes in the flight deck and cabin described as wet socks. During approach of CC4 reports smell of wet grass. Since CC4 is a new entrant 3 star CM tries to investigate further on the nature of the smell, making him explain well what kind of odour he was smelling and trying to rule out with his help all the critical smells (electrical etc.). CC4 remains sure its smell of wet grass. All passengers were wet for boarding during torrential rain and unprotected steps. CM asks the other CC but no one else could smell the odour. On the subsequent sector, also while preparing cabin for landing CC3 and CC4 smell a strong smell of wet socks in the cabin and in the front galley. CM reports it to the flight deck entering into the f/d and once there finds the smell there is strong and persistent. F/O reports to have smelt it as well. Once on the ground Cpt suggests crew to be checked by a doctor for toxic fumes. Doctor finds all crew fit to continue flying so crew accepts to operate last sector back on another a/c. Supplementary 27/3/14: During descent at around fl. 200 the first officer reported he smelled something out of the ordinary. It was the discussed with the captain who did not smell anything out of the ordinary and it was decided that whatever the smell was it seemed to disappear again. A few minutes later the cm comes into the flight deck and reports a smell of wet socks in the mid and forward part of the cabin. Upon entering the flight deck she also notices a smell in the flight deck of the same thing. We are in the last part of the initial approach into an area of high terrain and the captain decides to have a further conversation upon arrival as both the captain and first officer could not smell anything out of the ordinary at this point in time. Arriving on stand the cm reports the smell was noticed by all crew members and another cc had noticed a similar smell earlier on in the day but after conferring with the cm had thought it was because of heavy rain and boarding wet passengers. This was not communicated to the captain at that time. The cm also reported to have a bit of a burning sensation in her throat. The captain at this point decided to advice MOC of the problem and provide the crew with a doctor for a medical check before further flights. This was done and another ac was used to return to home base. Nothing out of the ordinary was found during the medical check up. REMOVED REMOVED AIRBUS - A321 200 - 231 Cabin crew illness. During climb, passing approx 10,000', purser reported to cap that four (out of total of five) cabin crew had reported various mild symptoms including lightheadedness, slight nausea, and mild headache. No odours, smoke, or fumes reported. No pax reported symptoms. Capt reviewed and considered QRH Smoke/Fumes procedure but since no perceptible odours/fumes, it was not relevant or actioned. Capt ensured that all crew were fully fit to continue flight, all crew agreed symptoms were mild and completely non-incapacitative. Capt and FO reviewed all options and discussed mitigation options, including use of crew O2 if any crew became faint or reported worsening symptoms. Flight continued. Capt conducted debriefing with crew, informed DFCM, DOMs, HS, and Occupational Safety Team. HS cleared flt crew to continue using self-assessment, as we remained asymptomatic. Engineering were informed; as no fumes or odours were reported/detected, no further action taken before next departure. REMOVED REMOVED AIRBUS - A319 100 - 131 Fumes in flight deck. Passing 6000 feet in descent, after prolonged idle power, selecting anti ice on, both pilots noticed strong odour in flight deck. Both describe as sweet almond like odour. Cabin crew immediately called to report strong sour burning smell in the cabin. Both packs turned off immediately. Consideration given to oxygen donning and smoke checklist. Smell immediately started to reduce in severity. Pilots both agreed better to remain off oxygen for communication, with option to don masks if smell returned. Smell dissipated completely and normal landing some 5 minutes later. Crew reported smell reduced after the packs were switched off too. Both pilots and crew chatted to observe each other and no symptoms of reduced function, or any other symptoms, noted. Noted aircraft had recent history. Page 7 Sheet1 REMOVED REMOVED AIRBUS - A319 100 - 131 Aircraft returned due to fumes in the flight deck causing flight crew illness. All crew members taken to hospital for tests. Shortly after take-off the FO (PNF) reported that he smelt fumes. I thought that it was possibly bread in the oven. FO then reported feeling ill. I then noticed the smell and also started to feel ill. Oxy masks donned. Engineers have reported that the vent blower had failed. Oxy masks donned and PAN declared with NITS to ATC. QRH smoke/fumes started but then fumes removal QRH deemed to be more relevant. Radar vectors to runway 07C. Control handed to FO and QRH stopped to focus on approach and landing. Alert call made and NITS briefing conducted. Brief PA made to passengers. Auto approach and auto land planned. Manual landing conducted. Stopped and reassessed on runway, liaised with fire services. Vacated runway and parked at nearby remote stand. Further PA made to passengers. Despite using oxygen at 100% and emergency, we both felt very ill and debilitated. After parking/shutting down we left the flight deck to be attended to by medics. Command was handed to fire chief who liaised with PSR and passengers disembarked via steps. No fumes or illness reported by passengers. ASR filed. Authorities liaised with and report completed. DFCM and duty tech manager contacted. Flight and cabin crew taken to hospital for tests. Flight crew hospitalised for 24 hours observation. CAA Closure: A review the Post Flight Report for this sector shows a 'Vent Blower Fault' maintenance message. Engineering carried out a smoke inspection iaw relevant task and the smell was isolated to the flight deck and a residual smell around the vent blower fan was identified. The vent blower fan was replaced. On replacing the vent blower fan, it was however noted that there was no sign of damage or burning on the removed fan and therefore the investigation continued. other checks were carried out and both engines and APU were inspected for signs of oil with no contamination found. During all pack/engine combinations the odour was present, and increased in strength at 1.26 EPR. The odour was also present at full hot and full cold temperature selections. At no point were any engine/APU oil, or hydraulic fluid leaks detected. The odour dissipated when APU air was selected and did not return. Investigations now focused on the air conditioning system with both cabin fan air recirculation filters and the avionic ventilation filter cartridge being replaced. The left hand pack condenser and reheater were replaced and swabs taken and routed to Powerplant for analysis. Both packs were purged and inspected and a specific Workpack was then applied to the left engine and left pack combination. The engine was run at 1.26 EPR and a very slight change in cabin air quality was noted which quickly dissipated. The engine continued to run at 1.26 EPR for two minutes and no further smells were observed. When engine power was increased to 1.3 EPR, the odour briefly appeared for five seconds and then disappeared. The bleed delivery temperature was greater than 185 degrees centigrade, with a similar pack outlet temperature and hot air selected on. The engine was run at various settings and through the full range of pack temperatures. The air quality remained good, however on increasing the pack temperature to hot, a brief odour would appear again and quickly dissipate. Applying the Workpack to the right engine and right pack combination produced similar results. However on running the APU and left/right pack combination, no change in air quality was observed. A consultation with Airbus indicated that pollen ingested by the engine into the air conditioning system may have been a factor as this will give off an odour at temperatures greater than 160 degrees centigrade. This may explain why the air quality did not change when running the APU, as this temperature was lower than 160 degrees centigrade. The engines/packs/APU were run for a total of ninety minutes at varying power settings and temperatures and no ill effects on personnel were reported. It is likely that the odour observed was a result of engine ingestion of external contaminant (possibly pollens), which was then dispersed throughout the air conditioning system. It is not possible to confirm or deny whether pollen was the only source of contaminant, but it is a likely scenario based on the fact that pollen will only produce an odour when burned at high temperatures similar to those recorded during the engine/pack runs, yet the smell was absent during runs using the lower temperatures of the APU. Airbus is confident that this is indeed the root cause and have subsequently added 'Ingestion of Pollens' to the list of 'Possible Sources Affecting Cabin Air Quality' in Wise article EngOps-16325. REMOVED REMOVED AIRBUS - A319 100 - 131 Smoke fumes evident in During the descent SCCM reported to FD that a smokey smell was evident in vicinity of rear toilet. Not a cigarette smell. Concentrated around floor area. vicinty of rear toilet. No source apparent and nothing visible. Flight crew actioned initial actions of smoke QRH. No smoke was visible, no ECAM warnings were present. ATC were informed that an expeditious approach was required as flight crew were investigating a strange smell. Approach continued to normal landing. After landing flight crew asked fire services to inspect outside of ac. Nothing was evident. SCCM reported same smell evident in forward part of ac. Permission gained from ATC to continue to stand with fire services in attendance. Passengers disembarked normally. Fire services inspected ac with heat cameras. Nothing found. Stn manager informed. REMOVED REMOVED AIRBUS - A319 100 - 131 Unpleasant smell/fumes reported in cabin as landing gear was lowered. REMOVED REMOVED AIRBUS - A319 100 - 131 Fume incident - Inbound Fume incident - Inbound crew handed over stating there was a smell of 'dirty socks' on both previous sectors. Aircraft was checked by engineers who crew handed over stating could not find a problem. Smell was observed around row 7 - 8 on the flight. Capt decided to go but use pack that supplied air to the flight deck (where there was a smell of no smell was reported). 'dirty socks' on both previous sectors. See MOR 201405627. REMOVED REMOVED AIRBUS - A319 100 - 131 Unpleasant smell/fumes Three to four minutes before landing, whilst the crew were completing their final checks, a foul cheesy smell- similar to sweaty feet was detected throughout the cabin. throughout the cabin. The flight deck reported the same. The smell was not detected on the way home. As gear was lowered on approach, cabin crew noticed an unpleasant smell throughout the cabin. It was variously described as being like cheese, vomit and smelly socks. They had experienced a similar smell on approach on the previous sector. No smell was evident to the flight crew. This was first reported to the Captain as the flight and cabin crew disembarked, after the AML part 1 had been completed. The Captain discussed this information with the flight and cabin crew which had arrived to take the aircraft for its next sector. It is understood that the Captain taking over the aircraft initiated an engineering inspection. Page 8 Sheet1 REMOVED REMOVED AIRBUS - A320 200 - 214 Fumes in the flight deck. Packs off take-off. After climb thrust was set and packs turned on, there was an immediate strong, penetrating and lasting oily smell in the flight deck. Since the situation was not improving we stopped the climb at FL100 and decided to return. Switching off one pack at a time did not improve the situation. Since we were overweight for an immediate landing we completed the overweight landing checklist. Switching on the APU bleed as per the overweight landing checklist worsened the oily smell so the QRH Smoke/Fumes removal checklist was performed as well. This very much improved the situation. Landed uneventfully. Pax were very understanding and co-operative, some had noticed the smell, some had not, depending on where they were seated. They disembarked and flew on a different aircraft. Some cabin crew also noticed the smell, again, depending on where they were seated. Crew did not complain of any significant ill-effects. Supplementary 14.5.14: Strong chemical smell during climb. A/c returned. REMOVED REMOVED AIRBUS - A319 100 - 131 Fumes in the aircraft caused cabin crew illness. REMOVED REMOVED BAE AVRO146RJ 200 - 85 Serious Incident: Smoke/fumes in flight deck. 52 POB, no injuries reported. Subject to foreign Authority investigation. After 10 minutes to landing and completing security checks, my colleague and I were aware of strong smell in the galley like "cheesy feet". My colleague rang the SCCM, who rang the flight crew and spoke to the first officer. At the same time, the SCCM had smelt something pungent in her galley, when the SCCM rang the flight crew, the FO said they had a "a whiff of something" in the flight deck. At this time, they were 3 miles out from landing and asked if we could see fumes/flames. They said they were keen to get the aircraft down asap. The SCCM said she felt light headed. I too felt light headed and when I got to my hotel room, I felt dizzy. Upon waking the next morning, I felt dizzy and had a headache and some nausea. 28 Fume event MORs from January 2014 to May 2014 Page 9