Flow In Pipes Pipe Flow In Water Supply

advertisement

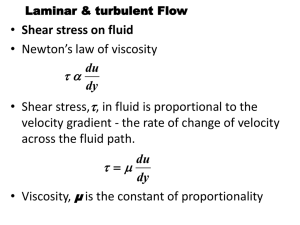

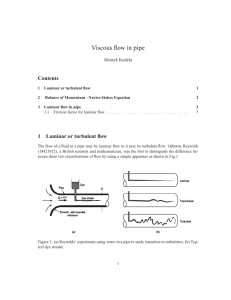

Pipe flow in water supply Flow in pipes A lecture by Gilberto E. Urroz March 2006 1 Pipe flow in irrigation 2 Pipe flow in dams 3 4 Pipe flow in dams Pipes and pumps 5 Pipes over rivers 6 Pipes in industrial setups 7 8 Laminar & Turbulent Flows • • • • • Flow films • • • • • • Laminar flow: orderly, in layers Turbulent flow: disorderly, eddies Transitional: intermittently turbulent Criteria: Reynolds number Critical Re = 2000 LaminarTurbulentFaucetFlow.MOV LaminarPipeFlow.MOV TurbulentPipeFlow.MOV TransitionalPipeFlow.MOV LaminarTurbulentCombo.MOV TurbulentFlowAroundUs.MOV 9 Laminar & turbulent flow out of a faucet 10 Laminar flow in a pipe 11 12 Turbulent flow in a pipe Transitional flow in a pipe 13 14 Hydraulic Radius - 1 Laminar and turbulent flow visualization • A = cross-sectional area • P = wetted perimeter (length of boundary in contact with water) • Hydraulic Radius: Rh = A/P 15 16 Example Hydraulic Radius - 2 • FOR PIPE FLOW • A = πD2/4 , P = πD2, Rh = A/P = D/4 17 18 Head losses and shear stress Analysis of motion of pipe flow hf = head loss in length L τo= wall shear stress γ = specific weight Rh = hydraulic radius τo ⋅ L hf = γ ⋅R h Applies to: • Any x-section • Laminar or turbulent flow 19 20 Smooth and rough walls Dimensional Analysis of Pipe Flow -1 • Examples: – Glass – Plexiglass – PVC • Examples: – Copper – Concrete Rough walls characterized by an absolute roughness (e) 21 Dimensional Analysis of Pipe Flow -2 22 Head Losses in Pipe Flow 23 24 Head losses in circular conduits • Start from hf = C f ⋅ Analysis of motion of pipe flow 2 L V ⋅ Rh 2 g • For a circular pipe, Rh = D/4 • Replace Cf = f/4 • Darcy-Weisbach equation: L V2 hf = f ⋅ ⋅ D 2g • f = Darcy-Weisbach friction factor • Cf = 4f = Fanning friction factor (used in gas flow) 25 Head losses and shear stress hf = head loss in length L τo= wall shear stress γ = specific weight Rh = hydraulic radius 26 Shear stress distribution • Equilibrium of forces on an element of radius r , steady flow. τo ⋅ L hf = γ ⋅R h ΣFx = ma x , a x = 0 Applies to: • Any x-section • Laminar or turbulent flow 27 28 Shear stress – linear distribution • From an ealier result: • Also, τ ⋅L hf = o γ ⋅R h hf = Wall shear stress and friction factor hf = • Combine the result 2τ (r ) L γ ⋅r L V2 hf = f ⋅ ⋅ D 2g • With Darcy-Weisbach • With Rh = D/4 = ro/2 r τ (r ) = τ o ⋅ ro τo ⋅ L τo ⋅ L = γ ⋅ Rh γ ⋅ (D / 4) f 8 τ o = ⋅ ρ ⋅V 2 29 Friction in non-circular conduits 30 Laminar flow in a circular pipe • Use D = 4Rh in Darcy-Weisbach • With L V2 L V2 = f⋅ ⋅ hf = f ⋅ ⋅ D 2g 4 Rh 2 g Re = ρVD ρV ⋅ 4 Rh = μ μ 31 32 Velocity and shear stress distributions Centerline and mean velocities – discharge and head losses 33 34 Combining Hagen-Poiseuille with Darcy-Weisbach Hagen-Poiseuille law for laminar flow 32νLV hf = gD 2 1. hf ~ V 2. Equation involves no empirical coefficient 3. Equation involves only fluid properties, g, and V 35 36 Exercises - 1 Exercises - 2 37 38 Exercises - 3 • • • 39 Rounded entrance produces uniform flow (inviscid flow behavior) Velocities at the wall are zero (no-slip condition) A viscous boundary layer develops, but an inviscid core remains before flow is fully developed 40 Exercise in flow development 41