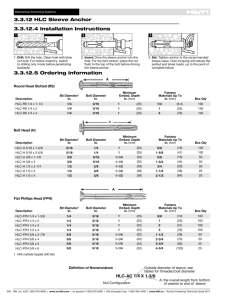

PDFProduct Technical Guide for HIT-HY 200 Fast Cure Hybrid

advertisement