2013 Business report

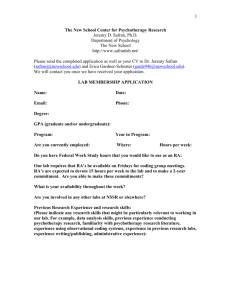

advertisement