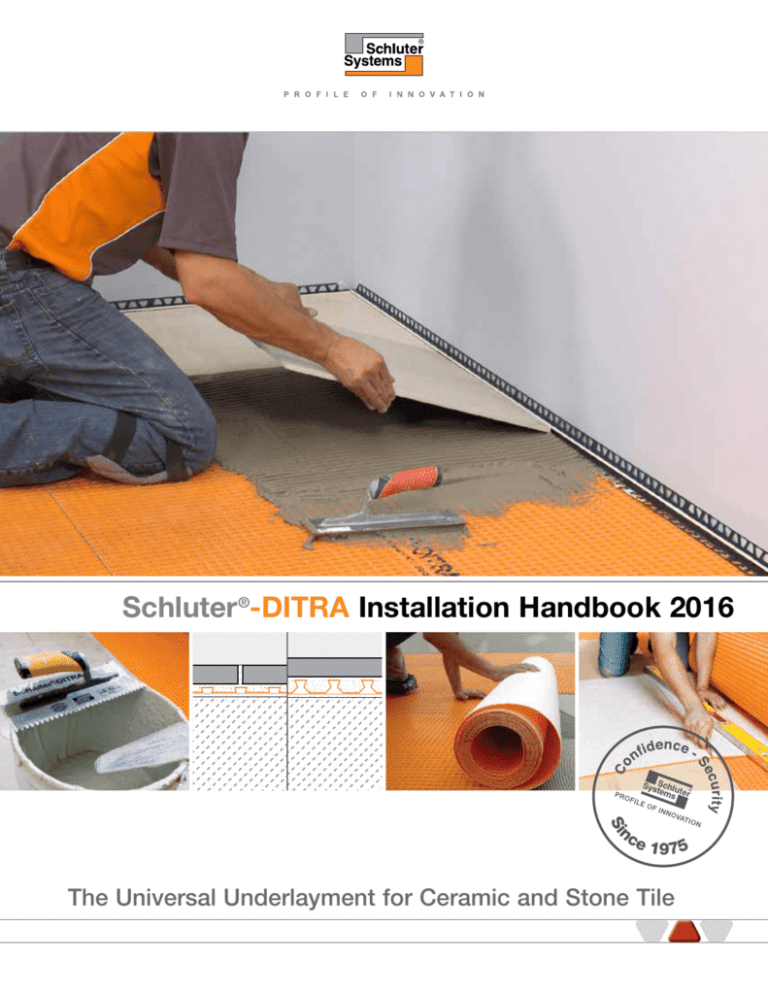

Schluter®-DITRA Installation Handbook 2016

advertisement