PROFINET: Easy Implementation & Performance Upgrade

advertisement

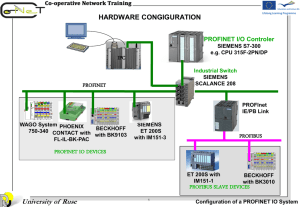

Easy PROFINET implementation siemens.com/profinet-technology Answers for industry. PROFINET – The Open Ethernet Standard PROFINET is the Ethernet standard for automation, enabling high-speed, secure data exchange between field devices from different manufacturers. Therefore, PROFINET makes it possible to create inno­va­ tive machine and system designs. The standard is supported by PROFIBUS & PROFINET International (PI), the world‘s largest fieldbus organization. A global network of 28 PROFINET competence centers is available to support you with all PROFINET related questions. PROFINET for field devices PROFINET provides manufacturers of field devices with new ways of making their products more attractive to end users through innovative functions. Integrated diagnostics and alarm functions ensure fast commissioning times and optimized machine maintenance. Besides diagnostics without engineering tools, direct access via TCP/IP also makes it ­possible to transfer large amounts of data such as quality assurance or traceability information parallel to IO communication. Besides these value-added services, PROFINET‘s centerpiece of IO data transfer also does not miss out. 2 Absolute deterministic behavior is ensured through prioritization of the Ethernet message frames. The use of Isochronous Real Time (IRT) with cycle times up to 31.25 µs also makes high-performance applications such as Motion Control possible. The PROFINET IO device model follows the same principle as the PROFIBUS DP device model. This makes it quick and simple for the field d ­ evice ­developer to complete the logical step from ­PROFIBUS to PROFINET. Also the principle of the ­device description has been retained as a GSD file and simplified through an XML-based variant. Engineering or diagnostics data is generally transferred via TCP/IP. An Ethernet-capable device can be integrated into a PROFINET network at any time via a free port. A field device can be accessed on the web server both locally and via remote diagnostics via a secure router using a standard Internet browser. The same mechanism is thereby effective from remote maintenance to the field device: i.e. standard Ethernet. PROFINET Stack IT services HTTP SNMP DHCP ... PROFINET Applications 1) Standard data Real-time data TCP/UDP Real Time IP 2) RT | 3) IRT Real time Ethernet 1) Standard channel ■■Parameter assignment and configuration ■■Reading the diagnostic data 2) Real-time channel ■■Cyclic data exchange ■■Alarms 3) IRT channel (optional) ■■Cyclic, synchronous data exchange ■■Jitter < 1 µs Real-time switch Application of standards PROFINET relies on established standards from the IT world in many areas. For example, the protocols LLDP and SNMP are used for the topological neighbor relationships. Non-time-critical data such as diagnostics records are transmitted via UDP/IP. In this way, web servers or other established services from the world of IT can be implemented without restriction on PROFINET devices. This openness of PROFINET introduces new possibilities for both field device manufacturers and end users. PROFINET is ■■100% Industrial Ethernet according to IEEE 802.xx with Auto Negotiation and Auto Crossover ■■Full Duplex Transmission ■■Switched Ethernet ■■100 MBit/s Ethernet Full information on PROFINET at Siemens: siemens.com/profinet Full information on the technology standard: profinet.com 3 PROFINET Implementation in Field Devices PROFINET is 100% standard Ethernet and at the same time offers appropriate mechanisms for very high real-time requirements. ■■PROFINET with real time (RT) can be used for process data transfer with a cycle time of up to 1 ms. Implementation can be realized on a standard Ethernet controller. ■■Siemens offers special ASICs which support PROFINET with isochronous real time (IRT) for the synchronous transfer of process data with a cycle rate of <1 ms and a jitter accuracy of 1 μs. The ERTEC ASIC is the perfect choice for a field device which is to support cycle times of <1 ms. If cycle times of 1 ms and more are sufficient, PROFINET integration can also be realized on the basis of standard Ethernet controllers. This facilitates easy and cost-efficient implementation thanks to the usability of existing hardware. PROFINET is based on switched Ethernet technology. This means that the communication between two field devices is always point-to-point connections, even if the field devices are connected in line. Thanks to standard Ethernet technology, PROFINET therefore guarantees the building of any desired topologies. In this way, in addition to line and ring topology, a star and tree topology is also possible, along with all mixed forms. The bandwidth in individual topology branches is divided, since data through direct point-to-point communication does not need to pass through each individual network participant. The application options to be offered to customers are decisive for field device manufacturers. Devices with a 1-port solution can only be integrated in star and tree topologies. In contrast, devices with a 2-port switch solution can also be used in line and ring structures. PROFINET technology implementation matrix depending on requirements Star and tree topology Star, tree, line, and ring topology Unsynchronized communication (Real Time) Standard Ethernet controller with 1-port Standard Ethernet controller plus 2-port switch or ERTEC 200P, ERTEC 200/400 Synchronized communication (Isochronous Real Time) ERTEC 200P ERTEC 200/400 ERTEC 200P ERTEC 200/400 siemens.com/profinet-technology 4 Performance Upgrade for PROFINET With IRT, the PROFINET performance upgrade facilitates attainable cycle times of 31.25 µs. This is supported by the fast forwarding, dynamic frame packing and fragmentation mechanisms. Find out more about these functions in a short video animation: Integration of additional features PROFINET enables additional functionalities to be integrated based on a standard Ethernet controller. Thanks to PROFINET development kits from Siemens, some of these features are already integrated in the PROFINET stack: Media Redundancy Protocol (MRP) Higher system availability can be achieved with a redundant installation through ring topology. Short reconfiguration times of 200 ms prevent any system standstill. Any required maintenance and repair work can be carried out with no time pressure. Shared Device Several controllers can use the same PROFINET device with this functionality. This results in easy and economical system configuration, for example for applications in which the standard CPU runs separately from the fail-safe CPU. PROFIenergy With this manufacturer and device-independent profile defined by PROFIBUS & PROFINET International (PI), any unnecessary devices can be purposefully switched off during rest periods. This is coordinated centrally through a higher-level controller. Field devices have an integrated switch-off function. Field device manufacturers can, in addition, integrate further manufacturer-independent profiles specified by PI: PROFIsafe PROFIsafe is the world‘s leading universal technology (IEC 61508 compliant) for functional safety in manufacturing and process automation. The PROFIsafe profile is tried and tested in many applications and has since become an international standard according to IEC 61784-3-3. PROFIdrive PROFIdrive is an interface between the control and the drive (IEC 61800-7) and it defines the device and access procedure to internal drive data for electrical drives – from the simple frequency converter to the high-performance servo regulator. PROFINET offers the field device manufacturer many additional options including the integration of a web server for access to diagnostics data with a standard Internet browser. 5 ERTEC products ERTEC ASICs The ASICs of the ERTEC range represent Ethernet controllers on the basis of ARM 9 processors with integrated IRT switch. They elegantly meet all capability requirements in terms of real time, line topology and IT integration. Cyclic data transfer for PROFINET on the basis of real time and isochronous real time is completely carried out via the integrated switch. As a result, sufficient processor resources are available for the processing of simple field device applications in the ARM processor. Various development packages are available for the development of field devices with ERTEC ASICs. Easy getting started is supported by simple application examples. ERTEC 200P – High-Speed with PROFINET The ERTEC 200P sets new standards with regard to the communication performance of PROFINET. Dimensioned for cycle times of up to 31.25 µs, the performance upgrade for PROFINET was for the first time integrated in the ERTEC 200P. Featuring a fast ARM 926-CPU and an increased number of interfaces, it accommodates maximized performance in minimized space. As a result, further application sequences besides PROFINET communication can be integrated in the ERTEC 200P. Technical Data of ERTEC ASICs Integrated IRT switch Evaluation Kit ERTEC 200P ■■Evaluation board with ERTEC 200P ■■PROFINET stack* for I/O device as source code, incl. example application based on the eCos opensource operating system ■■Example application, including GSD file Development Packages for ERTEC 200/400 ■■Evaluation board with ERTEC 200/400 ■■PROFINET stack for I/O device as source code, incl. example application based on the eCos opensource operating system ■■Example application, including GSD file ■■CP 1616 PCI card or SOFTNET PN IO as PROFINET controller test partner *Until the availability of PROFINET controllers with performance upgrade, the firmware stack of the evaluation kit for ERTEC 200P only supports cycle times up to 250 µs. An upgrade to 31.25 µs will be supported by a free firmware update. ERTEC 200P ERTEC 200 ERTEC 400 2-port 2-port 4-port Integrated PHYs X X - Support of copper and optical fiber cables X X X Minimum cycle time 31.25 µs 250 µs 250 µs ARM CPU ARM 926 ARM 946 ARM 946 Max. clock frequency 250 MHz 150 MHz 150 MHz Parameterizable I/Os, general-purpose I/Os max. 96 max. 45 32 17x17 mm 19x19 mm 19x19 mm 0.8 mm 0.8 mm 0.8 mm Enclosure size Ball pitch 6 ERTEC 200/400 ERTEC 200 and 400 facilitate the realization of field devices with IRT and isochronous cycle times up to 250 µs. Configuration of a development environment for ERTEC 200P PROFINET Controllers* Development System Possible PROFINET controller test partners – S7-300 with PN interface – CP 1616 – SOFTNET PN IO (only suitable for RT) Benefits on PC* with Windows XP/7*: – eCos operating system – Eclipse development environment – Terminal program ■■Optimized device implementation ■■Space and cost savings ■■Latest PROFINET functions available promptly and with pre-certification Terminal output: JTAG debugger Programming interface The EB 200P evaluation board is operated as a PROFINET IO device outside a PC. EB 200P evaluation board *P arts are not contained in the Development Kit. = optional Additional PROFINET IO Devices* Evaluation Board EB 200P ERTEC 200P block diagram JTAG/Debug ext. Memory Interface 25 MHz OSC PHY LEDs System Control Boot ROM ARM 926EJ-S (125/250 MHz) General DMA Controller Memory/ SDRAM Controller Host-Interface XHIF (LBU) (16/32 Bit) 4 x UART PeripherieInterface IRT-Switch (100 MBit/s) Peripherie-Ports 6x Timer, 2x Watchdog I²C 2 x SPI Port 1 Port 2 96 x GPIO out in in PHY PHY 80 x I-Filter ERTEC 200P Sync (PN PLL) 7 Further Development Kits Simple PROFINET integration – Development Kit for standard Ethernet controller If a field device already has an Ethernet interface and the full range of PROFINET functions are meant to be integrated into the field device then the Development Kit for the standard Ethernet controller is the first choice. The field device can be developed into a fully-fledged PROFINET device through expansion of the communication stack with no changes to the existing hardware. The CD with the Development Kit for standard Ethernet controllers contains the following components: ■■PROFINET IO device stack in the source code ■■Application example based on an ARM 9 controller ■■GSD file example ■■Software example for PROFINET IO controller test partner (test partner is not included in delivery) Minimum requirements for the Standard Ethernet Controller platform ■■32-Bit microcontroller, e.g. ARM 9 ■■32-Bit real-time operating system ■■Big endian or little endian ■■Approx. 1.5 MB of flash memory for non-volatile data (Device Name, IP address, etc.) ■■Approx. 3.5 MB RAM for code and data The values may differ depending on the platform used. 8 Safe PROFINET implementation – PROFIsafe Starter Kit PROFIsafe is a profile specified by PI for the secure exchange of IO data. The PROFIsafe Starter Kit is compatible with the current version of the PROFIsafe profile, as specified in IEC 61784-3-3. It meets a series of user requirements such as variable process data length at runtime. Along with all specifications required for development, the PROFIsafe Starter Kit contains the source files for the PROFIsafe Driver (PSD) and a detailed implementation guide in English and German. In addition, it includes various CRC calculation tools and tools for creating GSD files with security-related parameters. Example adjustments of the PSD to the PROFINET stack interfaces provide assistance for any application-specific adjustments that may be required. Special “slow-motion monitors“ allow the PROFIsafe protocol processes to be monitored in slow motion. Support for the iPar server and the TCI interface are also included. Solutions for the PROFINET controller PROFINET controller integration – the quick and easy way Siemens offers a solution based on PC cards for integrating the PROFINET IO controller and/or IO device functions: This solution consists of the CP 1616 PCI plug-in card and the CP 1604 in the PC/104 Plus format. CP 1616 Communications processor ■■PCI card for connecting PC-based systems to PROFINET ■■Integrated 4-port switch in the ERTEC 400 PROFINET technology from Siemens ensures the interplay of all PROFINET field devices. PC with CP 1616/1604 as a PROFINET Engineering PG/PC controller with STEP 7 S7-300 GSD CP 1604 Communications processor ■■PCI-104 card for connecting PCI-104-based systems to PROFINET ■■Integrated 4-port switch in the ERTEC 400 DK-16xx PN IO Development Kit for the CP 1604 and CP 1616 communications processors Both cards can be integrated into any operating system with the DK-16xx PN IO. In automation technology these are usually real-time operating systems. PROFINET PROFINET Device with standard processor PROFINET Device with ERTEC 400 PROFINET Device with ERTEC 200 PROFINET Device with ERTEC 200P The DK-16xx PN IO Development Kit contains everything required to use the CP 1616 and 1604 as a PROFINET IO controller and/or PROFINET IO device: Drivers, demonstration programs and documentation are all available free of charge. Benefits ■■PCI standard ■■Low software development costs ■■Solution for PROFINET IO device and IO controller ■■Supports PROFINET RT and IRT real-time features ■■Fast implementation Communications processor CP 1604 Communications processor CP 1616 9 PROFINET Competence Center For more than twenty years, Siemens has offered extensive support with the development and certification of PROFIBUS and PROFINET field devices over the entire product creation cycle. Through the PI-accredited Competence Center and ComDeC certification laboratory (Communication Development and Certification) in Germany, the PIC (PROFI Interface Center) in the USA and through ANF Data in the Czech Republic. The range of services of ComDeC, PIC and ANF Data extends from consulting and support via the telephone and e-mail, through to certification tests. Through the worldwide unique experience of these accredited institutions users can create competitive advantages for their field devices in order to fulfill the demands of their customers for high quality. PROFINET Development Kit Training PROFINET Development Kit training involves free, one-day training sessions for individuals interested in becoming effectively acquainted with the Siemens PROFINET IO Development Kits. A visit to a workshop provides all the information required to develop PROFINET field devices quickly and cost-effectively. Contents: ■■Commissioning Siemens PROFINET Development Kits ■■Functions in the PROFINET IO stack ■■Implementing PROFINET IO functions ■■Hardware-specific implementation (using the Evaluation Kits for ERTEC 200P as an example) ■■ASICs ERTEC 200P, ERTEC 200/400 ■■Preparation for certification Contact ComDeC to inquire about current dates. 10 PROFINET test laboratory Field devices are networked together in machines and systems via fieldbuses such as PROFINET. Using certified field devices thereby guarantees the interoperability of components from different manufacturers and thus contributes to higher system availability and to time and cost savings for the operator. The certification tests include: ■■Hardware tests ■■Load tests ■■State machine tests ■■Reaction to faults ■■Alarm tests ■■Check of the GSD file For this reason, device certification for PROFINET via an accredited test laboratory is mandatory. The PI-accredited test laboratories of ComDeC, PIC and ANF Data have now successfully completed over 800 certification tests. This ensures that devices in the field always meet the requirements of the industrial environment. ComDeC, PIC and ANF Data are also the global leaders for the PROFINET certification tests already carried out. All tests are carried out in practice-oriented and established automation systems, with the latest edition of the SIMATIC S7 programmable logic controllers from Siemens. External technical experts may be physically present for the certification tests at any time, thereby rectifying certain faults quickly and easily. Third-party know-how is always protected: the test laboratories are under an obligation to keep all customer information confidential. Certification sequence Certification is extremely simple for PROFINET field device manufacturers: the finished PROFINET device is checked by one of the accredited test laboratories. siemens.com/comdec 11 Contact ComDeC for Europe Würzburger Strasse 121 90766 Fürth, Germany Phone: +49 911 750 2080 Fax: +49 911 750 2100 comdec@siemens.com siemens.com/comdec PIC for the USA One Internet Plaza Johnson City, TN 37604 Phone: +1 423 262 2576 Fax: +1 423 262 2103 pic.industry@siemens.com profiinterfacecenter.com Siemens AG Industry Sector Industry Automation P.O. Box 48 48 90026 NÜRNBERG GERMANY Subject to change without prior notice Order No.: E20001-A24-M116-X-7600 DISPO 06334 WÜ/44031 MM.XXX.PN.52.3.01 WS 11123. Printed in Germany © Siemens AG 2012 siemens.com/profinet-technology ANF DATA for CEE Zeleny pruh 1560/99 140 00 Prague, Czech Republic Phone: +420 241 010 612 Fax: +420 241 010 609 profinet.anfdata@siemens.com The information provided in this brochure contains merely general descriptions or characteristics of performance which in actual case of use do not always apply as described or which may change as a result of further development of the products. An obligation to provide the respective characteristics shall only exist if expressly agreed in the terms of contract. All product designations may be trademarks or product names of Siemens AG or supplier companies whose use by third parties for their own purposes could violate the rights of the owners.