The Tennessee Pollution Prevention Roundtable: Jones

advertisement

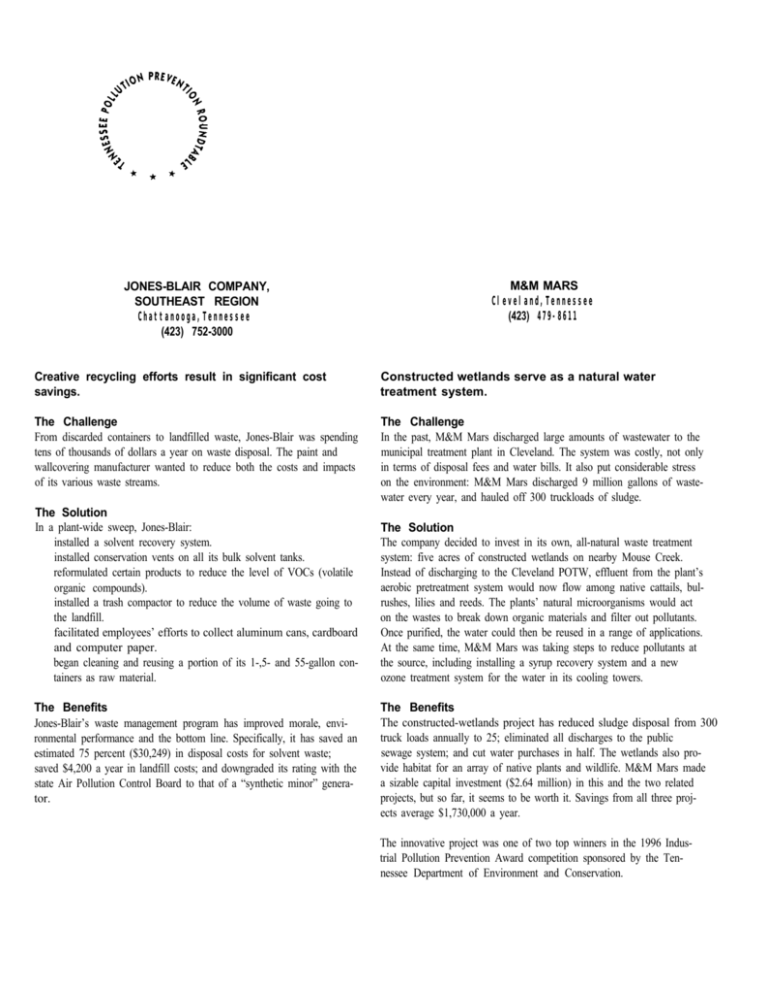

JONES-BLAIR COMPANY, SOUTHEAST REGION Chattanooga,Tennessee (423) 752-3000 M&M MARS Cleveland,Tennessee (423) 479-8611 Creative recycling efforts result in significant cost savings. Constructed wetlands serve as a natural water treatment system. The Challenge From discarded containers to landfilled waste, Jones-Blair was spending tens of thousands of dollars a year on waste disposal. The paint and wallcovering manufacturer wanted to reduce both the costs and impacts of its various waste streams. The Challenge In the past, M&M Mars discharged large amounts of wastewater to the municipal treatment plant in Cleveland. The system was costly, not only in terms of disposal fees and water bills. It also put considerable stress on the environment: M&M Mars discharged 9 million gallons of wastewater every year, and hauled off 300 truckloads of sludge. The Solution In a plant-wide sweep, Jones-Blair: installed a solvent recovery system. installed conservation vents on all its bulk solvent tanks. reformulated certain products to reduce the level of VOCs (volatile organic compounds). installed a trash compactor to reduce the volume of waste going to the landfill. facilitated employees’ efforts to collect aluminum cans, cardboard and computer paper. began cleaning and reusing a portion of its 1-,5- and 55-gallon containers as raw material. The Benefits Jones-Blair’s waste management program has improved morale, environmental performance and the bottom line. Specifically, it has saved an estimated 75 percent ($30,249) in disposal costs for solvent waste; saved $4,200 a year in landfill costs; and downgraded its rating with the state Air Pollution Control Board to that of a “synthetic minor” generator. The Solution The company decided to invest in its own, all-natural waste treatment system: five acres of constructed wetlands on nearby Mouse Creek. Instead of discharging to the Cleveland POTW, effluent from the plant’s aerobic pretreatment system would now flow among native cattails, bulrushes, lilies and reeds. The plants’ natural microorganisms would act on the wastes to break down organic materials and filter out pollutants. Once purified, the water could then be reused in a range of applications. At the same time, M&M Mars was taking steps to reduce pollutants at the source, including installing a syrup recovery system and a new ozone treatment system for the water in its cooling towers. The Benefits The constructed-wetlands project has reduced sludge disposal from 300 truck loads annually to 25; eliminated all discharges to the public sewage system; and cut water purchases in half. The wetlands also provide habitat for an array of native plants and wildlife. M&M Mars made a sizable capital investment ($2.64 million) in this and the two related projects, but so far, it seems to be worth it. Savings from all three projects average $1,730,000 a year. The innovative project was one of two top winners in the 1996 Industrial Pollution Prevention Award competition sponsored by the Tennessee Department of Environment and Conservation.