to see all of LBM's Awards through the last 2 decades.

advertisement

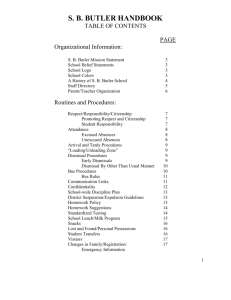

LBM Construction’s Butler Awards and Recognition 2012 Butler Mfg. Company “Builder of The Year” Award 2012 High Performance Builder, Butler Manufacturing Company 2010 Received cumulative Fifteen Million Dollar Award 2008 “Grand Prize Winner” Butler Regional Re-Roof Sales Promotional 2007 One Million Dollar Award (Single Year) 2007 High Performance Builder, Butler Manufacturing Company 2006 Butler Northern Regional Re-Roof “Dealer of the Year” Award 2004 One Million Dollar Award (Single Year) 2004 High Performance Builder, Butler Manufacturing Company 2003 One Million Dollar Award (Single Year) 2003 High Performance Builder, Butler Manufacturing Company 2003 Butler Northeast Regional Re-Roof “Dealer of the Year” Award 2001 Butler Northeast Regional Re-Roof “Dealer of the Year” Award 2001 Member, The Butler Club for Ten Million Plus in Butler Product Sales 2001 One Million Dollar Award (Single Year) 2001 High Performance Builder, Butler Manufacturing Company 2000 Recognized for 10 Years of Highest Quality Service 1999 One Million Dollar Award (Single Year) 1998 One Million Dollar Award (Single Year) 1998 High Performance Builder, Butler Manufacturing Company 1997 High Performance Builder, Butler Manufacturing Company 1996 One Million Dollar Award (Single Year) 1996 Member, The Butler Club for Five Million Plus in Butler Product Sales 1995 High Performance Builder, Butler Manufacturing Company 1995 One Million Dollar Award (Single Year) & High Performance 1994 Butler Manufacturing Company “Builder of the Year” Northeast Region 1994 High Performance Builder, Butler Manufacturing Company 1993 High Performance Builder, Butler Manufacturing Company 1992 Designated Butler Manufacturing Company “Career Builder” meeting high standards of performance in these key areas: *Construction Capability *Professional Design Services *High Local Reputation *Sound Business Management *Adequate Financial Resources *Marketing Competence *Career Dedication 1991 High Performance Builder, Butler Manufacturing Company Note: Builder must exceed their sales goals as set forth by Butler Manufacturing Company by more than 50% in order to qualify for the High Performance Award. Company Profile LBM Construction is recognized as one of Western New York’s premier, full-service general contractors specializing in high quality commercial and industrial construction projects. Founded in 1977, the firm numbers among its clients a virtual “who’s who” in the greater Buffalo business community. Companies which have engaged one or more of LBM Construction’s wide range of services include General Welding & Fabricating, Luminescent Systems, Inc., St. John’s Church, Bristol Myers-Squibb, Astronics Corporation, 3M Corporation, Derrick Corporation, DeCarolis Truck Rental, Fisher-Price, Inc., MTI Corp., the United States Postal Service, Wesleyan Church of Hamburg, Northtown Ice Center, Saint-Gobain Carborundum, Taylor Pohlman Industries, First Trinity Lutheran Church, Bible Presbyterian Church Family Life Center, St. Luke’s Lutheran Church, First Trinity Lutheran Church, Miller/Molson, Trico, Curtis Screw Machining, Accellent Corp., Try-it Distributing, Sallie Mae (PCR Credit Recovery), Exel Logistics (Dupont), Gintzler Graphics, Mod-Pac Corp., Roberts Gordon HVAC, Buffalo Niagara Court Center, to name a few. The firm’s reputation has been carefully crafted through demonstrated excellence in conventional, design-build and pre-engineered building programs in a wide variety of industries and problemsolving situations. The scope of these projects ranges from multi-million dollar new manufacturing, industrial, warehousing and office facilities to five and six figure construction renovations, remodeling and foundation work in industrial environments. Major industry segments served include light and heavy manufacturing, financial services, office park developments, medical professional parks, service businesses, warehousing and distribution facilities, transportation terminals, Churches and storage centers. The hallmark of LBM Construction’s success can be attributed to its commitment to the “designbuild” concept; to high quality construction practices; and to cost effective solutions for clients. Through the use of state-of-the-art CADD computer programs, LBM Construction’s designers create site analyses, preliminary floor plans, and budget estimates linked to “real world” expertise. This approach saves clients significant amounts of time and money and provides added control in the decision making process. In addition, LBM Construction is an award-winning “Career Builder” for Butler Manufacturing Company and offers a full complement of Butler (TM) pre-engineered building systems that can be incorporated into design-build or architecturally specified building plans. The company’s principals represent the third generation of a construction legacy first established as Harvey Myers & Sons, Inc. in 1950. Today, president Terry Myers Kelly, P.E., LEED AP, vice president-operations David W. Myers and vice president-sales John E. Myers competently direct the activities of their employees. Their dedication to detail, extensive problem-solving expertise, costdriven methods, and passion for customer satisfaction stand behind their corporate philosophy: “Working as a Team to Build Your Future.” Construction Capabilities LBM Construction’s expertise encompasses a wide range of building needs, from new construction, Re-Roofs to existing renovations to industrial plant work. Turn-Key New Construction Projects From site selection, analysis and financing, to engineering plans, blue prints, approval processes and actual execution, LBM Construction offers a full complement of services for “turn-key” construction projects with budgets up to $15 million dollars. Design-Build Construction Projects The hallmark of LBM Construction is its extensive design-build construction experience. The rapid growth of design-build construction projects has its foundation in sophisticated computer aided drafting and design tools that enable qualified architects and engineers to create floor plans and estimates in half the time and cost of traditional approaches. LBM Construction’s building designers use the latest AutoCAD program versions to generate building specifications and estimates. All design-build projects are then reviewed, embellished and approved by outside licensed architects and third party professional engineers. Design-build construction’s increased popularity has been enhanced by business professionals whose engagement in the development process brings personal satisfaction in seeing their company’s vision being built while keeping an eye on practical time and budget considerations. Conventional New Building Construction When a conventional or architecturally-rendered design is preferred, LBM Construction works closely with the chosen architects and the client to ensure that the integrity of the design elements are respected, while ensuring that appropriate and cost effective materials and methods are employed. LBM Construction has forged partnerships with a number of highly skilled architectural and engineering firms in the Western New York community. Butler (TM) Pre-Engineered Building Systems Whether the construction approach is design-build or architecturally-rendered, LBM Construction has the expertise to incorporate a vast array of Butler ™ pre-engineered building systems into every phase of construction, from the structural steel, exterior panels, and roofing to details such as flashings, gutters and downspouts. The Myers’ relationship with Butler Manufacturing dates more than 41 years. Butler is the most widely recognized and respected quality brand of versatile pre-engineered building systems in the industry and World today. Existing Building Renovations If the best solution is to renovate an existing facility, LBM Construction ensures high quality integration of structural, architectural and aesthetic components, while maintaining a safe work environment that minimizes disruptions during construction. New Interior Offices or Renovations Today’s high tech office environment demands sophisticated solutions. LBM Construction’s stateof-the-art CAD design tools and understanding of interior construction materials and methods together create quality work environments for demanding professionals. Office and Industrial Park Developments The Upstate New York business community has experienced a steady increase in the number of professional office and industrial parks, thanks in large part to the growth of service sector professionals, the commercialization of scientific research from major universities, and to shifting economic emphasis on light manufacturing, recreational facilities and service industries. LBM Construction has worked closely with several developers, landowners and entrepreneurs to plan and build office and industrial park developments. The general contractor’s key expertise includes an understanding of building codes and regulations in each municipality, environmental impact studies and implications, as well as accessibility and functionality. Property/Site Analysis LBM Construction has gained a reputation for excellence in its ability to locate and analyze property for proposed new construction. Thorough site analysis is essential to ascertain whether or not it is feasible to construct a building on a given property. The firm conducts subsoil base analyses to determine the amounts of clay, sand, silty loam or wetlands present, feasibility studies for foundations, transportation access, engineering requirements to alter pitch and grade, and helps determine “built costs” versus “land costs” for our new construction projects and clients. Butler MR-24 / VSR Re-Roofing Since 1969, the Butler MR-24 Roof System has been installed over 2.5 billion square feet of buildings. The MR-24 roof is specified 3:1 more than any other standing seam roof by owners, architects and engineers for use on new facilities or existing ones. With the advent of a well thought out and detailed approach of re-roofing existing structures, the MR-24 standing seam and VSR roof are the first choices in the industry to permanently solve the age old problem of leaky roofs on conventionally built structures or even other inferior pre-engineered metal building systems. Butler’s unique slope built-up system allows you to cover right over an existing flat roof, in most cases without having to disturb the environment below. Butler’s painted VSR roof is a prime solution for leaky roofs and offers an aesthetic architectural appearance with long-term proven performance. A non-prorated 25-year warranty is also included with this roofing system. You’ll begin to save immediately on maintenance costs. And additional insulation can be added to help you save even more on energy costs. We have collectively installed more than two million square feet of Butler’s MR-24 / VSR Roof System in the Western New York area with exceptional results. The original warranties have outlived themselves and the roofs are still going strong. “Working as a Team to Build Your Future” Professional Credentials LBM Construction has built a team of talented and dedicated professionals whose commitment to customer satisfaction ensures that high standards for quality materials, practices and construction methods are maintained. The company’s approach is personal, flexible and thorough. Attention to detail permeates the company’s culture. This level of service, together with years of expertise in all facets of design, planning, engineering, construction and project management, guarantee client satisfaction year after year. LBM Biographies Terry Myers Kelly President Terry Myers Kelly has served as president of LBM Construction since 1991, after serving more than six years as the company’s General Manager. She establishes the strategic priorities for the company, sets the construction quality assurance standards, including project management, and oversees executive administration and legal matters. Ms. Myers Kelly works closely with the Vice President-Operations and Vice President-Sales on new business development for the firm. With 35+ years of engineering experience, Ms. Myers Kelly provides LBM Construction with a solid broad range of knowledge in building design and construction. She works directly with company owners and presidents, professional engineers and architects to ensure that important details are addressed in all phases of the design-build construction process. Ms. Myers Kelly heads LBM Construction’s project team at Fisher-Price, Inc. and serves as on-site liaison with the corporate construction manager of this multi-million dollar program. Terry is also a LEED AP (Leadership Energy Environmental Design – Accredited Professional) Ms. Myers Kelly began her construction career as a design engineer and project manager with Raiser Architectural Group and Raiser Construction Company in San Mateo, California--one of the top 400 contractors, with sales in excess of $35 million. Ms. Myers Kelly was responsible for the site design of a five-story, 180,000 square foot structure on 13 acres at San Francisco Bay, as well as Pacific Gas and Electric’s maintenance facility, which was built into a hill on a 14-acre site. She also served as project manager for an addition to the San Mateo, California Airport and for a 33-unit condominium complex in downtown San Francisco. She joined Harvey Myers & Sons Construction in 1981 and became general manager of LBM Construction in 1984. Ms. Myers Kelly holds a Bachelor’s Degree in Civil Engineering from Michigan State University, is a registered Professional Engineer and LEED AP. She is active in the East Aurora Arsenals Soccer program and has served on the Board of Directors for the Southtowns YMCA. She resides with her husband in East Aurora, New York and has two children. David W. Myers Vice President-Operations As Vice President in charge of operations, David W. Myers brings over 30 years of experience to LBM Construction. Mr. Myers is responsible for the day-to-day administrative and field operations at the company, including the management of office personnel as well as job site superintendents. He ensures that the appropriate work assignments are made to all client projects, and oversees the time and material estimates and maintains records for project time schedules and budgets. In addition, Mr. Myers manages the accounting, insurance, labor, and regulatory agency requirements for the company. Mr. Myers began his construction career as a laborer in 1976 and subsequently became a member of the Carpenter’s Union. His direct building experience includes extensive work in concrete foundations, interior renovations and industrial projects for the clients of Harvey Myers & Sons Construction. He was promoted to carpenter-foreman in 1985, and in 1986 he became the job site superintendent for plant work and new construction. In 1990, Mr. Myers joined LBM Construction as estimator and project manager. Today he is responsible for ensuring that the firm’s high quality standards are maintained throughout each phase of construction, while keeping close tabs on each clients needs, and the specific job requirements such as construction methods and materials. Mr. Myers is a graduate of Orchard Park High School and resides with his family in East Aurora, New York. John E. Myers Vice President-Sales John E. Myers is responsible for establishing and implementing the marketing, new business development, advertising, web site and client account management activities at LBM Construction. His focus on delivering high levels of customer satisfaction ensures that each client’s building solutions are the most appropriate and cost effective ones. Mr. Myers also manages the company’s day-to-day marketing, sales and production operations with the Butler Manufacturing Company. Mr. Myers began his full time construction career in 1985 with Harvey Myers & Sons, Inc. as a sales associate for the Butler pre-engineered building product line. He joined LBM Construction in 1991 and assumed responsibility for the sales, order and delivery of all Butler manufactured products for LBM Construction’s design-build projects. Mr. Myers coordinates the specification, fabrication and delivery schedules between Butler Manufacturing, LBM Construction’s field operations, and the client’s building site. Mr. Myers represented LBM Construction on the firm’s achievement of the prestigious “2012 Builder of the Year” award for the Northern Region at Butler Manufacturing’s 2013 National Sales Meeting. LBM Construction was one of five (5) Butler franchises nationwide (total 1400 Butler Builders), and the winner among 250 Butler builders in the northeast, to be cited for excellence on numerous performance measures. Mr. Myers received his education from West Virginia University in Business Administration. Also, a graduate of Orchard Park High School, Mr. Myers is affiliated with the Orchard Park Little League, enjoys sports and percussion and currently resides with his family in Orchard Park, New York. Partial Client List: Light Manufacturing Alcor Envelope Company Astronics Corporation Cathedral Envelope Gintzler Graphics (Accellent) formerly Hayden Precision Industries Krepe Kraft Laidlaw Environmental Mod Pac Protective Closures PCB Piezotronics Luminescent Systems, Inc. Heavy Manufacturing Allied-Signal, Inc. Banite Loctite Corporation Bethlehem Steel Corporation Derrick Corporation Dunkirk International Glass E.I. Dupont DeNemours & Co. General Welding and Fabricating Mobil Corporation 3M/O-Cel-O TAM Ceramics Saint-Gobain Corp. Niagara Transformer Corp Service Industries Hamburg Gymnastics, Inc. Management Adjustment Bureau Schmitt’s Auto Sinclair Radio UniFirst Uniform Corporation United States Postal Service Western Division Credit Union (Re-Roof 15,000 sq.ft) Gymnastics Unlimited of Orchard Park Try-it Distributing, Inc. (120,000 sq. ft.) Service Industries Cont.…. Buffalo Niagara Court Center (BNCC) Dunn Tire Corp ECVA Eye Care Waste Management Services Ascension Industries Miller Tennis Center Guild Craft Industries St. Vincent DePaul Caplugs Industries Newstead Fire Hall Capway Systems Holland Boys & Girls Club Warehousing and Distribution Collins Marine (Boat Warehouse) Lancaster Self Storage Colonial Mini Storage Molson U.S.A. Sun Orchard Fruit Company MTI (Research Pkwy, Clarence) Roberts Gordon Heating K-Technologies Company Costanzo’s Bakery Transportation Consolidated Freightways DeCarolis Truck Rental Gorman Bus Sales and Service Pilot Air Freight Caring Harts Transportation Leonard Bus Sales Office, Professional and Industrial Fisher Price Team Center / Fisher Price Toy Store 475 International Drive 555 International Drive K.S.T. Property Management Seneca Development Corp. Western New York Pediatrics Lake Shore Medical & Hospital Expansion Chautauqua MRI Amherst Pepsi Center Ice Rink Facility (160,000 sq.ft. Butler Building) Carborundum (Saint-Gobain 45,000 sq. ft. Heavy Industrial Plant Expansion) Re-Roof / Specialty Roof Projects: Westwood-Squibb Bristol-Myers Pharmaceutical Re-Roof Project (100,000 sq.ft.) Gintzler Graphics Re-Roof Project (45,000 sq. ft.) Gintzler Graphics Re-Roof Project (7,000 sq. ft.) Monroe Tractor Re-Roof project (10,500 sq. ft.) Ellis Road, Inc. Re-Roof project (2,300 sq. ft.) Fisher Price Re-Roof Project (163,000 sq. ft.) Carborundum (Amherst Facility) MR-24 Re-Roof (5,000 sq.ft.) Fisher Bldg 12 Re-Roof (33,000 sq.ft.) St. John’s Church of Eden Re-Roof (13,600 sq.ft.) Bible Presbyterian Church Sanctuary Re-Roof (6,000 sq.ft.) Wesleyan Church of Hamburg – “The Hub” (25,000 sq.ft.) Niagara Falls Conference & Convention Center Re-Roof (160,000 sq.ft.) Village of Akron Water Authority Re-Roof (3,000 sq.ft.) Derrick Corp Machine Shop Re-Roof (23,000 sq.ft.) Saint-Gobain Re-Roof (10,000 sq.ft.) Pioneer Credit Recovery Arcade (30,000 sq. ft) Pioneer Credit Recovery Perry (40,000 sq. ft.) First Trinity Lutheran Church (15,000 sq.ft.) First United Methodist Church of Springville (8,000 sq.ft.) Bible Presbyterian Church of Grand Island (18,000 sq.ft.) Roswell Park Cancer Institute Re-Roof (30,000 sq.ft.)