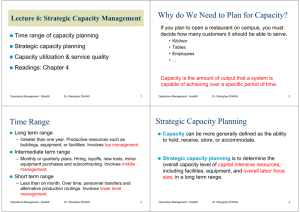

Lecture 11: MRP & JIT Material Requirements Planning Product

advertisement

Material Requirements Planning Lecture 11: MRP & JIT MRP provides a schedule: when each part or component should be ordered or produced produced. MRP is driven by dependent demand. MRP is a software system. Just in time and lean systems Just-in-time – Pull vs. Push systems – JIT requirements – JIT in services MRP (materials requirements planning ) is the logic for determining how many units of each part and component are needed and when they are needed. M t i l requirements Material i t planning l i – Product structure tree, BOM – MRP logic & Time fence Readings: Chapters 18 & 13 Operations Management – Note11 Dr. Shenghao ZHANG 1 Operations Management – Note11 Dr. Shenghao ZHANG 2 Product Structure Tree & MRP Logic Given the product structure tree and the lead time and demand information, provide a materials requirements plan that defines how many units of each component will be needed and when. Product Structure Tree for Assembly A A B(4) D(2) C(2) E(1) D(3) Operations Management – Note11 F(2) Dr. Shenghao ZHANG First, units of “A” are scheduled backwards to allow for the lead time. So,, in the materials requirement q plan, p , we p place an order for 50 units of “A” on day 9 so as to “receive” them on day 10. Lead Times A 1 day B 2 days C 1 dayy D 3 days E 4 days F 1 day Day: A Required Order Placement 1 2 3 4 5 6 7 8 9 10 50 50 LT = 1 day Demand Day 10 50 A Day 8 20 B (Spares) Day 6 15 D (Spares) 3 Operations Management – Note11 Dr. Shenghao ZHANG 4 Repeating the process for all components, we have the final materials requirements plan: Next, we schedule the components of “A”. E.g., we need 4 B’s for each A A, so for 50 A’s A s, we need 200 B’s B s. The lead time is 2 days days. Day : R e q u ire d O rd e r P la c e m e n t R e q u ire d O rd e r P la c e m e n t A B 1 2 3 4 5 6 20 LT = 2 7 9 20 50 200 10 50 200 Spares A 4x50=200 B(4) D(2) 8 A LT=1 B LT=2 C LT=1 D LT=3 E LT=4 F LT=1 Day: Required Order Placement R Required i d Order Placement Required Order Placement Required Order Placement Required Order Placement Required Order Placement Operations Management – Note11 D(3) F(2) Dr. Shenghao ZHANG D(2) 5 MRP programs are usually run every week for a planning horizon that is 8 to 12 weeks long long. MRP is a cost effective formal planning & control system but it requires commitment at all organization levels. MRP is data intensive. intensive Input data includes – Master Production Schedule (MPS): the quantity and timing of requirement for end items. – Bill of Materials (BOM): the quantities of components required to make each item (product structure trees). – Inventory Status: inventory on hand, scheduled receipts, order lead time, lot size, etc. Dr. Shenghao ZHANG 3 4 5 6 20 7 8 9 20 50 200 10 50 200 100 55 20 400 55 400 20 200 100 300 300 200 200 200 B(4) 7 Part D:: Dayy 6 40 + 15 = 55 C(2) E(1) D(3) Operations Management – Note11 Firm orders from known customers MRP: a computerized p planning p g system y Operations Management – Note11 2 A C(2) E(1) 1 F(2) Dr. Shenghao ZHANG Aggregate product p plan 6 Forecasts of demand f from random d customers Engineering design changes Master p production schedule (MPS) Inventory y transactions Bill of material file Material p planning g (MRP) Inventory record file Secondary Seco d y reports epo s Pi Primary reports Exception reports Planning reports R Reports t ffor performance f control t l Planned order schedule for inventory and production control Operations Management – Note11 Dr. Shenghao ZHANG 8 Closed Loop MRP Master Production Schedule (MPS) Time-phased Time phased plan specifying how many units of each end item the firm plans to build and when to build them. Aggregate Production Planning Master Production Scheduling Material Requirements Planning C Capacity it R Requirements i t Pl Planning i Aggregate Plan (Product Groups) No Realistic? Feedback Feedback Yes MPS (Specific End Items) Operations Management – Note11 Dr. Shenghao ZHANG Execute: Capacity Plans Material Plans 9 Types yp of Time Fences Operations Management – Note11 Dr. Shenghao ZHANG Master Production d i Schedule S h d l Time i Fences Frozen – No schedule changes allowed within this window Moderately Fi Firm Frozen Moderatel Firm Moderately Flexible Capacity – Specific p changes g allowed within p product g groups p as long as parts are available 10 Forecast and available capacity Firm Customer Orders Flexible – Significant g variation allowed as long g as overall capacity p y requirements remain at the same levels 8 15 26 Weeks Operations Management – Note11 Dr. Shenghao ZHANG 11 Operations Management – Note11 Dr. Shenghao ZHANG 12 The Demand-Pull Logic g of JIT Just-In-Timee (JIT) Jus (J ) An integrated set of activities designed to achieve highvolume production using minimal inventories (raw materials materials, work in process, and finished goods). Production is Just-In-Time Just In Time ((“pull”) pull ), not Just-In-Case Just In Case (“push”) ( push ). Elimination of waste in production effort. Th timing The ti i off production d ti resources ((e.g., parts t arrive i att th the next workstation “just in time”). Ultimate goal: smooth and rapid flow f through the system. “Big JIT” and “little JIT” Invented in Japan, used in various forms in other cultures. Fab Vendor Fab Vendor Fab Vendor Fab Vendor Sub Customers Finall Fi Assembly Sub Nothing ot g gets produced p oduced until u t needed. eeded Need is created by actual demand. A firm may have both “pull” and “push”. Operations Management – Note11 Dr. Shenghao ZHANG 13 Operations Management – Note11 Specific product areas Imported technologies Efforts concentrated on shop floor Focus on quality and reliability Two central philosophies Cooperative employee unions Subcontractor networks – Two bonuses a year in good times – Respect R ffor people l – Elimination of waste Operations Management – Note11 Quality circles – Small group improvement activities (SGIA) – Solution shared with management – High productivity and low unit costs Bottom-round management style – Decision D i i making ki att llowestt llevell possible ibl – Avoid major R & D expenditures and risks Level payrolls and secure employment – No pay cut or layoff when business conditions deteriorate – Workers as assets, not as human machines – Automotive assembly and consumer electronics 14 Respect for People The Japanese p Approach pp to Productivityy Dr. Shenghao ZHANG – Long term relationship; suppliers as part of the family Dr. Shenghao ZHANG 15 Operations Management – Note11 Dr. Shenghao ZHANG 16 Minimizing Waste (I): Uniform Plant Loading Waste in Operations p Waste is anything other than the minimum amount which hi h iis absolutely b l t l essential ti l to t production. d ti Suppose we operate a production plant that produces a single product. d t The Th production d ti could ld b be accomplished li h d using i either ith off th the two plant loading schedules below. ((1)) Waste from overproduction p Not uniform (2) Waste of waiting time (3) Transportation waste Jan. Units Feb. Units Mar. Units Total 1 200 1,200 3,500 3 500 or 4 300 4,300 9 000 9,000 Jan Units Jan. Feb Units Feb. Mar Units Mar. Total 3,000 3,000 3,000 9,000 (4) Inventory waste Uniform (5) Processing waste (6) Waste of motion (7) Waste from product defects Operations Management – Note11 How does the uniform loading help save costs? Dr. Shenghao ZHANG 17 Minimizing Waste (II): JIT Production Operations Management – Note11 Dr. Shenghao ZHANG 18 Minimizing g Waste (III): ( ) Inventoryy Reduction Produce what is needed when needed and no more. WHAT IT IS • A management philosophy • “Pull” system through the plant WHAT IT DOES • Attack waste • Expose problems and bottlenecks • Achieve streamlined production WHAT IT REQUIRES • • • • • Employee participation Industrial engineering/basics Continuous improvement Total quality control Small lot sizes Operations Management – Note11 M hi Machine downtime Scrap Work in process queues (banks) WHAT IT ASSUMES Paperwork backlog • Typically repetitive manufacturing • Stable environment Dr. Shenghao ZHANG 19 Operations Management – Note11 Vendor delinquencies Engineering design redundancies Inspection backlogs Dr. Shenghao ZHANG Change orders Design backlogs Decision backlogs 20 JIT Requirements q (A): ( ) Design g of Flow Process Linked operations Balanced workstation capacities Reduced lot sizes Reduced setup/changeover time Preventive maintenance Operations Management – Note11 Dr. Shenghao ZHANG 21 Level scheduling Underutilization of capacityy Freeze windows Operations Management – Note11 Dr. Shenghao ZHANG Build quality into the process Worker responsibility SQC (Statistical Quality Control) methods Fail-safe methods Operations Management – Note11 Dr. Shenghao ZHANG 22 JIT Requirements (D): Work with Vendors JIT Requirements (C): Stable Schedule JIT Requirements (B): Total Quality Control 23 Sharing of requirements schedule Vendor representatives on the factory floor Lead time reduction Frequent deliveries Quality expectations Operations Management – Note11 Dr. Shenghao ZHANG 24 JIT Requirements (E): Improve Product Design Standard product configuration Reduced number of parts Process design with product design Operations Management – Note11 Dr. Shenghao ZHANG 25 JIT in Services Problem-solving gg groups p Good housekeeping Clarification of flows Leveling of facility load Demand-pull scheduling Elimination of unnecessary y activities Quality at source and reliable process capabilities Long term term, cooperation with suppliers for mutual benefit Etc. Operations Management – Note11 Dr. Shenghao ZHANG 26