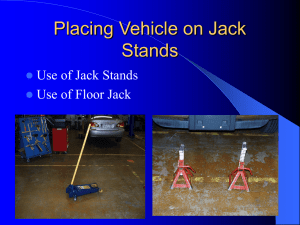

Vehicle mounted pneumatic car jack - UC DRC Home

advertisement