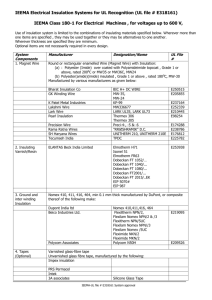

Technical Guide for NOMEX® Brand Fiber

advertisement