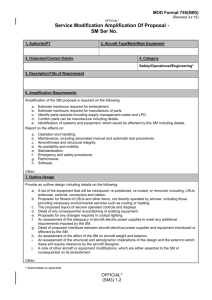

owner's & operator's guide: 777-200/-300

advertisement