1-Reynold's Experiment

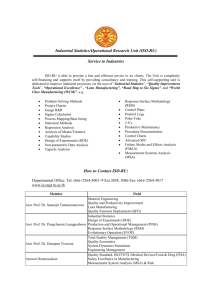

advertisement

Created by Simpo PDF Creator Pro (unregistered version) http://www.simpopdf.com Lect.No.8 Asst.Prof.Dr. Jaafar S. Maatooq 2nd Semester Flow Dynamics in Closed Conduit (Pipe Flow) 1 of 21 The flow in closed conduit ( flow in pipe ) is differ from this occur in open channel where the flow in pipe is at a pressure ( does not have a free surface ) . The flow in pipe can be demonstrated such as :- Laminar flow , - Transitional flow , - Turbulent flow . To distinction between the above features , the well known “ Reynold, s Number” can be used , according to experiments that given by “ Osborn Reynold in 19th century “ . 1-Reynold’s Experiment In 1883, Osborne Reynolds demonstrated that there are two distinctly different types of flow by injecting a very thin stream of colored fluid having the same density of water into a large transparent tube through which water is flowing. And from the feature of streaming this dye fluid , Reynold give a number can be considered as a boundary between flow faces , this number is a function of , flow velocity , fluid density , pipe diameter , and fluid viscosity , where ; R= f (V , ρ , υ (or μ ) , D ) …………………….. (1) and then , R= VDρ/μ or R = VD/υ ; R= Reynolds No., μ = dynamic viscosity , υ = kinematic viscosity . See Figure(1) , below for Reynold”s experiments ; Created by Simpo PDF Creator Pro (unregistered version) http://www.simpopdf.com Lect.No.8 Asst.Prof.Dr. Jaafar S. Maatooq 2nd Semester Flow Dynamics in Closed Conduit (Pipe Flow) 2 of 21 Fig.(1) : Experiments shows the flow state as demonstrated by Reynolds Observations (dye) Reynolds Number, Re Flow Classification <2000 Laminar Flow 2000 - 4000 Transitional Created by Simpo PDF Creator Pro (unregistered version) http://www.simpopdf.com Lect.No.8 Asst.Prof.Dr. Jaafar S. Maatooq 2nd Semester Flow Dynamics in Closed Conduit (Pipe Flow) 3 of 21 Transitional/ Turbulent > 4000 Turbulent Created by Simpo PDF Creator Pro (unregistered version) http://www.simpopdf.com Lect.No.8 Asst.Prof.Dr. Jaafar S. Maatooq 2nd Semester Flow Dynamics in Closed Conduit (Pipe Flow) 4 of 21 2-Viscous (Real) Flow in Conduits ,Head Loss in Pipes from Friction ( Major Losses) The head loss between two points in a circular pipe carrying a fluid under pressure can be found by ; hf= ΔP γ Where: ∆p = p1 − p2 , and can be measured by using piezometer tubes. The velocity of the flow can be found by using a Pitot tube. The reading of the Pitot tube is the total head = pressure head + velocity head Created by Simpo PDF Creator Pro (unregistered version) http://www.simpopdf.com Lect.No.8 Asst.Prof.Dr. Jaafar S. Maatooq 2nd Semester Flow Dynamics in Closed Conduit (Pipe Flow) 5 of 21 The total “ friction head loss “ (hL) , can be calculated using “ Darcy Equation” by well estimating of “ friction factor , f “ ; where :- Also the “ friction head loss“ (hL) , can be calculated by using Hazen William Equation , where ; Created by Simpo PDF Creator Pro (unregistered version) http://www.simpopdf.com Lect.No.8 Asst.Prof.Dr. Jaafar S. Maatooq 2nd Semester Flow Dynamics in Closed Conduit (Pipe Flow) 6 of 21 Created by Simpo PDF Creator Pro (unregistered version) http://www.simpopdf.com Lect.No.8 Asst.Prof.Dr. Jaafar S. Maatooq 2nd Semester Flow Dynamics in Closed Conduit (Pipe Flow) 7 of 21 Created by Simpo PDF Creator Pro (unregistered version) http://www.simpopdf.com Lect.No.8 Asst.Prof.Dr. Jaafar S. Maatooq 2nd Semester Flow Dynamics in Closed Conduit (Pipe Flow) 3-Head Loss versus Discharge 8 of 21 Created by Simpo PDF Creator Pro (unregistered version) http://www.simpopdf.com Lect.No.8 Asst.Prof.Dr. Jaafar S. Maatooq 2nd Semester Flow Dynamics in Closed Conduit (Pipe Flow) 9 of 21 The friction factor of “Darcy Equation” can be estimated , using “ Moody Diagram” as shown in Fig.(2) , below ; Fig.(2): Friction Factor estimation as presented by Moody Lect.No.8 Created by Simpo PDF Creator Pro (unregistered version) http://www.simpopdf.com Asst.Prof.Dr. Jaafar S. Maatooq 2nd Semester Flow Dynamics in Closed Conduit (Pipe Flow) 10 of 21 4-Method to Determine Darcy-Weisbach friction factor ( f ) PIPE FLOWS Laminar (R < 2,000) Turbulent (R > 4,000) f = 64/R Smooth (δv > e) Transitional Wholly Rough (0.071e ≤ δv ≤ e) (δv < 0.071e) Turbulent (Smooth): Prandtle ……….. 1 √f Blasisus ……….. f = = 2 log ( 0.316 R0.25 R√f 2.51 for R > 4000 ) for 3000 < R < 100000 Turbulent ( Transitional) : Colebrook …….. 1 √f = -2 log [ e D 3.7 + Turbulent ( Wholly Rough ): Von- Karamen … 1 √f = 2 log ( 3.7 e D ) 2.51 R√f ] Lect.No.8 Created by Simpo PDF Creator Pro (unregistered version) http://www.simpopdf.com Asst.Prof.Dr. Jaafar S. Maatooq 2nd Semester Flow Dynamics in Closed Conduit (Pipe Flow) 11 of 21 5-Minor Losses in Pipe Losses caused by fittings, bends, valves, enlargement , contraction . Losses are proportional to – velocity of flow, geometry of device , where; hL= K (V2/2g) The value of K is typically provided for various devices , where , K is a loss factor - has no units (dimensionless) . The following variation in design and installation devices in pipe systems which cause “ minor losses “ :- Lect.No.8 Created by Simpo PDF Creator Pro (unregistered version) http://www.simpopdf.com Asst.Prof.Dr. Jaafar S. Maatooq 2nd Semester Flow Dynamics in Closed Conduit (Pipe Flow) 12 of 21 • Sudden enlargement : Energy lost is because of turbulence. Amount of turbulence depends on the differences in pipe diameters . The values of K have been experimentally determined and provided in Fig.(3) , below . Fig.(3): Loss Factor for Sudden Enlargement Lect.No.8 Created by Simpo PDF Creator Pro (unregistered version) http://www.simpopdf.com Asst.Prof.Dr. Jaafar S. Maatooq 2nd Semester Flow Dynamics in Closed Conduit (Pipe Flow) 13 of 21 • Gradual Enlargement : If the enlargement is gradual , the energy losses are less. The loss again depends on the ratio of the pipe diameters and the angle of enlargement. hL= K (V12/2g) K can be determined from Fig.(4) , Below ; Fig.(4): Loss Factor for Gradual Enlargement Lect.No.8 Created by Simpo PDF Creator Pro (unregistered version) http://www.simpopdf.com Asst.Prof.Dr. Jaafar S. Maatooq 2nd Semester Flow Dynamics in Closed Conduit (Pipe Flow) 14 of 21 Notes ; • If angle increases (in pipe enlargement) – minor losses increase • If angle decreases – minor losses decrease, but you also need a longer pipe to make the transition – that means more FRICTION losses - therefore there is a tradeoff and minimum loss including minor and friction losses occur for angle of 7 degrees . • Exit Loss : • Case of where pipe enters a tank – a very large enlargement , • The tank water is assumed to be stationery, that is, the velocity is zero. • Therefore all kinetic energy in pipe is dissipated . hL= 1.0 (V12/2g) where K=1 for this case of exit . Lect.No.8 Created by Simpo PDF Creator Pro (unregistered version) http://www.simpopdf.com Asst.Prof.Dr. Jaafar S. Maatooq 2nd Semester Flow Dynamics in Closed Conduit (Pipe Flow) 15 of 21 • Sudden Contraction : Decrease in pipe diameter ; Loss is given by :hL= K (V22/2g) Note that the loss is related to the velocity in the second (smaller) pipe . The loss is associated with the contraction of flow and turbulence at the change of diameter and vena contracta ,which is formed at the beginning of the smaller diameter . See fig.(10.8) , below . The section at which the flow is the narrowest is called Vena Contracta , at vena contracta, the velocity is maximum . K can be computed based on diameter ratio and velocity of flow using Fig.(5) below. Note that the energy losses for sudden contraction are less than those for sudden enlargement . Lect.No.8 Created by Simpo PDF Creator Pro (unregistered version) http://www.simpopdf.com Asst.Prof.Dr. Jaafar S. Maatooq 2nd Semester Flow Dynamics in Closed Conduit (Pipe Flow) 16 of 21 Fig.(5): Loss Factor for Sudden Contraction • Gradual Contraction: Again a gradual contraction will lower the energy loss (as opposed to sudden contraction). θ is called the cone angle. Lect.No.8 Created by Simpo PDF Creator Pro (unregistered version) http://www.simpopdf.com Asst.Prof.Dr. Jaafar S. Maatooq 2nd Semester Flow Dynamics in Closed Conduit (Pipe Flow) 17 of 21 hL= K (V22/2g) K is given by Fig.(6) , below , Note that K values increase for very small angles (less than 15 degrees) . Fig.(6): Loss Factor for Gradual Contraction Lect.No.8 Created by Simpo PDF Creator Pro (unregistered version) http://www.simpopdf.com Asst.Prof.Dr. Jaafar S. Maatooq 2nd Semester Flow Dynamics in Closed Conduit (Pipe Flow) • Entrance Losses : 18 of 21 Lect.No.8 Created by Simpo PDF Creator Pro (unregistered version) http://www.simpopdf.com Asst.Prof.Dr. Jaafar S. Maatooq 2nd Semester Flow Dynamics in Closed Conduit (Pipe Flow) 19 of 21 • Resistance Coefficient for Valves and Fittings : The minor losses resulting when using any fittings (such as valve , elbow , bend , etc. ) can be computed by :hL= K (V 2/2g) Where “ K “ is computed by using a so called “ Equivalent Length “ as :K= Le D fT Le = equivalent length (length of pipe with same resistance as the fitting/valve) , fT = friction factor . The equivalent ratio (Le/D) for various valves/fittings , and “fT” for new steel pipe can be computed using Tables below ; For OLD pipes however, fT cannot be computed by this table. You have to use the procedure we used for Moody’s diagram :• Get “ε” for the pipe type from Table(3.8) , • Determine “D/ ε” for the pipe , • Then use the Moody diagram to determine the value of “fT” , for the zone of complete turbulence . Lect.No.8 Created by Simpo PDF Creator Pro (unregistered version) http://www.simpopdf.com Asst.Prof.Dr. Jaafar S. Maatooq 2nd Semester Flow Dynamics in Closed Conduit (Pipe Flow) 20 of 21 Lect.No.8 Created by Simpo PDF Creator Pro (unregistered version) http://www.simpopdf.com Asst.Prof.Dr. Jaafar S. Maatooq 2nd Semester Flow Dynamics in Closed Conduit (Pipe Flow) 21 of 21