SURFACE

MINING

EXTRACTION

EQUIPMENT

PART C

Caterpillar

Performance

Handbook

®

Edition 44

800.437.4228

www.hawthornecat.com

© 2014 Caterpillar. All Rights Reserved. CAT, CATERPILLAR, BUILT FOR IT, their respective logos, “Caterpillar Yellow,” the “Power Edge” trade dress as well as

corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission.

ELECTRIC ROPE SHOVELS

CONTENTS

ELECTRIC ROPE SHOVELS

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digging Envelopes. . . . . . . . . . . . . . . . . . . . . . . .

General Dimensions . . . . . . . . . . . . . . . . . . . . . .

Ground Bearing Pressure . . . . . . . . . . . . . . . . . .

Dipper Selection . . . . . . . . . . . . . . . . . . . . . . . . .

Truck Match . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FEATURES

16-29

16-29

16-32

16-35

16-42

16-49

16-50

16-51

AC IGBT Electrics

With over 30 years of AC experience and over 200

operating AC machines, Bucyrus led the industry in AC

electric rope shovels. Caterpillar will carry on this proud

tradition. Since its launch in 1981, the AC electric rope

shovel has gained strong industry acceptance.

●

Superior availability: AC IGBT electric rope shovels

have routinely demonstrated electrical availabilities

of greater than 98%.

●

Greater reliability: Fewer components including interchangeable inverters. IGBT systems require no fuses

or circuit breakers.

●

Reduced maintenance: No regular maintenance is

required on IGBT power control modules. Motor

maintenance on AC machines is reduced to greasing

and replacing bearings every 30,000 hours.

●

Reduced inventory: Cat IGBT is a mine quality system

with rugged welded cabinets to withstand harsh mining conditions.

INTRODUCTION

Electric rope shovels are one of the largest loading

tools on the market. They run in a truck-shovel operation with mining trucks in order to move large quantities of material at a low cost per ton. Electric rope

shovels are used to mine a variety of minerals including

oil sands, coal overburden, copper, gold, iron ore, etc.

They operate at extreme climates in tough surface mining applications all over the world.

16

Edition 44

PHB-Sec16-ElectricRopeShovels(pg029-052).indd 29

16-29

12/20/13 8:54 AM

Electric

Rope Shovels

Features

Robust Front End Design

The Cat free-floating tubular handle design presents

many benefits over traditional rack-and-pinion systems,

including:

●

Fast swing times: The Cat deck-mounted, rather than

boom-mounted, crowd machinery greatly reduces

front end weight for reduced swing inertia and fast

swing times.

●

Elimination of torsional loading: The free-floating handle design allows the Cat handle to rotate under torsional stress, transferring stress into the ropes rather

than into the boom.

●

Improved line of sight: Cat machines provide operators with a much-improved left-hand line of sight by

moving around the crowd machinery from the boom

to the deck.

●

Efficient digging: Wide-set boom point sheaves stabilize the dipper as it engages the bank for easier and

more efficient digging.

Cat Cab

Caterpillar’s state-of-the-art operator’s cab is the product of a multi-year collaboration between Caterpillar,

mining companies and shovel operators. The cab provides industry-leading visibility with excellent line of

sight supplemented by five optimally-mounted cameras

and display screens. It provides enhanced safety through

dual access/egress doors and an optimally-placed trainer

seat with independent emergency stop. Additionally, the

new cab offers the smoothest, most comfortable ride

available with an ergonomic, adjustable operator’s seat

with a fully pneumatic suspension system, low-effort

joysticks and dual display screens optimized for operator comfort.

Power Demand Management System

Caterpillar’s exclusive Power Demand Management

System for 7495 Series machines allows an electric rope

shovel to operate in spite of electrical infrastructure

challenges. This patented energy storage and power

management technology reduces the number of generators required to run an electric rope shovel, giving

mines the option of production without grid power.

Additionally, this technology lowers the machine’s peak

power requirement, resulting in more alternatives when

mines plan for power.

16-30

HydraCrowd™

HydraCrowd represents the first new crowd technology developed in the past 70 years. A hydraulic cylinder

inside the tubular dipper handle maintains all the benefits

of the Cat front end while eliminating the need for routine

crowd/retract rope replacements. HydraCrowd cuts

downtime by reducing the number of maintenance events

needed to keep the machine operational. HydraCrowd

is controlled with proven Cat IGBT technology and has

complete diagnostic and troubleshooting information

with step-by-step instructions. It is designed to operate in

all climates to ensure each shovel will be able to deliver

maximum productivity in the harshest conditions.

LatchFree™

The LatchFree Dipper System is Caterpillar’s solution to customers’ number-one cause of downtime —

the latch assembly. The LatchFree dipper eliminates

the latch assembly, replacing it with a strong steel link

mounted to the dipper back — away from material flow.

The system enhances safety by reducing the number of

maintenance events required to maintain the system and

increase reliability by reducing unplanned downtime.

The LatchFree dipper system comes complete with a

comprehensive training program to ensure customers

achieve maximum system benefits.

FastFil™ Dipper Design

The unique FastFil dipper provides customers with

faster and fuller dipper loads where the application permits. Its trapezoidal shape accommodates the natural

configuration of the load, eliminating voids that occur

with box-shaped dippers for improved fill factors. The

trapezoidal shape also reduces dipper size and weight

for improved maneuverability and faster swing times.

Additionally, optimized lip and rake angles lead to

improved bank penetration and eliminate bulldozing

for reduced material turbulence. Finally, a shorter dipper body cuts load and dump time. Combined, FastFil

features optimize fill factor.

Edition 44

PHB-Sec16-ElectricRopeShovels(pg029-052).indd 30

12/20/13 8:54 AM

Features

AccessDirect™

AccessDirect is an electrical interface system that

facilitates remote access to a machine’s onboard computer via the Internet. With AccessDirect, maintenance

personnel can analyze faults from off-site locations and

arrive on-site prepared to resolve the issues — leading to reduced machine downtime. AccessDirect also

enables factory experts to remote-access and troubleshoot faults, resulting in superior response times and

reduced mean time to repair.

MIDAS

The MIDAS health monitoring system continues to

optimize machine performance by providing, logging

and analyzing data on a variety of machine variables.

MIDAS comes complete with a built-in report generator that outputs data in a format that can be easily

analyzed to identify opportunities to improve machine

performance. When paired with AccessDirect, MIDAS

provides real-time monitoring of shovel operation and

provides users with a 3D model to watch the shovel in

motion.

AccuLoad

AccuLoad is a data analysis system that provides

real-time feedback on dipper loads. AccuLoad’s load

calculation is accomplished without mechanical sensors, eliminating the need for recalibration, a common

problem with other load-weighing systems. The system

can be employed to calculate material moved, to monitor overloading of trucks or to allow operators to study

their load and shift performance. It can also log operator performance data which, when paired with MIDAS,

can generate reports to help identify training opportunities to increase shift production.

Electric

Rope Shovels

Major Structures

Cat major structures are designed for extended performance in harsh mining conditions. Structures are

manufactured using cold-weather, impact-resistance,

high-strength steel with select welds of full-penetration,

profiled and ground type. All welds undergo visual

inspection, with critical welds also receiving MT, UT

or X-ray inspection. Large furnaces are used to stressrelieve entire weldments for reduced susceptibility to

cracking. Interiors of finished structures are painted

white to facilitate field inspection.

Safety

Safety plays an integral role in everything we do

at Caterpillar, from our factory floors to our service

centers to our clients’ mine sites. Caterpillar’s commitment to safety is apparent in our product designs, which

undergo risk assessments and are designed to meet

strict codes and regulations. Examples of our safety

focus include the development of a cab with dual egress

doors and flat floors to provide stretcher-to-operator

access, LatchFree dipper and HydraCrowd for reduced

unplanned maintenance, and extensive training programs to help keep your operators and maintenance personnel out of harm’s way. Additionally, the electric rope

shovel product line has incorporated additional safety

product enhancements as part of Caterpillar’s engagement and dedication to the Earth Moving Equipment

Safety Round Table or EMESRT.

16

Edition 44

PHB-Sec16-ElectricRopeShovels(pg029-052).indd 31

16-31

12/20/13 8:54 AM

Electric

Rope Shovels

Specifications

MODEL

Payload

Operating Weight

Dipper Range

Drive

Distribution System Requirements (separate system)

Distribution System Requirements (large system)

Average 15 Minute Demand

Peak Power

Crowd Type

Hoist Ropes

Number

Diameter

Type

Construction

Crowd/Retract Ropes

Number

Diameter

Type

Construction

16-32

7295

7395

45 tonnes

50 tons

789 251 kg

1,740,000 lb

19.1-38.3 m³

25-50 yd³

AC IGBT

2000 kVA

1320 kVA

538-753 kW

2152 kW

Tubular handle rope crowd

64 tonnes

70 tons

1 288 656 kg

2,841,000 lb

20.7-55.8 m³

27-73 yd³

AC IGBT

3500 kVA

2000 kVA

777-1087 kW

3106 kW

Tubular handle rope crowd

2

57 mm

2.25"

Twin dual

6×41

2

70 mm

2.8"

Twin dual

8×37

1 crowd, 1 retract

60 mm

2.4"

Single dual

8×37

1 crowd, 1 retract

64 mm

2.5"

Single dual

8×37

Edition 44

PHB-Sec16-ElectricRopeShovels(pg029-052).indd 32

12/20/13 8:54 AM

Specifications

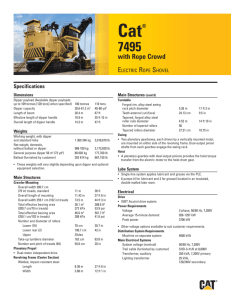

MODEL

Payload

Operating Weight

Dipper Range

Drive

Distribution System Requirements

(separate system)

Distribution System Requirements

(large system)

Average 15 Minute Demand

Peak Power

Crowd Type

Hoist Ropes

Number

Diameter

Type

Construction

Crowd/Retract Ropes

Number

Diameter

Type

Construction

Electric

Rope Shovels

7495 HD

7495

7495 HydraCrowd

82 tonnes

90 tons

1 306 346 kg 2,880,000 lb

27.5-60.4 m³

36-79 yd³

AC IGBT

109 tonnes

120 tons

1 369 246 kg

3,018,670 lb

30.6-62.7 m³

40-82 yd³

AC IGBT

109 tonnes

120 tons

1 382 400 kg

3,047,670 lb

30.6-62.7 m³

40-82 yd³

AC IGBT

3500 kVA

4000 kVA

4000 kVA

2000 kVA

832-1165 kW

3330 kW

Tubular handle rope crowd

—

926-1297 kW

3706 kW

Tubular handle rope crowd

—

945-1322 kW

3778 kW

Tubular handle HydraCrowd

2

70 mm

2.8"

Twin dual

8×37

2

70 mm

2.8"

Twin dual

8×37

1 crowd, 1 retract

64 mm

2.5"

Single dual

8×37

1 crowd, 1 retract

64 mm

2.5"

Single dual

8×37

2

70 mm

2.8"

Twin dual

8×37

N/A

N/A

N/A

N/A

N/A = Not Available.

16

Edition 44

PHB-Sec16-ElectricRopeShovels(pg029-052).indd 33

16-33

12/20/13 8:54 AM

Electric

Rope Shovels

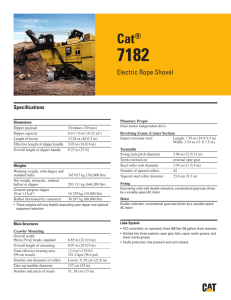

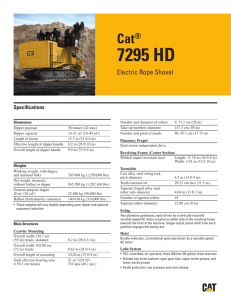

Specifications

MODEL

Payload

Operating Weight

Dipper Range

Drive

Distribution System Requirements (separate system)

Average 15 Minute Demand

Peak Power

Crowd Type

Hoist Ropes

Number

Diameter

Type

Construction

Crowd/Retract Ropes

Number

Diameter

Type

Construction

7495 HF

7495 HF HydraCrowd

109 tonnes

120 tons

1 429 120 kg

3,150,670 lb

30.6-62.7 m³

40-82 yd³

AC IGBT

4000 kVA

926-1297 kW

3706 kW

Tubular handle rope crowd

109 tonnes

120 tons

1 442 274 kg

3,179,670 lb

30.6-62.7 m³

40-82 yd³

AC IGBT

4000 kVA

945-1322 kW

3778 kW

Tubular handle HydraCrowd

2

70 mm

2.8"

Twin dual

8×37

1 crowd, 1 retract

64 mm

2.5"

Single dual

8×37

2

70 mm

2.8"

Twin dual

8×37

N/A

N/A

N/A

N/A

N/A = Not Available.

16-34

Edition 44

PHB-Sec16-ElectricRopeShovels(pg029-052).indd 34

12/20/13 8:54 AM

Digging Envelopes

● 7295

Electric

Rope Shovels

m

ft

m

ft

MODEL

Dumping Height

Dumping Height at Maximum Crowd Limit

Dumping Radius

Cutting Height

Cutting Radius

Effective Length of Dipper Handle

7295

9.22 m

7.00 m

18.69 m

15.56 m

21.78 m

9.45 m

30'3"

23'0"

61'4"

51'1"

71'5"

31'0"

16

Edition 44

PHB-Sec16-ElectricRopeShovels(pg029-052).indd 35

16-35

12/20/13 8:54 AM

Electric

Rope Shovels

Digging Envelopes

● 7395

m

ft

m

ft

MODEL

Dumping Height

Dumping Height at Maximum Crowd Limit

Dumping Radius

Cutting Height

Cutting Radius

Effective Length of Dipper Handle

16-36

7395

10.00 m

7.91 m

20.50 m

16.70 m

23.30 m

14.30 m

32'11"

25'11"

67'2"

54'11"

76'5"

47'0"

Edition 44

PHB-Sec16-ElectricRopeShovels(pg029-052).indd 36

12/20/13 8:54 AM

Digging Envelopes

● 7495 HD

Electric

Rope Shovels

m

ft

m

ft

MODEL

Dumping Height

Dumping Height at Maximum Crowd Limit

Dumping Radius

Cutting Height

Cutting Radius

Effective Length of Dipper Handle

7495 HD

10.60 m

8.45 m

21.00 m

17.30 m

23.97 m

14.30 m

34'10"

27'9"

69'0"

56'10"

78'8"

47'0"

16

Edition 44

PHB-Sec16-ElectricRopeShovels(pg029-052).indd 37

16-37

12/20/13 8:54 AM

Electric

Rope Shovels

Digging Envelopes

● 7495

m

ft

m

ft

MODEL

Dumping Height

Dumping Height at Maximum Crowd Limit

Dumping Radius

Cutting Height

Cutting Radius

Effective Length of Dipper Handle

16-38

7495

10.06 m

8.61 m

21.64 m

17.80 m

25.20 m

14.30 m

33'0"

28'3"

71'0"

58'5"

82'8"

47'0"

Edition 44

PHB-Sec16-ElectricRopeShovels(pg029-052).indd 38

12/20/13 8:54 AM

Digging Envelopes

7495 HydraCrowd

●

Electric

Rope Shovels

m

ft

m

ft

MODEL

Dumping Height

Dumping Height at Maximum Crowd Limit

Dumping Radius

Cutting Height

Cutting Radius

Effective Length of Dipper Handle

7495 HydraCrowd

10.06 m

8.61 m

21.64 m

17.80 m

25.20 m

14.30 m

33'0"

28'3"

71'0"

58'5"

82'8"

47'0"

16

Edition 44

PHB-Sec16-ElectricRopeShovels(pg029-052).indd 39

16-39

12/20/13 8:54 AM

Electric

Rope Shovels

Digging Envelopes

● 7495 HF

m

ft

m

ft

MODEL

Dumping Height

Dumping Height at Maximum Crowd Limit

Dumping Radius

Cutting Height

Cutting Radius

Effective Length of Dipper Handle

16-40

7495 HF

10.06 m

8.61 m

21.64 m

17.80 m

25.20 m

14.30 m

33'0"

28'3"

71'0"

58'5"

82'8"

47'0"

Edition 44

PHB-Sec16-ElectricRopeShovels(pg029-052).indd 40

12/20/13 8:54 AM

●

Digging Envelopes

7495 HF HydraCrowd

Electric

Rope Shovels

m

ft

m

ft

MODEL

Dumping Height

Dumping Height at Maximum Crowd Limit

Dumping Radius

Cutting Height

Cutting Radius

Effective Length of Dipper Handle

7495 HF HydraCrowd

10.06 m

8.61 m

21.64 m

17.80 m

25.20 m

14.30 m

33'0"

28'3"

71'0"

58'5"

82'8"

47'0"

16

Edition 44

PHB-Sec16-ElectricRopeShovels(pg029-052).indd 41

16-41

12/20/13 8:54 AM

General Dimensions

● 7295

CL ROTATION

CL ROTATION

Electric

Rope Shovels

MODEL

Boom Length

A

B

C

D

E

F

G

H

I

16-42

Height

7295

18.00 m

59'0"

18.15 m

59'7"

A-Frame Height

11.94 m

39'2"

Overall Width

12.39 m

40'8"

Tail Swing Radius

7.98 m

26'2"

Clearance Radius

17.48 m

57'4"

Radius of Level Floor

15.58 m

51'1"

Minimum Ground Clearance

0.78 m

2'6"

Track Length

10.26 m

33'8"

Operator Eye Level

8.20 m

26'11"

Edition 44

PHB-Sec16-ElectricRopeShovels(pg029-052).indd 42

12/20/13 8:54 AM

General Dimensions

● 7395

MODEL

Boom Length

A

B

C

D

E

F

G

H

I

Electric

Rope Shovels

7395

19.51 m

64'0"

Height

19.50 m

63'11"

A-Frame Height

13.30 m

43'8"

Overall Width

13.01 m

42'8"

Tail Swing Radius

8.67 m

28'5"

Clearance Radius

19.05 m

62'6"

Radius of Level Floor

15.40 m

50'6"

Minimum Ground Clearance

0.86 m

2'10"

Track Length

10.41 m

34'2"

Operator Eye Level

8.64 m

28'4"

16

Edition 44

PHB-Sec16-ElectricRopeShovels(pg029-052).indd 43

16-43

12/20/13 8:54 AM

Electric

Rope Shovels

General Dimensions

● 7495 HD

MODEL

Boom Length

A

B

C

D

E

F

G

H

I

16-44

7495 HD

20.40 m

67'0"

Height

20.10 m

65'10"

A-Frame Height

13.30 m

43'8"

Overall Width

13.01 m

42'8"

Tail Swing Radius

8.67 m

28'5"

Clearance Radius

19.74 m

64'9"

Radius of Level Floor

16.92 m

55'6"

Minimum Ground Clearance

0.86 m

2'10"

Track Length

10.41 m

34'2"

Operator Eye Level

8.64 m

28'4"

Edition 44

PHB-Sec16-ElectricRopeShovels(pg029-052).indd 44

12/20/13 8:54 AM

General Dimensions

● 7495

MODEL

Boom Length

A

B

C

D

E

F

G

H

I

Electric

Rope Shovels

7495

20.40 m

67'0"

Height

20.87 m

68'6"

A-Frame Height

14.00 m

46'0"

Overall Width

13.11 m

43'0"

Tail Swing Radius

9.34 m

30'8"

Clearance Radius

19.65 m

64'5"

Radius of Level Floor

17.47 m

57'4"

Minimum Ground Clearance

0.90 m

3'0"

Track Length

11.43 m

37'6"

Operator Eye Level

10.61 m

34'10"

16

Edition 44

PHB-Sec16-ElectricRopeShovels(pg029-052).indd 45

16-45

12/20/13 8:54 AM

Electric

Rope Shovels

General Dimensions

● 7495 HydraCrowd

MODEL

Boom Length

A

B

C

D

E

F

G

H

I

16-46

7495 HydraCrowd

20.40 m

67'0"

Height

20.87 m

68'6"

A-Frame Height

14.00 m

46'0"

Overall Width

13.11 m

43'0"

Tail Swing Radius

9.34 m

30'8"

Clearance Radius

19.65 m

64'5"

Radius of Level Floor

17.47 m

57'4"

Minimum Ground Clearance

0.90 m

3'0"

Track Length

11.43 m

37'6"

Operator Eye Level

10.61 m

34'10"

Edition 44

PHB-Sec16-ElectricRopeShovels(pg029-052).indd 46

12/20/13 8:54 AM

General Dimensions

● 7495 HF

MODEL

Boom Length

A

B

C

D

E

F

G

H

I

Electric

Rope Shovels

7495 HF

20.40 m

67'0"

20.87 m

68'6"

A-Frame Height

14.00 m

46'0"

Overall Width

13.96 m

46'1"

Tail Swing Radius

9.34 m

30'8"

Clearance Radius

19.65 m

64'5"

Radius of Level Floor

17.47 m

57'4"

Minimum Ground Clearance

0.90 m

3'0"

Track Length

11.43 m

37'6"

Operator Eye Level

10.61 m

34'10"

Height

16

Edition 44

PHB-Sec16-ElectricRopeShovels(pg029-052).indd 47

16-47

12/20/13 8:54 AM

Electric

Rope Shovels

General Dimensions

● 7495 HF HydraCrowd

MODEL

Boom Length

A

B

C

D

E

F

G

H

I

16-48

7495 HF HydraCrowd

20.40 m

67'0"

20.87 m

68'6"

A-Frame Height

14.00 m

46'0"

Overall Width

13.96 m

46'1"

Tail Swing Radius

9.34 m

30'8"

Clearance Radius

19.65 m

64'5"

Radius of Level Floor

17.47 m

57'4"

Minimum Ground Clearance

0.90 m

3'0"

Track Length

11.43 m

37'6"

Operator Eye Level

10.61 m

34'10"

Height

Edition 44

PHB-Sec16-ElectricRopeShovels(pg029-052).indd 48

12/20/13 8:54 AM

Ground Bearing Pressure

GROUND BEARING PRESSURE

conditions. Selecting links that require higher ground bearing pressure than what exists at site will make propelling

the machine difficult. A link too narrow for the application

may even cause the crawlers to sink into the ground.

Ground bearing pressure, or the amount of weight

that can be supported by ground conditions, determines

the link width (and occasionally the machine model)

that can be used at a mine site. Softer ground conditions

require wider links while the softest conditions (i.e. oil

sands) require a specific model (7495 HF) which was

designed to operate under low ground bearing pressure

MODEL

Standard Link Length

Ground Bearing Pressure

Optional Link Length

Ground Bearing Pressure

The chart below lists the link length options for each

electric rope shovel model as well as the corresponding

minimum ground bearing pressures.

7295

140 cm

372 kPa

183 cm

284 kPa

7395

55"

53.9 psi

72"

41.2 psi

Electric

Rope Shovels

213 cm

395 kPa

274 cm

308 kPa

MODEL

7495 HydraCrowd

Standard Link Length

Ground Bearing Pressure

Optional Link Length

Ground Bearing Pressure

200 cm

374 kPa

259 cm

289 kPa

79"

54.2 psi

102"

50 psi

7495 HD

84"

57.4 psi

108"

44.6 psi

213 cm

401 kPa

274 cm

311 kPa

7495 HF

318 cm

245 kPa

356 cm

219 kPa

125"

35.6 psi

140"

31.8 psi

7495

84"

58.1 psi

108"

45.2 psi

200 cm

372 kPa

259 cm

288 kPa

79"

53.9 psi

102"

41.8 psi

7495 HF HydraCrowd

318 cm

248 kPa

356 cm

221 kPa

125"

35.9 psi

140"

32.1 psi

16

Edition 44

PHB-Sec16-ElectricRopeShovels(pg029-052).indd 49

16-49

12/20/13 8:54 AM

Electric

Rope Shovels

Dipper Selection

DIPPER SELECTION

density, divide insitu (undisturbed material density) by

1 + swell factor.

Selecting the correct dipper size plays an integral role

in maximizing productivity from a truck shovel operation. Optimal dipper size is a function of truck size,

material loose density, and fill factor.

Material loose density =

Insitu

(1 + swell factor)

The first step in calculating dipper size is to determine the machine’s optimal payload based on truck

size. To calculate this, divide truck payload by three and

four (three or four pass even loading is ideal for high

productivity). Compare these values to the machine’s

maximum payload. The machine’s optimal payload is

the largest value that is less than the maximum payload.

Once material loose density is calculated, use the

equation below to find the optimal dipper size.

For example, consider a mine operating a 7495 shovel

(maximum payload = 120 tons) and 797 trucks (payload = 400 tons). 400 ÷ 3 = 133.3 and 400 ÷ 4 = 100.

133.3 can be eliminated as it is greater than the shovel’s

maximum payload (120 tons). 100 tons is the largest

value less than the machine’s maximum payload, and

therefore, is the machine’s optimal payload.

For example: For a mine with the following conditions:

Optimal machine

payload

Optimal dipper size =

× Fill factor

Material loose

density

Insitu: 2.276 ton/yd³

Swell factor: 35%

Fill factor: 95%

Optimal machine payload: 100 tons

Optimal dipper size =

Once optimal machine payload is determined, material loose density and fill factor are used to calculate

the optimum dipper size. To calculate material loose

MODEL

Dipper Range

MODEL

Dipper Range

16-50

7295

19.138.3 m³

7395

2550 yd³

20.755.8 m³

7495 HydraCrowd

30.6-62.7 m³

40-82 yd³

100 tons

× .95 = 62.5 yd³

2.276 ÷

(1 + 0.35)

7495 HD

2773 yd³

27.560.4 m³

7495 HF

30.6-62.7 m³

40-82 yd³

7495

3679 yd³

30.662.7 m³

4082 yd³

7495 HF HydraCrowd

30.6-62.7 m³

40-82 yd³

Edition 44

PHB-Sec16-ElectricRopeShovels(pg029-052).indd 50

12/20/13 8:54 AM

Truck Match

Electric

Rope Shovels

TRUCK MATCH

Truck shovel match, or the number of passes necessary

to load a truck, has a major impact on an operation’s

productivity. To optimize productivity, 3 to 4 even pass

loading of trucks is ideal. The chart below shows pass

match between Cat electric rope shovels and Cat trucks.

MODEL

772G

773G

775G

777G

MT3300 AC

785D

789D

MT3700 AC

MT4400 AC

793F

795F AC

MT5500 AC

MT6300 AC

797F

Payload

7295

7395

7495 HD

7495

7495 HF

tonne (ton)

45 (50)

64 (70)

82 (90)

109 (120)

109 (120)

45 (50)

57 (63)

65 (72)

97 (107)

2

136 (150)

3

2

2

136 (150)

3

2

2

2

181 (200)

4

3

186 (205)

4

3

2

221 (244)

5

4

3

2

2

227 (250)

5

2

4

3

2

313 (345)

5

4

3

3

326 (360)

5

4

3

3

363 (400)

4

4

4

363 (400)

4

4

4

16

Edition 44

PHB-Sec16-ElectricRopeShovels(pg029-052).indd 51

16-51

12/20/13 8:54 AM

Notes —

16-52

Edition 44

PHB-Sec16-ElectricRopeShovels(pg029-052).indd 52

12/20/13 8:54 AM