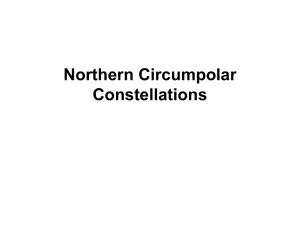

Cat®

7295 HD

Electric Rope Shovel

Specifications

Dimensions

Dipper payload

Dipper capacity

Length of boom

Effective length of dipper handle

Overall length of dipper handle

Weights

Working weight, with dipper,

and standard links

Net weight, domestic,

without ballast or dipper

General-purpose dipper

20 m3 (26 yd3)

Ballast (furnished by customer)

38 tonnes (42 tons)

14-31 m3 (18-40 yd3)

15.7 m (51 ft 6 in)

8.2 m (26 ft 10 in)

9.9 m (32 ft 6 in)

703 068 kg (1,550,000 lbs)

545 290 kg (1,202,160 lbs)

22 680 kg (50,000 lbs)

140 616 kg (310,000 lbs)

• These weights will vary slightly depending upon dipper and optional

equipment selection

9, 71.1 cm (28 in)

147.3 cm (58 in)

96, 45.1 cm (17.75 in)

Planetary Propel

Dual-motor independent drive

Revolving Frame (Center Section)

Welded impact-resistant steel

Length: 11.18 m (36 ft 8 in)

Width: 3.91 m (12 ft 10 in)

Turntable

Cast alloy steel swing rack

pitch diameter

Teeth external cut

Tapered, forged alloy steel

roller rails diameter

Number of tapered rollers

Tapered rollers diameter

4.5 m (14 ft 9 in)

29.21 cm face (11.5 in)

4.04 m (13 ft 3 in)

45

22.86 cm (9 in)

Swing

Two planetary gearboxes, each driven by a vertically mounted

variable-speed AC motor, located on either side of the revolving frame

towards the front of the machine. Single-output pinion shaft from each

gearbox engages the swing rack

Main Structures

Crawler Mounting

Overall width 139.7 cm

(55 in) treads, standard

Overall width 182.88 cm

(72 in) treads

Overall length of mounting

Total effective bearing area

(139.7 cm treads)

Number and diameter of rollers

Take-up tumblers diameter

Number and pitch of treads

Hoist

8.2 m (26 ft 11 in)

Double-reduction, conventional gearcase driven by a variable-speed

AC motor

8.63 m (28 ft 4 in)

10.26 m (33 ft 8 in)

21 m2 (224 ft2)

331 kpa (48.1 psi.)

Lube System

• PLC-controlled, air-operated, three 208 liter (55 gallon) drum reserves

• Divided into three systems: open gear lube, upper works grease, and

lower works grease

• Faults protection: low pressure and vent release

Electric Rope Shovel—7295 HD

Optimal Working Ranges

A Dumping height

A1 Dumping height at maximum

electric crowd limit

B Dumping radius (maximum)

C Cutting height (maximum)

D Cutting radius (maximum)

E Radius of level floor

G Clearance height

(boom point sheaves)

H Clearance radius

(boom point sheaves)

I Clearance radius

(revolving frame)

J Clearance under frame (to ground)

K Height of A-frame

L Overall width

M Clearance under lowest point in

truck frame/propel gearcase

N Operator’s eye level

8.4 m (27 ft 5 in)

Electrical

Drive

6.1 m (20 ft 1 in)

17.5 m (57 ft 5 in)

15.6 m (51 ft 4 in)

20.7 m (68 ft)

14.7 m (48 ft 1 in)

IGBT Acutrol drive system

15.9 m (52 ft 3 in)

Distribution System Requirements

Machine on separate system

2 000 kva

15.2 m (49 ft 9 in)

7.8 m (25 ft 8 in)

0.8 m (2 ft 6 in)

10.9 m (35 ft 11 in)

11.1 m (36 ft 6 in)

0.8 m (2 ft 6 in)

7 m (23 ft)

Power Requirements

Voltage

Average 15-minute demand

Peak power

3 phase, 50/60 Hz, 7200 V

450-630 kW

1 799 kW

• Other voltage requirements available to suit customer requirements

Main Electrical Systems

System voltage (nominal)

Trail cable

(furnished by customer)

Transformer, auxiliary

Lighting transformer

7200 V

SHD-3-#4 at 8000 V

250 kva, 7200 V primary

480 V secondary

1 x 25 kva

120/240 V secondary

Electric Rope Shovel—7295 HD

Front End

Boom

Boom

Boom point sheaves

Boom point sheave diameters

Handle diameter single stick

Wall thickness (nominal)

ASTM A678 grade C quench

and temper carbon steel

twin-grooved, flame-hardened

cast steel

1.7 m (5 ft 6 in)

0.6 m x 1.04 m

(2 ft x 3 ft 4.75 in)

3.81 cm (1.5 in) top,

4.45 cm (1.75 in) bottom,

3.175 cm (1.25 in) side

Rope Data

Hoist

No. Diameter

2

Boom susp. 4

Dipper trip 1

50.8 mm (2 in)

Type

Construction

twin dual 6x41

69.8 mm (2.75 in)

12.7 mm (.5 in)

6x37

6x37

Crowd

Single stick rack-and-pinion system - a boom-mounted AC motor drives

double-reduction spur gearing to crowd pinions, which engage twin

machined racks on the dipper handle

For more complete information on Cat products, dealer services, and industry solutions,

visit us on the web at mining.cat.com and www.cat.com

© 2011 Caterpillar Inc.

All rights reserved

CAT, CATERPILLAR, their respective logos, “Caterpillar Yellow” and the “Power Edge” trade

dress, as well as corporate and product identity used herein, are trademarks of Caterpillar and

may not be used without permission.

AEHQ6514