The State of the Paper Industry

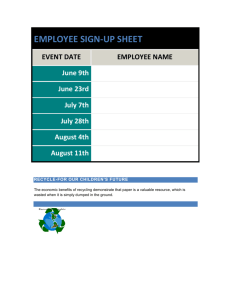

advertisement