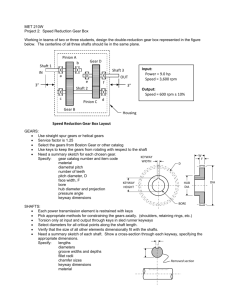

Shaft Guidance Systems

advertisement