FAULTS DIAGNOSIS OF CONTROL SYSTEM USING THE

advertisement

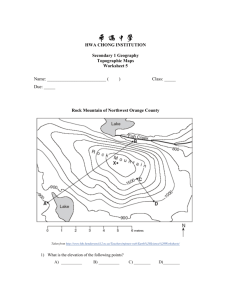

DETERMINISTIC METHOD FOR OPTIMIZING VSWR Jozef BUCHWALD, **Juraj PÚČIK * *Department of Computers and Informatics, Faculty of Electrical Engineering and Informatics, Technical University of Košice, Letná 9, 042 00 Košice, tel. 095/602 3175, E-mail: buchwald@tuke.sk **Department of Theoretical Electrotechnics and Electrical Measurement, Faculty of Electrical Engineering and Informatics, Technical University of Košice, Letná 9, 042 00 Košice, tel. 095/602 2707, E-mail: pucik@tuke.sk ABSTRACT In the article presented we deal with behaviour system of an observed rotor that is a model of the finite element method at a specific time. Time behaviours of faulty and failure-free controlling units (shaft), respectively, with different fault places represent the dynamic behaviour. In such cases effects of the own weight and unbalance transpire. Thereafter, the induced system is considered, with the nominal signal depending on the amplitude of harmonic or segmenting aberration. Model of the finite element method stands for the "experimental" investigation method of the dynamic system behaviour if there are neither the decomposition of systemic arrangement nor the accurate systemic reactions present. It is impossible to anticipate and lay out all of the possible cases of faults. There is the measurement being the result of last experiences attained on one side and the deterministically and stochastically unexpected factors on the other hand. Besides, one´s experiences from the past are not proven and cannot serve as a prediction for the future. For example, material detrition is slow and hardly to be calculated in the stage of projecting and planning. Countermeasures are needed not only when projecting and planning but also during the operation. At the beginning they are obviously difficult to be perceived by senses. Faults, as a part of this category, lead to shaft breaking and cause aggregate damages. This especially concerns cases when broken parts are coupled with other part of the shaft. This is the problem in continuous operation. Therefore, this is a way to optimally recognise fault symptoms and to localise them so that during operation avoided could be danger to both operators and the environment and consequential costs could be saved. It is not easy to solve the problems mentioned for there is still lack of universal methods of solving the fault diagnosis. Effective methods are still to be elaborated [1]. Keywords: diagnosis, observer, fault, rotor, intensity, simulation. fra fzik KzUi k (t ) DvUi k (t ), ik 7 1. INDRODUCTION Kinetic behaviour of turborotor is followed up at a rotor containing two hydrodynamically adjustable bearings laid at the end of shaft. The rotor consists of seven independent controlling units with equal average, length and homogeneous characteristics of the material. Systemic data for geometry and material of an individual rotor unit are described in the following parts of this paper. 2. BEARING The bearing chosen can be characterised as dynamic segmented bearings connected massively with journals of a shaft at its both ends. The total bearing weight is made up of journals of the shaft, saucepans, segments and the coach-box bearing. Shaft load, as well as an alternatively effective load upon system is carried to coach-box bearing. The average of the journals is identical with the shaft average. Based on the theory of a short bearing [1], we choose the close bearing, neglecting both the fundamental oscillation and the oscillation of bearing bearer. Equation (1) and (2) express that the assumed dynamic intensity is equal to that of journals (regardless bearings shifting) [2] fla fzik KzUi k (t ) DvUi k (t ), ik 1 (1) (2) where U is axis of shifting, D is the matrix of damping, K is matrix of the bearing resistant to t fault and F is power of unbalance. 2.1. Systemic parameters Systemic parameters comprise the geometry of data and material and the operating parameters of a resonant (oscillating system) system. Shaft systemic parameters are as specified below: 1. Average: d e 0,25m 2. Distance of an individual controlling unit: l e 2m 3. 4. Number of individual controlling units: 7 Material of controlling centre: Sl 54 5. E - modules: E 2,1 10 N / m 11 2 3. TIME BEHAVIOUR OF THE NO-FAULT ROTOR As it is evident from Fig. 1, the system approaches in its centre the harmonic motional reactions. Maximum coordinate divergence U 2 of about 3.8 mm, being a result of inert system since there is not only the effecting unbalanced intensity but also the weight intensity in vertical direction. Microwave and Wireless Technology 2004, September 13-14, Košice, Slovakia 8 The maximum amplitude U1 3.5 mm is less when compared with U 2 . Missing weight intensity represents physical reasons. In Fig. 1 there are also the U 3 and U 4 – being the reactions of moments at [Nm]. Maximum values are 0.5 Nm. Figure 2 presents behaviours of the left and the right bearing. Reactions of both of the bearings resemble the reactions at axis of U1 and U 2 , respectively. The same anomalies may be considered the dynamic dislocation of a bearing. Maximum values constitute half of values of the centre (2 mm). The changing coordinates moments U 3 and U 4 have opposite marks but identical values. The reason can be found in the symmetric arrangement. The motion bearing reactions differ from the motion reactions at the middle. and quick abolishment an absolute must. In complex technical facilities special attention should be paid to a systemic fault due to possible massive damages. Thanks to the computer capacity and thereby increased exploitation of computer monitoring it is possible to diagnose the fault simultaneously and visually already at present. REFERENCES [1] Mrkvička, J : Diagnosis methods of mechanical machineries using the parallel systems, Acta Mechanica Slovaca, Volume 4, No. 3/2000, Vienala, pp. 133-140, ISSN 1335-2393 (in Slovak) [2] Petržlen, M : Modellbildung eines Komplizierten Systems mit Riß. Fascicola Matematica – Informatica, Buletinul Stiintific al Universitatii din Baia Mare, vol. XVI, Nr. 11-12, 2000, pp. 64-70. BIOGRAPHY Fig. 1 Time behaviour in the middle area of fault. Fig. 2 Time reaction on the left and right bearing. 4. CONCLUSION The fault in a complex system is considered systemic fault. This fault is a risk factor because of people security. Not only for safety and economics, but also from ecological reasons is the diagnosing Jozef Buchwald was born on 17.11.1966. In 1991 he graduated (MSc.) with distinction at the department of Computers and Informatics of the Faculty of Electrical Engineering and Informatics at Technical University in Košice. He defended his PhD. in the field of programming device and systems in 2000; his thesis title was "Diagnosis of compound systems using the Data Flow applications". Since 1995 he is working as a tutor with the Department of Computers and Informatics. His scientific research is focusing on parallel computers of the Data Flow type. In addition, he also investigates questions related with the diagnostics of complex systems.