SCA BECOMES MORE EFFECTIVE

WHEN GLOBAL PROCESSES ARE

INTEGRATED IN ONE SYSTEM WITH

SAP PI

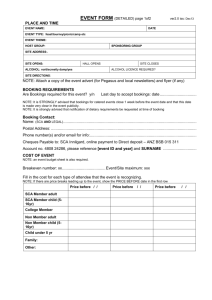

QUICK FACTS

The client

• Client: SCA AB

• SCA has 52 000 employees in 60 different

countries

• Industry: paper products

• Business: SCA offers personal hygiene products,

soft paper, packaging, print paper and sawing

timber in over 90 countries.

• Net profit sales 2008 was SEK 110 billion (€11.5

billion).

• SCA is quoted on OMX Nordic Stock Exchange

Stockholm, Large Cap.

Website

• www.sca.com

Greatest challenges

“By consolidating to SAP PI, SCA can

meet the business goals for lower

total costs and increased service

levels.”

Mark Ritter, responsible for the migration at

SCA Hygiene

• Competence was required on several applications

/ systems

• Large and complex infrastructure

• Many points of failure to monitor and track

• Disparate platforms and fragmented business

processes

• Complex change management

• High Costs and desire to improve Service

SCA’s customers started to centralize their purchase

processes whereas SCA Hygiene had different systems to manage supplier and customer demands. To

continue being a competitive supplier SCA Hygiene

needed to integrate three of their most important

platforms to one system, without interrupting the

ongoing activity and new customer sales.

Objectives

• Decrease costs and increase the quality of service

• Reduce the number of systems and interfaces to

make processes more uniform.

• Reduce the number of people involved in

maintaining the integration landscape

• Reduce the number of manual processes

• Ability to satisfy all demands from business and be

a leader in Ecommerce trends from one solution

• Quicker turnaround time for trouble-shooting,

maintenance, enhancements and new development

SAP Case Study

• Central “end-to-end“ monitoring of internal

and external processes

• Increase B2B/EDI connectivity with trading

partners

SAP solution and services

• SAP PI (Process Integration) with integrated

B2B/EDI functionality from SAPs partner

SEEBURGER

Why SAP

• SCA already uses PI as a tool between

different SAP-modules, so competence about

the platform already existed internally.

• With PI SCA could integrate the different

platforms without adding another system. All

competence focused on one system.

• SCA uses SAP as a strategic partner.

• PI counterpart SCA’s global demands internally

and externally on the cost front.

• PI could be used for integration of both SCAs

internal and external platforms.

• A platform change is a long-term investment

and SAP was a stable and secure choice. A

leading product gives the customer comfort

that product development will continue in the

future.

• A comparative study showed that there were

no advantages with alternative products.

Roll out

• SCA chose SAP PI in the summer of 2006 and

the project started in October 2006. Most

partners and countries had been migrated to

the new platform by December 2008.

Benefits

• Reduce the costs and increase the quality of

service.

Partner

• Seeburger

• www.seeburger.com

SCA BECOMES MORE EFFECTIVE WHEN GLOBAL

PROCESSES ARE INTEGRATED IN ONE SYSTEM

WITH SAP PI

SCA’s customers centralized their purchasing processes while SCA had 10 different systems that

managed supplier and customer demands within the group. SCA Hygiene used 5 different platforms

and to continue to be a competitive supplier, SCA Hygiene needed to integrate three of their most

important platforms to one system, without interrupting the ongoing activity and new customer sales.

With the assistance of Seeburger, SCA managed to migrate the old systems into one with SAP PI.

”We have improved our processes and changed the way we work. The feedback we have received

from customer support is that the new model has saved them a considerable amount of time”, says

Mark Ritter, SCA.

The need

The global consumer goods and paper

company SCA grew rapidly during the

1980s and 90s through for example

acquisitions. As new companies were

integrated into the business, the

number of different integration

platforms at SCA increased, which was

manageable when processes were

decentralized. But as customers

became more and more global, the

complexity in handling information

increased dramatically. Customers had

different demands on the purchasing

processes and when their purchases

got more standardized, SCA was stuck

with several systems that handled the

same tasks.

SCA Hygiene had a total of 5 different

tools to manage supplier and customer

demands in the form of invoices,

payments and other business

documentation that flow between

companies. It meant that if a problem

occurred, it was complicated and time

consuming to localize and solve it.

Another disadvantage was that when

new demands came from suppliers or

customers, SCA had to develop

solutions for several platforms for the

process to work. The total cost was

high and the service quality was not

sufficient.

The solution

In 2006, SCA Hygiene chose to

consolidate three of the systems to

one platform with the help of the

systems integration platform SAP PI in

order easily monitor and manage all

processes. SCA already used SAP PI

as a tool to connect different SAP

modules so the internal competence

was already in place. In addition, PI was

the only platform that effectively could

integrate all systems and processes.

The roll-out

Seeburger was contracted as a

strategic advisor for the global EDI

strategy, global and local

implementation strategy and managed

both the migration and new projects in

parallel. The project started in October

2006 and the migration of existing

platforms was completed in December

2008 for most partners and countries,

within time and budget. The migration

included SCA Hygiene in Europe and

parts of North America. During this

period, SCA had also acquired a

division from another company and the

new business was included in PI with

maintained quality of the main migration

plan. This was done without any

notable problems within three months.

The result

The implementation of SAP PI resulted

in big cost savings as SCA can get rid

of several systems that generate costs

for licenses, hardware etc. Since

competence was required within

several systems and applications, SCA

had previously had employees

assigned to each system. From now

on, the number of support staff could

be reduced since a globally distributed

competence group could now handle

the same work. Because focus was

now on only one system, the team was

able to increase their knowledge of PI

www.sap.com /contactsap

and the total service quality levels

increased. It was also possible to give

support to different local PI-projects

because all employees in the group had

knowledge of the same platform.

Since processes often are local and

the different sales offices need

transparency in the business

processes, SCA implemented the

Professional Message Tracking

module, so that customer support

could easily trace and monitor

problems within different processes.

The system is very user friendly so

customer support has better

possibilities to quickly evaluate and

solve issues themselves, instead of

having to contact IT support.

”We have improved our processes and

changed the way we work. The

feedback we have received from

customer support is that the new

model has saved them a considerable

amount of time”, says Mark Ritter,

SCA.

B2B/EDI had previously been a strain

on the business, but it has now been

turned in to an opportunity when SCA

negotiated for new customers. SCA

can meet customer demands quicker

and offer advanced integration with

both suppliers and customers, to the

benefit of all parties. The future

The consolidation project has been

completed, but SCA continues to

investigate how IT processes can

support main business goals. For

example, SCA plans to consolidate the

two remaining systems with SAP PI.

There is still a need to continue the

harmonization processes in other

geographies and divisions within SCA.

PI and B2B/EDI will continue to be vital

for continued good communication with

existing customers and suppliers, as

well as when SCA aim to win new

business.

50 xxx xxx (YY/MM)

©20YY by

©2010

by SAP

SAP AG.

AG. All

All rights

rights reserved.

reserved. SAP,

SAP, R/3,

R/3, mySAP, ­

mySAP, ­m

mySAP.com,

ySAP.com,

xApps, xApp, SAP NetWeaver, Duet, Business ByDesign, ByDesign,

PartnerEdge, and other SAP products and services mentioned

herein as well as their respective logos are trademarks or registered

trademarks of SAP AG in Germany and in several other countries

all over the world. All other product and service names mentioned

are the trademarks of their respective companies. Data contained in

this document serves informational purposes only. National product

specifications may vary.

These materials are subject to change without notice. These materials

are provided by SAP AG and its affiliated companies (“SAP Group”)

for informational purposes only, without representation or warranty of

any kind, and SAP Group shall not be liable for errors or omissions with

­respect to the materials. The only warranties for SAP Group products

and services are those that are set forth in the express warranty

­statements accompanying such products and services, if any. Nothing

herein should be construed as constituting an additional warranty.