Drilling Hydraulic Parameters Design Method under the Limited

advertisement

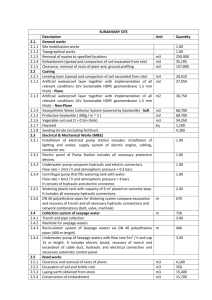

Journal of Applied Science and Engineering, Vol. 18, No. 3, pp. 303-308 (2015) DOI: 10.6180/jase.2015.18.3.11 Drilling Hydraulic Parameters Design Method under the Limited Circulating System Bearing Capacity Condition Zhichuan Guan, Yuming Liu, Qiandeng Li, Yuqiang Xu* and Hua Pang School of Petroleum Engineering, China University of Petroleum (East China), Qingdao 266580, P.R. China Abstract Hydraulics design is important for achieving the maximum bit hydraulic horsepower or jet impact force and improving the bottom hole cleaning. The existing hydraulic parameters design method is suitable for the low pump capacity. As the large-power-and-high-pressure pump is widely used on the drilling site, the existing hydraulic parameters design method is not sufficient to make the drill bit obtain the maximum hydraulic energy. In this paper, a new hydraulics design method is presented, and a larger bit hydraulic horsepower can be achieved compared to the existing design method. A contrastive analysis under different modes of pump pressures is conducted using the new design method, which shows that the improvement of the limited pump pressure can significantly increase the bit hydraulic horsepower. The circulating system pressure bearing capacity should be improved as much as possible. Key Words: Ground Pump, Circulating System, Bit Hydraulic Horsepower, Hydraulic Parameter, Design Method 1. Introduction As the world energy consumption increases, considerable effort has been expended on how to explore and utilize energy resources [1-8]. Drilling is widely used to explore the onshore and offshore oil and gas across the world. Hydraulic parameters design is an important part of the drilling design, which aims to achieve the maximum bit hydraulic horsepower, clean the rock fragments near the bit, carry the drill cuttings to the surface, and improve the rate of penetration (ROP) under given ground pump conditions. Many studies [9-19] have been conducted on the hydraulic parameters design, but most of which focus on the bit and circulating system, not on the ground pump. As the development of the oil and gas exploration, drilling pumps with large power and displacement and high pressure are manufactured to meet the onsite needs [20-22]. The existing hydraulic parameters *Corresponding author. E-mail: auyuqiang@163.com design method was designed based on the low pump capacity (i.e. low power and displacement, low rated pressure). Therefore, the existing hydraulic parameters design method needs further discussion. Furthermore, when the pump pressure increases, the pressure bearing capacity of the circulating system has limited the use of the pump pressure. It is necessary to investigate how to make full use of the capacity of the ground pump to maximize the drill bit hydraulic power. 2. The Existing Hydraulic Parameter Design Method and the New Method The general steps of the existing hydraulic parameter design method are as follows [23]: (1) Determine the minimum displacement that ensures the drill cuttings to be carried to the surface; (2) Divide the entire wellbore into several well sections and calculate the circulating system pressure loss coefficient for each section; (3) Determine the pump cylinder diameter. Select the smallest 304 Zhichuan Guan et al. cylinder size whose rated displacement is bigger than the minimum cuttings-carrying displacement; (4) Determine the hydraulic parameter optimization criterion, accordingly calculate the first and the second critical depth, and then calculate the optimum displacement and determine the bit nozzle size and other jet parameters. In this study, the maximum bit horsepower is selected as the hydraulic parameters design criterion. The hydraulic design method for selecting other criterion such as the maximum bit jet force is similar. In the step 3, the purpose of selecting small-diameter cylinder is to obtain a larger rated pump pressure to overcome the pressure loss of the drilling fluid in the circulating system. As the improvement of the pump capacity, the rated pressures of different-size cylinders are sufficient to meet the drilling requirements in most cases. The performance parameters of the 3NB1600 pump are shown in Table 1. When the circulating system pressure bearing capacity is smaller than the rated pressure of the pump cylinder, the maximum allowable operating pressure of the ground pump is actually the circulating system pressure bearing capacity. In this case, the pump displacement becomes the primary consideration instead of the cylinder size. The bit hydraulic horsepower is a function of the pump displacement, and the optimum pump displacement can be found corresponding to the maximum bit hydraulic horsepower on the bit hydraulic horsepower -displacement curve, as shown in the example. Based on the analysis above, the general steps of hydraulic parameters design under the limited circulating system pressure bearing capacity can be expressed as follows: Step 1 and step 2 are similar with the existing design method. Step 3: determine the optimum pump displacement corresponding to the maximum bit hydraulic horsepower through formulas or by drawing curves. Step 4: choose the cylinder whose rated displacement is closer and larger than the optimum displacement with the rated pump pressure larger than the circulating system pressure bearing capacity. Step 5: calculate other bit hydraulic parameters. 3. Comparison of the Two Design Methods The analysis above shows that the existing hydrau- lic parameter design method should be improved when ground pump performance parameters change. The comparison of the new method with the existing method is shown in the example below. The drilling parameters are as follows: two 3NB1600 drilling pumps, a 241.3 mm drill bit, 140 m drill collars with an outer diameter of 241.3 mm and inner diameter of 71.4 mm, internal flush drill pipes with an outer diameter of 139.7 mm and inner diameter of 118.6 mm. The circulating system pressure bearing capacity is 18 MPa based on common experiences; the circulating pressure loss coefficient of ground pipelines Kg is 1.07 ´ 10-3 MPa.s.L-1.8; the fluid density is 1.60 g/cm3 at the depth of 3000 m; the plastic viscosity is 0.045 Pa.s; the minimum annular velocity is no less than 0.6 m/s. The first two steps of the two design methods are similar: (1) Determine the minimum cuttings-carrying displacement Qa. The minimum annular velocity: (1) Because the minimum annular velocity is no less than 0.6 m/s, Va takes the value of 0.6 m/s. Therefore, the minimum cuttings-carrying displacement: (2) where r is the fluid density, g/cm3; dh is the wellbore diameter, cm; dp is the drill pipe outer diameter, cm. (2) Calculate the circulating pressure loss coefficient at this depth. Table 1. Performance parameters of 3NB1600 drilling pump [24] Cylinder size (mm) Pump stroke rate (times/min) Rated displacement (L/s) Rated pump pressure (MPa) 190 180 170 160 150 140 130 120 120 120 120 120 120 120 120 120 51.9 46.6 41.5 36.8 32.3 28.2 24.3 20.7 20.7 23.1 25.9 29.2 33.2 38.1 44.2 51.9 Drilling Hydraulic Parameters Design Method under the Limited Circulating System Bearing Capacity Condition 305 (8) (3) The pressure drop at the drill bit: (9) (4) The drill bit nozzle flow area: (10) (5) The circulating pressure loss coefficient of the whole system at the depth of 3000 m: The jet velocity: (11) The jet impact force: KL = mD + a = 0.0158 (12) where mpv is the fluid plastic viscosity, Pa.s; dpi is the drill pipe inner diameter, cm; dc is the drill collar outer diameter, cm; dci is the drill collar inner diameter, cm; Lc is the total length of the drill collar, m; B is an constant for inner flush drill pipe, which is 0.51655; K c is the drill collar circulating pressure loss coefficient. The next steps of the existing hydraulic parameter design method are as follows: Choose the smallest-size cylinder while ensuring that the rated displacement is larger than the minimum cuttings-carrying displacement. In this example, select the 120 mm cylinder whose rated displacement is 20.7 L/s and rated pump pressure is 51.9 MPa, according to Table 1. Set 18 MPa as the limited pump pressure because the ground pump pressure is no more than 18 MPa. The first critical well depth: (6) Below the first critical well depth, the drilling pump works in the rated pump horsepower state, and the drill bit horsepower decreases with the increase of the pump displacement. The drill bit horsepower reaches its maximum value at the rated pump displacement, so the optimum pump displacement to achieve the maximum bit horsepower is the rated pump displacement. Because the depth of 3000 m is less than the first critical well depth Dp c , the rated pump displacement 20.7 L/s is selected as the optimum displacement. The circulating pressure loss at this displacement: (7) The bit hydraulic horsepower: The next steps of the new hydraulic parameters design method are as follows: When the drilling pump pressure is limited, the output pump pressure ps is a constant of 18 MPa, so the bit hydraulic horsepower: (13) Let dPb dP = 0, so b = ps - 2.8 KLQ1.8 = 0. dQ dQ Therefore, the optimum displacement: (14) Because d 2 Pb dQ 2 0. 8 = -504 . KL ( pr 1. 8 ) < 0, the bit hydrau28 . KL lic horsepower corresponding to the optimum displacement is the maximum bit hydraulic horsepower. Therefore, the 140 mm cylinder is selected whose rated displacement is 28.2 L/s, according to Table 1. The circulating pressure loss: (15) The maximum bit hydraulic horsepower: (16) Comparing the two methods, the bit hydraulic horsepower of the new method is 10.02% larger than the existing method, so the new design method will achieve a better bottom hole cleaning effect and larger ROP. The curve of the relationship between the bit hydraulic horsepower and different displacements can be 306 Zhichuan Guan et al. drawn from Eq. (13), as shown in Figure 1. The dash lines indicate the values of the bit hydraulic horsepower corresponding to the rated displacements when selecting the two different sized cylinders. It can be seen from Figure 1 that selecting the 140 mm cylinder in the new design method can make the bit hydraulic horsepower achieve the maximum value under limited pump pressure while selecting the 120 mm cylinder cannot achieve it. The comparison of the hydraulic design parameters when choosing different cylinders is presented in Table 2. It can be seen from Table 2 that when choosing the 140 mm cylinder rather than the 120 mm cylinder, the drill bit horsepower and jet impact force increase, which indicates better bottom hole cleaning when using the new design method. The drill bit pressure drop and the jet velocity decrease because the parasitic pressure loss in the circulating system increases as the displacement increases. 4. New Method Analysis 4.1 Comparison of the Bit Hydraulic Horsepower under Different Limited Pump Pressures Using the Same Drilling Pump In the example, increasing the circulating system pressure bearing capacity from 18 MPa to 20 MPa with other parameters unchanged, calculate the maximum bit hydraulic horsepower under these two different limited pump pressures using the new design method, and the result is shown in Table 3, where P1 is the bit horsepower corresponding to 18 MPa and P2 is the bit horsepower corresponding to 20 MPa. It can be seen from Table 3 that increasing the limited pump pressure can greatly increase the bit hydraulic horsepower because the increase of the pump power supply will directly provide more energy for the drill bit. Therefore, increasing the limited pump pressure is favorable for increasing the ROP. 4.2 Comparison of the Bit Hydraulic Horsepower under Different Ground Pumps Redesign the hydraulic parameters in the previous example using the 3NB1000 drilling pump and the 3NB1600 drilling pump under the limited or not limited pump pressure. The limited pump pressure is assumed to be 18 MPa. Select the 140 mm cylinder for the 3NB1000 pump whose rate displacement is 27.1 L/s and rated pump pressure is 24.3 MPa. Select the 160 mm cylinder for the 3NB1600 pump whose rate displacement is 37.58 L/s and rated pump pressure is 39.3 MPa. The relationship among the maximum bit hydraulic horsepower at the optimum displacement, different well depths and different limited pump pressures is shown in Figure 2. Figure 2 indicates that: (1) for the same pump, the maximum bit hydraulic horsepower under the not limited pump pressure is much larger than that under the Figure 1. Relationship between the bit hydraulic horsepower and displacements. Table 2. Comparison of the hydraulic design parameters when choosing different cylinders Cylinder size (mm) 120 140 Optimum displacement (L/s) Drill bit horsepower (kW) Pressure drop at the drill bit (MPa) Jet velocity (m/s) Jet impact Force (kN) 20.70 28.16 296.15 325.81 14.31 11.57 128.41 115.45 4.25 5.20 Table 3. Comparison of the bit hydraulic horsepower under different limited pump pressures Well depth (m) 3000 3500 4000 4500 5000 5500 6000 6500 7000 P1 (kW) P2 (kW) 326 385 308 363 292 344 279 328 267 314 256 302 247 290 238 280 230 271 Drilling Hydraulic Parameters Design Method under the Limited Circulating System Bearing Capacity Condition 307 ing capacity of the ground pipelines and other drill tools should also be improved. Otherwise, the incidents of frequently breaking drilling tools will offset the benefits of using high pressure and power pumps [25]. 5. Conclusions Figure 2. The maximum bit hydraulic horsepower under different drilling pump pressures at different depths. limited pressure; (2) when the pump pressure is not limited, using a pump with larger rated pressure can get a larger maximum bit hydraulic horsepower; (3) when both of the pump pressures are limited, the maximum bit hydraulic horsepower for the 3NB1600 drilling pump is a bit larger than that for the 3NB1000 drilling pump at the shallow well section, but with the increase of the well depth, the maximum bit hydraulic horsepower for both pumps becomes consistent. The reason is that the rated displacement of the 3NB1600 drilling pump cylinder is sufficient to reach the optimum displacement at the shallow well section, while the rated displacement of the 3NB1000 drilling pump cylinder cannot, and hence the bit hydraulic horsepower using the 3NB1600 drilling pump is a bit larger than that using the 3NB1000 drilling pump. However, with the increase of the well depth, the optimum displacement corresponding to the maximum bit hydraulic horsepower decreases with the change of drilling parameters, and thus the rated displacements for both pump cylinders are larger than the optimum displacement. It can be seen from Eq. (14) that the optimum displacement only changes with the limited pump pressure, so the maximum bit hydraulic horsepower using the two different drilling pumps are consistent. Although the power capacity of the 3NB1600 drilling pump is larger than that of the 3NB1000 pump, but it cannot perform its maximum capacity because of the limitation of the circulating system pressure bearing capacity, which also reflects the importance of improving the circulating system pressure bearing capacity. Although larger bit hydraulic horsepower, better cuttings-cleaning effect and larger ROP can be achieved with the increase of the pump capacity, the pressure bear- (1) The existing hydraulic parameter design method that selects the small size cylinder to obtain a larger pump pressure to overcome the pressure loss along the wellbore is suitable for the low ground pump capacity. (2) A new hydraulic parameter design method under the limited circulating system pressure bearing capacity is presented, and a larger maximum bit hydraulic horsepower can be achieved using the new design method. (3) The maximum bit hydraulic horsepower using different ground pumps under limited or not limited pump pressures are analyzed. The effect of using the new design method greatly depends on the limited pump pressure. The circulating system pressure bearing capacity should be improved as much as possible. References [1] Kheshti, M., Kang, X. N., Song, G. B. and Jiao, Z. B., “Modeling and Fault Analysis of Doubly Fed Induction Generators for Gansu Wind Farm Application,” Canadian Journal of Electrical and Computer Engineering, Vol. 38, No. 1, pp. 52-64 (2015). doi: 10.1109/ CJECE.2014.2359682 [2] Sreerama K. R. and Chandrasekharan, E., “A Parallel Distributed Computing Framework for Newton-Raphson Load Flow Analysis of Large Interconnected Power Systems,” International Journal of Electrical Power and Energy Systems, Vol. 73, pp. 1-6 (2015). doi: 10.1016/j.ijepes.2015.03.020 [3] Favoino, F., Overend, M. and Jin, Q., “The Optimal Thermo-Optical Properties and Energy Saving Potential of Adaptive Glazing Technologies,” Applied Energy, Vol. 156, pp. 1-15 (2015). doi: 10.1016/j.apenergy. 2015.05.065 [4] Liu, F. J. and Chang, T. P., “Optimizing the Tilt Angle of Solar Collector under Clear Sky by Particle Swarm Optimization Method,” Journal of Applied Science and Engineering, Vol. 18, No. 2, pp. 167-172 (2015). doi: 10.6180/jase.2015.18.2.09 308 Zhichuan Guan et al. [5] Ramasamy, M. and Tangavel, S., “Optimal Utilization of PV Solar System as DVR (PV-DVR) for a Residence or Small Industry,” Journal of Applied Science and Engineering, Vol. 16, No. 3, pp. 295-304 (2013). doi: 10.6180/jase.2013.16.3.09 [6] Dangayach, S., Singh, D. N., Kumar, P., Dewri, S. K., Roy, B., Tandi, C. and Singh, J., “Thermal Instability of Gas Hydrate Bearing Sediments: Some Issues,” Marine and Petroleum Geology, Vol. 67, pp. 653-662 (2015). doi: 10.1016/j.marpetgeo.2015.05. 034 [7] Yue, W. T. and Wang, J. Y., “Feasibility of Waterflooding for a Carbonate Oil Field through Whole-Field Simulation Studies,” Journal of Energy Resources Technology, Transactions of the ASME, Vol. 137, No. 6, pp. 1-8 (2015). doi: 10.1115/1.4030401 [8] Mashaba, V. and Altermann, W., “Calculation of Water Saturation in Low Resistivity Gas Reservoirs and PayZones of the Cretaceous Grudja Formation, Onshore Mozambique Basin,” Marine and Petroleum Geology, Vol. 67, pp. 249-261 (2015). doi: 10.1016/j.marpetgeo. 2015.05.016 [9] Harris, O. O. and Osisanya, S. O., “Evaluation of Equivalent Circulating Density of Drilling Fluids under High-Pressure/High-Temperature Conditions,” The 2005 SPE Annual Technical Conference and Exhibition, Dallas, U.S.A., pp. 1-10 (2005). [10] Guan, Z. C., Chen, T. G. and Liu, X. S., “Review of Studies of PDC Bit Hydraulic Configurations,” Journal of the University of Petroleum, China, Vol. 16, No. 6, pp. 136-142 (1994). [11] Bailey, W. J. and Peden, J. M., “A Generalised and Consistent Pressure Drop and Flow Regime Transition Model for Drilling Hydraulics Suitable for Slimhole, Underbanlanced and Horizontal Wells,” The 1997 SPE/ IADC Middle East Drilling Technology Conference, Bahrain, pp. 279-296 (1997). [12] Nguyen, D. and Rahman, S. S., “A Three-Layer Hydraulic Program for Effective Cuttings Transport and Hole Cleaning in Highly Deviated and Horizonta1 Wells,” The 1996 IADC/SPE Asia Pacific Drilling Technology, Lumpur, Malaysia, pp. 163-173 (1996). [13] Patel, A., Chaudhari, R. and Deendayal, P., “Optimization of Well Hydraulics for Riserless Deepwater Drilling Operations under High Temperature and High Pressure Environment,” SPE Annual Caspian Technical Conference and Exhibition, Astana, Kazakhstan, pp. 1-15 (2014). [14] Kuru, E., Okunsebor, O. M. and Li, Y., “Hydraulic Optimization of foam Drilling for Maximum Drilling Rate in Vertical Wells,” SPE Drilling & Completion, Vol. 20, No. 4, pp. 258-267 (2005). [15] Andersen, H., Vigrestad, A. and Kuru, E., “Hydraulic Optimization of Aerated Mud Drilling for Maximum Drilling Rate,” IADC/SPE Managed Pressure Drilling and Underbalanced Operations Conference and Exhibition, San Antonio, Texas, pp. 1-15 (2009). [16] Aadnoy, B. S., “A New Method for Hydraulic Optimization,” Society of Petroleum Engineers of AIME, Vol. 1991, pp. 1-14 (1991). [17] Lim, K. M. and Chukwu, G. A., “Bit Hydraulics Analysis for Efficient Hole Cleaning,” Western Regional Meeting, Anchorage, Alaska, pp. 171-184 (1996). [18] Zoellner, P., Thonhauser, G., Lueftenegger, M. and Spoerker, H. F., “Automated Real-time Drilling Hydraulics Monitoring,” SPE/IADC Drilling Conference and Exhibition, Amsterdam, Netherland, pp. 1-10 (2011). [19] Wright, J. and Chukwu, G. A., “An Economic Appraisal of Hole Cleaning Using Hydraulic Horsepower and Jet Impact Force,” SPE western Regional/AAPG Pacific Section Joint Meeting, Long Beach, California, pp. 1-14 (2003). [20] Sun, M. G. and Peng, J. S., “Development of Petroleum Drilling Equipment at Home and Abroad,” Petroleum Drilling Techniques, Vol. 36, No. 6, pp. 86-91 (2008). doi: 1001-0890(2008)06-0086-06 [21] Zeng, X. C., Song, Z. G., Huang, Y. H. and Pu, R. C., “Presence and Application of Large Power Drilling Pump,” Oil Field Equipment, Vol. 43, No. 9, pp. 56-59 (2014). doi: 1001-3482(2014)09-0056-04 [22] Miu, X. C., ZY3NB-1600 Drilling Pump Research, Master’s Dissertation, Southwest Petroleum University, Chengdu, China (2005). [23] Chen, T. G. and Guan, Z. C., Drilling Engineering Theory and Technology, Petroleum University Press, Dongying, pp. 143-164 (2000). [24] Information on http://www.doc88.com/p-5156822413 603.html [25] Ma, L. M. and Zhang, W. L., “The Development of Petroleum Drilling Technique and High Horsepower Mud Pump,” Oil Field Equipment, Vol. 29, No. 3, pp. 1516 (2000). doi: 1001-3482(2000)03 -0015-02 Manuscript Received: Mar. 27, 2015 Accepted: Aug. 4, 2015