Belt Conveyor System Technical Data Questionnaire

advertisement

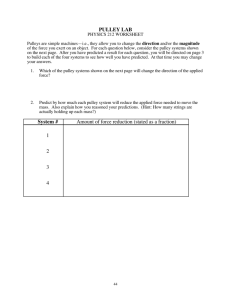

Questionnaire Technical Data – for the Layout of Belt Conveyor Systems Company Person in charge Project Name Project No. Phone Country Email Outdoors – open Location of use – covered Underground Indoor Details of climatic conditions Conveying flight (provide a diagram on page 4 of the questionnaire if necessary) Centre distance m Conveying length L m Conveying height H m Gradient of the system δ º uphill downhill º Section with maximum (descending) gradient δmax Curve – convex: Radius Re m – concave: Radius Ra m Sections with differing gradients Material flow m/s t/h m3/h Conveying speed v Mass flow Im Volume flow IV Degree of uniformity of mass or volume flow Load coefficient Designation of the material handled t/m3 º Bulk density ρ Angle of repose Properties of the material handled Temperature Max. lump size Chemically corrosive Sharp-edged Wet permanent ºC min. ºC max. ºC mm Questionnaire – Technical Data Feeding direction – in longitudinal direction – in tranverse direction m Height of fall Material feed Garland idlers º Troughing angle Impact idlers Feeding device (impact plates or similar) Chute constriction Material discharge Length of constriction m Via head pulley Tripper car Scraper Conveyor belt Width B mm Endless belt length m Support on top run: Support on return run: on carrying idlers sliding on carrying idlers sliding with support rings Carrying idler arrangement -part Idlers – Top run Troughing angle λo º Spacing Io m Mass (rotating components of an idler set) mRo kg Moment of inertia kg/m2 Diameter dRo mm Tilted position Flat-to-trough transition length l Ü mm Pulley lift hTr mm Trough-to-flat transition length l Ü mm Pulley lift hTr mm Troughing angle λu º Spacing Iu m Return idler arrangement -part – Return run Mass (rotating components of an idler set) mRu kg Diameter dRu mm Tilted position Questionnaire – Technical Data Tail Head Conveying direction FT4 FT1 ␣1 FTr4 ␣4 4 FTr1 1 FT3 FT2 ␣3 FT3/4 Pulleys driven/braked Diameter DTr Angle of wrap Pulley surface Condition 3 : : : : Number of drives at Power (total) FTr3 1 FTr2 , 2 , ␣2 ␣1 bare dry 2 ␣2 , 3 , ␣3 rubberized Pulley 1: - installed - estimated Pulley 2: Pulley 3: PM inst PM inst Starting aid pA0 Start-up-time (related to the motor torque in the steady operating state at rated mass flow): (related to the rated motor torque): s tA Pulley 1: Pulley 2: Number of brakes on Total braking torque (related to the motor shaft) Braking factor pB pB0 Braking distance sB Conveyor belt cleaning Conveyor belt type Pulley 4: kW kW Squirrel cage motor Starting factor pA Takeup device Takeup pulley Takeup device at Scraper Other devices Belt turnover New system Extension Replacement Pulley 3: Pulley 4: Nm (related to the motor torque in the steady operating state at rated mass flow): (related to the rated motor torque): m – flying System head Existing takeup length – fixed System tail m Further details Projected design Required design Previous design Suitability satisfactory yes Observations Conveyor belt splicing mm º , 4 , ␣4 Ceramic wet Slip ring motor Drives Braking FT1/2 In-situ curing Delivery open Mechanical fastener endless no Questionnaire – Technical Data Space for sketches E 09.09 PHOENIX CONVEYOR BELT SYSTEMS GMBH Hannoversche Strasse 88 21079 Hamburg, Germany Phone +49 40 7667-03 Fax +49 40 7667-2411 E-mail info@phoenix-cbs.com www.phoenix-conveyor-belts.com Send Questionaire