HYSYS v8.6 - Inside Mines

advertisement

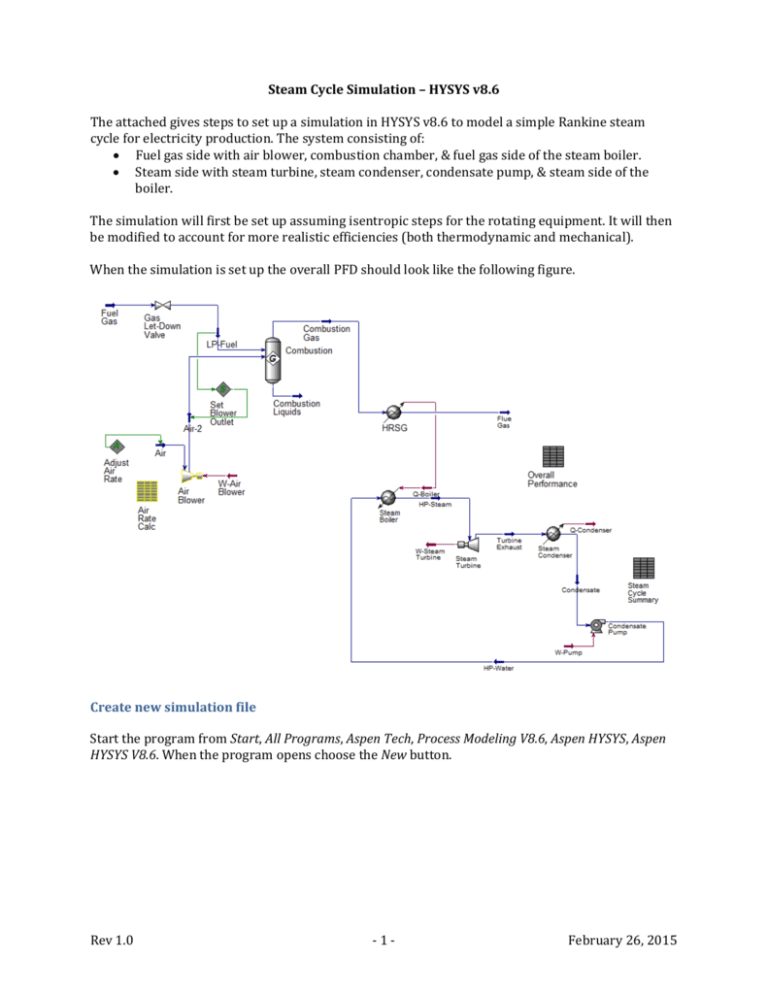

SteamCycleSimulation–HYSYSv8.6 TheattachedgivesstepstosetupasimulationinHYSYSv8.6tomodelasimpleRankinesteam cycleforelectricityproduction.Thesystemconsistingof: Fuelgassidewithairblower,combustionchamber,&fuelgassideofthesteamboiler. Steamsidewithsteamturbine,steamcondenser,condensatepump,&steamsideofthe boiler. Thesimulationwillfirstbesetupassumingisentropicstepsfortherotatingequipment.Itwillthen bemodifiedtoaccountformorerealisticefficiencies(boththermodynamicandmechanical). WhenthesimulationissetuptheoverallPFDshouldlooklikethefollowingfigure. Createnewsimulationfile StarttheprogramfromStart,AllPrograms,AspenTech,ProcessModelingV8.6,AspenHYSYS,Aspen HYSYSV8.6.WhentheprogramopenschoosetheNewbutton. Rev1.0 ‐1‐ February26,2015 DefinetheComponents&thePropertyModels Specifycomponents,fluidpropertypackages,&crudeoilassays Thefirststepistoaddtwosetsofpurechemicalspeciestorepresent: Steamasmodeledbypurewater&usingpropertycorrelationsconsistentwiththeASME SteamTables. Thenaturalgasfuel,air,&combustionexhaustaspurelightcomponentsmodeledbythe Peng‐Robinsonequationofstate(EOS). Let’sdothesteamfirst.WithComponentListshighlightedclickontheAddbutton.Fromthelistof purecomponentspickwater.We’renowreadytopickthepropertymodel. Rev1.0 ‐2‐ February26,2015 Thenextstepistopickafluidpropertypackage.FromtheFluidPackagesscreenclicktheAdd button.ChoosetheASMESteamoptionandmakesureitisassociatedwithComponentList–1. Nowlet’saddcomponentstomodelthefuelsideofthesystem.GobacktotheComponentListsitem &clickontheAddbuttontocreateComponentList‐2.Weneedcomponentsforthefollowing: Naturalgas.Fornowlet’smodelthisasapossiblemixtureofmethane,ethane,&propane. Air.Fornowwe’llmodelthisasamixtureofoxygen&nitrogen. Combustiongases.Attheminimumwe’llalsoneedcarbondioxideandwater.However, we’llalsowanttotakeintoaccountincompletecombustion(formingcarbonmonoxide)as wellasNOxformation(fornowjustasNO,NO2,&N2O). Fromthelistofpurecomponentspickthefollowingchemicalspecies.Thenextstepistoassociatea differentfluidpropertypackageforthesecompounds(sincetheASMESteamTablesareonly appropriateforpurewater).GobacktotheFluidPackagesscreen&clicktheAddbutton.Choose thePeng‐RobinsonoptionandmakesureitisassociatedwithComponentList–2. Rev1.0 ‐3‐ February26,2015 Nowisagoodtimetosavethefilebeforewestartsettinguptheprocesssimulation.ClicktheFile tab&thentheSaveAsitem. Rev1.0 ‐4‐ February26,2015 Setup&SolvetheFlowsheet WorkingUnits ActivatetheSimulationoption.Notethatyou’llseeablankflowsheet. WewouldliketoshowthecalculationswithamodifiedsetofSIunits,inparticular: Temperatureas°C. Pressureasbar(absolute). Massflowaskg/sec. Molarflowaskg.mol/sec. HeatdutyaskJ/sec. PoweraskW. UndertheHometabclickthe UnitSetsbutton.Underthe AvailableUnitsSetsselectSI. Youcanexaminethelist underDisplayUnitsto determinewhatwillbeused forthedisplayoftheresults aswellasthedefaultunits fortheinput.Mostofthe unitsarewhatwedesire,but notall.Forexample,youcan seethatPressurewillbe reportedinkPa,notquite whatwewant. Let’screateanewsetof units&callit“SI‐bar‐sec”. WiththeSIunitshighlighted intheAvailableUnitsSetslist clicktheCopybutton.Change theUnitSetNametoSI‐bar‐ sec.Let’snowexaminethe DisplayUnitsfortheonesof interest(Temperature, Pressure,etc.)andmake surethatareconsistentwith whatwewant.Tochangewe needonlyclickonthe dropdownlistintheUnits column.Forexample,to changePressurefromkPato barweonlyneedtochoose theappropriateoptionfrom thelist.Whendoneclickthe OKbutton. Rev1.0 ‐5‐ February26,2015 SteamCycle WewillwanttocreateasimpleRankinecyclewiththefollowingprocessconditions: Saturatedsteamproductionat125bar. Finalcondensationto20°C. Steamturbineoperatingatidealreversibleconditions. Condensatepumpoperatingatidealreversibleconditions. Noextrapressuredropthroughheatexchangersorpiping. Let’splacethefollowingunitsfromtheModelPalettetotheflowsheet1:Heater,Cooler,Expander,& Pump.Ultimatelyitwillbedepictedasfollows. Let’sdefinethecondensatepumpfirst. Doubleclickonthepumpicon(probably calledP‐100).Changethenameto CondensatePump.Specifynewstreams fortheinlet,Condensate,theoutlet,HP‐ Water,&theenergystream,W‐Pump. MakesurethattheBasis‐1fluidpackage ischosen. 1IftheModelPaletteisnotvisiblechoosetheViewtab&clickontheModelPalettebutton. Rev1.0 ‐6‐ February26,2015 Wewanttomakethisanidealreversible pump.ClickontheParametersoption& changetheAdiabaticEfficiencyto100%. Wecaninitializethewatercirculatingintheloopfrom here,too.ClickontheWorksheettab&choosethe Compositionoption.Enter1fortheH2Ovalueunderthe Condensatecolumn.Aninputformwillpopup&allow youtoverifythatthisrepresentstheMolesFractions basis.ClicktheOKbutton. ClickonConditionssowecanentervalues fortheCondensateenteringthepump. SpecifytheTemperatureas20°Candthe Vapourfractionas0(i.e.,asaturated liquid).Let’suseaflowbasisof1kg/s. NoticethatCondensatestreamisfully defined&otherassociatedvaluesare calculated(suchasthepressure,molar flow,heatflow,etc.) Nowlet’sdefinethesteamsideofthe boiler.Doubleclickontheheatericon (probablycalledE‐100).Changethename toSteamBoiler.Pulldownthelistforthe inputstream&chooseHP‐Water.Specify newstreamsfortheoutlet,HP‐Steam,& theenergystream,Q‐Boiler.Makesure thattheBasis‐1fluidpackageischosen. Rev1.0 ‐7‐ February26,2015 Wewanttoassumeanegligiblepressure dropthroughthisexchanger.Clickonthe Parametersoption&changetheDeltaPto 0. Nowlet’sspecifytheconditionsforthe highpressuresteam.Clickonthe Worksheettab&theConditionsoption. SpecifythePressureas125barandthe Vapourfractionas1(i.e.,asaturated vapor). Noticethatafterenteringthepressurethe restoftheconditionsfortheHP‐Water streamarecalculated(sincewenowknow theoutletpressureofthepump,too).After enteringthevaporfractiontherestofthe conditionscanbecalculatedfortheoutlet HP‐Steam&therequireddutyQ‐Boiler. Nowlet’sdefinethesteamturbine. Doubleclickontheexpandericon (probablycalledK‐100).Changethe nametoSteamTurbine.Pulldownthe listfortheinputstream&chooseHP‐ Steam.Specifynewstreamsforthe outlet,TurbineExhaust,&theenergy stream,W‐SteamTurbine.Makesure thattheBasis‐1fluidpackageis chosen. Rev1.0 ‐8‐ February26,2015 Wewanttomakethisanideal reversibleexpander.Clickonthe Parametersoption&changethe AdiabaticEfficiencyto100%. Donotapplyanyotherconditionsatthistime. Nowlet’sdefinethecondenser. Doubleclickonthecoolericon (probablycalledE‐101).Change thenametoSteamCondenser.Pull downthelistfortheinputstream &chooseTurbineExhaust.Pull downthelistfortheoutletstream &chooseCondensate.Specifya newenergystream,Q‐Condenser. MakesurethattheBasis‐1fluid packageischosen. Wewanttoassumeanegligible pressuredropthroughthis exchanger.ClickontheParameters option&changetheDeltaPto0. Nowallunits&streamsshouldbefullycalculated.Therearevariouswaystoviewtheresults.One wayistoclickontheWorkbookitem.UndertheMaterialStreamstabwecanseetemperatures, pressures,&phaseconditions(i.e.,vaporfractions).UndertheEnergyStreamstabwecanseethe calculatedexchangerduties&rotatingequipmentpowers. Rev1.0 ‐9‐ February26,2015 Wecanalsoviewthisbasicinformationdirectlyontheflowsheet.Rightclickthevariousstreams& choosetheShowTableoption.Thiscanbedoneforallofthestreamsofinterest.(Thetableswill probablyhavetobemovedaroundtomaketheresultsreadable.) Bydefaultthematerialstreamtablesshowthetemperature,pressure,&overallmolarflow.Toadd vaporfractiondouble‐clickonthetable,clickAddVariable,chooseVapourFraction,clickOK,& closethePFDTableform. Rev1.0 ‐10‐ February26,2015 Thereisathirdoptionthatwouldallowyoutocalculatethethermalefficiencyofthesteamcycleas wellassummarizetheresults–addaSpreadsheettothesimulation. FromtheModelPaletteadd aSpreadsheet;doubleclick toopen.Changethenameto SteamCycleSummary.Click ontheParameterstaband changetheNumberof Columnstoatleast5and theNumberofRowstoat least11.Clickonthe Spreadsheettab&setup textfieldsthatlooklikethe figureontheright. Rev1.0 ‐11‐ February26,2015 Wenowwanttoassociatemanyof thecelllocationstoresults calculatedbyHYSYS.Forexample, right‐clickoncellB2&choose ImportVariable;choose Condensate,Temperature,&then clickOK.Notethatthetemperature of20.00Cappearsinthetable;also notethatitisformattedasbold blue,meaningthatthisisauser‐ inputvalue.(Italsodenotesthatit canbechangedfromhere,but moreofthatlater.). Whenallvariablesare associatedwiththe appropriatecellsthe spreadsheetshouldlookas follows. Nowlet’saddacouplecalculations. ThenetpowerproducedwillbethatfromtheSteamTurbineminusthatneededbythe CondensatePump.IncellD10entertheformula“=D8‐D9”. Wealsowouldtodirectlycalculatethethermalefficiencyofthesteamcycle,i.e.,theratioof thenetpowerproducedbytheheatinfromtheboiler.IncellD11entertheformula “=100*D10/B8”. Rev1.0 ‐12‐ February26,2015 Nowwehaveasummary tablethatwillshowina singleplacematerialstream results,energystream results,unitoperation parameters,&calculated results.Forexample,wecan seethatthiscombinationof conditionswillresultina steamcyclewitha41.25% thermalefficiency. Notethatthisisalsoa“live” table.Wecanchange parametershere&the othervalueswill automaticallyrecalculate. Forexample,ifwewereto changetheSteamTurbine& CondensatePumpadiabatic efficienciesto85%,thenall valueswouldbe recalculatedandwecould seethatthethermal efficiencydropsto34.94%. Fuel&CombustionSystem Wewillwanttocreateasimplenaturalgasburner/boilerwiththefollowingprocessconditions: Naturalgasisavailableatindustrialdeliverypressure,20bar‐g&15°C.Wewill characterizethenaturalgasas100%methane. Airisavailableat25°C.Wewillcharacterizetheairasa21/79O2/N2molarmixtureand bonedry(i.e.,nowater).Wewanttoaddenoughairsothatthereis20%excessoxygen basedoncompletecombustionofthenaturalgas. Thecombustionprocessoccursnearsatmosphericconditionssothenaturalgasmustbelet downinpressure.However,ablowerisneededtopushtheairintothecombustion chamber. Thepressuredropthroughtheburner/boiler/fluecombinationis0.3bar. Rev1.0 ‐13‐ February26,2015 Thefluegasisexhaustedtotheatmosphereat120°C,atemperaturehighenoughtoprevent anyliquiddropout&subsequentcorrosionproblems. Let’splacethefollowingunitsfromtheModelPalettetotheflowsheet:Valve,Compressor,Gibbs Reactor2,&Cooler.Ultimatelyitwillbedepictedasfollows.(We’lldiscusstheSpreadsheet,Set,& Adjustoperationsaswego.) Let’sdefinethenaturalgas& let‐downvalvefirst.Double clickonthevalveicon (probablycalledVLV‐100). ChangethenametoGasLet‐ DownValve.Specifynew streamsfortheinlet,FuelGas, &theoutlet,LP‐Fuel.Make surethattheBasis‐2fluid packageischosen. 2NotethatreactormodelsareundertheColumnstaboftheModelPalette. Rev1.0 ‐14‐ February26,2015 Wewillinitializethenaturalgasfromhere. ClickontheWorksheettab&choosethe Compositionoption.Enter1fortheMethane valueundertheFuelGascolumn.Aninput formwillpopup&allowyoutoverifythat thisrepresentstheMolesFractionsbasis. ClicktheNormalizebuttontosettheother compositionsaszero.ClicktheOKbutton. ClickonConditionssowecan entervaluesfortheFuelGas enteringthepump.Specifythe Temperatureas15°Candthe Pressureas20bar‐g(notethat thepressuregetsautomatically adjustedtoanabsolutebasis). Let’suseaflowbasisof1 kg.mol/s. Let’sspecifytheoutletpressure of0.3bar‐gintheLP‐Fuel column(notethatthepressure getsautomaticallyadjustedtoan absolutebasis). NoticethatboththeFuelGas&LP‐Fuelstreamsarefullydefined&otherassociatedvaluesare calculated(suchasthemassflow,heatflow,etc.) Rev1.0 ‐15‐ February26,2015 Nowlet’sdefinethe air&theairblower. Doubleclickonthe compressoricon (probablycalled K‐100).Changethe nametoAirBlower. Specifynew streamsforthe inputstream,Air, theoutlet,Air‐2,& theenergystream, W‐AirBlower.Make surethattheBasis‐ 2fluidpackageis chosen. Wewanttomake thisanideal reversible compressor.Click ontheParameters option&changethe AdiabaticEfficiency to100%. Rev1.0 ‐16‐ February26,2015 Wewillinitializetheairstreamfromhere. ClickontheWorksheettab&choosethe Compositionoption.Enter0.21forthe OxygenvalueundertheAircolumn.An inputformwillpopup&allowyoutoverify thatthisrepresentstheMolesFractions basis&finishenteringtherestofthevalues. Enter0.79fortheNitrogenvalue.Clickthe Normalizebuttontosettheother compositionsaszero.ClicktheOKbutton. ClickonConditionsso wecanentervalues fortheAirentering thepump.Specifythe Temperatureas25°C andthePressureas0 bar‐g(notethatthe pressuregets automatically adjustedtoan absolutebasis).Asa startingpointlet’s definetheflowrateas 12kg.mol/hr. Finally,let’sspecify theoutletpressurefor Air‐2as0.3bar‐gto matchthatofthefuel gasafterthelet‐down valve. NoticethatboththeAir&Air‐2streamsarefullydefined&otherassociatedvaluesarecalculated (suchasthemassflow,heatflow,etc.) Nowit’stimetomodelthecombustionportionofthefuelgasburner.Therearevariousoptionsfor doingthis.Oneofthesimplest(andwouldnormallybedoneforhandcalculations)wouldbeto defineallcombustionreactions&specifytheextentofconversionforeach.Instead,we’regoingto takeadvantageofthefullthermodynamiccapabilitiesofHYSYS&useareactorthatwillminimize theGibb’sfreeenergy.Allwehavetodoislisttheexpectedproducts&HYSYSwillcalculatethe resultingproductdistributionthathonorsthematerial&energybalancesaswellasanychemical equilibriumlimitations. Rev1.0 ‐17‐ February26,2015 DoubleclickontheGibbs Reactoricon(probably calledGBR‐100).Change thenametoCombustion. SelecttheexistingLP‐Fuel &Air‐2streamsasinlets. Specifynewstreams, CombustionGas,asthe vapouroutlet& CombustionLiquidsasthe liquidoutlet.Makesure thattheBasis‐2fluid packageischosen. That’sprettymuchit.The defaultsarezeropressure drop&includeallspecies inthecomponentlistas potentialproduct. Wecanexaminethe resultsbyclickingonthe Worksheettab.Selecting Conditionsshowsthat thereisonlyagas producedatatemperature of1731°C.Wecanthen lookattheresulting compositionbyselecting Composition.Theresults are,bydefault,shownas molefractions.Notethat allofthemethanehas beenconsumed.Thereisa smallamountofCO formed(asincomplete combustion)butsome NOxhasalsobeencreated fromtheN2intheair. Nowlet’sseehowmuchheatcanbetransferredoutofthecombustiongases. Rev1.0 ‐18‐ February26,2015 Nowlet’sspecifythe combustiongassideofthe boiler.Doubleclickonthe heatericon(probablycalled E‐100).Changethenameto HRSG.Pulldownthelistfor theinputstream&choose CombustionGas.Specifynew streamsfortheoutlet,Flue Ga,&theenergystream,Q‐ HRSG..Makesurethatthe Basis‐2fluidpackageis chosen. Wewillnotspecifyapressure dropacrosstheexchanger. Rather,we’llspecifythe pressureoutthestack.Click ontheWorksheettab&the Conditionsoption.Specifythe Pressureas0bar‐gandthe Temperatureas120°C. Nowtheconditionsforthe inlet&outletstreamscanbe determinedaswellasthe dutyavailable(asQ‐HRSG). Therearestillacoupleitemstobedoneto“cleanup”thesimulation.Thefirstisforamatterof convenience–howshouldwespecifythepressureoftheAir‐2streamoutoftheblower?Rightnow thepressureintotheCombustionoperationissetseparatelyforthetwoinletstreams(LP‐Fuel& Air‐2).Ifastudywastobeperformed&thepressureweretochangethenhavingthespecifications intwoseparatelocationscouldleadtothembeingchangeddifferently.Itsurewouldbenicetoset itonlyinonelocation&thenhavetheotherlocationupdateautomatically.Wecandothiswitha Setoperation. FromtheModelPaletteplaceaSetoperationonthe flowsheet.Double‐clickonit(probablycalledSET‐1). RenameasSetBlowerOutlet.DefinetheTargetVariable asthepressureoftheAir‐2stream.We’llusetheSource asthevaluefromLP‐Fuel. Oncethisisimplementedanychangesmadetothe pressureofLP‐Fuelwillbeautomaticallytransmittedto theoutletpressureoftheairblower. Rev1.0 ‐19‐ February26,2015 Thesecondchangeinvolvesaconvenientwaytomakesurethatthecorrectamountofairisadded tomatchthe“excessoxygen”spec.Theamountofstoichiometricoxygenisdeterminedfromthe combustionreactions.Formethane,ethane,&propanethereactionsare,respectively: CH4+2O2CO2+2H2O C2H6+3.5O22CO2+3H2O C3H8+5O23CO2+4H2O Thisshowsthatweneedtoknowthecompositionofthefuelgas(inmolaramounts)todetermine thestoichiometricamountofoxygenneeded.The“excess”partisadditionaloxygen(asa multiplier)thatisadded.ThefinalconsiderationisthatthespecificationinHYSYSisnotjustforthe rateofoxygenbutratheroftheair;sowehavetotakeintoaccountthecompositionoftheair accountforthelargeamountofnitrogenalsobeintroducedintotheCombustionoperation. Sincewehavesetthecompositionofthefuelgastobepuremethane&thebasisflowrateto1 kg.mol/secthenthestoichiometricoxygenflowrateistwicethis,2kg.mol/sec.Wealsoneedto increasethisby20%toincludethedesiredexcess.Andweneedtotakeintoaccounttheoxygen contentintheairtodeterminetheairrate.Sooverall: nO2 1 fexcess 2 1 0.2 stoich 11.43kg.mol/sec . nair 0.21 yO2 WecoulddothesecalculationspriortorunningHYSYSandentertheairrate.Orwecoulddothe calculationswithinHYSYS. FromtheModelPaletteadd aSpreadsheet;doubleclick toopen(probablycalled SPRDSHT‐1).Changethe nametoAirRateCalc.Use thedefaultnumberofrows &columns.Clickonthe Spreadsheettab&setup textfieldsthatlooklikethe figureontheright. Rev1.0 ‐20‐ February26,2015 Wenowwantto associatemanyof thecelllocations toresults calculatedby HYSYS.For example,right‐ clickoncellD3& chooseImport Variable;choose Air,Mast ComponentMole Frac,Oxygen,& thenclickOK. Let’sassociateallofthe desiredmolarflowrates. Forexample,forthefuel, right‐clickoncellB4& chooseImportVariable; chooseFuelGas,Molar Flow,&thenclickOK. Associatethemolarflowfor theairtothecellD7. Nowlet’saddthefollowingcalculations: cellD4,“=(B2*2+B3*3.5+B4*5)*B5” cellD4,“=D4*(1+D2)” cellD4,“=D5/D3” cellD4,“=D7‐D6” Rev1.0 ‐21‐ February26,2015 Nowwehaveatablethat willcalculatethedesiredair flowrateforthespecified fuelgasflowrate.Though thespreadsheetcannot directlysettheairflowrate wecandoitmanuallyby directlychangingthevalue incellD7. EventhoughthespreadsheetitselfcannotdirectlysettheflowrateoftheAirstreamitcanbeused aspartofanAdjustoperation. FromtheModelPaletteplacean Adjustoperationonthe flowsheet.Double‐clickonit (probablycalledADJ‐1). RenameasAdjustAirRate. DefinetheAdjustedVariableas themolarflowoftheAirstream. We’llusethecalculationforthe differencebetweenthedesired airrate&theactualasthe TargetVariable;thisiscellD8in theAirRateCalcspreadsheet. SettheSpecifiedTargetValueas 0. Rev1.0 ‐22‐ February26,2015 Tofinishwehavetosetvalues tocontrolthecalculations.Click ontheParameterstab.Increase thenumberofiterations(here setfrom10to100).Setthe minimumallowedvalueto0& themaximumallowedvalueto somethingabovetheactual value(heresetto100).The statusareawillswitchtoOK wheniterationsaecompleted. WecanopenuptheAirRate Calcspreadsheet&seethat theAirflowratehasbeen adjustedtomatchtheexcess oxygenspecification. TyingtheTwoSystemsTogether Eventhoughthesteamcycle&fuelgassystemsareinthesameHYSYSflowsheettheyarereally modeledseparately.Thesteamcyclehasconvergedwithabasisof1kg/secwatercirculationrate &thefuelsystemhasconvergedwithabasisof1kg.mol/secfuelgas.Wewilltiethesystems togetherby“pushing”thedutyavailablefromthefuelsideoftheboilertothesteamside& adjustingthewatercirculationrateinthesteamcycle. Rev1.0 ‐23‐ February26,2015 Beforewemakeanydirect connectionslet’screatea spreadsheettosummarize theresultsfromthetwo systems.FromtheModel PaletteaddaSpreadsheet; doubleclicktoopen. ChangethenametoOverall Performance.Clickonthe Spreadsheettab&setup textfieldsthatlooklikethe figureontheright. Associatethematerial flows,temperature,& energyflowsasshownin thefigureontheright. Nowlet’sconnectthetwosystems. Rev1.0 ‐24‐ February26,2015 DoubleclickontheCondensate streaminthesteamcycleanddelete thevalueforthemassflowrate. Noticethattheintrinsicproperties forthestreamarestillcalculated (suchasthemolarenthalpy)butthe extrinsicpropertiesthatdependon theflowratearenowmissing. Double‐clickontheiconfortheHRSG exchanger.GototheDesigntab& changetheEnergystreamfromQ‐HRSG toQ‐Boiler.Thesimulationwillstill showthatitiscomplete. Youwillwanttodeletethe unnecessarystreamQ‐HRSGfromthe Flowsheet. Sowhat’schanged?Goback&look attheCondensatestream.Noticethat HYSYShascalculatedawater circulationratetomatchupthe amountofboilerheatneededinthe steamcycle(onakJ/kgbasis)with theproperwaterflowrate(ona kg/secbasis). AdditionalStream&UnitAnalyses Thereareadditionalanalysesthatwemaywanttoperformforthissimulation.Sincethegoalofthe processistocreatepowerweshouldbeveryinterestedtodeterminethevariousthermal Rev1.0 ‐25‐ February26,2015 efficienciesofthesystems.Wehavealreadystartedthisanalysisbyputtingcalculationsintothe SteamCycleSummaryspreadsheettocalculatethesteamcycle’sthermalefficiencybasedonthe HYSYSresults. Tocalculatetheefficiencyoftheboilerweneedtodeterminetheheatingvalueofthefuelgasused. WehavealreadysetuptheformatoftheOverallPerformancespreadsheettodothesecalculations. OpentheOverall Performancespreadsheet AssociatecellB3willthe HHV–right‐clickonthe cell&chooseImport Variable;chooseFuelGas, HigherHeatingValue,then clickOK.AssociatecellB4 willtheLHV–right‐click onthecell&choose ImportVariable;choose FuelGas,LowerHeating Value,thenclickOK.Add formulasintoD2&D3to puttheheatingona flowingbasis(i.e.,multiply theheatingvaluebythe molarflowrate). Notethateventhoughthe numbersappearunitless theyreallyhaveunitsof kJ/sec. Let’sadd2columnsforthe efficiencyvalues.Gotothe Parameterstab&change thenumberofcolumns from4to6.Setuplabels asshownontheright. Nowwewanttoaddformulastocalculatethevariousvalues: Rev1.0 ‐26‐ February26,2015 cellF2,“=D4/D2”(alsochangeVariableTypetoUnitless) cellF3,“=D4/D3”(alsochangeVariableTypetoUnitless) cellF5,“=(D8‐D7)/D4” cellF7,“=(D8‐D7‐D6)/D2”(alsochangeVariableTypetoUnitless) cellF8,“=(D8‐D7‐D6)/D3”(alsochangeVariableTypetoUnitless) TherearemanyothercapabilitiesthatcanbeaddedsincetheSpreadsheetoperationcanmake changes&calculationsina“live”fashion.Forexample,anentirecontrolsheetcouldbesetupto modifyvalues&directlycalculateresults.Cellscouldbesetupforthefollowinginputs: Fuelgasflowrateanditspressure&temperature. Theair’satmosphericpressure&temperature. Air’shumidity(wouldalsorequireadditionaloperationstoproperlyaddwaterwhile keepingtherestofthecomponents’relativeamountsthesame). Desiredexcessair. Pressuredropthroughtheboilersystem. Allowablestackoutlettemperature. Condensationtemperatureinthesteamcycle. Pressuredropthroughthesteamsideoftheboiler. Degreesofsuperheatintheboilersystem. Adiabatic&mechanicalefficienciesofallrotatingequipment. Rev1.0 ‐27‐ February26,2015