Annual Report 2014 - toyota uk media site

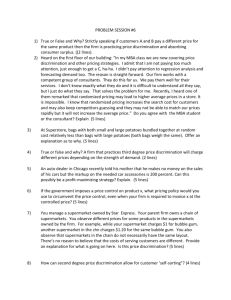

advertisement