GPlus User R eport - KNUTH Machine Tools KNUTH Machine Tools

advertisement

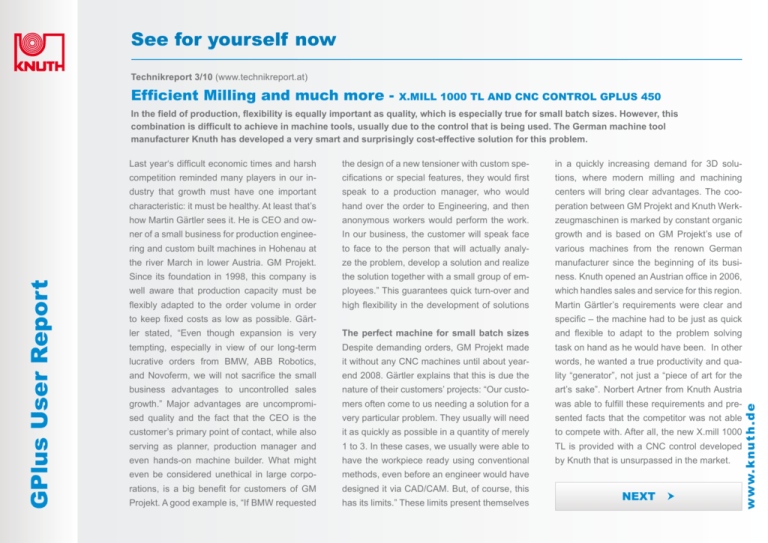

See for yourself now Technikreport 3/10 (www.technikreport.at) Efficient Milling and much more - X.MILL 1000 TL AND CNC CONTROL GPLUS 450 Last year‘s difficult economic times and harsh the design of a new tensioner with custom spe- in a quickly increasing demand for 3D solu- competition reminded many players in our in- cifications or special features, they would first tions, where modern milling and machining dustry that growth must have one important speak to a production manager, who would centers will bring clear advantages. The coo- characteristic: it must be healthy. At least that’s hand over the order to Engineering, and then peration between GM Projekt and Knuth Werk- how Martin Gärtler sees it. He is CEO and ow- anonymous workers would perform the work. zeugmaschinen is marked by constant organic ner of a small business for production enginee- In our business, the customer will speak face growth and is based on GM Projekt’s use of ring and custom built machines in Hohenau at to face to the person that will actually analy- various machines from the renown German the river March in lower Austria. GM Projekt. ze the problem, develop a solution and realize manufacturer since the beginning of its busi- Since its foundation in 1998, this company is the solution together with a small group of em- ness. Knuth opened an Austrian office in 2006, well aware that production capacity must be ployees.” This guarantees quick turn-over and which handles sales and service for this region. flexibly adapted to the order volume in order high flexibility in the development of solutions Martin Gärtler’s requirements were clear and to keep fixed costs as low as possible. Gärt- specific – the machine had to be just as quick ler stated, “Even though expansion is very The perfect machine for small batch sizes and flexible to adapt to the problem solving tempting, especially in view of our long-term Despite demanding orders, GM Projekt made task on hand as he would have been. In other lucrative orders from BMW, ABB Robotics, it without any CNC machines until about year- words, he wanted a true productivity and qua- and Novoferm, we will not sacrifice the small end 2008. Gärtler explains that this is due the lity “generator”, not just a “piece of art for the business advantages to uncontrolled sales nature of their customers’ projects: “Our custo- art’s sake”. Norbert Artner from Knuth Austria growth.” Major advantages are uncompromi- mers often come to us needing a solution for a was able to fulfill these requirements and pre- sed quality and the fact that the CEO is the very particular problem. They usually will need sented facts that the competitor was not able customer’s primary point of contact, while also it as quickly as possible in a quantity of merely to compete with. After all, the new X.mill 1000 serving as planner, production manager and 1 to 3. In these cases, we usually were able to TL is provided with a CNC control developed even hands-on machine builder. What might have the workpiece ready using conventional by Knuth that is unsurpassed in the market. even be considered unethical in large corpo- methods, even before an engineer would have rations, is a big benefit for customers of GM designed it via CAD/CAM. But, of course, this Projekt. A good example is, “If BMW requested has its limits.” These limits present themselves next Ü www. kn u t h . d e GPlus User Report In the field of production, flexibility is equally important as quality, which is especially true for small batch sizes. However, this combination is difficult to achieve in machine tools, usually due to the control that is being used. The German machine tool manufacturer Knuth has developed a very smart and surprisingly cost-effective solution for this problem. Norbert Artner from Knuth Austria and Martin Gärtler from the GM Projekt in front of the X.mill 1000 TL (left to right) Productive work instead of time-consuming around.” This is made possible by the intuitive- combination of X.mill 1000 TL and GPlus 450: programming ly programmable user interface, which provides We can do anything, but we don’t have to“. The The Knuth GPlus 450 in combination with the real-life machining cycles with many suppor- control hardware is based on a standard indus- X.mill 1000 TL milling center convinces with it ting graphics in its own Cycle Editor. Using this trial PC, which provides many advantages. The- well-designed, extremely user-friendly interface, graphically supported Cycle Editor, typical ma- re are no storage space problems, since all NC allowing very quick programming. This results in chining sequences can be programmed within programs are stored on a hard disk with large an above average speed for the completion of minutes. During programming, the operator storage capacity, and the 2-GHz Intel processor the finished product. This brings significant time is guided by self-explanatory input masks. No can process 450 NC blocks per second.Ethernet advantages, especially for small batch sizes. But knowledge of the basic M-Code Instruction Set and USB ports allow worldwide remote diagnos- what exactly differentiates the GPlus 450 from and no prior programming knowledge are re- tics and integration of the machine in factory net- controls of major manufacturers? First of all, quired. Gärtler stated, “With a little experience, works, including connections to Profibus, CAN- it’s the concept of the operator interface. Martin I can single-handedly and easily define the ma- open, DeviceNet. Gärtler says: “The Knuth control supports ex- chining cycles directly at the machine, without actly my way of approaching the production of using complex CAD/CAM software. If necessa- workpieces. I would describe it like the system ry, we can use DIN/ISO programming to create adapts to my way of working – not the other way NC programs. And that’s the beauty about this back Ü www. k n u t h . d e GPlus User Report The GPlus 450’s user interface provides ease of use and optimum user-guidance