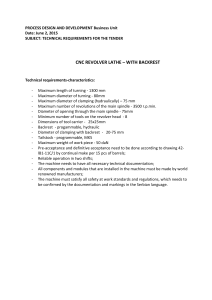

GM 300

advertisement