quality manual - Magee Plastics Company

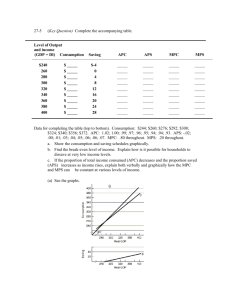

advertisement