Distillation

advertisement

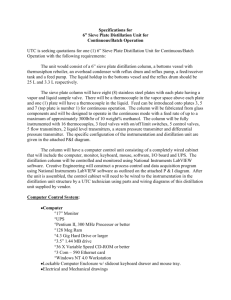

Fenton/Coughlin/Fall 01 CHEMICAL ENGINEERING LABORATORY CHEG 237 Bubble-Cap Distillation Column Objective: The objective of this experiment is to gain experience in operation of large equipment, to practice sampling and analysis techniques, to review the principles and hardware of distillation, and to compare experimental results to theoretical predictions. Theory: Information on the theory of distillation is given in References 1-5. Theoretical prediction of compositions throughout the column can by obtained by solving simultaneous material and energy balances using ASPEN or other means. The references provide equations for estimating limiting conditions in the column such as minimum reflux and minimum number of stages at total reflux. SAFETY PRECAUTIONS: 1. The reagents used in this lab may be flammable. Smoking in the laboratory is reason for immediate ejection and safety glasses must be worn at all times. Hard hats are required in the bay area. 2. Make sure the condenser vent is open and that all other valves are properly positioned before turning on steam. There are many drain lines, etc., which may be open to the atmosphere. 3. During shut-down, do not turn the condenser water off until the reboiler temperature has dropped to 140oF. This is to prevent escape of uncondensed distillate out the vent. On shut-down, turn off two valves in series on the reboiler system. 4. Concentration analysis will be performed using a gas chromatograph. Make a group inspection of the apparatus. 5. THINK BEFORE YOU ACT !!!!! Preliminary Preparations: 1. Review the necessary theory. 2. Examine the spare column sections. Note the details of the sample piping and the plate construction. 3. Plan your experiments. Note that steady state operation is required to give meaningful results and determine an efficient procedure for getting to steady state. Plan a technique for sampling from the trays to avoid compositional changes and include a trial to evaluate the reproducibility of your experimental runs and the precision of your sampling and analytical techniques. Run at total reflux until the group is familiar with all aspects of the operation. 4. Develop a specific plan for converting the gas chromatograph output into the concentrations you desire. Review the information in the instruction manuals. Procedure: Review continuous operation of distillation columns before operating the equipment. The column is to be run continuously using various reflux ratios (making sure the column is operating above the predicted minimum reflux). Students should include a run at total reflux. Students may also choose to investigate the effect of feed plate location at constant reflux on component distribution or experimentally determine the minimum reflux ratio. The instructor will specify the mixture to be separated. Rich Kozel will review start-up and shut-down procedures for the distillation column with students prior to operation. Determine the precision of your measurements and the reproducibility of your runs by making repeat measurements and performing repeat trials. Analysis: For all runs check mass and energy balances. Determine the effect that various controllable variables have on the distribution of components throughout the column (including the tops and bottoms products). Using published correlations or ASPEN, estimate the minimum reflux ratio, minimum number of trays at total reflux, and optimal feed plate location for this process. Report: Describe the design of your experiments and the results obtained, including an error analysis. Provide thoughtful and quantitative discussion of results, explain trends using physical principles and relate your experimental observations to predicted results (optimal feed plate location, minimum number of trays, minimum reflux ratio, etc). Express any discrepancies between observed and predicted results in terms of quantified experimental uncertainties or limitations of the correlations or computational software used. References: 1. 2. 3. 4. 5. Bennett, C. O. and Myers, J. E., Momentum, Heat, and Mass Transfer, 3rd Ed, McGraw-Hill, New York, NY (1982), Chapters 4 and 6. Geankoplis, C.J., Transprot Processes and Unit Operations, 3rd Ed., Prentice Hall, New Jersey, (1993). Hengsteback, R. J., Distillation Principles and Design Procedures, Reinhold Publishing Corp., New York, (1961). McCabe, W. L. and Smith, J. C., and Harriott, P., Unit Operations of Chemical Engineering, 6th Ed., McGraw-Hill Publishing Co., New York, NY, (2001). Perry, J. H, Ed., Chemical Engineer’s Handbook, 7th Ed., McGraw-Hill, New York, NY (1997).