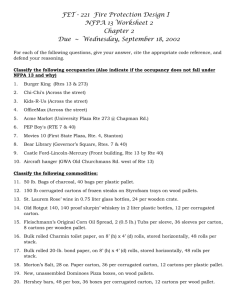

Routing, Shipping and Packaging Instructions

advertisement