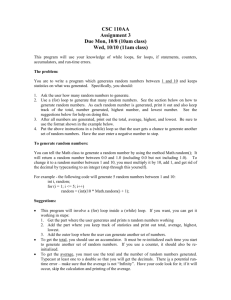

Process Control Fundamentals

advertisement