Improving Polymer Blend Dispersions in Mini

advertisement

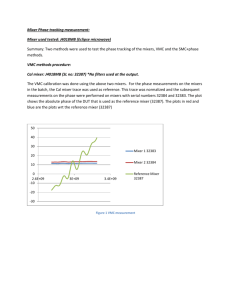

Improving Polymer Blend Dispersions in Mini-Mixers MILAN MARIĆ * and CHRISTOPHER W. MACOSKO† Department of Chemical Engineering and Materials Science University of Minnesota—Twin Cities Minneapolis, Minnesota 55455 The simple cup and rotor mini-mixer, designed to blend very small polymer batches (0.3 g, MiniMAX), was compared to larger lab scale mixers: an internal batch mixer (50 g, Haake); a conical, recirculating twin screw extruder (5 g, DACA); and a 16 mm co-rotating twin screw (300 g/hr, PRISM). All were compared at the maximum shear rate in the cup and rotor mixer, 110 s –1. Particle sizes of poly(propylene) (PP) dispersed in poly(styrene) (80 wt% PS) were measured by dissolving the PS, filtering and using scanning electron microscopy. The 16 mm twin screw gave somewhat smaller particle sizes than the lab scale mixers (1.2 m vs 1.7 and 1.9 m), but dispersion in the cup and rotor mini-mixer was much poorer. Simply adding three steel balls to the cup as suggested by Maréchal et al. (Polym Networks Blends, 1997) greatly improved the dispersion (1.8 m). Modifying the rotor design to allow recirculation yielded similar improvement. The benefit of adding three balls was confirmed in blends of low viscosity poly(dimethyl siloxane) PDMS in PS. When anhydride terminal PDMS was blended with amino terminal PS, the particle sizes were much smaller (10 vs. 0.3 m) and the differences between the three versions of the cup and rotor were much less pronounced. INTRODUCTION R ecent research suggests a common morphology development mechanism for polymer blends in mixers such as twin-screw extruders (1–8), internal batch mixers (2, 9–13) and even cup and rotor batch mixers compounding less than a gram of material (2, 14). However, the final blend morphology in these cup and rotor mixers was coarser, with many large dispersed phase domains existing even after 20 minutes mixing (2). Our objective here was to find a better small dispersive mixer. Our goal is to compound polymer blends in a small cup and rotor mixer so that we can predict the morphology expected in larger, production-scale extruders without consuming large quantities of polymer. The mixers used in this study are summarized in Table 1. The Couette flow geometry in the cup and rotor mixer (MiniMAX) shown in Fig. 1a does not provide the secondary flows needed for good distributive mixing. Periodically lifting up the rotor caused some folding of material to occur and improved mixing (2). However, lifting the rotor may not reproduce mixing conditions from one blend to another since not all *Current address: Xerox Research Centre of Canada, 2660 Speakman Drive, Mississauga, ON L5K 2L1, Canada †To whom correspondence should be addressed. 118 materials will adhere to the rotor identically. Maréchal et al. added three steel balls to the MiniMAX (Fig. 1b) (14). They found a more homogeneous and finer dispersion comparable to samples taken from a larger internal batch mixer (14). The improved mixing caused by the three balls was attributed to re-orientation of the melt from the top to the bottom of the mixer and from the mixer center to the walls. This introduced extensional flows and a wide range of shear rates needed for effective break-up of the dispersed phase. Removing relatively large samples from the MiniMAX with the balls present was awkward, thereby prompting the design modification shown in Fig. 2. Besides rotating axially, the shaft can move vertically to periodically re-orient the fluid as indicated in Fig. 2c. A larger mixer (10 g capacity) with a similar design to that of our modified MiniMAX was used by Horiuchi et al. (15, 16). However, in their study no comparison was made to other mixers. This report compares the MiniMAX under three conditions for PS/PP blends: a) original MiniMAX design (MM), b) original MiniMAX with three steel balls (MM-3b), and c) modified MiniMAX (MM-m) design. Nonreactive and reactive blends of PS with poly(dimethylsiloxane) (PDMS) compounded in the minimixers were also examined. These blends are more difficult to mix, owing to the large difference in viscosities between PS and PDMS. For the PS/PP blends, samples from the mini-mixers were compared to those POLYMER ENGINEERING AND SCIENCE, JANUARY 2001, Vol. 41, No. 1 Improving Polymer Blend Dispersions in Mini-Mixers Table 1. Small Scale Mixers for Polymer Blending. Mixer cup and rotor (13 mm cup diameter) Instrument Name (abbreviation) Manufacturer MiniMAX (MM) Capacity Custom Scientific Instruments, Cedar Knolls, N.J. 0.5 g MiniMAX with three steel balls (MM-3b) modified MiniMAX (MM-m) internal batch mixer, roller blades Haake System 90 (Haake) Haake Instruments,. Paramus, N.J 50 g vertical, conical twin-screw extruder DACA Micro Compounder (DACA) DACA Instruments, Santa Barbara, Calif. (designed by DSM, Netherlands) 1–5 g 16 mm diameter co-rotating intermeshing twin-screw extruder PRISM Model CS/16V2 (16 mm TSE) Welding Engineers, Blue Bell, Pa. up to 5 kg/h taken from a vertical, conical twin-screw extruder (Fig. 3), an internal batch mixer (Fig. 4) and a 16 mm diameter co-rotating twin-screw extruder (Fig. 5). The twin-screw extruder was used in two modes. Besides mixing continuously over the entire length of the screw after feeding the dry-blended pellets from a hopper, the blend components were added through the middle vent port downstream (5 g of polymer was added), and were mixed in a short section of the entire screw. Interestingly, adding only 5 g of a PS/PP blend in the batch mode generated a dispersion comparable to blends mixed in the continuous mode. To compare the morphology in the various mixers, it is desirable to match the deformation rates. This may be difficult to do since the material in each mixer may have different levels of shear or extensional flow. Anticipating that mixing would be most difficult in the MiniMAX, we operated it at its maximum rotational rate, hoping to facilitate breakup of the minor phase. The maximum shear rate in all other mixers was then matched to the MiniMAX by assuming Couette flow in the minimum gap between the mixing element and the wall. Thus, the rotation rates used in the various mixers were based on matching this shear rate. We Fig. 1a. Original MiniMAX design (MM). b) The MiniMAX with three steel balls (MM-3b). The ball diameters are 3.8 mm each. The arrows indicate the possible flow lines of the fluid around the balls. POLYMER ENGINEERING AND SCIENCE, JANUARY 2001, Vol. 41, No. 1 119 Milan Marić and Christopher W. Macosko Fig. 2. Schematic of the modified MiniMAX mixer (MM-m). are aware of the simplicity of such an assumption but we also note that morphology development did not change significantly by doubling the rotation rate in a twin-screw extruder (1). Further, the maximum shear rate was used since it is likely to be the dominant disturbance causing drop breakup and also because it was used for scaling up to a 51 mm diameter twinscrew extruder (2). Our ultimate goal was to evaluate the dispersions in these smaller mixers relative to large scale equipment such as this 51 mm diameter twin-screw extruder. 120 EXPERIMENTAL Materials. The polymers used with their abbreviations and sources are summarized in Table 2. The amine terminated PS (PS16-NH2) was synthesized by Cernohous et al. (17). The anhydride functional PDMS (PDMS43-(An)2) was produced by a hydrosilation reaction between commercial telechelic Si-H terminated PDMS (PDMS43-(SiH)2, United Chemical Technologies) and allyl succinic anhydride (Polysciences) (18). Reaction between the amine and the anhydride on the POLYMER ENGINEERING AND SCIENCE, JANUARY 2001, Vol. 41, No. 1 Improving Polymer Blend Dispersions in Mini-Mixers Fig. 3. Cross-sectional view of the DACA conical miniature twin-screw extruder. Typical sample sizes are 1–5 g. The screw diameter is 14 mm at the entrance and 5.5 mm at the exit. Note the recirculation channel which allows for variable mixing times. respective homopolymers forms block copolymer in situ at the interface during melt blending, which leads to a reduction in the dispersed phase size and prevention of coalescence (18). The complex viscosity (*) versus frequency () for the polymers at 200°C are shown in Fig. 6. Rheological measurements were performed using the Rheometrics Dynamic Stress Rheometer (DSR) in the oscillatory shear mode with a parallel plate geometry having a gap of 0.5 mm or a Couette geometry for the PDMS. The strain was kept below 10% to remain in the linear viscoelastic regime. Mixers. The MiniMAX mixer (MM) consisted of a heated mixing cup and a rotor and was run at its maximum rotation rate, N 330 rpm, with 0.3 g of polymer (Fig. 1a). Given a gap of 2 mm and the cup diameter D, the maximum shear rate, ˙max can be calculated: DN # max ⫽ ⫽ 110 s–1 gap (1) At various times, small samples (20 mg) were taken from near the cup edge with tweezers and quenched in liquid nitrogen to freeze the morphology. Mixing was also performed in the MM mixer by adding three steel balls (MM-3b) having a diameter of 3.8 mm each and samples were taken near the cup edge (Fig. 1b). It was run at the same rotation rate, and thus, owing to the presence of the balls, in some locations the shear rate will be higher. The modified MiniMAX mixer (Fig. 2) had its rotor end threaded into a cylindrical mixing element. The gap between the element and the cup wall was 0.25 mm, which is close to the clearance between the screw flight and the wall in the 16 mm twin-screw extruder. Vertical raising and lowering of the rotor was done manually at a rate of about 0.5 mm/s. This will result in a low shear rate in the 0.25 mm gap, but the periodic redistribution and elongational flow should aid mixing. The intended mixing action is illustrated in Fig. 2c. Sample removal was longer compared to the MM or MM-3b because of loosening the bolts. This process typically took about 20 s. The DACA micro-compounder is a vertical, co-rotating conical twin-screw extruder following a design from the DSM Company (Fig. 3). A re-circulation channel was used to recycle the melt for more thorough POLYMER ENGINEERING AND SCIENCE, JANUARY 2001, Vol. 41, No. 1 121 Milan Marić and Christopher W. Macosko Fig. 4. The Haake internal batch mixer. The typical sample size is about 50 g which fills approximately 80% of the mixer volume. The minimum gap between the blade and the wall is 0.5 mm. mixing. Five grams of polymer was fed into the extruder. Mixing times of 5 and 15 minutes and a screw rotation rate of 50 rpm were used. The Haake internal batch mixer (Fig. 4) was set to a rotor speed of 80 rpm with 50 g of polymer. At various times, the mixer was stopped, the front face plate was removed, and samples were quickly removed and quenched in liquid nitrogen. The face plate was then reattached and mixing commenced. This entire process took about 15–20 seconds. The PRISM 16 mm twin-screw extruder (16 mm TSE) had a clam shell barrel design with a length to diameter ratio of 25:1 (Fig. 5). One of our goals was to test the mixing capability of this small extruder relative to a larger 51 mm diameter extruder (1, 2). The flow rate was 0.3 kg/h at the screw rotation rate of 27 rpm. This may seem low for an extruder, but the tighter clearances in such a small extruder can produce relatively high shear rates. The maximum and minimum gaps in the 16 mm TSE are 0.2 mm and 3.3 mm, respectively. The screw configuration matched that in a larger 51 mm diameter twin-screw extruder used elsewhere (1, 2). The extruder was run without a die since its presence may elongate the dispersed phase domains (10). Samples were taken at various locations shown in Fig. 5 after the motor drive was stopped and the bolts removed. The samples were then quenched in liquid nitrogen. This process took 1 minute, which was somewhat longer than the sampling times for the mini-mixers. The results of Sundararaj et al. (2) show that these differences in quenching times will not effect particle size comparisons. Sample Preparation for Microscopy. As discussed above, all samples were quenched within 20 s 122 of cessation of mixing in liquid nitrogen with the exception of the 16 mm TSE. The PS/PP blend samples were placed in a vial containing methylene chloride (CH2Cl2) at a concentration of 10 mg of blend/mL solvent. CH2Cl2 selectively dissolved the PS, thus allowing observation of the PP dispersed phase. After 8 h, the solution was centrifuged for 10 minutes to further separate the PP from the PS/CH2Cl2 solution. A few drops of the solution were filtered under vacuum through a polytetrafluoroethylene or poly(propylene) membrane filter (both had pore sizes 0.10 m, Millipore). Then, fresh solvent was also filtered to remove any residual PS particles on the membrane. A section of the membrane was cut and glued onto an aluminum stub for observation by scanning electron microscopy (SEM). A similar preparation technique was used by Luciani and Jarrin (19). The sample was sputter-coated with 50 Å gold-palladium to make the sample conductive and then viewed with a JEOL 840II HRSEM at an accelerating voltage of 10 kV. For the PS/PDMS blends, quenched samples were glued onto an aluminum stub and microtomed at –140°C (below the glass transition temperature of PDMS) using a Reichert Ultramicrotome with a freshly cut glass knife. The sample was then placed in hexane for no more than 5 minutes to selectively remove the dispersed PDMS phase. The sample was viewed with SEM after the same coating procedure described above was applied. Image Analysis. To better resolve the minor phase drops from each other and the filter surface (see Fig. 7), the particles were traced onto a transparency and scanned at a resolution of 200 dpi. From the scanned transparency, the areas Ai of ni particles were measured using Ultimage Version 2.6.1 software. The Ai were converted to an equivalent sphere diameter Di. At least 300 particles were counted from each sample to ensure reliable statistics. The size of the dispersed phase was characterized by the number average diameter, D n, and the volume to surface average diameter, D vs. D vs gives the average interfacial area per unit volume, which can be used in reactive blending studies to determine how much block copolymer is at the polymer/polymer interface (18, 20). For the PS/PDMS blends, Di may be underestimated as a result of microtoming or freeze fracturing (21). However, some small particles are also missed during cutting. These effects tend to nullify each other. Applying stereological corrections to some of the non-reactive PS/PDMS blends gave an error of about 10% in D n (21) and less for D vs. Thus the corrections were not made on the data reported here. RESULTS AND DISCUSSION Comparison of PS/PP Blends in Cup and Rotor Mixers. After 2 and 10 minutes of mixing, the morphology in each of the mixers was in various stages of sheet breakup and thread formation (18). The key difference between the mixers was observed at 20 POLYMER ENGINEERING AND SCIENCE, JANUARY 2001, Vol. 41, No. 1 Improving Polymer Blend Dispersions in Mini-Mixers Fig. 5. The 16 mm diameter co-rotating twin screw extruder (PRISM, Welding Engineers). The numbers 1–8 at the top of the extruder indicate the sampling positions. All dimensions are given in mm. Table 2. Polymers and Viscosities at 200°C. Polymer (abbreviation) Source Viscosity at ␥˙ ⴝ 110 s–1 (Pa.s) poly(styrene) (PS) Dow Chemical (Styron 685) 700.82 poly(propylene) (PP) Eastman Kodak (PP Tenite) 340.82 nonreactive poly(styrene) (PS22) Cernohous amine terminated poly(styrene) (PS16-NH2) Cernohous (17) 6.0 nonreactive poly(dimethylsiloxane) (PDMS47) Aldrich 0.82 modified from PDMS43-(SiH)2 (18) 0.78 anhydride-terminated poly(dimethylsiloxane) (PDMS43-(An)2) POLYMER ENGINEERING AND SCIENCE, JANUARY 2001, Vol. 41, No. 1 15.3 123 Milan Marić and Christopher W. Macosko Fig. 6. Complex viscosity (*) of polymers versus frequency () at 200°C. minutes of mixing (Fig. 7). Some very large elongated particles were still present in the original MM while droplet-type morphologies existed in the MM-3b (D vs 1.85 m) and the MM-m mixers (D vs 2.47 m). Since the software calculates an equivalent sphere diameter, D vs was estimated to be about 45 m from the sample taken from the MM mixer. The observed drop size was compared to Taylor’s simple model, which assumes a single Newtonian drop deforming in simple shear flow: D⫽ 4⌫ 1r ⫹ 12 19 # m a r ⫹ 4 b 4 r 6 2.5 (4) where is the interfacial tension, ˙ is the shear rate and the viscosity ratio r is the ratio of the dispersed phase (d) to the matrix phase (m) viscosity (22). For the PS/PP blends, inserting 5.0 mN/m (2), ˙ 110 s–1 and r 0.48 (Fig. 6) into Eq 4 gives D 0.06 m. Not surprisingly, this estimate is much lower Fig. 7. PP morphology after 20 minutes mixing at 200°C in the cup and rotor mixers. The PS matrix has been extracted with methylene chloride leaving only PP particles on the filter membranes. A PP membrane was used in Fig. 7a while polytetrafluoroethylene membranes were used in Figs. 7b and 7c. Their pore sizes are identical. The samples are from a) MiniMAX mixer (MM), b) MiniMAX with three steel balls (MM-3b) and c) modified MiniMAX (MM-m). 124 POLYMER ENGINEERING AND SCIENCE, JANUARY 2001, Vol. 41, No. 1 Improving Polymer Blend Dispersions in Mini-Mixers Fig. 8. PP morphology at 200°C in the DACA mini-extruder: a) after 5 minutes of mixing and b) after 15 minutes mixing. Fig. 8c indicates the PP morphology after 12 minutes mixing in the Haake internal batch mixer. These particle sizes are similar to samples taken from the MM-3b, Fig. 7b. (See Table 3 for comparison of particle sizes.) more shear transients caused by the twin screws. The PS/PP blend morphology compounded in the Haake internal batch mixer was similar (Fig. 8c). The close agreement of the PP particle size in the MM-3b compared to the DACA or Haake batch mixer (Table 3) suggests the MM-3b possesses similar deformation rate changes and elongational flows. 16 mm Twin-Screw Extruder. The PS/PP blend morphology observed at various locations of the 16 mm twin-screw extruder is shown in Fig. 9. The morphology development closely resembles that witnessed in larger twin-screw extruders for a similar blend system (2). The dispersed phase sheets (Fig. 9, Sampling position #1) rapidly broke up into threads at the midpoint of the first kneading section (#2). The threads were almost completely disintegrated into drops after passing through the first kneading section (#4). The drops observed from the sample taken at the extruder exit (#8) were not much smaller than those at position #4. This indicates that an equilibrium between drop breakup and coalescence had been established. The morphology was finer (D vs 1.18 m) and was attained in a much shorter residence time compared than the observed data since Taylor’s model does not account for coalescence of the dispersed phase or the elasticity of the PS and PP. Wu used a semi-empirical correlation applicable for blends mixed in an extruder with a dispersed phase concentration of 15 wt% (23): 冓 D 冔n ⫽ 4⌫ ;0.84 r # m (5) where the plus sign () pertains to blends with r 1 and the minus sign () pertains to blends with r 1. The Wu equation gives D n 0.48 m, which is closer to the experimental data. Using an average shear rate of 10 s–1 yields D n 2 m by Eq 5. DACA Miniature Twin-Screw Extruder and Haake Internal Batch Mixer. The dispersed phase particle size in the DACA mixer was essentially constant after 5 minutes (Fig. 8a–b). The average particle size of the sample mixed in the DACA was similar to that observed from samples mixed in the MM-3b but the droplet morphology was achieved faster. This may be due to a greater elongational flow component or Table 3. PP Particle Sizes for PS/PP Blends in Various Mixers.1 Mixing Time (min) 具D典n (m) (m)2 具D典vs (m) MM MM-3b MM-m 20 20 20 5.1 1.1 1.6 10.3 0.6 0.9 45.8 1.8 2.5 DACA 5 15 1.3 1.2 0.6 0.7 1.9 2.0 Haake 12 1.1 0.5 1.7 End-Fed 16 mm TSE 16 mm TSE 2 3 1.0 0.7 0.4 0.4 1.5 1.2 Mixer at 200°C, ˙max 110 s–1 is the standard deviation associated with the number average particle size. 1Compared 2 POLYMER ENGINEERING AND SCIENCE, JANUARY 2001, Vol. 41, No. 1 125 Milan Marić and Christopher W. Macosko Fig. 9. PP morphology at 200°C taken at various locations (see Fig. 5) along the 16 mm twin-screw extruder. The finest dispersion (D vs 1.2 m) was achieved in the twin-screw despite the relatively short residence time (3 minutes). to samples taken from the batch mixers. The smaller particle sizes observed from samples mixed in the twin-screw extruder is likely due to higher shear rates, the existence of elongational flow and more transients or re-orientations of the fluid. Although only one possible screw configuration was studied here, we recognize the importance of screw design studied more thoroughly elsewhere (4, 6, 7). The PS/PP blend morphology when only 5 g of material was fed near the end of the extruder is indicated in Fig. 10. The average PP particle size of the sample taken from the end of the kneading section was strikingly similar to samples taken from the MiniMAX or Haake mixers despite the short residence time (Table 3). The addition or removal of kneading blocks affected the particle size. Adding one pair of reversing elements resulted in a lower particle size while adding two pairs of reversing elements or none at all resulted in slightly higher particle sizes. PS22/PDMS47 Non-Reactive Blends. The morphology of PS/PDMS (80/20) blends is depicted in 126 Figs. 11a–c for the three cup and rotor mixers. More particles in the sub-micron range were present for the blends prepared in the MM-3b and MM-m mixers compared to the MM mixer (Fig. 11). In particular, D vs was much lower after 20 minutes of mixing in the MM-3b compared to the other mixers, although D n was similar for both the MM-3b and MM-m mixers (Table 4). PS16-NH2/PDMS43-(An)2 Reactive Blends. The reactive PS16-NH2/PDMS43-(An)2 (80/20) blend morphology developed rapidly into small PDMS drops of D vs 0.5 m within five minutes mixing (Fig. 12a–e, Table 4). The much smaller particles relative to the non-reactive blends (D vs 10 m) observed in samples taken from all three mixers suggest reactively formed block copolymer strongly reduced the interfacial tension and prevented coalescence of the dispersed phase (24–26). Gel permeation chromatography (GPC) confirmed the formation of block copolymer as a result of reaction between the PS16-NH2 and PDMS43-(An)2 and this data is presented elsewhere POLYMER ENGINEERING AND SCIENCE, JANUARY 2001, Vol. 41, No. 1 Improving Polymer Blend Dispersions in Mini-Mixers Fig. 10. PP morphology at 200°C at various locations (see Fig. 5) of the twin-screw extruder. Here, the extruder was operated in the batch mode with 5 g fed near the end of the extruder. Note that a reversing element was added after kneading section (d) to increase back-mixing. (18). D vs was lowest in the MM-3b for the nonreactive PS/PDMS blends mixed in the MiniMAX type mixers. However, for the reactive blends D vs was slightly lower in the MM-m. A disadvantage of the MM-m mixer is the time required (15–20 s) to loosen the clamps and remove the sample. If the reaction studied is very fast (20) or frequent sampling is required, the MM-3b is preferable. However, if larger samples are desired and they are to be removed infrequently, the MM-m provides the best dispersion of PDMS in PS. The MM mixer was the worst small dispersive mixer since the shear rate was zero at the center of the cup and no cross flow existed to re-orient the fluid. The final drop size is caused by Rayleigh instabilities governed by a critical disturbance such as a deformation rate change (2, 27). As the dispersed phase morphology develops from sheets into threads, thread disintegration may be facilitated by such oscillations. In both the MM-3b and MM-m mixers, the flow was periodic with large changes in shear rate, leading to smaller drops compared to the MM mixer. The MM-3b probably has more rapid transients compared to the MM-m. The elongational flow in the MM-3b may have also been superior compared to that in the MM-m. If the threads were thinned prior to breakup, smaller drops would result. Khakhar and Ottino found that drop size decreased more rapidly in steady elongation, Rdrop ˙–0.9, while Rdrop ˙–0.3 in steady shear (28). A simulation of the flows in these mini-mixers using finite element techniques would be interesting because it may suggest which mixer has the higher elongational flow component and whether the flow is similar to that studied in other mixers such as an internal batch mixer (29). CONCLUSIONS Simply adding three 3.8-mm steel balls to a cup and rotor mixer (0.3 g sample, MiniMax) can significantly improve the dispersion achieved in polymer POLYMER ENGINEERING AND SCIENCE, JANUARY 2001, Vol. 41, No. 1 127 Milan Marić and Christopher W. Macosko Fig. 11. PS22/PDMS47 (80/20) non-reactive blend morphology after 20 minutes mixing in different MiniMAX mixers at 200°C. a) MiniMAX (MM), b) MiniMAX with three steel balls (MM-3b), c) modified MiniMAX (MM-m). More smaller particles ( 1 m) were present in samples taken from the MM-3b and the MM-m mixers compared to the MM mixer. The finest dispersion was achieved for the blend mixed in the MM-3b mixer (see Table 4). ACKNOWLEDGMENTS blends. This is valuable for blend research, which often starts with very small amounts of specially synthesized functional polymers or block copolymers. The balls primarily help circulate material from the low shear rate center of the cup to high shear rates near the perimeter. They also aid drop breakup by producing higher local shear rate, shear rate transients, and elongational flow. With reactive compatibilizers, however, the differences with and without balls is much less significant. With three balls, the cup and rotor mixer produced blends of PP in PS of the same particle size as that achieved with an internal batch mixer (50 g, Haake) and a recirculating, conical twin screw extruder (5 g, DACA) operating at the same maximum shear rate as the empty cup. A 16 mm twin screw extruder produced the smallest particles. Nearly the same dispersion was achieved by feeding just 5 g batchwise into this twin screw through a vent port about two-thirds of the way down the screws. This method provides a new, simple method for preparing small samples. The authors wish to thank the Dow Corning Corporation for their financial support, Dr. Jeff Cernohous for donating the PS16-NH2 and PS22, and Mr. Paul Nowatzki for performing some of the rheological measurements. We also thank Dr. Olivier Martins of the Monsanto Chemical Co. for the preparation of the blends mixed in the DACA conical twin-screw extruder. REFERENCES 1. U. Sundararaj, C. W. Macosko, R. J. Rolando, and H. T. Chan, Polym. Eng. Sci., 32, 1814 (1992). 2. U. Sundararaj, C. W. Macosko, A. Nakayama, and T. Inoue, Polym. Eng. Sci., 35, 100 (1995). 3. T. Sakai, Adv. Polym. Tech., 14, 277 (1995). 4. M. A. Huneault, M. F. Champagne, and A. Luciani, Polym. Eng. Sci., 36, 1694 (1996). 5. D. Bourry and B. D. Favis, Polymer, 39, 1851 (1998). 6. L. Y. Yang, T. G. Smith, and D. Bigio, Int. Polym. Proc., 12, 11 (1997). 7. J. K. Kim, S. C. Lee, and H. K. Park, Int. Polym. Proc., 10, 19 (1995). Table 4. PDMS Particle Sizes for Nonreactive and Reactive PS/PDMS Blends in the Cup and Rotor Mixers. Mixer Blend Mixing Time (min) 具D典n (m) (m) 具D典vs (m) MM MM-3b MM-m PS22/PDMS47 PS22/PDMS47 PS22/PDMS47 20 20 20 6.8 2.7 3.5 4.40 1.80 3.10 11.8 5.2 10.9 MM PS16-NH2 /PDMS43-(An)2 5 20 0.3 0.2 0.20 0.10 0.6 0.3 MM-3b PS16-NH2 /PDMS43-(An)2 5 20 0.2 0.2 0.08 0.08 0.3 0.3 MM-m PS16-NH2 /PDMS43-(An)2 5 20 0.2 0.2 0.06 0.05 0.2 0.2 is the standard deviation associated with the number average particle size. 128 POLYMER ENGINEERING AND SCIENCE, JANUARY 2001, Vol. 41, No. 1 Improving Polymer Blend Dispersions in Mini-Mixers Fig. 12. Comparison of reactive PS16-NH2/PDMS43-(An)2 (80/20) blend morphology at 200°C after 5 and 20 minutes of mixing in the original MiniMAX (a,b), MiniMAX plus three balls (MM-3b) (c, d) and the modified MiniMAX (MM-m) (e, f). Finer dispersions of PDMS were achieved earlier in blends prepared in the MM-3b and MM-m compared to the MM mixer (see Table 4). POLYMER ENGINEERING AND SCIENCE, JANUARY 2001, Vol. 41, No. 1 129 Milan Marić and Christopher W. Macosko 8. T. Nishio, Y. Suzuki, K. Kojima, and M. Kakugo, J. Polym. Eng., 10, 124 (1991). 9. H. P. Schreiber and A. Olguin, Polym. Eng. Sci., 23, 129 (1983). 10. J. Karger-Kocsis, A. Kallo, and V. N. Kuleznev, Polymer, 25, 279 (1984). 11. B. D. Favis, J. Appl. Polym. Sci., 39, 285 (1990). 12. C. E. Scott and C. W. Macosko, Polymer, 36, 461 (1995). 13. B. D. Favis and J. P. Chalifoux, Polym. Eng. Sci., 27, 1591 (1987). 14. P. Maréchal, T. Chiba, and T. Inoue, Polym. Networks Blends, 7, 61 (1997). 15. S. Horiuchi, N. Matchariyakul, K. Yase, T. Kitano, H. K. Choi, and Y. M. Lee, Polymer, 37, 3065 (1996). 16. S. Horiuchi, N. Matchariyakul, K. Yase, and T. Kitano, Macromolecules, 30, 3664 (1997). 17. J. J. Cernohous, C. W. Macosko, and T. R. Hoye, Macromolecules, 31, 3759 (1998). 18. M. Marić and C. W. Macosko, Polym. Eng. Sci, in press (2000). 19. A. Luciani and J. Jarrin, Polym. Eng. Sci., 36, 1619 (1996). 130 20. C. A. Orr, A. Adedeji, A. Hirao, F. S. Bates, and C. W. Macosko, Macromolecules, 30, 1243 (1997). 21. R. T. DeHoff and F. N. Rhines, Quantitative Microscopy, Chap. 6, McGraw-Hill, New York (1968). 22. G. I. Taylor, Proc. R. Soc. London, A138, 41 (1932); A146, 501 (1934). 23. S. Wu, Polym. Eng. Sci., 27, 335 (1987). 24. U. Sundararaj and C. W. Macosko, Macromolecules, 28, 2647 (1995). 25. N. C. Liu and W. E. Baker, Adv. Polym. Tech., 11, 249 (1992). 26. L. A. Utracki, Polymer Alloys and Blends, Hanser Publishers, Munich (1989). 27. S. Tomotika, Proc. R. Soc. London Ser. A, 150, 322 (1935). 28. D. V. Khakhar and J. M. Ottino, Int. J. Multiphase Flow, 13, 71 (1987). 29. H.-H. Yang, T.H. Wong, and I. Manas-Zloczower, in Mixing and Compounding of Polymers: Theory and Practice, I. Manas-Zloczower and Z. Tadmor, eds., Hanser Publishers, Munich (1994). POLYMER ENGINEERING AND SCIENCE, JANUARY 2001, Vol. 41, No. 1