A

M a t e r i a l s

T e c h n o l o g y

I n s t i t u t e

P u b l i c a t i o n

COMMUNICATIONS

“Maximizing resources through a global network of materials specialists”

|

SUMMER 2014

Duplex

Stainless

Steel

Take an Up Close

Look at the New Atlas

of Microstructures

Page 3

Inside this Issue

2. RBI Training

in China

6. New

Member:

SES

10. EuroTAC

Highlights

7. New

Member:

ITRI

8. AsiaTAC

Highlights

h t t p://www.m t i-global.or g

11. N

ew EuroTAC

Chair

16. Refiners

Roundtable

About this Publication:

MTI Communications is published by the

Materials Technology Institute, Inc. (MTI).

MTI is a unique, cooperative research and

development organization representing

private industry. Its objective is to conduct

generic, non-proprietary studies of a

practical nature on the selection, design,

fabrication, testing, inspection, and

performance of materials and equipment

used in the process industries.

Copyright © 2014 Materials Technology

Institute, Inc. All rights reserved.

Contact:

Submit all correspondence regarding

MTI Communications to:

Materials Technology Institute, Inc.

1215 Fern Ridge Parkway, Suite 206

St. Louis, MO 63141-4408

1-314-576-7712 (telephone)

1-314-576-6078 (fax)

mtiadmin@mti-global.org

MTI Communications

Editorial Board:

Michael Anderson, Syncrude

David Barber, The Dow Chemical Company

Eileen Chant, Becht Engineering

Debby Ehret, MTI

Gene Liening, The Dow Chemical Company

John Aller, MTI

Steve Springer, DuPont

Heather Stine, MTI

Michael Turner, AkzoNobel

Bill Watkins, MTI

Editor: Kirk Richardson, MTI

Subscriptions:

For a free subscription, write to MTI or

contact mtiadmin@mti-global.org

Calendar:

AmeriTAC 114

June 16-19, 2014

Denver, CO

AsiaTAC Fall Meeting

September 25-26, 2014

Shanghai, China

AmeriTAC 115

October 20-23, 2014

Columbus, OH

AmeriTAC 116

February 23-26, 2015

Miramar Beach, FL

EuroTAC Spring 2015

Dates: TBD

Düsseldorf, Germany

Please contact us at 314-576-7712 or

mtiadmin@mti-global.org for more

information or to find out how your

company can become a member.

Web Site:

http://www.mti-global.org

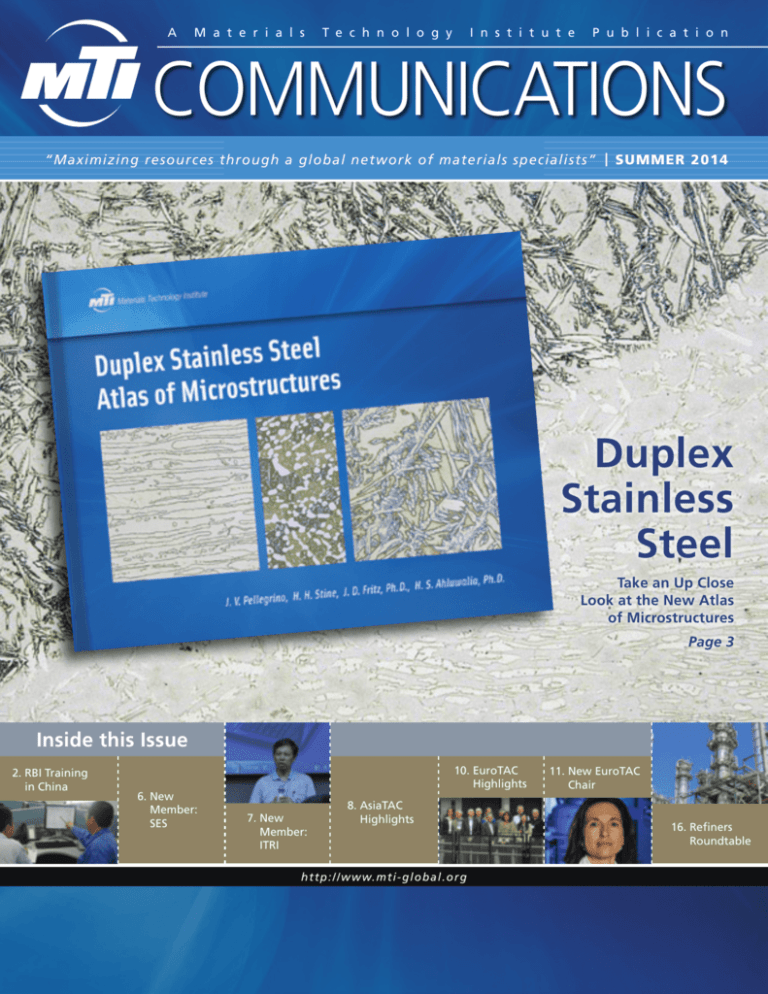

Cover: Graphic artist Steve O’Neal was

instrumental in designing MTI’s new

book, Duplex Stainless Steel Atlas

of Microstructures.

Dow Corning Applies MTI

RBI Training in China

M

any Processing Industry

companies depend on Risk

Based Inspection (RBI) to

manage the risks associated with

their process-containing equipment

and minimize costly upsets, shutdowns, and turnarounds. RBI is a

systematic approach to the management of inspection programs by

prioritizing equipment inspection

activities. The approach consists of

a detailed analysis of prior inspections, corrosion, materials of construction, process, plant operations,

and consequence to identify the

risk associated with the operation

of the equipment. The analysis provides the basis to make informed

decisions on inspection frequencies, level of detail, and methods of

nondestructive evaluations.

RBI methodology was written

into regulation in China in 2009,

and today, a comprehensive inspection program for pressure vessels

used in operating the country’s CPI

plants is required. To comply with

the new regulations, Dow Corning built a special team, consisting

of mechanical integrity engineers,

process engineers and process safety

SUMMER 2014

|2

engineers, aligning it with a local

certified inspection authority, and

initiated its own RBI project.

In October 2012, MTI conducted a two-day RBI training course in

Shanghai, China prior to its Annual AsiaTAC Meeting. Peiwu Sun,

Mechanical Integrity Team Leader

at Dow Corning (ZJG) Co., Ltd.

in Jiangsu, China, led the Project

Team that planned and organized

the seminar. John Aller, MTI’s new

Executive Director and an internationally recognized RBI expert,

taught the well-attended session.

“It was very helpful to learn the RBI

Program,” according to Sun.

Dow Corning has already put

the information to good use. The

company’s China-based ZJG plants

include nearly 500 pressure vessels.

The RBI program has enabled Dow

Corning to understand potential

failure modes as well as accurately

assess the likelihood of failure

(LOF) and consequence of failure

(COF) of the equipment using

modeling software purchased

from DNV.

> CONTINUED ON PAGE 4

New Atlas of Microstructures

Takes an Up Close Look at Duplex SS

M

TI will fill another void in

the materials engineering

world this summer when

it publishes the Duplex Stainless

Steel Atlas of Microstructures.

According to Co-Champion and

Metallurgist Hira Ahluwalia

(representing Nickel Institute),

the book was prepared to meet the

industry’s need for an atlas with

high quality, instructive images of

duplex stainless

steel microstructures.

This one-of-a-kind atlas fills a

gap in knowledge, according to

Ahulwalia. He adds that the 30

member companies who participated points to the need for this

kind of resource in industry. “We

wanted this atlas to be a teaching

tool and not just a bunch of photomicrographs,” notes Ahulwalia.

Making the leap from a coffee-table

picture book to a useful metallurgical guide and failure analysis tool

required considerable attention

to detail.

Co-Champion and fellow Metallurgist Jim Fritz (representing

Outokumpu) believes that the new

atlas could help industry members

avoid costly problems. “With the

duplex family of stainless steels, it

is important to maintain an appropriate austenite/ferrite

phase ratio

and avoid

undesirable

secondary

phases, such

as sigma

and chi,”

according

to Fritz. “Hence,

the microstructure is important in

determining the properties of a duplex stainless steel, particularly the

toughness and corrosion resistance.

“The value of the atlas is that it

shows the reader both good and

bad microstructures. The atlas also

shows the microstructures for all

the product forms, including plate,

sheet, pipe, tube, bar, forgings,

castings, and weldments. This is

important because the microstructures of different product forms

can look quite different. The atlas

will be a useful QA tool for screening duplex products, evaluating

weld procedures, and performing

failure analyses.”

“Duplex stainless steels in general are being used to a greater extent

than they had been before,” reports

Ahluwalia. “They are replacing 304

and 316 stainless steels for many

applications in the Chemical Industry. More people are dealing with

these alloys, but at the same time,

they aren’t

familiar with the

metallurgy of these

alloys. It’s important for them to

know what the microstructures look

like (good or bad),

SUMMER 2014

|3

so that they can make informed

decisions for their application.

Some of the intermetallic phases

in these alloys are very brittle.

Failures can be catastrophic!”

According to Fritz, findings

came out of the project that have

not been previously reported, including:

• The superiority of the

Pellegrino’s etchant for preparing samples for identification

of secondary phases

• The difference in resolution

of carbides and nitrides with

backscatter versus secondary

electron images and how this

can help in identifying phases

• The tendency of the oxalic acid

etchant to selectively leach the

secondary austenite phase

Making these and other discoveries was no easy task considering the

veritable obstacle course that the

leadership trio faced along the

> CONTINUED ON PAGE 5

Dow Corning Applies MTI RBI Training in China

> CONTINUED FROM PAGE 2

Through September of 2013,

Dow Corning applied RBI modeling to 347 vessels, determining that

only 40 needed to be opened for

inspection, and avoiding more

than $1 million in associated

maintenance costs in the process.

“Inspection man-hours are a small

cost savings,” reports Sun. “The

bigger cost saving from the RBI program is that the vessels don’t need

to be cleaned (purged and washed

out) for internal inspection. That

means that more wastewater is

avoided to be dealt with at a high

cost.” Additionally, Dow Corning

was able to avoid costs associated

with the construction scaffolding,

insulation removal and replacement, and internal inspection for

more than 300 vessels.

“We also understand the impact

of thermal damage in the future,”

adds Sun. “Based on the RBI

model, we can limit the location

of inspections.”

This is an ongoing process for

Sun and his Mechanical Integrity

Team. “We focus on preventive

maintenance of existing, fixed

equipment (pressure piping, pressure vessels, rupture disks, relief

valves, etc.),” he explains. Every

year, inspectors monitor shell

thickness and conduct external

visual inspection of the vessels.

Sun adds that a small number of

vessels are opened and inspected

during scheduled shutdowns,

adding: “All the available data we

get will be input into RBI software

for periodic re-assessment.”

Risk Based Inspection helps

engineers understand potential

failure modes. “Various process

conditions involve different

potential failure mechanisms,”

explains Sun. “RBI provides

failure models to analyze

possible failure mechanisms

due to the process conditions.”

Dow Corning engineers continue to work with JSSIE (China

Jiangsu Province Special Equip-

ment Safety Supervision Inspection

Institute), a certified inspection

organization. JSSIE uploads the

equipment and process data into

the RBI software, analyzes the

information, identifies the damage

mechanisms, and together with

Dow Corning’s Mechanical Integrity Team, plans the RBI inspection

strategy.

Project Champion Sun is pleased

that the MTI RBI training course

proved beneficial and hopes to

hear other stories of its successful

application by Chinese member

companies. MTI regularly provides

its members with tailored training

sessions on a variety of technical

topics in North America, Europe,

and Asia.

RBI DEFINED

Risk-Based Inspection (RBI)

technology has revolutionized the

process industry and its approach

to managing the inspection of process plants. It is a unique technology that can provide improvements

in safety and production while

reducing costs.

A traditional definition describes risk as the product of the

likelihood and consequence of failure. For the purposes of Risk-Based

Inspection, the pertinent risks are

the inspectable risks. Inspectable

risks are those that are caused by

equipment deterioration that can

be identified by plant inspections.

The likelihood of failure is

driven by those factors causing the

structural component to deteriorate, offsetting the factors allowing

the component to withstand the

damage. The key drivers that affect

the likelihood of failure are the

material damage mechanisms, their

rate of progression, the tolerance

of the equipment to damage, and

the amount and type of inspection

activities that have been performed

in the past.

The consequence of failure is an

analysis of the outcome or effect of

SUMMER 2014

|4

the failure. The consequence of a

failure is a function of what fluid

might be released because of the

failure and what impact that fluid

would have in the uncontained

state. For example, a large release

of compressed gasses will have an

overpressure effect associated with

the energy release. A release of a

hydrocarbon might have one of several flammable effects, such as a liquid pool fire or vapor cloud explosion. A toxic release will result in a

health hazard in the affected area.

Other non-safety related events

might have the consequence measured by the maintenance costs,

lost production, product quality,

or reputational consequences.

The benefits of RBI are quantifiable. In an existing operating

company, the simplest way to create

value is to improve the utilization

of resources. In a plant implementing RBI, measurable value can be

created by minimizing the risk

of equipment failure or reducing

inspection and maintenance costs.

In general, the cost of inspection

and maintenance can be reduced

by extending turnaround intervals,

shortening turnaround duration,

lowering the number and frequency of internal inspections, the

quantity of thickness monitoring

locations, and the frequency of relief device maintenance. Improved

uptime can be a byproduct of

reducing maintenance and inspection events. This is particularly

valuable when working in a regulated environment requiring short

plant turnaround intervals that can

be extended by incorporating a risk

based inspection program.

Today, Processing Industry

companies apply these principles

in their worldwide operations and

realize benefits from improved

production resulting in a better

bottom line. MTI has been involved

with RBI technology for nearly 20

years, publishing Implementing

and Evergreening RBI in Process

New Atlas of Microstructures

> CONTINUED FROM PAGE 3

Plants (available at mti-global.org)

in 2005. In the nine years since

that book was written, the technology has continued to develop,

and adoption of RBI continues

to expand to world-class processing industry companies, like

Dow Corning.

ABOUT DOW CORNING

AND ITS ZJG SITE

Dow Corning (dowcorning.com)

provides performance-enhancing

solutions to serve the diverse needs

of more than 25,000 customers

worldwide. A global leader in silicones, silicon-based technology and

innovation, Dow Corning offers

more than 7,000 products and services via the company’s Dow Corning® and XIAMETER® brands.

Dow Corning is equally owned by

The Dow Chemical Company and

Corning, Incorporated. More than

half of Dow Corning’s annual sales

are outside the United States.

Dow Corning Zhangjiagang

(ZJG) site is one of the largest

integrated silicone manufacturing

sites in the world. It consists of

four production plants, including

a siloxane plant and a fumed silica

plant, both of which are jointly

managed by Dow Corning and its

joint venture partner, as well as

finished silicone production plants,

which are owned and operated

independently by each company in

full competition.

Dow Corning is fully committed

to sustainable production in China.

Like their other facilities across the

world, Dow Corning’s manufacturing sites in China actively implement the concept of sustainable

development. Its environmental,

health, safety and security (EHSS)

management system accords with

Responsible Care® initiative, a

stringent set of international standards designed to advance the safe

and secure management of chemical products and processes.

n

way. “From my perspective there

were two big hurdles,” recalls

Fritz. “The sheer number of

product forms, etchants, and heat

treat conditions made it difficult

to select the best images and

conditions to include in the final

draft without the atlas growing to

an unruly size. The second hurdle

was to identify and describe the

many microstructures using the

acquired images. Typically you

would identify phases in the

microstructure while the sample

is on the optical microscope or

in the scanning electron microscope.” Since that didn’t happen,

Fritz and Ahluwalia had to painstakingly re-examine and write

descriptions for each and every

image that appears in the book.

Ahluwalia enjoyed working

with a Co-Champion. “I think it

kind of helps by not putting all

of the burden on one person,”

he observes. “We did a nice job

of interacting with membership,

keeping them in the loop, and also

being able to interact with our

vendors. I like the Co-Champion

model, especially if you get people

from different industries and

backgrounds working together,

because it makes the project even

stronger. But I also believe the

more you give to MTI projects,

the more you get out of them.”

Stine shares credit for the

success story, starting with MTI

member companies. “This Duplex Atlas project beautifully

illustrates the strength of the MTI

organization and member collaborative efforts,” she concludes. “A

large project team consisting of

representatives from over 30 different member companies designed the scope and objectives of

the project, and then donated the

alloy samples, including performing a variety of different welds, to

bring it together. The project

Co-Champions then took on the

task of completing the project to

the highest standards, resulting

in a work that will be very valuable to the industry. This type of

project would never have been

produced if it were not for the

combined efforts of MTI

member companies.”

n

A Super Duplex stainless steel plate sample isothermally aged at 982°C (1800°F) for one

hour shows widespread precipitation of intermetallic compounds (brown colored precipitates) throughout the cross section of the plate. The thermal treatment is well within the

intermetallic temperature range for this 255/Uranus 52N+ dual certified super duplex

stainless steel. NaOH etchant, 750X.

SUMMER 2014

|5

SES Brings New Capabilities,

Connections, and Perspectives to MTI

I

mmediately after Derrick Rogers

presented The Development of

Industry Standards for Composite

Repair Systems at AmeriTAC 112

in Savannah, Georgia last October,

he was the one who was sold. Rogers, who is Business Development

Leader/Staff Consultant at Stress

Engineering Services (SES), was

impressed enough with the MTI

model that he was already planning

on coming to future meetings, but

as a member company representative. Of course, Rogers knew that

he would have support back in

Houston from new hire Brian

Fitzgerald, a fixture at TAC

meetings when he was a Materials

Engineer with ExxonMobil.

Rogers was right. SES recently

joined MTI and is already active in

helping plan a Refiners Roundtable

forum for October 2014 (see article on page 16). But SES hopes to

add much more value as it becomes

involved in projects, forum discussions, seminars, and meetings.

The company’s insights on aging

plant issues, such as reliability,

could prove valuable to member

companies who are focusing on

identifying potential problems

and possible solutions.

“SES is a specialty engineering

company that utilizes an extensive knowledge base from across a

wide range of industries to provide

innovative solutions that meet all

code and industry guidelines,” explains Rogers. “Our team of highly

skilled engineers and technicians

use a multi-disciplinary approach,

advanced engineering tools, and

technology to provide cost-effective

solutions that improve performance, reliability, quality,

and safety.

“SES is a unique organization

with a combined suite of capabilities, expertise, and resources. We

Stress Engineering Services’ facilities in Mason, Ohio (top). Full scale testing, materials

characterization , and other capabilities in SES’ Houston, Texas headquarters include a load

frame with 6.5-million-pound capacity used to test threaded and welded connections for

OCTG piping (bottom).

specialize in performing full scale

testing, material characterization,

and analysis for solving complex

problems where the consequence

of failure is catastrophic.”

The company’s broad range of

capabilities includes Life Assessments; Fitness for Service Evaluations; Failure Analysis; Acoustic

Emission Testing; Field Instrumentation/Monitoring; Fracture and

Defect Assessment; High Tem-

SUMMER 2014

|6

perature Pressure Part Assessment;

B31.1 Covered Piping System

Compliance; Vibration Analysis

and Remediation (FIV); Computational Fluid Dynamics; and Full

Scale Testing. “SES provides value

to our customers by having all of

those resources under one roof,”

points out Rogers. “This enables

a seamless integration between

testing and analysis, allowing us

to solve complex problems.”

There are plenty of organizations that include the participation

of oil & gas and CPI producer companies, but SES zeroed in on MTI’s

> CONTINUED ON PAGE 12

New Member ITRI Opening

Doors in Southeast Asia

E

verything in the world is moving at an accelerated pace and

that includes the period of

time it takes a new member to have

a positive impact on the organization. Since joining MTI in January

2014, the Industrial Technology

Research Institute (ITRI) has already been a focal point in planning

a major AsiaTAC FFS Training session as well as the Spring AsiaTAC

Meeting in Taiwan (see article on

page 8). MTI Associate Director

Jesse Chen took advantage of a

great opportunity, asking ITRI’s

new TAC Representative T. P.

Cheng to join the AsiaTAC Steering Committee. Cheng was instrumental in landing Co-Sponsors

CPC Corporation and Formosa

Plastics and helping organize the

successful meeting.

Although ITRI conducts its own

research, it was attracted to MTI’s

breadth of knowledge and unique

projects. “Serving the industry is

one of the main missions of ITRI

and can be performed well only

with the assistance of capable and

experienced researchers and engineers,” notes Cheng. “So the continued training, learning, and self-improving are an important and vital

task. MTI as an organization has a

huge knowledge-base, database and

forum, established during the past

30 or more years and still growing,

that meets the needs of ITRI.”

One topic of great interest to

ITRI is corrosion under insulation

(CUI). The reason is quite simple

and straightforward, according to

Cheng: “Taiwan’s geographic location is in the subtropical region

of the Pacific Rim in which the

marine atmosphere causes a considerable corrosion loss to CUI every

year,” he explains. “Therefore, CUI

inspection and its mitigation were

proposed as the highly interesting

New MTI Member ITRI Co-hosted the AsiaTAC Taiwan Meeting in May. TAC Representative

TP Cheng of ITRI (shown here) was a member of the Spring AsiaTAC Planning Committee.

topic by local CPI engineers. One

warning and preventive system was

presented and discussed during

the AsiaTAC meeting and might

be considered in the near future

as a potential project worthy of an

in-depth study and field trial.”

ITRI brings its own experience

and resources that will be beneficial to MTI and may help expand

its network in Asia. “Networking

with Taiwan’s and the Asia Pacific’s

industries is one of the valuable assets,” he continues. “ITRI can help

MTI promote and maximize the asset performance of CPI companies

in this region.”

Cheng foresees a future where

MTI can be an even more valuable

technical resource in the region.

“As more and more joint-venture

businesses are being expanded in

the Asia Pacific region, including

Southeastern Asian countries,

MTI’s already built database and

ability will be very useful to help

new startup companies to solve

material application and corrosion

problems and to train the inexperienced engineers,” he predicts.

SUMMER 2014

|7

Until then, Cheng will continue to

participate in AsiaTAC meetings

and look for possible collaborative

projects that could benefit ITRI

and potential member companies

in the region. MTI welcomes ITRI

to its worldwide materials engineering community.

ABOUT ITRI

ITRI is one of the world’s leading

technology R&D institutions

aiming to innovate a better future

for society. Since its inception,

ITRI has been dedicated to helping industries stay competitive and

sustainable with the mission of

expediting the development of industrial innovation, facilitating the

process of industrial upgrades,

and creating value-added applications for industrial technologies.

Through multi-disciplinary integration of resources and talents,

ITRI keeps building its R&D capacity and strengthening industrial

services. It is also keen on developing smart technology and green

solutions that can improve quality

of life and protect the environment. Headquartered in Taiwan,

ITRI has five branch offices in

Silicon Valley, Tokyo, Berlin,

Moscow, and Eindhoven to

extend its reach across the globe.

n

FFS Training Session Highlights

AsiaTAC Taiwan Meeting

T

he AsiaTAC Steering Committee started looking at

Taiwan as a future meeting

site more than a year ago. Since

that idea surfaced, a lot of planning

went into the effort. The Committee’s considerable effort paid off

in a successful Fitness for Service

(FFS) Training session and MTI’s

second successful Spring AsiaTAC

Meeting, held May 15-16 in Chia

Yi City, Taiwan.

AsiaTAC Chair Henry Ye,

DuPont, called it an excellent

conference. “MTI AsiaTAC just

made a new landmark type of

achievement,” emphasizes Ye.

“Almost all major Taiwan

petrochemical and chemical

companies were included.”

According to Jesse Chen, MTI

Associate Director, more than 60

people attended the FFS Training

seminar and AsiaTAC proceedings.

Themes that concentrated on CPI

Corrosion Issues (first day) and Corrosion Under Insulation (second

day) generated plenty of interest

and conversation. “Not surprisingly,

many plants in this region share the

same need of getting this issue under better control by understanding it better,” Chen says of CUI.

“Many organizations have started to

work independently of each other

SUMMER 2014

|8

or are attempting to cooperate. MTI

is the organization that can help

them in leveraging the team and

resource-sharing approach, leading

to better solutions to this problem. We received a lot of positive

feedback from the people that we

talked to in this meeting.”

Like Ye, Chen was very pleased

with the mix of MTI member companies and prospective members

attending AsiaTAC. “With a wellorganized technical program under

the leadership of Dr. T.P Cheng of

ITRI, we were able to attract many

long time MTI member companies

that operate in Taiwan and in the

region, such as DuPont, Dow, Air

Products, BP, Outokumpu, Rath

Gibson, Asahi-Kasei and Mitsui

Chemicals,” reports Chen. “MTI’s

newest member, ITRI, and several

non-member major Taiwan companies, such as CPC Corporation,

Formosa Plastics and China Steel,

were also very well represented

along with many smaller

Taiwanese companies.”

That broad range of experience

and perspectives added value to

the interactive exchanges. “Prominent Professors Wen-Ta Tsai from

National Cheng Kung University,

Taiwan, and Masatoshi Kubouchi

from Tokyo Technology Institute,

Japan, also presented papers,”

continues Chen. “Finally, we also

had participation from Taiwan

government bodies in both the FFS

Training and the AsiaTAC Meeting,

which will improve the mutual understanding between the governing

bodies and the operating companies

in Taiwan. We had a wide spectrum

of organizations that all got together for the first time discussing key

common material and processing

issues facing the industry.”

Ye applauded CPC Corporation

for its hospitality and enjoyed the

opportunity to explore its fascinating facilities . “It was like a history

tour,” he remarks. “Because CPC is

one of the largest companies in Taiwan, it goes up and down as Taiwan

goes. During World War II, nearly

all facilities were bombed down.

But it has still been able to develop

itself back into a large and successful company, which was amazing.”

Chen points out that the tour

and technical program were the

result of resource sharing and

teamwork stretching beyond

member companies. “MTI is

fortunate to have many valuable

partners namely, ITRI, The Corrosion Association of the Republic

of China, and Co-Sponsors CPC

Corporation and Formosa Plastics,”

he concludes. “Without our local

partners, this meeting would not

have been possible.”

AsiaTAC ANNUAL MEETING ON

THE CALENDAR

After holding a successful meeting

in Taiwan, the AsiaTAC Steering

Committee is already busy planning the AsiaTAC Annual Fall

Meeting. That interactive forum

will take place in Shanghai, China,

September 25-26, 2014. MTI plans

to offer a special one-day training

seminar on Reliability Technology in conjunction with the Fall

AsiaTAC meeting. “Another day

may be devoted to a training session

on polymeric materials,” reports

Associate Director Jesse Chen, a

member of the Organizing Committee. “Our first steering team

planning meeting for this event

will be held early June, so more

details will follow.”

Chen encourages members

who want to be involved and

present technical information

at AsiaTAC to contact him at

jchen@mti-global.org. Further

details, including the name of the

host hotel and reservation links,

will be posted on the MTI web site

as they become available.

n

(Top Left) Participants at AsiaTAC

Taiwan 2014, (Top Right) FFS

Training Session Presenter John

Young, DuPont, (Bottom Left)

Professor Wen-Ta Tsai of National

Cheng Kung University of Taiwan

(Bottom Right) Jesse Chen, MTI,

with Keynote Speaker Professor

Tsai, National Cheng Kung

University of Taiwan

SUMMER 2014

|9

EuroTAC 2014 participants gather at TNO’s research facilities in Eindhoven, The Netherlands.

EuroTAC 2014 Yields New Ideas,

Plans, and Leadership

A

lot can be accomplished

in a very short time when

you bring the right people

together. Such was the case at the

Spring 2014 EuroTAC Meeting,

held March 25-26 at TNO’s

headquarters in Eindhoven, The

Netherlands. An insightful tour

of the science-focused facility

was followed by a variety of

technical presentations and

valuable discussions.

“TNO gave the EuroTAC

membership two tours of facilities

showing state of the art materials engineering research projects,”

reports MTI Associate Director Heather Stine. “They have a

tribology lab and creep rupture

apparatus that may be helpful

resources for future MTI projects

and demonstrated new technological research, such as fiber optic

sensors that may have future MTI

applications as well. Being aware

of the depth and breadth of their

capabilities will be valuable for

MTI member companies as well

as for being considered as a

potential contractor for future

MTI projects.” Minds filled with new ideas and

possibilities, Stine, fellow MTI

Associate Director Emory Ford,

and Executive Director John Aller

joined members and guests for

a variety of technical presentations. Thirty four people attended

the spring meeting, representing

16 member companies, and one

prospective member, Sonomatic.

EuroTAC featured presentations on

FRP Global Standards, Inspection

Techniques, Guided Wave for Tank

Bottoms, Accelerated Testing to Determine Remaining Lifetime, Heat

Resistant Cast Alloys, MTI Flange

Project and Polymer Permeability

Book Updates, and A Technique

for the Evaluation of Toughness of

Carbon Steel.

“The talks were informative

and the questions and answers and

discussions after each one were

engaged and showed great interest,” reports Stine. “Natalie Gelder

also hosted a Special Case Studies

session, where members brought

SUMMER 2014

| 10

current engineering problems to

the group and received helpful,

pertinent feedback and input on

the problems they presented. The

level of participation and support

was encouraging.”

Future support and participation could flow into an international project. “The EuroTAC membership supports participating in a

project on CUI (Corrosion Under

Insulation) that has been proposed

by a Japanese member company,”

according to Stine. “It has not yet

been formulated into a formal project, but EuroTAC, AmeriTAC and

AsiaTAC will all likely collaborate

in providing data to develop strategies in best solving this universal

problem that all chemical processing plants experience.”

In the annual business meeting,

the group elected a new EuroTAC

Chair, Dietlinde Jakobi of Schmidt

+ Clemens (see article on page 11).

Natalie Gelder of BASF will remain

as the Vice Chair. “Jakobi has been

an active participant and presenter

> CONTINUED ON PAGE 12

Schmidt + Clemens’ Jakobi

Steps Up to Chair EuroTAC

D

r. Dietlinde Jakobi, who

has been a very active participant at MTI’s technical

meetings in Europe, was named

EuroTAC Chair at the group’s most

recent meeting in Eindhoven, The

Netherlands. Member company

representatives were unanimous

in selecting Jakobi, who has been

a regular presenter at previous

meetings.

It’s easy to see why Jakobi’s MTI

peers selected her to lead the EuroTAC. “In my role as R&D Director

for the Schmidt + Clemens Group,

my responsibilities cover five manufacturing sites worldwide and the

coordination of a team of 20 highly

qualified researchers and technicians, currently working on 30

different R&D projects,” reports

Jakobi. “These are carried out

in close cooperation with partners, customers from different

industries like the petrochemical

industry, chemical plants, on- and

off-shore industry, and power

technology. This large number of

research projects necessitates an excellent research network, including

experts from different institutes,

organizations and associations.”

That is where a strong connection

to MTI is helpful.

“The MTI community offers an

excellent opportunity to network,

to share the experiences and knowledge with professionals and to meet

members during MTI meetings,”

she notes. “I have always been very

impressed and inspired by the work

of MTI.”

Jakobi is already thinking ahead,

considering potential projects and

seeking members’ input. “As the

new EuroTAC Chair, I will make

every effort necessary to

sustain the earlier success

of EuroTAC, under the

lead of Michael Turner

Dietlinde Jakobi, MTI EuroTAC Chair

(AkzoNobel), and to additionally

expand the research activities in

Europe by evaluating the specific

requests of the European market,”

she says. “I am convinced that we

can successfully increase MTI

European member engagement,

and I very much hope that we will

also increase the number of MTI

members in Europe.”

Members will have a big opportunity to engage when MTI

introduces its first Aging Plants

Conference & Expo with industry

partner KCI in March 2015

(refer to ad on page 13). In fact

Jakobi and EuroTAC participants

helped establish the initial agenda

at TNO in Eindhoven. She believes

that the event will

SUMMER 2014

| 11

be an extremely valuable meeting for MTI’s European members.

“Many chemical, petrochemical

plants and refineries currently operating in Europe face the problem

that they have reached or surpassed

their life expectancies and still

need to remain very productive,”

observes Jakobi. “Plant managers

must guarantee that the plants can

be kept profitable and safe as well

as economically sustainable, even

though present day regulations and

norms are quite different from the

standards in place when the plants

were originally built.” She is ready

to contribute to the discussion

when the conference launches

next spring.

In the meantime, Jakobi is

already working with Vice Chair

Natalie Gelder and Associate Director Heather Stine to strengthen

MTI’s technical community in

Europe. The leadership team has a

variety of plans, including potential

new projects and a second meeting in Europe. “This opportunity

should be used to improve the MTI

member network and to introduce

new members to MTI EuroTAC,”

she says of a possible Fall session.

There are no shortages of opportunities for those willing to lead, and

Jakobi will undoubtedly make the

most of them.

n

EuroTAC 2014 Yields New Ideas, Plans, and Leadership

> CONTINUED FROM PAGE 10

at EuroTAC for several years,”

points out Ford. “We have a nice

leadership team in place.”

Jakobi’s background makes her

a great choice for her new role

at MTI. She is R&D Director for

member company Schmidt +

Clemens Group, where her

responsibilities encompass five

manufacturing sites worldwide

and coordination of a team of 20

researchers and technicians working on 30 R&D projects. Moving

forward, the new EuroTAC Chair

says that she hopes to expand MTI’s

research activities and projects in

Europe by evaluating the specific

requests of the European market.

Following the election, Jakobi,

Gelder, and member company

representatives discussed plans for

future EuroTAC Meetings, including the potential for a Fall session.

“This will increase momentum and

strengthen networking opportunities among the membership and is

an important step in increasing the

value of MTI for European members,” notes Stine.

That isn’t all that MTI has

planned for EuroTAC. Fast-forward

a year, when the next Spring Meeting will include a special twist.

Aller and John Butterfield of KCI

(producers of Stainless Steel World)

announced the Aging Plants

Conference, a brand new industry

event co-hosted by the two Processing Industry-focused organizations,

slated for March 2015 in Düsseldorf, Germany (see ad on page 13).

The presenters encouraged member companies and guests to help

plan and participate in this event

that will address one of the hottest

topics in the CPI and associated

industries.

“We see regulations spreading

throughout the world that are putting much stronger requirements

on operating companies to properly

manage their aging infrastructure,”

according to Aller. “More and more

facilities are running beyond their

original design intent. There is a big

gap in our knowledge base to provide assurance that those plants can

continue to run safely once they’re

beyond their original design life

criteria.” Aller adds that a recent

survey of MTI member producer

company stakeholders demonstrated that they are constantly looking

for valuable/useful information

on plant integrity and reliability

issues, which is exactly what

Managing Aging Plants is focused

on delivering.

Watch for conference and

project updates, EuroTAC Meeting

information, and other important

news at mti-global.org.

n

SES Brings New Capabilities, Connections, and Perspectives to MTI

> CONTINUED FROM PAGE 6

collaborative, project-oriented

model. “What attracted SES to

MTI is the ability to meet with

all of the petrochemical industry

plant owner /operators in one

forum to hear their issues,” continues Rogers. “We currently do

business with a large number of

chemical plant owner /operators,

and we have an appreciation for

the problems we are exposed to

by those customers. In an effort to

better assist our customers we like

to be on the forefront of identifying problems and developing

solutions. By participating in the

development of those solutions,

SES will have a better vision for our

future investment strategies and

the ability to acquire resources to

better serve the industry and our

customers. We embrace the collaborative model as it enables the best

and brightest to have input when

solving problems.”

Rogers notes that he and his

colleagues are interested in many

MTI projects and hot topics,

including Prediction of Material

Degradation; Polymers; Integrity

and Condition Assessment; and

Metals. But it will take time to

identify all of the opportunities

of interest.

“When we look into the

future, we hope to gain a deeper

understanding of the problems

the petrochemical industry is

facing, and be a part of developing solutions that can be leveraged throughout the industry,”

he says. “During the course of

participating in the PDCs and

projects, we look forward to

meeting individuals, learning

more about the companies they

represent, and determining how

SES’ expertise and resources

can assist.

“As a first step, we would like

SUMMER 2014

| 12

to participate in more PDCs and

gain a better understanding of

MTI’s current events. We would

like to be integral in building

bridges with the other industry organizations. SES will be

celebrating its 42nd anniversary

this year, and we would like to

leverage the relationships and

expertise we have developed.”

The “bridge building” is

already underway. “SES is

currently serving customers

in the energy (oil & gas, power

generation, and petrochemical),

consumer products, and medical industries,” explains Rogers.

“SES would like to take a more

active role in helping in the cross

pollination of technology and

information and speeding up

the process of innovation.”

In MTI, SES found the right

environment to help make

that happen.

n

Preserving Industry in Europe with

Safe & Sustainable Operations for the Future

The Materials Technology Institute (MTI) in cooperation with KCI Publishing is organizing a twoday Conference & Expo devoted to the topic of “Managing Aging Plants”, 3–4 March, 2015, at the

Messe Düsseldorf Congress Center in Düsseldorf, Germany.

Conference Program at a Glance

The conference will cover the following topics and more:

• Acceptable risk/risk-based inspection

• Lack of effective management systems

• Aging phenomena that occur late in life

• Loss of experience/competence in the industry

• Deteriorating equipment

• Materials/fabrication quality

• European multi-nationals’ best practices • Planning for the future and Industry 4.0

• European regulations

• Positive materials identification (PMI)

• Inadequate/outdated design

• Tracking the incidence of failure

• Insuring aging plants

If you are interested in presenting a paper, contact John Butterfield, KCI,

at j.butterfield@kci-world.com or tel.: +31 575 585 294 for more information.

http://www.mti-global.org

Future Looks Bright for 2014

MTI Scholarship Winners

M

TI recently awarded its

2014 Bert Krisher Memorial Scholarships to

Zackary Lerch and David Waligorski, both seniors studying Materials

Engineering at the University of

Akron. Paul Manning (Haynes

International) and John Aller

(MTI) presented the awards at

the NACE Annual Conference

in San Antonio, Texas in March.

NACE received 16 applications

for MTI’s two $5000 awards. Selecting the winners from that talent

pool of tomorrow’s CPI professionals wasn’t an easy task. Committee

Members Dale Heffner (Electro

Chemical Engineering and Manufacturing), Robert Sinko (Eastman

Chemical), Manning, Kirk Richardson (MTI) and Committee Chair

Srini Kesavan (FMC) reviewed

many worthy candidates, several

of whom displayed both outstanding classroom performance as well

as relevant materials engineering

background and co-op work.

Overall, Kesavan noted that he

was very pleased with the universities’ participation this year, with

applications submitted from as far

as Australia and with an impressive level of participation from the

University of Akron. The scholarship is creating value for MTI

member companies by connecting

them with the next generation of

engineering talent and their new

ideas. “The Scholarship Program is

achieving the objectives of promoting awareness of MTI among students and CPI Materials Engineering as a career choice,” he observes.

It has certainly made an impact on

this year’s winners.

Lerch and Waligorski won the

two awards based on their academic excellence and pertinent work

with materials. It helped that both

of them are passionate about

2014 MTI Scholarship Winners (David Waligorski, center-left, and Zackary Lerch,

center, right) receive their awards at NACE’s Annual Conference in March.

their studies and chosen career

paths. “What’s not to be fascinated

about within the realm of materials

science?” asks Waligorski. “Everything we deal with in this world

is made of materials, and these

materials all have various properties that allow them to perform

certain tasks.

“As an engineer, I have the opportunity to orchestrate a beautiful system of these materials to

solve problems – problems such as

transportation (airplanes and automobiles), technology (computers

and circuits), energy (oil refineries

and power plants), and structures

(buildings and bridges). As society

progresses, our material demands

will only increase. We will need materials that are cheaper, last longer,

and can perform in more extreme

environments. Because of this, I

expect that the job market will be

quite good in the future, which

gives me comfort in choosing it as

a career. Perhaps more importantly,

SUMMER 2014

| 14

there will be many challenges and

problems to solve in this arena

going forward, which makes it an

interesting and important topic

to work on.” He is taking all of the

necessary steps to prepare for the

eventual opportunity.

“The degree I am working

towards, a Bachelor’s Degree in

Corrosion Engineering, is a mixture of Chemical Engineering and

Materials Science, which is a very

unique combination,” says Waligorski. “The main goal of the program

is to develop knowledge about how

to prevent a system from degrading, and thus last longer. From a

materials standpoint, this can include things such as materials and

coating selection. From a chemical

engineering standpoint, this may

involve selecting corrosion inhibitors to inject into the system, or

process redesign to better suit available materials. An understanding

of both materials and the chemical

processes that these materials are

AmeriTAC

113 Recap

expected to contain is paramount

in properly developing a solution.

This is what makes the University

of Akron’s program unique. And

since many of the large chemical

processing facilities, such as refineries, are very old, there is no shortage

of these problems to solve. Much

research is being done on these

topics, and unfortunately failures

of pipelines and other systems are

becoming more common. For these

reasons, finding and developing

solutions to these problems is an

important and challenging task,

but also an interesting and

worthwhile one, and that is

why I am studying it.”

Waligorski recalls that his first

project involved testing coatings for

the Air Force, research that he presented at NACE in 2012. He has

also participated in cathodic protection, materials characterization,

and coatings degradation modeling

projects as well as corrosion inhibitor testing, research, modeling, and

development. “The corrosion inhibitor research has been the most

extensive, and we actually filed for

a patent based on my findings a few

weeks ago,” he reports.

Lerch has been dreaming about

a future in science since boyhood.

“Ever since I have been little, I have

been fascinated by technology,

especially military aircraft and cutting-edge advancements,” he recalls.

“Material engineering interests me

because without materials engineering, the advancement of technology such as aerospace, chemical

production, oil and gas exploration,

and infrastructure would not have

been possible.”

Waligorski notes that he would

love to move expeditiously up the

ranks at a corporation and be revered for his accomplishments, but

doesn’t expect that to happen with-

in the next five years. “I still have

one year left before I graduate with

my Bachelor’s degree,” he explains.

“I’m still uncertain as to whether

I will pursue graduate school after

obtaining my Bachelor’s or if I will

go straight to work. But I do intend

to continue working in the Chemical Process Industry, whether it is

related to research or actual industry experience. This is because the

Corrosion Engineering degree I

am working toward is a combination of Chemical Engineering and

Materials Science, which makes the

CPI an excellent fit for my skill set.

Beyond that, both of these areas

interest me greatly, which is why

I decided to pursue this degree

in the first place.”

As for his plans, Lerch has his

mind set on becoming a corrosion

engineer working on corrosion

mitigation and failure analysis

within the oil and gas industry.

He is a step closer to making that

dream a reality. “Fortunately,

my hard work and dedication to

become a corrosion engineer has

resulted in being a recipient of the

MTI Bert Krisher Memorial, which

will allow me to focus more on my

educational goals rather than the

financial burden upon graduation,”

explains the ultra-busy student. “I

am truly grateful, and words will

never convey how thankful I am to

be a recipient of this scholarship.”

“Without scholarships such as

these, I wouldn’t be able to focus on

school and research as I have, and

that is why I am very appreciative

of such support,” adds Waligorski.

“My thanks go out to everyone that

made this possible.”

The future certainly looks bright

for Lerch, Waligorski, and the

Chemical Processing Industry, and

MTI continues to lead the way.

n

SUMMER 2014

| 15

M

TI’s winter meetings are

usually among its busiest,

and AmeriTAC 113 was

no exception. In all 88 people representing 39 companies attended

the Project Team, PDC, and AmeriTAC sessions February 24-27 in

Fort Worth, Texas. New member

Stress Engineering Services (featured on page 6) attended as well as

pending members Huntsman and

ITRI (both have since joined MTI).

Presentation highlights included a

comparison between four different

international design codes for

FRP vessels by Adriano Urena of

OLLEARIS and a Final Report on

the Investigation of Technologies

Common to Other Industries by

Steve Springer of DuPont.

For further details about the

meeting, including a full list of

presentations, projects approved,

and other valuable information,

visit mti-global.org.

NEW DRs AND TAC REPS

MTI welcomes the following new

DRs and TAC Representatives.

• Jan van de Wetering

(AkzoNobel) – EuroTAC • Sunila “Nina” Young

(Huntsman) – Designated

Representative, AmeriTAC

• TP Cheng (ITRI) – Designated

Representative, AmeriTAC,

AsiaTAC, EuroTAC

• Justin Muscarella (TITAN

Metal Fabricators) – Designated

Representative

Bridget Egan and Chis LaBelle of Oregon

State University presented on web-based

eLearning opportunities at AmeriTAC 113

PRSRT. STD.

U.S. POSTAGE

• • • PAID • • •

PERMIT NO. 751

SALEM, OREGON

1215 Fern Ridge Parkway, Suite 206

St. Louis, MO 63141-4408

http://www.mti-global.org

M a t e r i a l s

T e c h n o l o g y

I n s t i t u t e

Refiners Roundtable Slated for October

C

orrosion and other material

challenges aren’t particular

about what kind of processing plant they vex. On October 20,

MTI will bring together some of

the best minds in the industry to

discuss materials issues during a

Refiners Roundtable. The one-day

session will be held in conjunction

with MTI’s Fall Project Team Meetings and AmeriTAC 115, October

20-22 in Columbus, Ohio. All

MTI member companies, whether

or not they operate refineries, are

invited to participate. In addition,

other major refiners will be invited

to participate as guests.

John Aller, MTI Executive

Director, explains that the Refiners Roundtable is a way for MTI to

identify the materials-related issues

in the refining sector and formulate a way to deliver value to its

current and potential members in

this sector. The meeting itself will

provide members and guests with

rapid access to critical technical

information. It will include technical presentations and a roundtable

forum as well as discussions on

longer term refinery-related potential projects. “MTI is unlike other

industry organizations because we

have funds waiting for good projects to get formulated, rather than

good ideas looking for funding,”

according to Aller. “The participating companies have immediate

access to the knowledge that is being developed by the project team.”

Kevin Ganschow, a Materials

Engineer at Chevron Energy

Technology Company, adds that

MTI is very agile and able to move

quickly on the kinds of projects

that he and colleagues at refineries

would be interested in participating in, including corrosion under

insulation. Ganschow is looking

forward to the roundtable session

and discussion of MTI’s refineryrelevant past, current, and potential projects.

There will be plenty of chances

to identify research opportunities,

starting with a tour of the nearby

Edison Welding Institute. EWI

develops and applies manufacturing technology innovation within

the manufacturing industry. The

institute is noted for helping manufacturers optimize the fabrication,

operation, maintenance, and repair

of complex refinery equipment.

Following the tour, MTI will

host a lunch presentation and

roundtable session. Technical

presentations will include:

• MTI Projects of Special Interest

to Refining

• Inherently Safer Design

• Stress Corrosion Cracking

Concerns in Refining

• Fire Damage Assessment

• Other Special Presentations and

Topics of Interest to Refiners

SUMMER 2014

| 16

In addition, each refinery or

producer company in attendance

will receive a free copy of MTI’s

book, “Damage Assessment:

Investigating Fires, Explosion and

Storm Damage in Chemical Plants”

(an $850 value).

The event will conclude with

a reception on Monday evening,

but refiners are invited to stay and

attend MTI Project Team Meetings

and AmeriTAC 115. This event is

free of charge, but space is limited

to member companies and select

guests. Contact Kirk Richardson

(krichardson@mti-global.org),

Emory Ford (eford@mti-global.

org), or the MTI Office at

314-576-7712 for more

information and to

request an invitation.