Sunnen System is the Weapon of Choice for Paintball Barrels

advertisement

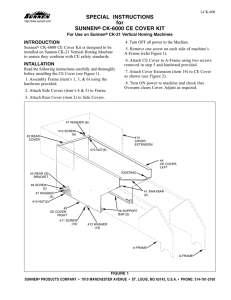

A PPLICATION R EPORT ABOVE AND BEYOND H O N I N G NEW SUNNEN BORE MACHINING SYSTEM IS THE "WEAPON OF CHOICE" FOR PRECISION PAINTBALL MARKER BARRELS Dale Carpenter, owner of Custom Products, shows precision paintball marker barrels produced with the Sunnen SV-1000 Series vertical honing machine and metal-bond diamond MMT tool. Custom Products makes more than 1,000 different barrels - all sized with the single MMT tool - to supply paintball marker OEM’s, retailers and its own retail operation via internet sales and on-site at paintball tournaments. GILBERT, AZ – With its roots in forestry and agriculture, paintball has evolved from a means to mark trees and cattle to an organized team sport played by millions of people in more than 60 countries worldwide. Players now compete in paintball tournaments where $10K-plus purses are common. As the sport has evolved, so too has the equipment. Manufacturers now specialize in the production of aftermarket parts for high-performance paintball guns - called "markers" by those who play the game. One such equipment manufacturer is Mesa Custom Machining, which is better known as Custom Products or CP to paintball aficionados. Mesa Custom Machining owner Dale Carpenter has always had his own products to sell, along with machine time. Under the Custom Products banner, Carpenter has enjoyed great success with performance go-cart parts and high-tech yo-yos. In the last decade, Custom Products has become a "big gun" in the world of paintball, employing 30 people at its 15,000 square-foot facility. CP uses a Sunnen SV-1000 Series vertical honing machine to create a competitive advantage on and off the paintball playing field, producing one and two-piece marker barrels made to precise specifications for pro-level paintball players. The surface finish and diameter of a paintball marker barrel are key components in its performance, as are the barrel's straightness and roundness, according to Carpenter. Shooters want the paintball to fit as perfectly as possible down the entire length of the bore. However, paintballs are non-uniform due to their composition – essentially a large, round "gel capsule" filled with paint. "Paintballs are somewhat 'squishy' and their dimensions can vary Control bores for two-piece paintball marker barrels. Advantage of two-piece barrels is the paint ball only comes in contact with the 5.5-inch control bore. High level players keep multiple control bores, each sized for a specific diameter paintball. Note the barrel size engraved near the top of the bore. based on atmospheric conditions, such as temperature and humidity," says Carpenter. "This, in turn, affects how the ball travels through the barrel, so tournament players compensate by having multiple barrels, each with a few thousandths of an inch difference in diameter." (continued) 1 Custom Products, manufactures one- and two-piece paintball marker barrels in five diameters (0.682”, 0.685”, 0.689”, 0.693” and 0.696”). CP uses a Sunnen SV-1000 Series Vertical Honing machine to meet the specifcations of pro-level paintball players. Tournament-level players may have 8-10 different barrels to accommodate inconsistencies in the dimensions of their ammunition. That's where the SV-1000 honing system has earned a reputation as the weapon of choice for quick production of single pieces or hundreds. CP manufactures one-piece and twopiece barrels in five diameters - 0.682", 0.685", 0.689", 0.693" and 0.696" - to fit the various makes of paintball markers. While one-piece and two-piece barrels are almost equal in performance, the advantage of a two-piece barrel is that the ball is only in contact with the barrel for the first 5.5", known as the control bore, resulting in less total friction and less use of valuable compressed air. Sometimes the difference in winning and losing a tournament is the last 20 or so shots. Less air per shot equals more shots and a greater chance for victory. "With the different bore sizes and barrel lengths for the various makes of markers, we have more than 1000 different part numbers for barrels available from our inventory," says Carpenter. While CP typically produces lots of several hundred barrels, the CNC hone gives it the flexibility to provide quick turnaround and meet customer needs. "Quick shipping is a big issue for us," says Carpenter. "The CNC honing system lets us knock out a special barrel in minutes if we have to. We save a program for every part by name, length, and bore size. If we get an order for a part that we don't have on the shelf and we need right away, we can drop an un-honed part into the machine and in a couple of minutes I've got one ready to go. I can have it polished, sent out for overnight anodizing and out the door the next day." The success of CP in manufacturing precision aftermarket paintball marker barrels was not overnight. "We started with only 12" barrels and they go to 16"," says Carpenter. "Initially, we struggled to get the bore size and finish produced on a consistent basis. I never realized how much science is in this." The Sunnen SV-1000 Series vertical honing machine on the Custom Products shop floor with paintball marker barrels loaded and ready for honing. A clip-in-place fixture allows loading of five parts per cycle. CP has a program saved for each part number - allowing quick turnaround times to meet customer needs. A single Sunnen MMT tool can adjust to produce any bore size made by CP. CP uses a Citizen screw machine to manufacture barrel blanks, starting with precision tubing at 1" OD. The tubing is extruded using dies Carpenter had made to order. The Citizen does all the outside (continued) 2 Custom Products-sponsored pro team San Antonio X-Factor takes to the battlefield. CP also sponsors five-time World Champion pro team San Diego Dynasty. Prize money for professional-level players can reach $10,000 or more per tournament. Note the paintballs in flight on the left side of the photo. work from porting to cut off. It goes from there to the hone. "The bore is already true, concentric, round to the OD," says Carpenter. "It's just not dead accurate dimensionally and the hone brings it out to size in one shot." Prior to the CNC hone, CP had four employees on dayshift and 2 on nightshift running manual hones. Now there is one operator on the CNC hone and one employee doing hand polishing, and the two produce more parts per day in a single shift than six did before – approximately 250 barrels. Custom Products makes more than 1,000 different barrels in various lengths and bore diameters to fit the many makes of paintball markers. Initially, Carpenter looked into broaching and drilling options to produce final bore size, before settling on honing. "I spent thousands with engineers who said they could drill this part," said Carpenter. "We would drill a 16" barrel on an HMC, and get a good one, but the next one would not be concentric with the OD. We also tried working with just one size of tubing using broaching, but we just could not get the dead-on accuracy we wanted." Honing was determined to be the best option to consistently produce precision bore size, but productivity and flexibility were issues. Carpenter went to Sunnen with his requirements for cycle time, production volume and part accuracy and charged it with developing a solution. "We told Sunnen we wanted as many parts as possible processed in one loading cycle," says Carpenter. Sunnen came back with an idea for a five-position rotary table, and together with CP developed the best way to fixture the part without distorting it. The operator loads five parts per cycle via a clip-in-place arrangement suggested by Carpenter and developed by Sunnen. A steel collar is threaded onto the barrel, dropped into the fixture and locked in place. Fixturing the collar prevents any tension or pressure that would cause distortion of the aluminum tube during honing. The table rotates under CNC control, five parts cycle under the spindle, they get honed and then the operator reloads. Carpenter says he uses only a fraction of the SV-1000's accuracy potential, requiring only ±0.001" accuracy in his parts, but gets the advantages of exceptional consistency, flexibility and productivity from the CNC machine. "This machine will produce parts all day that are accurate to ±0.000010", but this becomes moot when you have a hand polishing step after honing," he explains. "We hone our parts undersize by 0.0005" to allow for some slight bit of metal removal in the polishing step. Sunnen's metal-bond diamond MMT tool essentially does not wear on aluminum, so we rarely offset the tool. More important from a cost and (continued) 3 A Custom Products machine operator loads the Sunnen SV1000 Series Vertical Honing Machine with paintball marker barrels for precision honing. A metal collar is threaded onto the barrel, then it’s dropped into the fixture and locked in place. Fixturing the collar prevents tension or pressure that would cause distortion of the barrel during honing. productivity standpoint, this single MMT tool is capable of sizing the entire range of bore diameters we produce." The added capacity of the CNC machine enables CP to supply barrels to paintball marker OEM's, retailers, and its own retail operation (www.customproducts.us). In addition, the company has a traveling staff that attends paintball tournaments with a 53-foot Volvo tractor trailer conducting on-site sales of their barrels, regulators and other marker accessories. CP also sponsors several pro paintball teams, which helps increase brand awareness with the target market. "We have very limited job shop work now," Carpenter says. "Our own product line takes most of our capacity. We have doubled our sales since 1996, with only a small percent of it now as job shop work." From selling high-tech yo-yos, to speed parts for go-carts to paintball marker barrels, Carpenter will always be on the lookout for the next niche to fill … and his next big idea. 4 A LEGACY OF EXCELLENCE SINCE 1924. WORLDWIDE Our global manufacturing, distribution, and sales and service network allows us to deliver quality Sunnen solutions worldwide. And our state-of-the-art Technical Services Centers allow our technical experts to develop innovative solutions to customer application challenges. The Centers also provide answers for customer questions and training for Sunnen representatives around the world. SUNNEN PRODUCTS COMPANY St. Louis, MO - USA World Headquarters Phone 1.314.781.2100 Fax 1.314.781.2268 Toll Free 1.800.325.3670 Email sunnen@sunnen.com www.sunnen.com SUNNEN AG Ennetaach - Switzerland Phone +41 71 649 33 33 Fax +41 71 649 33 34 Email sales@sunnen.eu www.sunnen.eu SUNNEN DO BRASIL LTDA. São Paulo - Brasil Phone +55 11 4177 3824 Fax +55 11 4362 3083 Email sunnen@sunnen.com.br www.sunnen.com.br SUNNEN ITALIA S.R.L. Arese - Italy Phone +39 02 383417 1 Fax +39 02 38341750 Email sunnen@sunnenitalia.com www.sunnenitalia.COM SUNNEN POLSKA SP. Z.O.O. Warszawa - Poland Phone +48 22 814 34 29 Fax +48 22 814 34 28 Email sunnen@sunnen.pl www.sunnen.pl SUNNEN SAS Saclay - France Phone +33 1 69 30 0000 Fax +33 1 69 30 1111 Email info@sunnen.fr www.sunnen.fr SUNNEN RUS LLC Moscow - Russia Phone +7 495 258 43 43 Fax +7 495 258 91 75 Email sunnen@sunnen-russia.ru www.sunnen.ru SUNNEN BENELUX BVBA Kontich - Belgium Phone +32 3 880 28 00 Fax +32 3 844 39 01 Email info@sunnen.be www.sunnen.be SUNNEN S.R.O Strakonice - Czech Republic Phone +420 383 376 317 Fax +420 383 376 316 Email sunnen@sunnen.cz www.sunnen.cz SUNNEN PRODUCTS LTD. Hempstead Herts - United Kingdom Phone +44 1442 393939 Fax +44 1442 391212 Email hemel@sunnen.co.uk www.sunnen.co.uk SHANGHAI SUNNEN MECHANICAL CO. LTD. Shanghai - China Phone +86 21 58133990 Fax +86 21 58132299 Email shsunnen@sunnensh.com www.sunnensh.com Sunnen reserves the right to change or revise specifications and product design in connection with any feature of our products contained herein. Such changes do not entitle the buyer to corresponding changes, improvements, additions, or replacements for equipment, supplies or accessories previously sold. Information contained herein is considered to be accurate based on available information at the time of printing. Should any discrepancy of information arise, Sunnen recommends that user verify the discrepancy with Sunnen before proceeding. 2013 SUNNEN PRODUCTS CO. Printed in USA X-NR-1004 01/14-POD