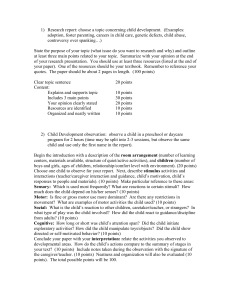

Date Problem Severity Analyze Potential Solutions Final Solution

advertisement

Date Problem Severity 2/10/2015 UHMW will not be able to support the load of the device domponents Major Bottom pole we received from MSD scrap 2/12/2015 pile was misplaced Ordinary Analyze FEA analysis in CAD shows that the UHMW material will not be able to support the weight of all the components Bottom pole is gone, need to change size and material of poles since we won't be using the scrap pole anymore The springs will not be strong enough to keep the driving omni-wheels on the ground to enable device movement, push-pull cables are not user-friendly since we will need 4 of them to lift the weight of the electrical components Potential Solutions Final Solution Replace UHMW with 1/4" Aluminum Order new poles, change size and material of poles Order 3/4" and 1" telescoping Order new poles, change size and material of pol aluminum poles Remove omni-wheel lifting functionality, purchase bigger springs, create Remove all omni-wheel lifting functionality mechanical subsystem to pull all 4 cables The omni-wheel lifting mechanism and 2/17/2015 springs are not feasible Critical Ping sensors will not be able to detect 2/18/2015 protruding objects above 12 inches off the ground (such as tray tables) Major The ping sensors have a significant Add two more ping sensors that are horizontal detection range, but a very small mounted perpendicular to the existing vertical range ping sensors Add two more ping sensors that are mounted perpendicular to the existing ping sensors 2/25/2015 Remake two wheel hubs Major The surface finish on the hubs was such that they were not able to be used. FInish Machining on 2/27/2015 & indicate deliverable is completed 3/10/2015 Quick Release buttons do not spring back after release Major Battery will not charge, loses charge too 4/14/2015 fast Critical Welded motor mounts prevent the bearing 4/14/2015 from lining up with the base, furthermore, presence of weld does not allow the motor to sit flush with the mount. Critical 4/16/2015 Voltage regulators get really hot Major 4/21/2015 Motor Sides no longer allow clearance for motors Major Implement Order 1/4" Aluminum through the machine shop, change material in CAD model Thicker UHMW, Aluminum Spend more time in the machine shop and edit the deliverable date 1. Try to open up the through hole slightly The pole is near the the button's minimum in order to allow easier passage 2. functional diameter causing them to bend a Order new buttons that are rated for a 1. Try to open up the through hole slightly in little, this makes it difficult for the button to smaller pole ID (.5-1.25" ID: 92988A530 order to allow easier passage spring back out after use or .5-.875" ID:92988A510) The battery charger will not charge the battery. The circuit requires the thermistor to be closed and the circuit will not close, as indicated by the NO LED light on the battery 1. Bypass the breeched cell 2. Purchase 2. Purchase a new battery without an extra a new battery without an extra thermistor thermistor charger when plugged in. This could be 3. Charge the battery in the EE Lab caused by a breached cell in the battery pack. The battery is also losing charge at a very fast rate (less than 30 seconds). 1. Mill off 4 millimeters from the base When the motor rests on the base, the plate where the motors are located Redesign motor mounts (longer and taller) , motor shaft does not line up with the 2.Remove old motor mounts, redesign remachine and send back to Rob for Welding bearing in the motor mount them, and reweld 2 Voltage regulators in parallel is not very 1. Check wire connections 2. reliable for getting 12VDC for the arduino Reconfigure wiring 3. Buy a step down with out the risk of overpowering the arduino transformer mega Due to the increase in height of the motor Mill out extra material to increase slot mounts, the motor side no longer allows height enough clearance for the motor shaft Remove the electrical device platform, don't order push-pull cables and extra aluminum, redesign layout of the base and placement of all electrical components We decided not to add two more ping sensors because it would further complicate the arduino code and wiring Evaluate Increased strength of base, lost money since UHMW was already ordered Date Problem Solved 2/17/2015 Better fitting and better size poles were ordered 2/24/2015 Weight of device was reduced by 11 pounds and diameter of base was reduced from 27.5 in. to 22.8 in. 2/24/2015 This is an area for improvement for further iterations of this project 4/14/2015 The remade hubs have Go to the machine shop on Friday smoother surfaces & 2/27 from 8am-12pm. If needed connect appropriately to the also from 12:30-3PM shafts. 3/9/2015 Go back to machine shop tomorrow to expand holes The buttons now fit snug in the holes 4/14/2015 Receive battery and wire it to the electrical system The battery now powers the system adequately 4/30/2015 Mounts have been machined and sent back to welding (4/21) Motor mounts work now 4/21/2015 Buy a new 24V to 12V step down transformer Transformer doesn't overheat and Everything works good connections are made 4/29/2015 Milled out extra material Finished milling (4/21) 4/21/2015 Motor shafts fit through hole Critical The motor can not align properly with the bearing. Also the wheels would be missaligned resulting in further issues. Un weld the mount, drill, and thread Un-weld the mount and re-weld to the base to it holes in the bottom of the mount to fix it to the base. Talk to Rob for best solution. proper orientation Motor mount was re-welded to the The motor mount properly base now through the bearing. The Arduino Mega was not responding 5/1/2015 when connecting to a laptop Critical Connection problem between board and laptop. Will not run or receive new code. Buy another Arduino Mega Board Bought another Arduino Mega Board Connected new board to laptop and verified connection 5/1/2015 RoboClaw Motor controller- the 2nd Hbridge got fried. Critical As a result motor #2 will not be powered. 1. Buy a new controller and/or unplug and run only 3 motors 2. Buy 2 new controllers 3. Create a protective casing for the motor controllers Purchased plastic containers and Buy 2 new motor controllers and create protective toothpicks so that we could press The motor controllers work casing for motor controllers the buttons on the motor controller now, without problems while in the containers 5/7/2015 Major Center mount screw for outside of the hub loosens when stand goes backwards and left. Re-design system for captivating the omni wheels to the hub & shaft. Unscrewed the screws and re-aligned the system. 5/7/2015 4/29/2015 5/2/2015 While assembling the base. One of the motor mounts was welded upside down Motor mounts unscrew after continuous use Retractable tether doesn't fit through the 5/2/2015 hole in the base cover Ordinary Motor #4 is much slower than the rest of 5/8/2015 the motors Major 5/8/2015 Critical Motor controller trace blown 5/11/2015 Major Encoder is not spinning freely Critical Major Ordinary Tightened the screws New board works and responds to connected laptop Tested the movement of the stand and it worked The alignment of the motor, bushing, and mount prevent the motor from achieving appropriate speed dictated by the code. 1. Drill a bigger hole 2. Remove metal Drill a bigger hole: 0.5" piece from tether line 1. Drill the holes bigger Loosened all the mounting screws, re-aligned the Implemented the Final Solution 2. Lossen and re-align motor & bushing, motor, secure motor to the mount mupltiple times after testing it each It works and tighten screws time. Motor contoller was too close to case and cause the trace to short Encoder not spinning would prevent the stand from moving properly as desired. 1. Buy new contoller 2. patch traces 1. spray with WD-40 2. Line the groove of the pulley with electrical tape Hole needs to be bigger Traces are patched Line the groove of the pulley with electrical tape 4/29/2015 5/1/2015 5/11/2015 5/8/2015 5/8/2015 Added the electrical tape It works, but more friction is needed in order to better track distance 5/14/2015